Flame-retardant electrolytic solution for aluminum electrolytic capacitor

A technology for aluminum electrolytic capacitors and electrolytes, applied in electrolytic capacitors, liquid electrolytic capacitors, capacitors, etc., can solve problems affecting safety, high conductance and flashover voltage, complex imidazole/imidazoline salt preparation process, etc., to achieve good Effect of flame retardant effect, high electrical conductivity and flashover voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

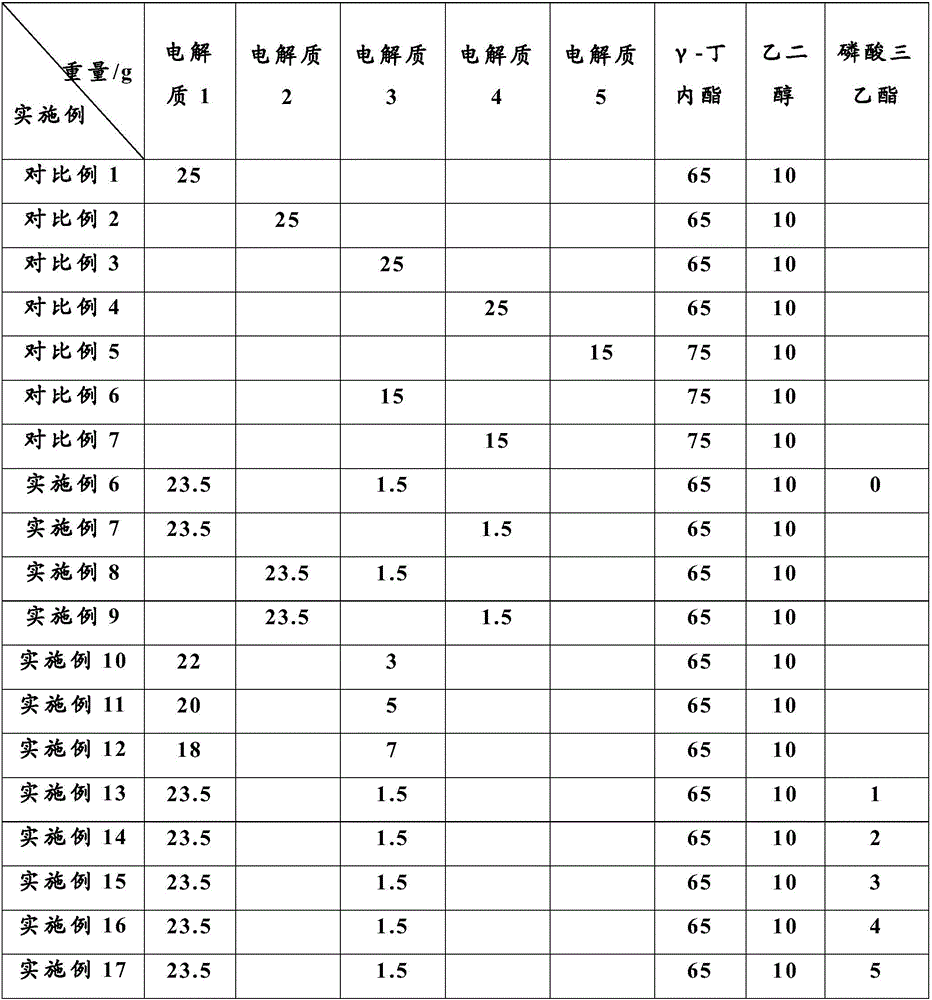

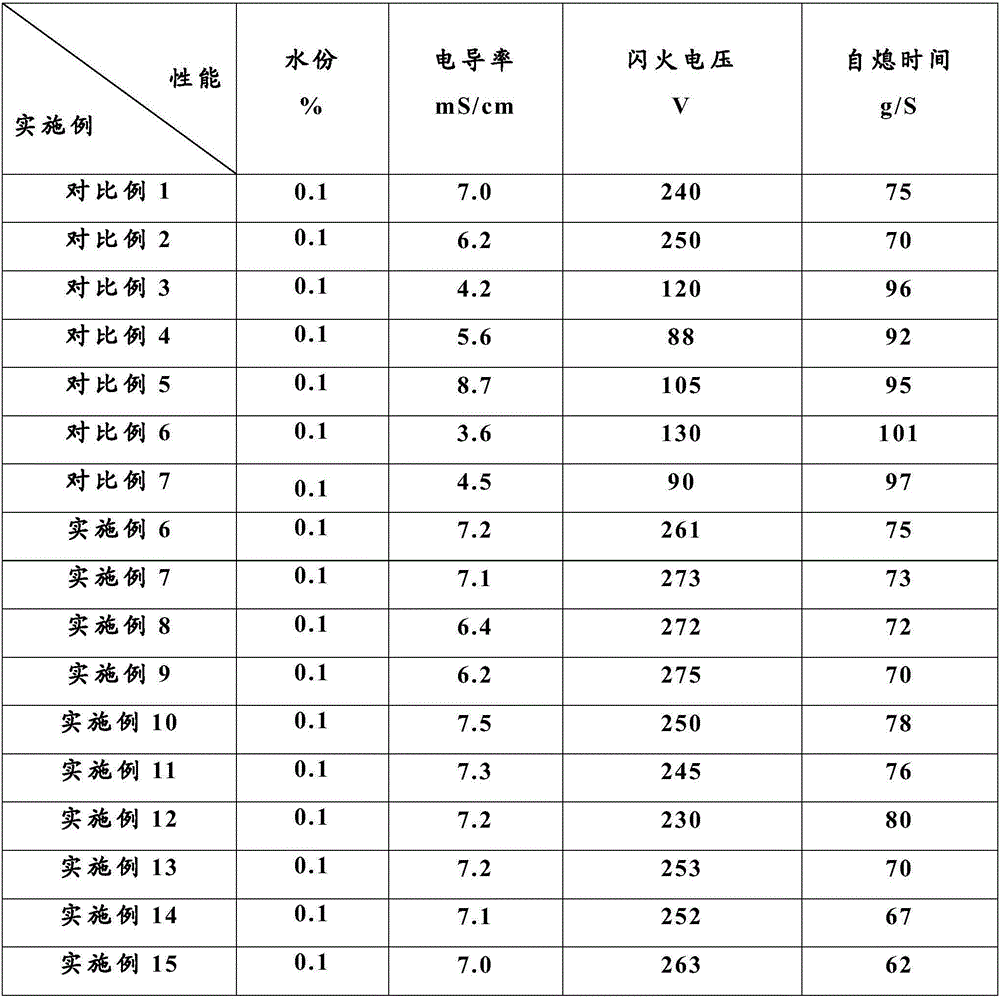

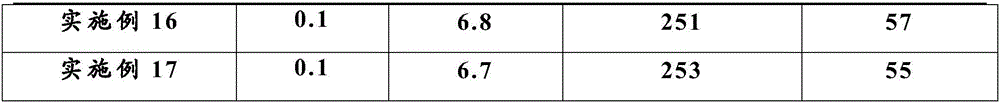

Examples

Embodiment 1

[0026] Embodiment 1: Electrolyte 1: Preparation of 1-ethyl-3-methylimidazolium diethyl phosphate

[0027] Add 1-ethylimidazole dropwise to the methanol solution of dimethyl carbonate, and stir at 120°C for 36 hours to obtain a methanol solution of 1-ethyl-3-methylimidazole dimethyl carbonate

[0028] Diethyl phosphate (provided by Chengbei Chemical) was added to the methanol solution of 1-ethyl-3-methylimidazole dimethyl carbonate for salt exchange reaction. The reaction produces a large number of bubbles, which are CO2, and a methanol solution of 1-ethyl-3-methylimidazolium diethylphosphate anion is obtained. Distill the methanol and CO2 in the system from the above solution under normal pressure, and then under negative pressure conditions (the degree of reduced pressure below 5KPa, 80°C), the residual methanol in the system and the incompletely reacted 1-ethylimidazole, dicarbonate Raw materials such as methyl esters are removed. Electrolyte 1 thus obtained: 1-Ethyl-3-met...

Embodiment 2

[0029] Embodiment 2: Electrolyte 2: Preparation of 1-ethyl-3-methylimidazolium dibutyl phosphate

[0030] In the methanol solution of dimethyl carbonate, 1-ethylimidazole was added dropwise, and stirred at 120° C. for 36 h to obtain a methanol solution of 1-ethyl-3-methylimidazole dimethyl carbonate.

[0031] Dibutyl phosphate (provided by Chengbei Chemical) was added to the methanol solution of 1-ethyl-3-methylimidazole dimethyl carbonate for salt exchange reaction. The reaction produces a large number of bubbles, which are CO2, and a methanol solution of 1-ethyl-3-methylimidazolium dibutyl phosphate anion is obtained. Distill the methanol and CO2 in the system from the above solution under normal pressure, and then under negative pressure conditions (the degree of reduced pressure below 5KPa, 80°C), the residual methanol in the system and the incompletely reacted 1-ethylimidazole, dicarbonate Raw materials such as methyl esters are removed. Electrolyte 2 thus obtained: 1-E...

Embodiment 3

[0032] Embodiment 3: Electrolyte 3: Preparation of dimethylethylamine hydrogen phthalate

[0033] Water was added to phthalic anhydride, stirred and hydrolyzed at 100°C for 4 hours to obtain an aqueous solution of phthalic acid.

[0034] Dimethylethylamine was added to the above-mentioned aqueous solution of phthalic acid, and neutralization reaction was carried out for 1h. After the reaction is finished, the water in the system is removed under negative pressure conditions (lower than 5KPa, 80° C.), until the total water content of the reaction solution is lower than 1%. Electrolyte 3 thus obtained: Dimethylethylamine hydrogen phthalate

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com