Electrolyte for high-voltage-resistant aluminum electrolytic capacitor and preparation method of electrolyte

An aluminum electrolytic capacitor, high-voltage-resistant technology, applied in the direction of electrolytic capacitors, liquid electrolytic capacitors, capacitors, etc., can solve the problems of reduced conductivity, reduced flash voltage, increased moisture content, etc., to achieve good resistance to large ripple current performance, improve Effect of less flashover voltage and appearance change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a preparation method of an electrolyte for a high-voltage aluminum electrolytic capacitor, comprising the following steps:

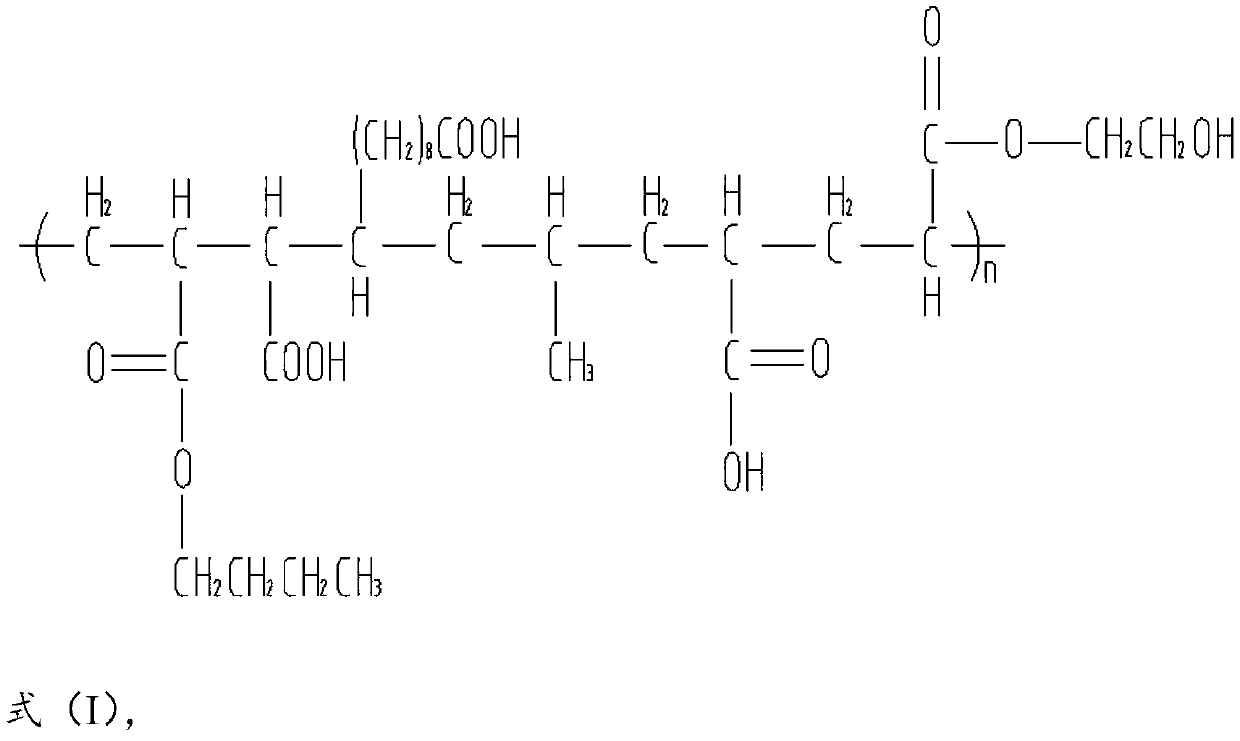

[0047] (1) Weigh 5-30 parts of solute, 40-60 parts of main solvent, 10-30 parts of auxiliary solvent and 03.-10 parts of additive, wherein, the solute is the ammonium of the high molecular polymer shown in formula (I) Salt,

[0048]

[0049] Its molecular weight distribution range is 20000-100000;

[0050] (2) Mix 70%-85% of the main solvent and auxiliary solvent, heat to 50-80°C, add 10%-20% of the solute, stir until the mixture is uniform, and obtain the mixed solution A;

[0051] (3) Continue heating the mixed solution A to 130-160°C and keep it warm for 30-70min;

[0052] (4) Cool the heated mixed solution A to 90-110°C, add 80%-90% solute, stir until mixed evenly, obtain mixed solution B, and keep it warm for 60-90min;

[0053] (5) Add the additive to 15%-30% of the main solvent and the auxiliary solv...

Embodiment 1

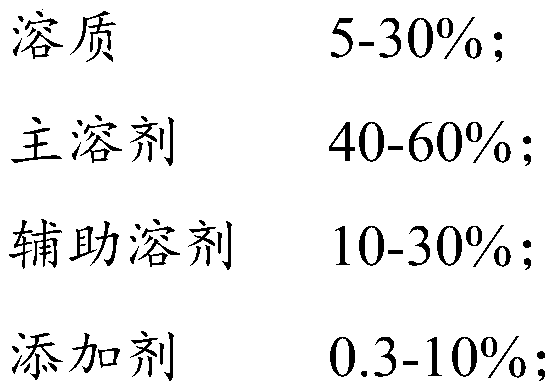

[0058] The mass percent of described solute, main solvent, auxiliary solvent and additive is:

[0059]

[0060] The preparation method of the electrolytic solution for the high-voltage aluminum electrolytic capacitor comprises the following steps:

[0061] (1-1) Weigh 18 parts of solute, 55 parts of ethylene glycol, 25 parts of ethylene glycol monobutyl ether, 0.3 part of p-nitrobenzoic acid, 0.7 part of ammonium phosphate and 1 part of polymerized fatty acid;

[0062] (1-2) Mix 80% ethylene glycol and ethylene glycol monobutyl ether, heat to 58°C, add 10% solute, stir until the mixture is uniform, and obtain a mixed solution A;

[0063] (1-3) Continue heating the mixture A to 140°C and keep it warm for 70min;

[0064] (1-4) Cool down the heated mixed solution A to 90°C, add 90% of the solute, stir until mixed evenly, obtain the mixed solution B, and keep it warm for 86 min;

[0065] (1-5) Add 0.3 part of p-nitrobenzoic acid, 0.7 part of ammonium phosphate salt and 1 part o...

Embodiment 2

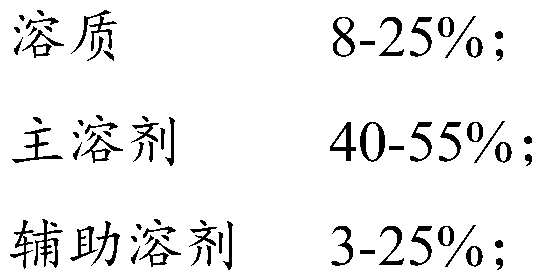

[0068] The mass percent of described solute, main solvent, auxiliary solvent and additive is:

[0069]

[0070] The preparation method of the electrolytic solution for the high-voltage aluminum electrolytic capacitor comprises the following steps:

[0071] (2-1) Weigh 25 parts of solute, 50 parts of ethylene glycol, 18 parts of γ-butyrolactone, 0.7 part of p-nitrobenzyl alcohol, 1.3 parts of ammonium hypophosphite and 5 parts of polypropylene glycol;

[0072] (2-2) Mix 80% ethylene glycol and ethylene glycol monobutyl ether, heat to 58°C, add 10% solute, stir until the mixture is uniform, and obtain a mixed solution A;

[0073] (2-3) Continue heating the mixture A to 140°C and keep it warm for 70min;

[0074] (2-4) Cool down the heated mixed solution A to 90°C, add 90% of the solute, stir until evenly mixed to obtain the mixed solution B, and keep it warm for 86 min;

[0075] (2-5) Add 0.3 part of p-nitrobenzoic acid, 0.7 part of ammonium phosphate salt and 1 part of poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com