Electrolyte used for 650-700V aluminium electrolytic capacitor

A technology of aluminum electrolytic capacitors and electrolytes, which is applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve the problems of immature capacitors, etc., and achieve the effects of small changes in conductivity, good conductivity, and high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] What is described below is the preferred implementation of the present invention, and the protection of the present invention is not limited to the following preferred implementation. It should be pointed out that for those skilled in the art, some modifications and improvements made on the basis of this inventive concept all belong to the protection scope of the present invention.

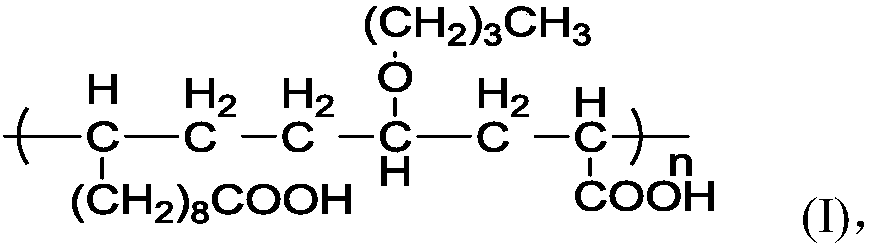

[0036] The synthesis of formula (I) polymer ammonium salt

[0037] 1) Add undecylenic acid (18.4g), vinyl n-butyl ether (20.0g), acrylic acid (5.0g) in the round bottom flask of 1000mL, add initiator benzoyl peroxide (0.48g), solvent simultaneously N,N-dimethylformamide (200 g);

[0038] 2) Stir for 30 minutes, then transfer it to an oil bath and heat up to 80°C for 24 hours;

[0039] 3) Add an equal volume of water dropwise to the reactor, continue to stir for 4 hours, then filter, wash the filter cake with water, and dry to obtain the high molecular polymer (30.9 g) of formula (I), with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com