Magnesium alloy anodizing electrolyte and method for preparing anodic oxide film by electrolyte

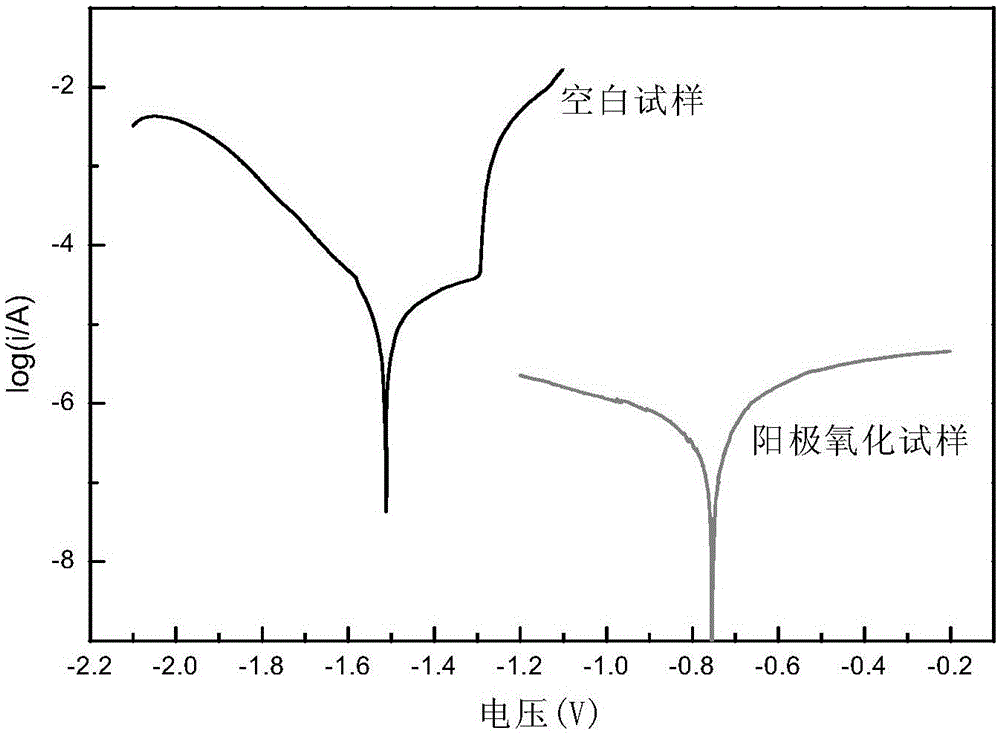

An anodizing and electrolyte technology, applied in anodizing and other directions, can solve the problems of film morphology, color uneven, affecting the practical value of magnesium alloys, different electrical parameters, etc., to achieve excellent corrosion resistance, low cost, and economical energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A magnesium alloy anodic oxidation electrolyte consists of: sodium tetraborate 20g / L, boric acid 10g / L, sodium hydroxide 5g / L, sodium carbonate 5g / L, sodium citrate 6g / L; adopt 20wt% sodium hydroxide The solution adjusts the pH of the electrolyte to 8.5.

[0026] The method for preparing a black anodized film by utilizing the above-mentioned magnesium alloy anodic oxidation electrolyte comprises the following steps:

[0027] 1) Pre-treatment: sand paper to 1500#, then put the magnesium alloy into the alkaline washing solution at 55°C for 15 minutes; the alkaline washing solution consists of 50g / L sodium hydroxide and 20g / L trisodium phosphate , anhydrous sodium carbonate 5g / L;

[0028] 2) Anodizing: Put the magnesium alloy that has been pretreated in step 1) into the above-mentioned anodizing electrolyte for AC anodizing; when AC anodizing, set the waveform as a sinusoidal waveform, the voltage is 8V, and the current density is 4A / dm 2 , the frequency is 50Hz, the tem...

Embodiment 2

[0032] A magnesium alloy anodic oxidation electrolyte consists of: sodium tetraborate 30g / L, boric acid 20g / L, sodium hydroxide 5g / L, sodium molybdate 5g / L, sodium citrate 8g / L; The sodium solution adjusted the pH of the electrolyte to 8.8.

[0033] The method for preparing a black anodic oxidation film by adopting magnesium alloy anodic oxidation electrolyte comprises the following steps:

[0034] 1) Pre-treatment: sand paper to 1500#, then put the magnesium alloy into the alkali washing solution at 60°C for 10 minutes; the alkaline washing solution consists of 50g / L sodium hydroxide and 20g / L trisodium phosphate , anhydrous sodium carbonate 5g / L;

[0035] 2) Anodizing: Put the magnesium alloy that has been pretreated in step 1) into the above-mentioned anodizing electrolyte for AC anodizing; when AC anodizing, set the waveform as a sinusoidal waveform, the voltage is 10V, and the current density is 6A / dm 2 , the frequency is 50Hz, the temperature of the anodic oxidation el...

Embodiment 3

[0039] A magnesium alloy anodic oxidation electrolyte consists of: sodium tetraborate 40g / L, boric acid 15g / L, sodium hydroxide 10g / L, sodium molybdate 6g / L, sodium citrate 10g / L; The sodium solution adjusts the pH of the electrolyte to 9.0.

[0040] The method for preparing a black anodized film by using the above-mentioned magnesium alloy anodic oxidation electrolyte comprises the following steps:

[0041] 1) Pre-treatment: sand paper to 1500#, then put the magnesium alloy into the alkali washing solution at 50°C for 30 minutes; the alkaline washing solution consists of 50g / L sodium hydroxide and 20g / L trisodium phosphate , anhydrous sodium carbonate 5g / L.

[0042] 2) Anodizing: Put the magnesium alloy that has been pretreated in step 1) into the above-mentioned anodizing electrolyte for AC anodizing; when AC anodizing, set the waveform as a sinusoidal waveform, the voltage is 12V, and the current density is 8A / dm 2 , the frequency is 50Hz, the temperature of the anodic ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com