Method for preparing aluminium oxide nano-form photon crystal

An alumina nanometer and photonic crystal technology, applied in the field of electrochemistry, can solve the problems of limiting alumina nanotemplates, unable to obtain alumina nanotemplates, etc., and achieves the effects of low production cost, controllable number of layers, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

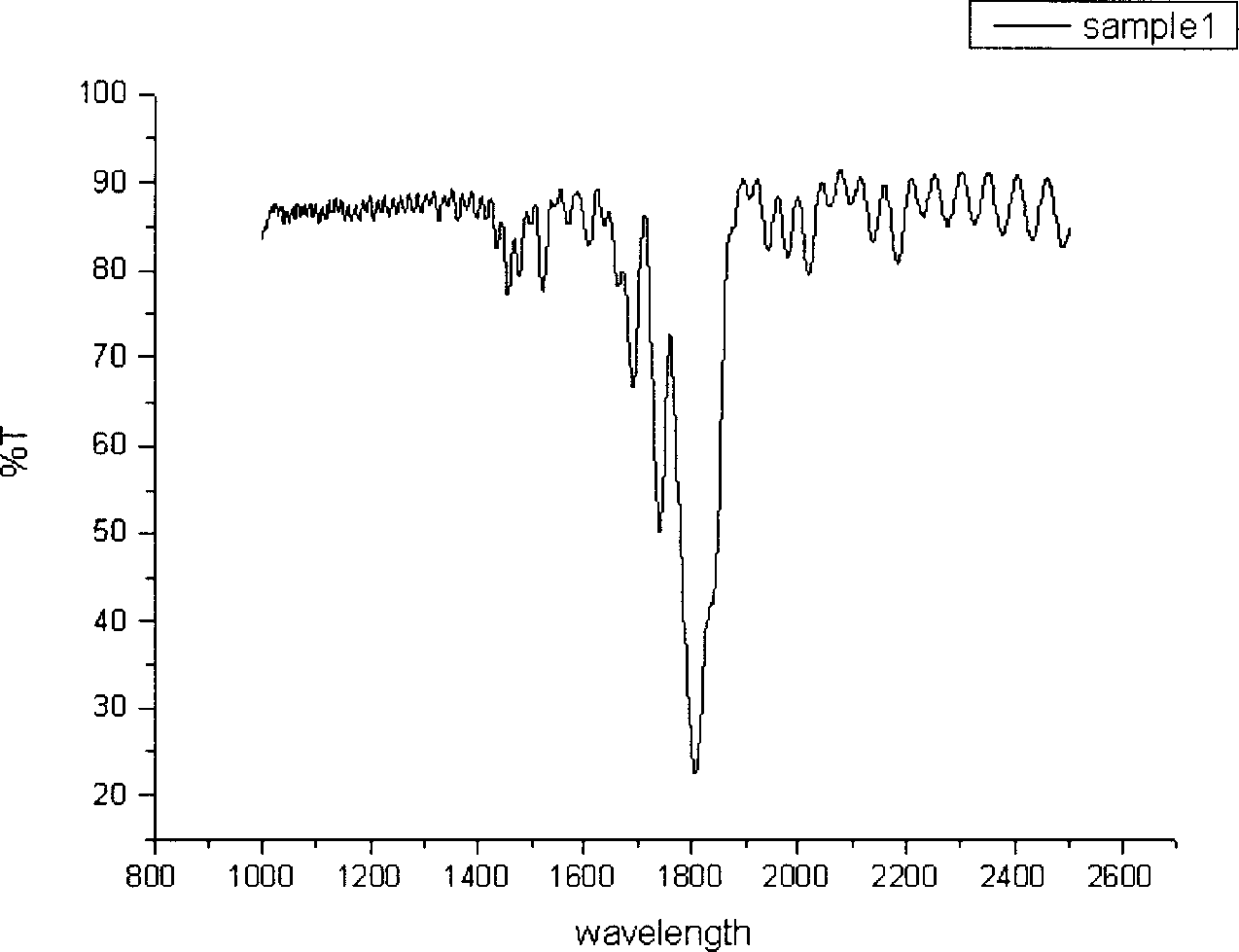

Image

Examples

Embodiment 1

[0025] When the ambient temperature is about 20 degrees Celsius, follow the steps below:

[0026] (1) Cut an aluminum sheet with a thickness of 0.2mm into a shape of 2.5cm×3cm.

[0027] (2) Use acetone to remove oil, then use 0.1mol / L dilute sulfuric acid and dilute sodium hydroxide solution to wash the aluminum sheet.

[0028] (3) In the electrolyte of 80wt% absolute alcohol and 20wt% perchloric acid mixed solution, the treated aluminum sheet was used as the anode, and the platinum sheet was used as the cathode for electrochemical polishing with a voltage of 16v for 3 minutes.

[0029] (4) Use 0.3mol / L oxalic acid as the electrolyte, the polished aluminum sheet as the anode, and the platinum sheet as the cathode, and anodize the aluminum sheet. Voltage 52v, time 6 hours.

[0030] (5) Use a mixed solution of 6 wt% phosphoric acid and 1.8 wt% chromic acid to dissolve the aluminum oxide film formed on the surface of the aluminum sheet.

[0031] (6) Use oxalic acid as the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com