Preparation method of double-layer titanium dioxide nanotube thin film with pear-shaped structure

A technology of titanium dioxide and nanotubes, which is applied in the field of double-layered titanium dioxide nanotube films, can solve the problems that nanotube films have not been reported, and achieve the effects of facilitating new bone formation, easy promotion and application, and promoting adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

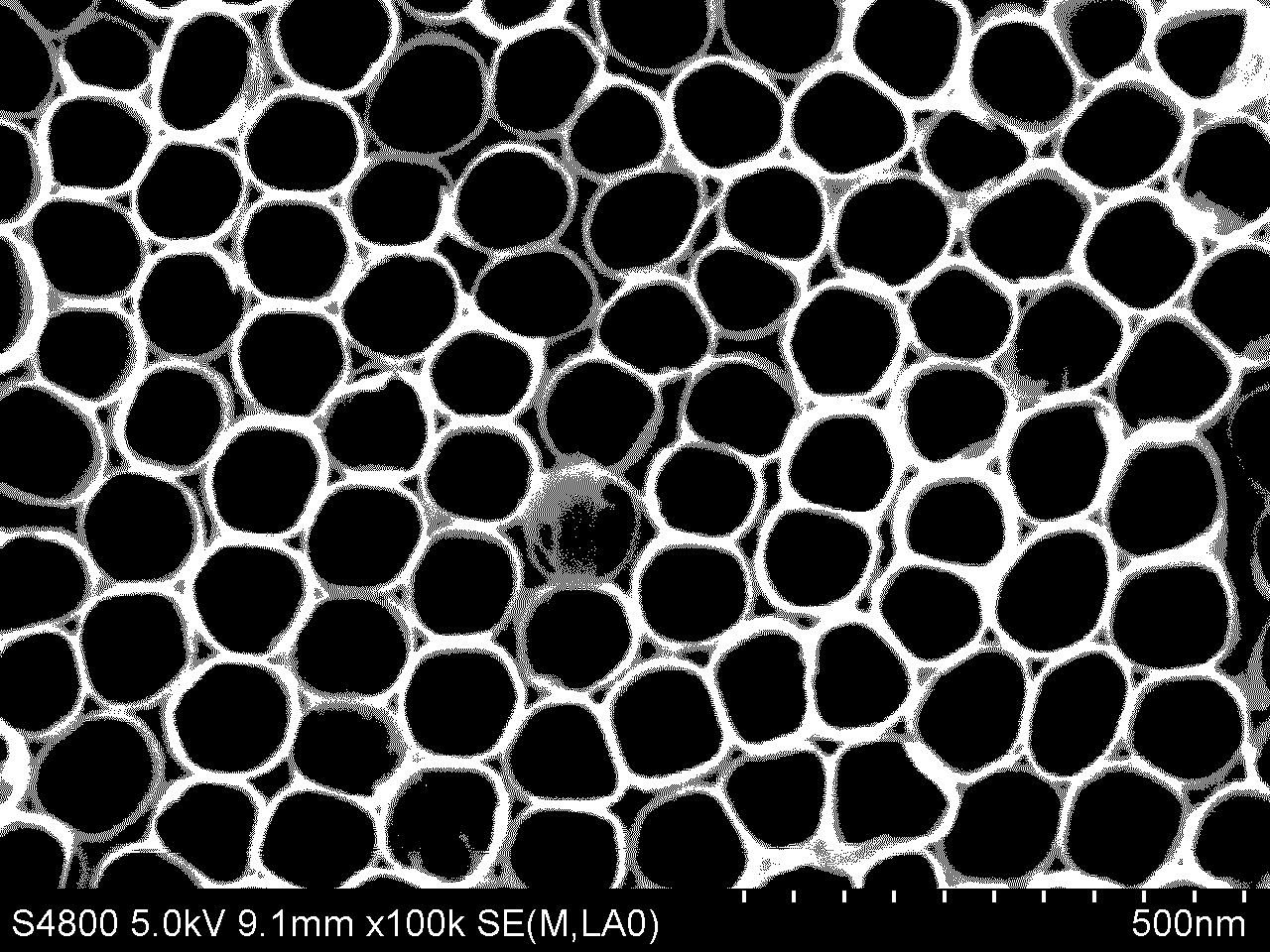

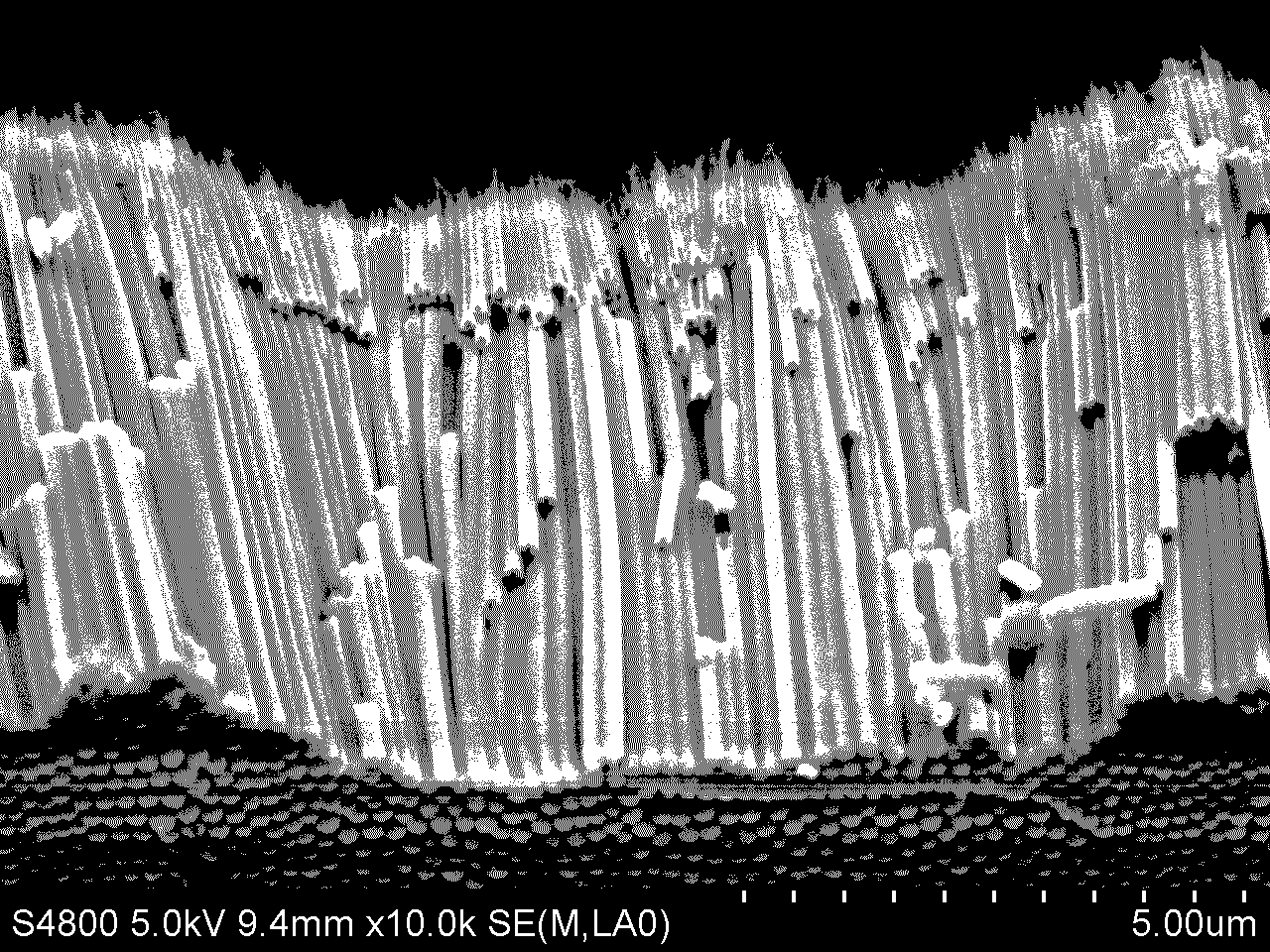

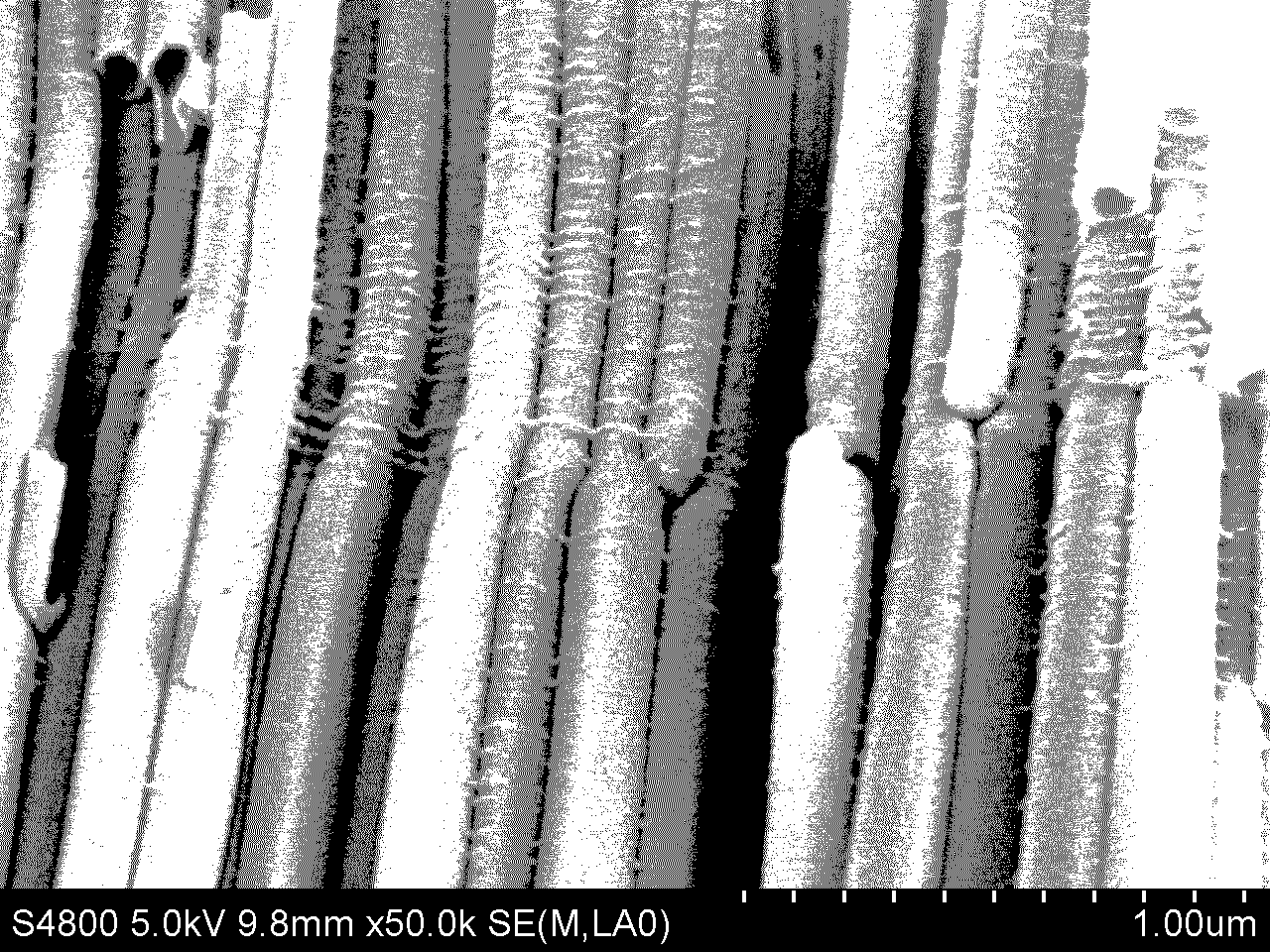

[0025] Example 1: The pure titanium sheet (TA2) with a size of 10 × 10 × 1 mm was polished and polished with 400#, 600#, 800#, 1000# metallographic sandpaper in sequence, and then ultrasonically cleaned with acetone, absolute ethanol and deionized water for 5 min; at 0.3 wt% NH 4 F, 2 vol% H 2 In the ethylene glycol electrolyte of O, the sample was subjected to one-step in-situ step-up anodizing treatment as follows: the applied voltage was increased from 0 V to 40 V and then maintained for 80 min, and then increased from 40 V to 80 V and maintained for 40 min. The DC step-up mode is adopted in the boosting process, and the boosting rate is selected as 2 V / min; that is, the step is 2 V, and it is kept for 1 min under each voltage condition. After electrolysis, the samples were ultrasonically cleaned with absolute ethanol and deionized water, heat treated at 500 °C for 2 h, and cooled in the furnace. Scanning electron microscope observation shows that the surface of the oxi...

Embodiment 2

[0026] Example 2: The pure titanium sheet (TA1) with a diameter of 15 mm was polished and polished with 400#, 600#, 800#, 1000# metallographic sandpaper in sequence, and then ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 5 min respectively; 0.2 wt% NH 4 F, 6 vol% H 2 In the ethylene glycol electrolyte of O, the samples were subjected to one-step in-situ step-up anodizing treatment as follows: the applied voltage was raised from 0 V to 20 V and kept for 3.5 h, and then raised from 20 V to 50 V and kept for 50 min. The DC linear boost mode is adopted in the boost process, and the boost rate is selected as 15 V / min. After electrolysis, the samples were ultrasonically cleaned with absolute ethanol and deionized water, heat treated at 450 °C for 2.5 h, and cooled in the furnace. Scanning electron microscope observation shows that the surface of the oxide film is closely arranged, and the opening diameter is 80 nm. 0.61 μm, the outer diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com