Method for preparing anodic aluminum oxide (AAO) template with large pore diameter and thin wall on silicon substrate

An anodized aluminum, anodized technology, applied in the direction of anodic oxidation, ion implantation plating, coating, etc., can solve the problems of uneven distribution, small wall thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

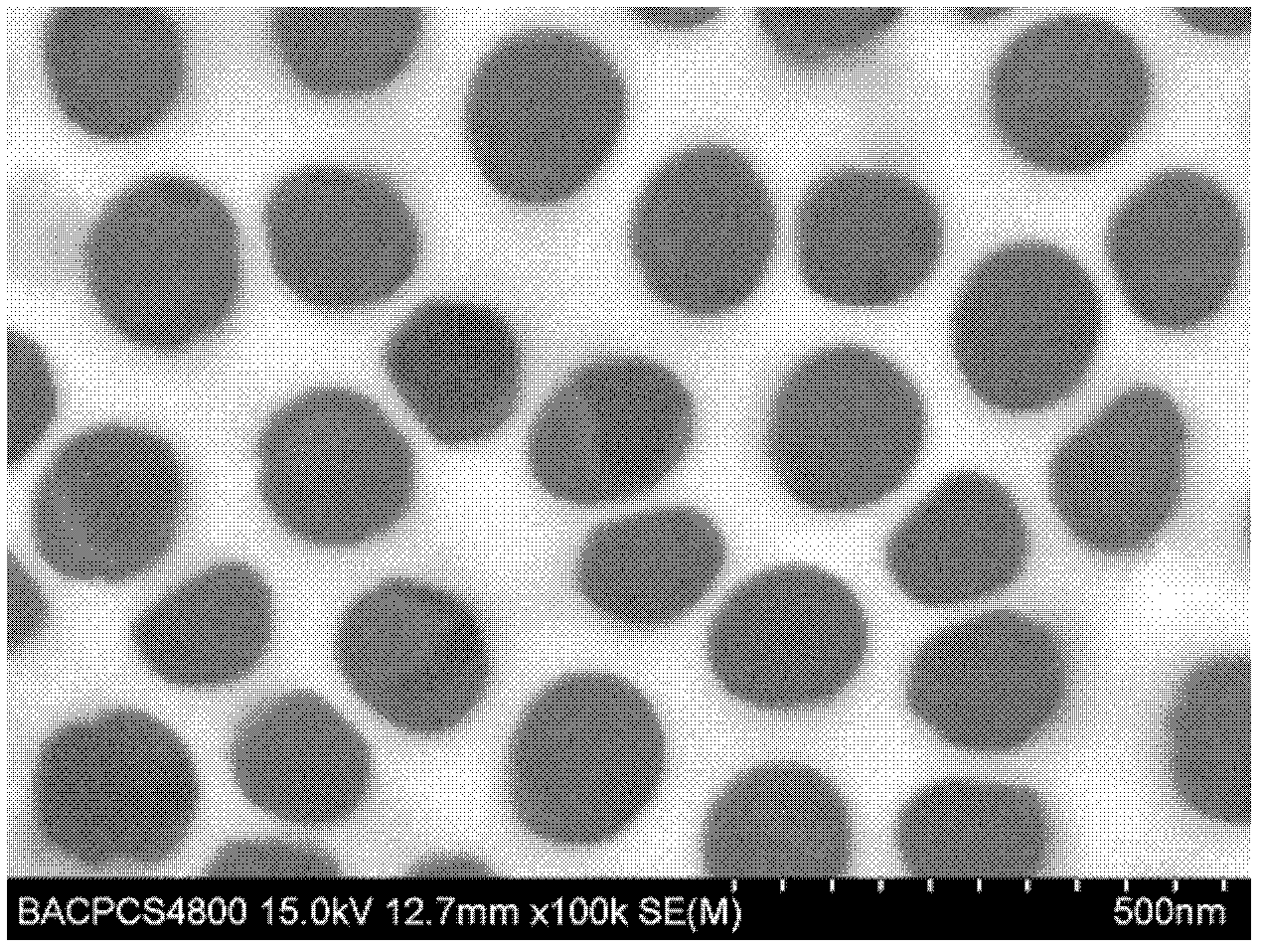

[0019] Carry out standard RCA cleaning to the silicon substrate, and then use vacuum thermal evaporation to deposit an aluminum layer with a thickness of 1000 nanometers on the surface of the silicon substrate; put the silicon substrate deposited with the aluminum layer into an anodic oxidation tank, and The anodizing tank is placed in a mixture of ice and water, and a magnetic stirrer is used to stir the anodizing solution to control the temperature at 0-5°C. The anodizing solution is an ethylene glycol solution of phosphoric acid, and the volume percentage of phosphoric acid is 18%. , anodized at a voltage of 210V for 5 minutes; then the sample was taken out, washed repeatedly with deionized water, and placed in 5 wt% phosphoric acid aqueous solution at room temperature to expand the pores for 20 minutes. Thus, a large-aperture thin-wall anodized aluminum template on a silicon substrate is obtained. figure 1 It is a scanning electron microscope (SEM) photo of the large-apert...

Embodiment 2

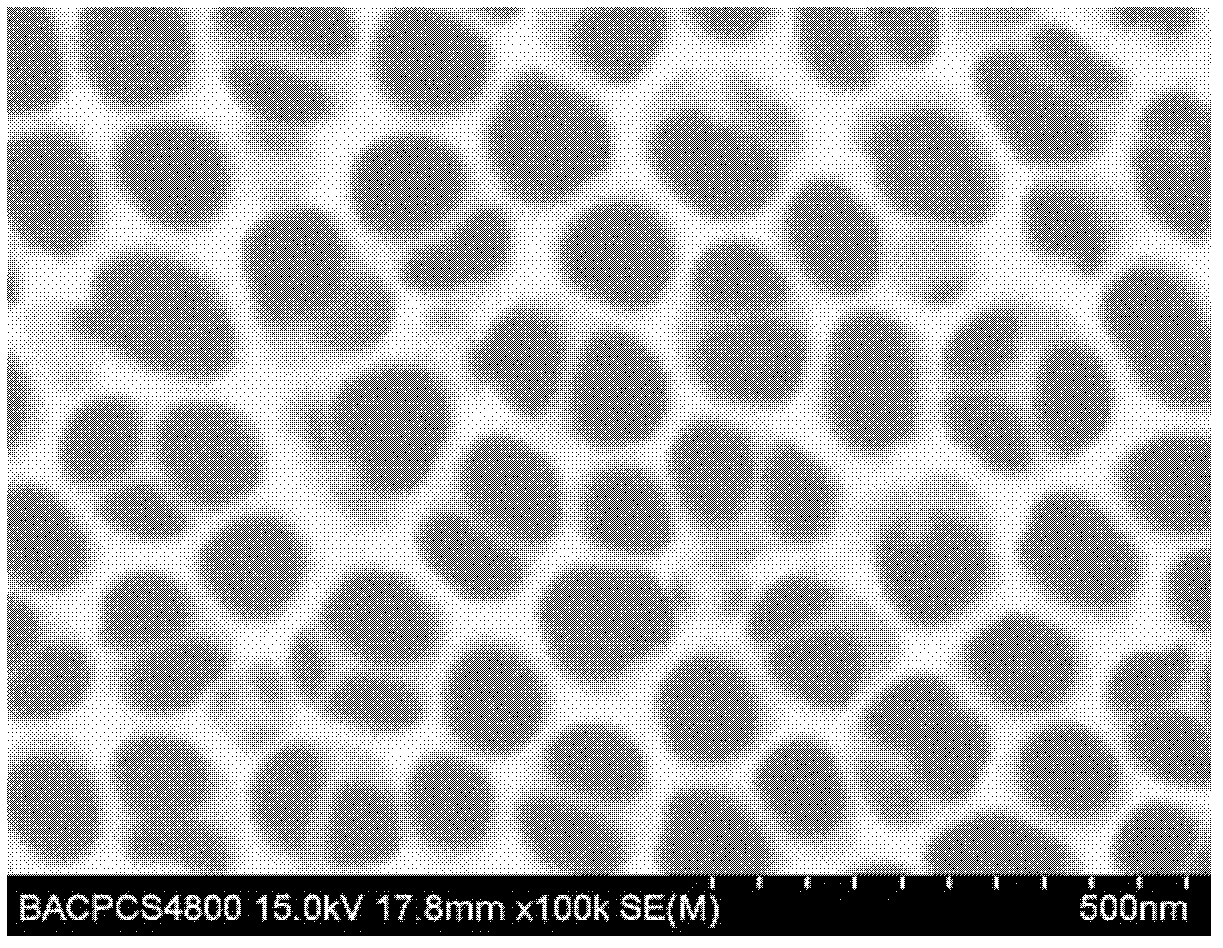

[0021] Carry out standard RCA cleaning to the silicon substrate, and then use vacuum thermal evaporation to deposit an aluminum layer with a thickness of 750 nanometers on the surface of the silicon substrate; the silicon substrate deposited with the aluminum layer is placed in an anodic oxidation tank, and the The anodizing tank is placed in a mixture of ice and water, and a magnetic stirrer is used to stir the anodizing solution to control the temperature at 0-5°C. The anodizing solution is an ethylene glycol solution of phosphoric acid, and the volume percentage of phosphoric acid is 24%. , anodized at a voltage of 250V for 1 minute; the sample was taken out, washed repeatedly with deionized water, and placed in 5 wt% phosphoric acid aqueous solution at room temperature to expand the pores for 30 minutes. Thus, a large-aperture thin-wall anodized aluminum template on a silicon substrate is obtained. figure 2 It is a scanning electron microscope (SEM) photo of the large-ape...

Embodiment 3

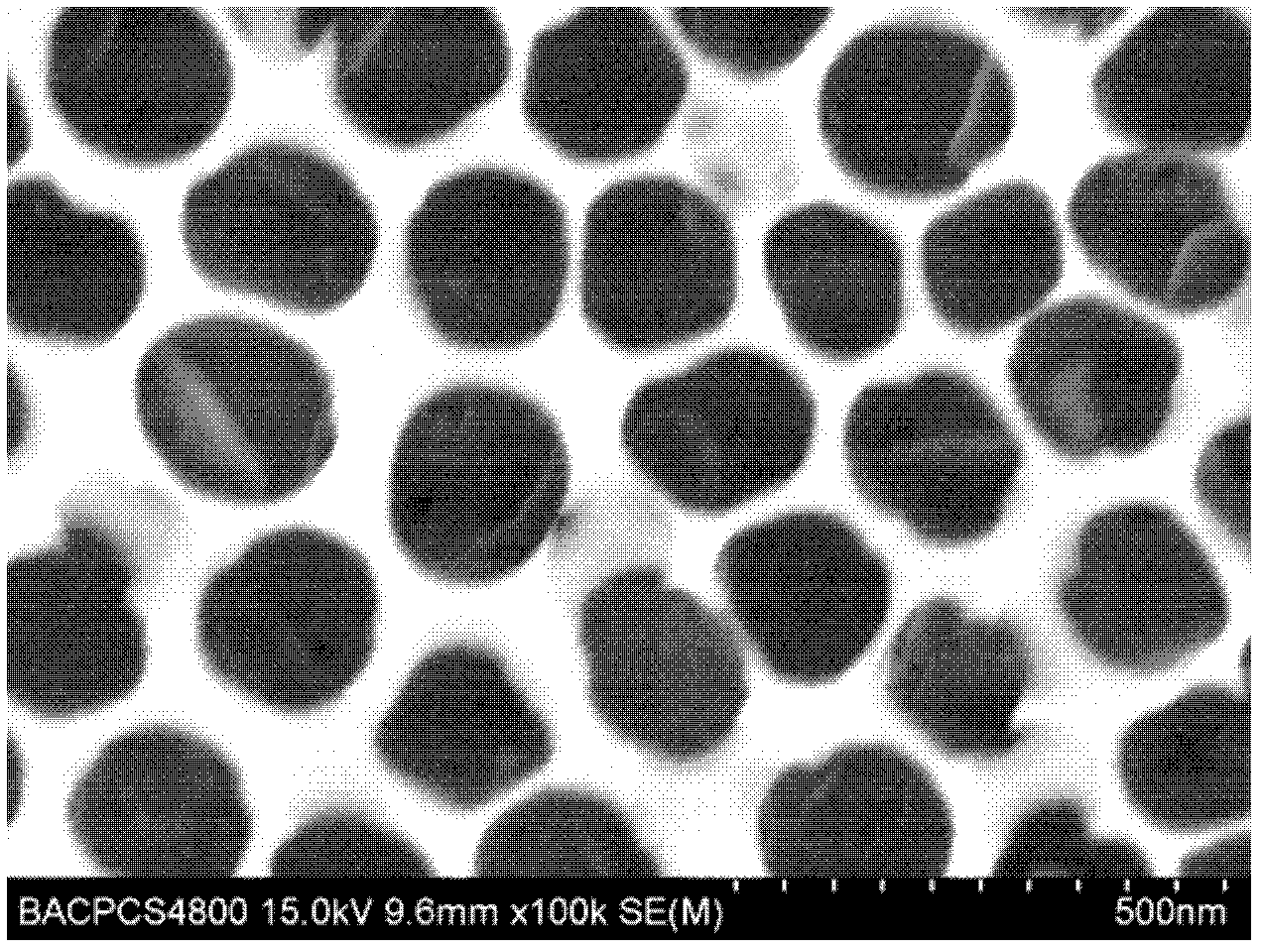

[0023] Use a concentrated strong alkaline hot solution to remove the damaged layer on the surface of the silicon substrate to make the surface smooth, then perform standard RCA cleaning on the silicon substrate, and then use vacuum thermal evaporation to deposit an aluminum layer with a thickness of 500 nanometers on the surface; Put the silicon substrate deposited with the aluminum layer into the anodizing tank, put the anodizing tank in the mixture of ice and water, and use a magnetic stirrer to stir the anodizing solution so as to control the temperature at 0-5°C, anodizing The solution is an ethylene glycol solution of phosphoric acid, wherein the volume percentage of phosphoric acid is 21%, anodized at a voltage of 230V for 2 minutes; the sample is taken out and cleaned repeatedly with deionized water, and placed in 5wt% phosphoric acid at room temperature Pore expansion in aqueous solution for 50 minutes. Thus, a large-aperture thin-wall anodized aluminum template on a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com