Honeycomb ordered titanium dioxide nanotube array film and preparation method thereof

A technology of nanotube array and titanium dioxide, which is applied in chemical instruments and methods, nanotechnology, crystal growth, etc., to achieve the effect of low-cost equipment and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

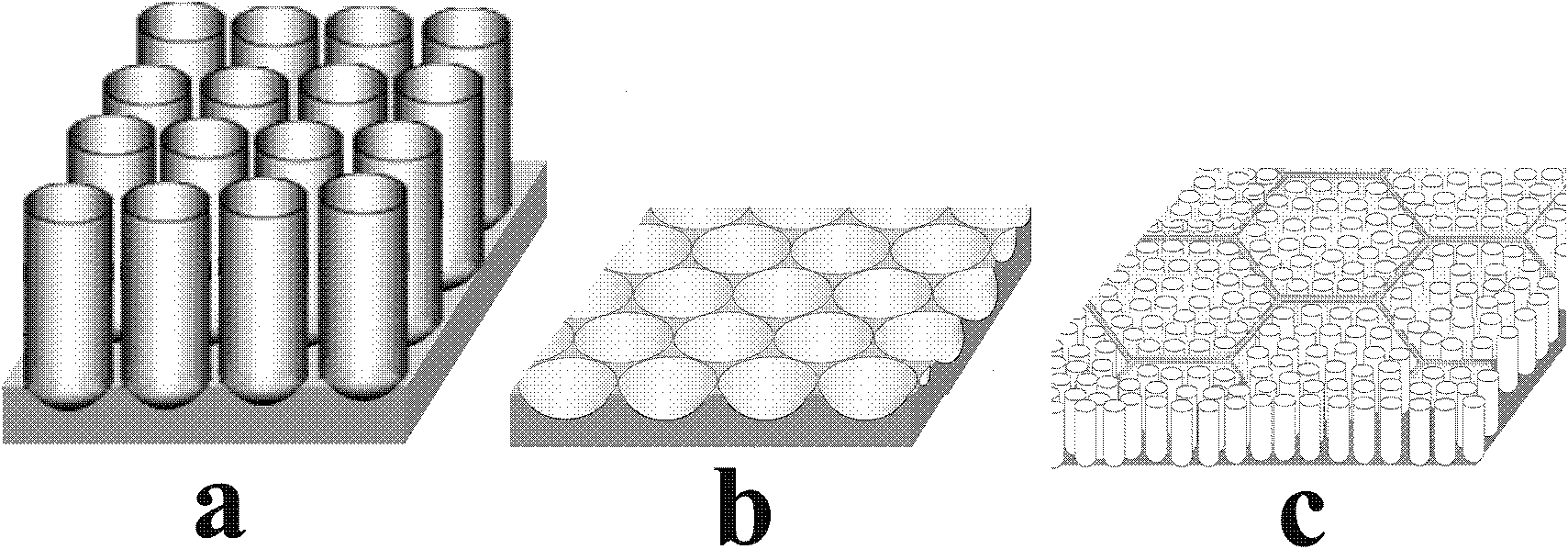

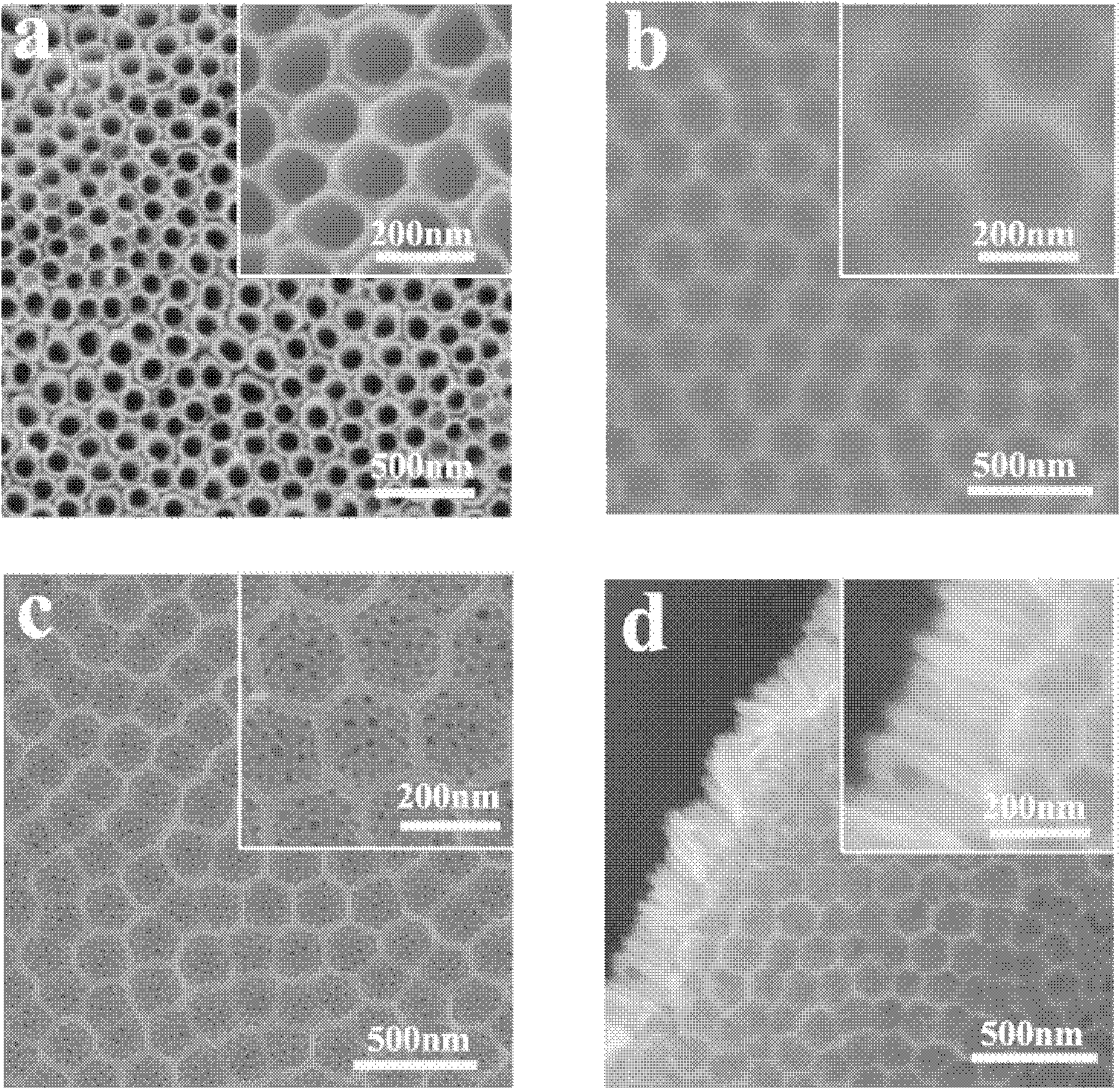

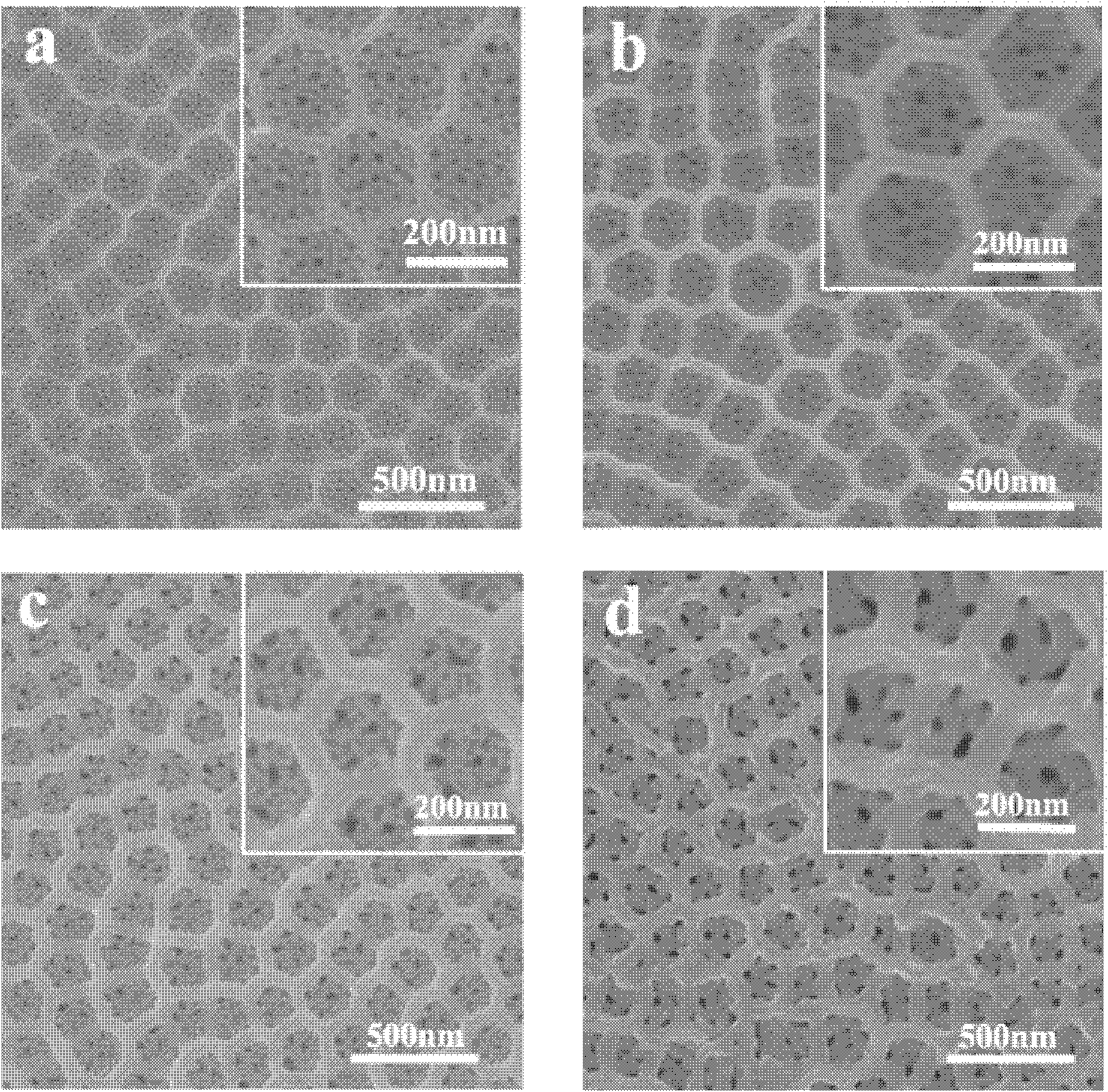

[0027] Example Honeycomb ordered titanium dioxide nanotube array film, the honeycomb ordered titanium dioxide nanotube array film is composed of upper and lower layers of titanium dioxide nanopores, and is supported on a titanium sheet substrate;

[0028] The titanium dioxide nanopore in the upper layer is an ordered regular hexagonal array, and its aperture is 70-250nm;

[0029] The titanium dioxide nanopores in the lower layer are actually titanium dioxide nanotubes, the open ends of which are located in the upper nanopores, and the open ends of the tubes are bonded to each other in the axial direction, and the aperture of the lower layer holes is 15-40nm, and the depth is 100-2000nm .

[0030] A method for preparing a honeycomb ordered titanium dioxide nanotube array film, comprising the following steps:

[0031] (1) First put the pure titanium sheet into a mixed solution of ethanol and acetone and ultrasonically clean it for 55-65 minutes to remove the organic matter on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com