Method for improving high-temperature oxidation resistance of titanium-based alloy

A technology for resisting high temperature oxidation and titanium-based alloys, which is applied in the field of high temperature oxidation resistance of metal materials, can solve problems such as large energy consumption, and achieve the effects of simple preparation process, easy realization and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

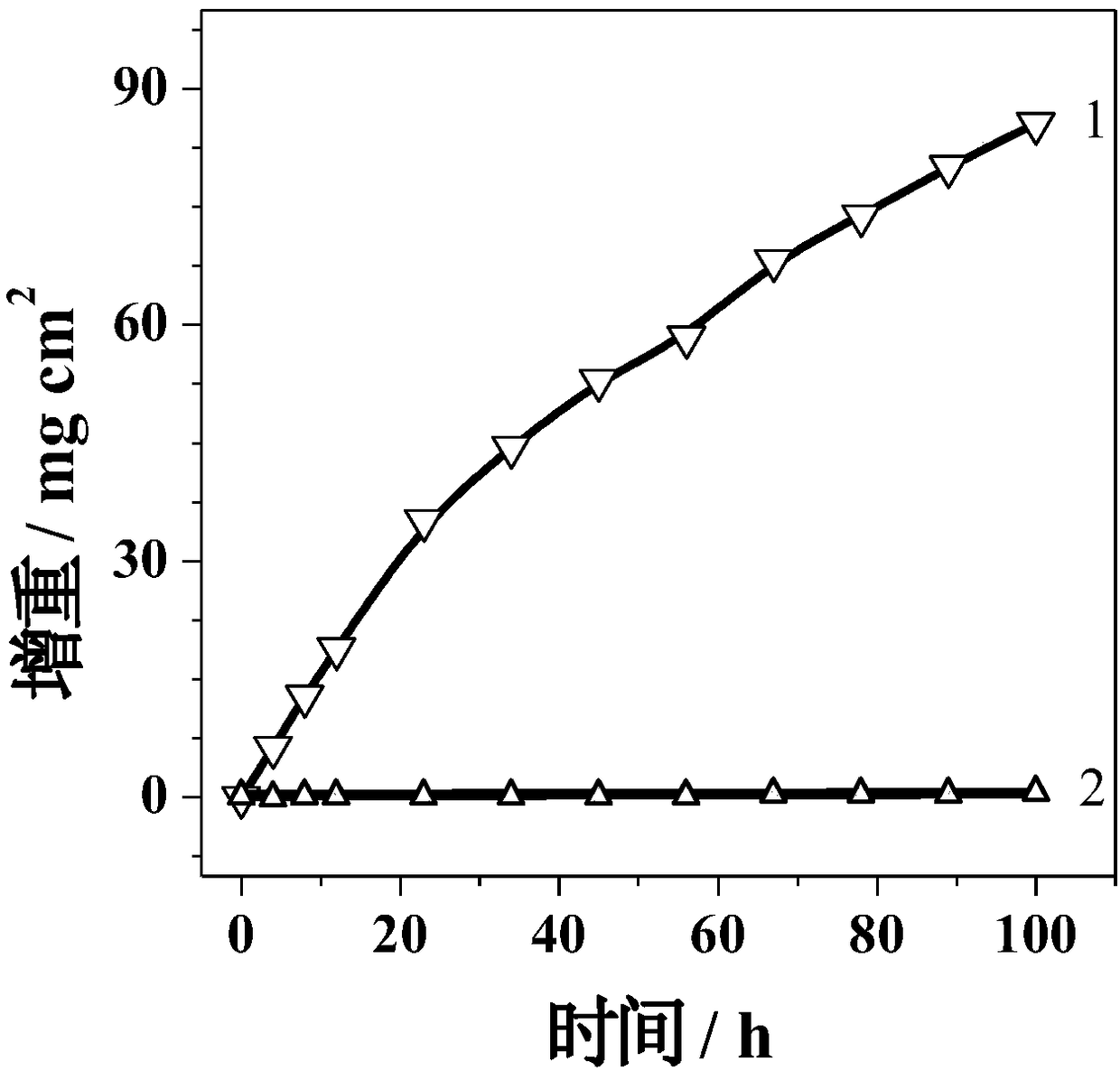

Embodiment 1

[0021] A method to improve the high-temperature oxidation resistance of titanium-based alloys. First, use 60-mesh iron sandpaper to polish the titanium-based alloy sample to the mirror surface, then scrub it with absorbent cotton dipped in absolute ethanol, ultrasonically clean it in acetone for 3 minutes, and finally blow it with hot air. dry to prepare polished and cleaned titanium-based alloy samples. The polished and cleaned titanium-based alloy sample (Ti-50Al) is used as the anode, and the graphite electrode is used as the counter electrode. The distance between the electrodes is 2.5cm. The constant voltage mode is used for anodic oxidation, and the anodic oxidation electrolyte used is 0.1molL -1 CeCl 3 ·7H 2 O and 0.5wt% ammonium fluoride in ethylene glycol solution, the voltage is set to 1V, the temperature is controlled at 25°C with a water bath, and after anodizing for 60min, the sample is taken out and rinsed with deionized water and then ultrasonically cleaned wi...

Embodiment 2

[0023] A method to improve the high-temperature oxidation resistance of titanium-based alloys. First, use 60-mesh iron sandpaper to polish the titanium-based alloy sample to the mirror surface, then scrub it with absorbent cotton dipped in absolute ethanol, ultrasonically clean it in acetone for 3 minutes, and finally blow it with hot air. dry to prepare polished and cleaned titanium-based alloy samples. The polished and cleaned titanium-based alloy sample (Ti-10Al) is used as the anode, and the graphite electrode is used as the counter electrode. The distance between the electrodes is 1cm. The constant voltage mode is used for anodic oxidation, and the anodic oxidation electrolyte used is 0.05molL -1 CeCl 3 ·7H 2 O and 0.1wt% ammonium fluoride in ethylene glycol solution, the voltage is set to 60V, and the temperature is controlled at 25°C by using a water bath. After anodizing for 5 minutes, the sample is taken out and rinsed with deionized water, and then ultrasonically c...

Embodiment 3

[0026] A method to improve the high-temperature oxidation resistance of titanium-based alloys. First, use 60-mesh iron sandpaper to polish the titanium-based alloy sample to the mirror surface, then scrub it with absorbent cotton dipped in absolute ethanol, ultrasonically clean it in acetone for 3 minutes, and finally blow it with hot air. dry to prepare polished and cleaned titanium-based alloy samples. The polished and cleaned titanium-based alloy sample (Ti-20Al) is used as the anode, and the graphite electrode is used as the counter electrode. The distance between the electrodes is 10cm. The constant voltage mode is used for anodic oxidation, and the anodic oxidation electrolyte used is 0.2molL -1 CeCl 3 ·7H 2 O and 10wt% ammonium fluoride in ethylene glycol solution, the voltage is set to 30V, the temperature is controlled at 25°C with a water bath, and after anodizing for 30 minutes, the sample is taken out and rinsed with deionized water, and then ultrasonically clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com