Nickel-based electrode material and preparation method thereof

An electrode material, nickel-based technology, applied in the field of supercapacitor electrode materials, can solve the problems of reducing the cycle life of supercapacitors, weak bonding force between nickel-based active materials and current collectors, and falling off of active materials, and achieves reduced process, electrical conductivity, etc. Good performance and the effect of improving specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

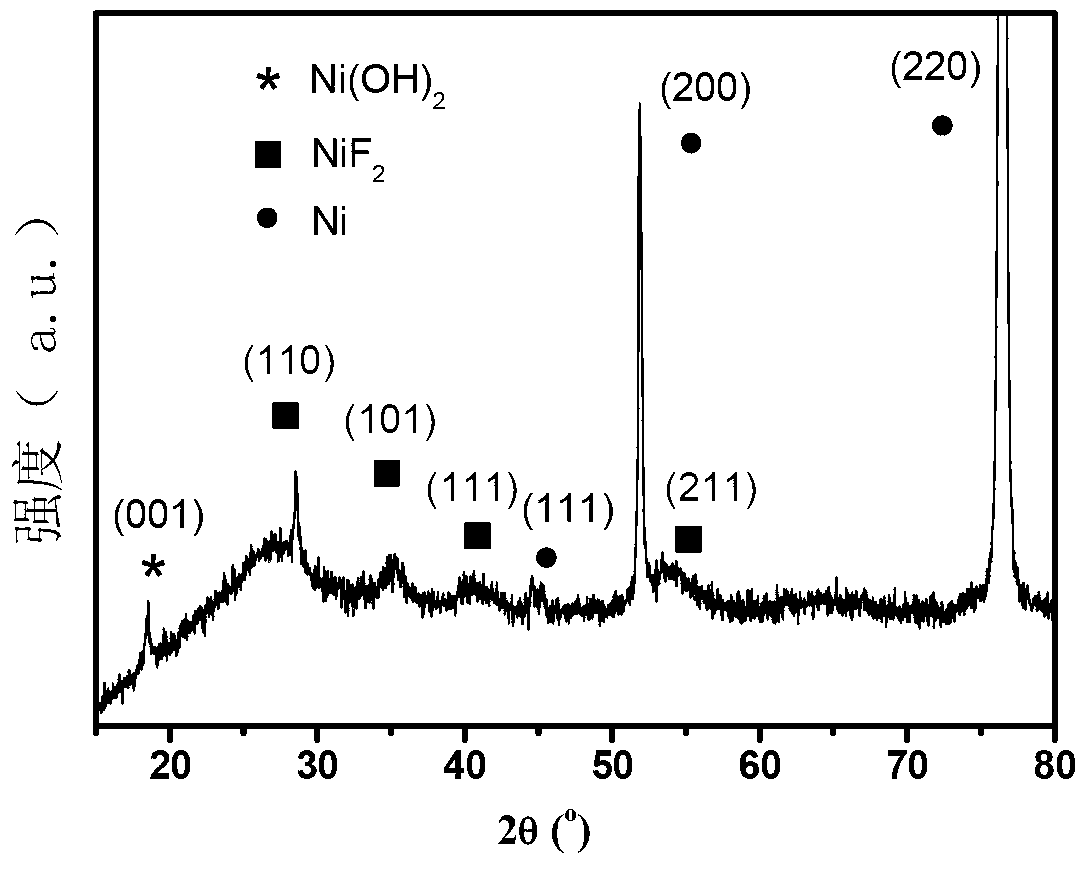

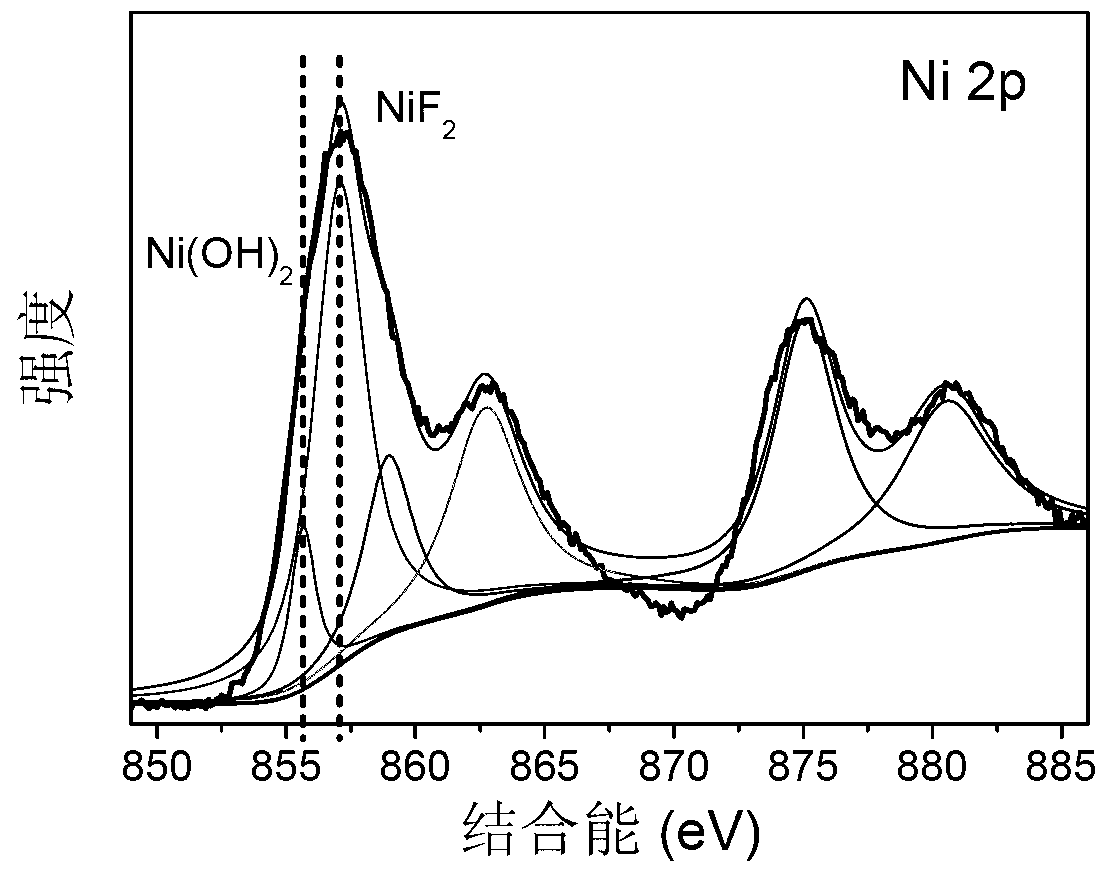

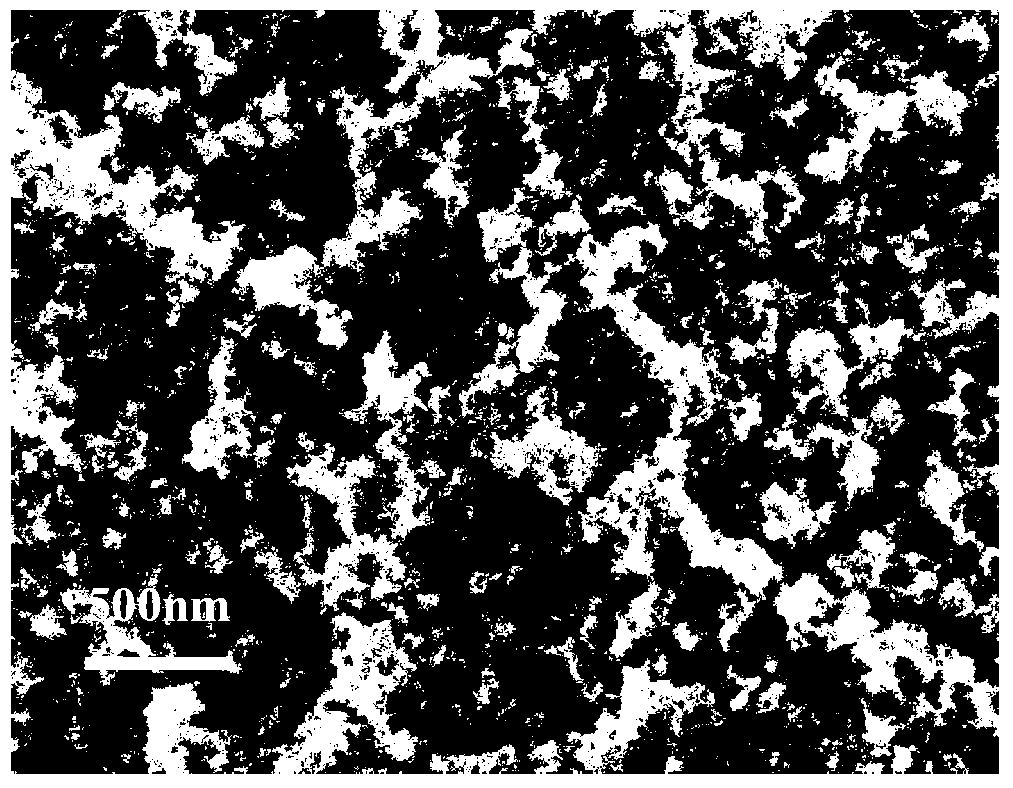

[0030] A kind of preparation method of nickel base electrode material, concrete steps are as follows:

[0031] (1) Sample preparation: soak the nickel sheet in acetone and clean it in an ultrasonic cleaning tank for 20 minutes, then soak the cleaned nickel sheet in absolute ethanol.

[0032] (2) Anodic oxidation of nickel sheet: configure anodic oxidation electrolyte, H in the solution 3 PO 4 The mass fraction of ammonium fluoride is 80wt%, the mass fraction of ammonium fluoride is 1wt%, the mass fraction of EDTA is 0.1wt%, the mass fraction of sodium citrate is 0.2wt%, and the balance is water (mass fraction is 18.7wt%). The pH of the electrolyte was adjusted to 1. Take out the nickel sheet soaked in absolute ethanol and dry it with a hair dryer. A nickel sheet was used as the anode, a stainless steel sheet was used as the cathode, and a saturated potassium chloride calomel electrode was used as the reference electrode. The anodic oxidation voltage was increased to 3.5V at...

Embodiment 2

[0037]A kind of preparation method of nickel base electrode material, concrete steps are as follows:

[0038] (1) Sample preparation: the same as in Example 1.

[0039] (2) Anodic oxidation of nickel sheet: configure anodic oxidation electrolyte, H in the solution 3 PO 4 The mass fraction of ammonium fluoride is 80wt%, the mass fraction of ammonium fluoride is 1wt%, the mass fraction of EDTA is 0.5wt%, the mass fraction of sodium citrate is 0.2wt%, and the balance is water (mass fraction is 18.3wt%). The pH of the electrolyte was adjusted to 1. Take out the nickel sheet soaked in absolute ethanol and dry it with a hair dryer. A nickel sheet is used as the anode, a stainless steel sheet is used as the cathode, and a saturated potassium chloride calomel electrode is used as the reference electrode. The anodic oxidation voltage is increased to 3V at a rate of 100mV / s, and then maintained at 3V for 40 minutes.

[0040] (3) post-processing: the same as in Example 1.

[0041] T...

Embodiment 3

[0043] A kind of preparation method of nickel base electrode material, concrete steps are as follows:

[0044] (1) Sample preparation: the same as in Example 1.

[0045] (2) Anodic oxidation of nickel sheet: configure anodic oxidation electrolyte, H in the solution 3 PO 4 The mass fraction of ammonium fluoride is 85wt%, the mass fraction of ammonium fluoride is 1wt%, the mass fraction of EDTA is 0.5wt%, the mass fraction of sodium citrate is 0.2wt%, and the balance is water (mass fraction is 13.3wt%). The pH of the electrolyte was adjusted to 0.5. Take out the nickel sheet soaked in absolute ethanol and dry it with a hair dryer. A nickel sheet is used as the anode, a stainless steel sheet is used as the cathode, and a saturated potassium chloride calomel electrode is used as the reference electrode. The anodic oxidation voltage is increased to 3.5V at a rate of 10mV / s, and then maintained at 3.5V for 15 minutes.

[0046] (3) post-processing: the same as in Example 1.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com