Preparation method of vulcanized conducting polymer composite anode for lithium ion battery

A conductive polymer, lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor reversibility, poor electronic conductivity, and low utilization rate of active material S, and achieve the effects of cheap raw materials and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

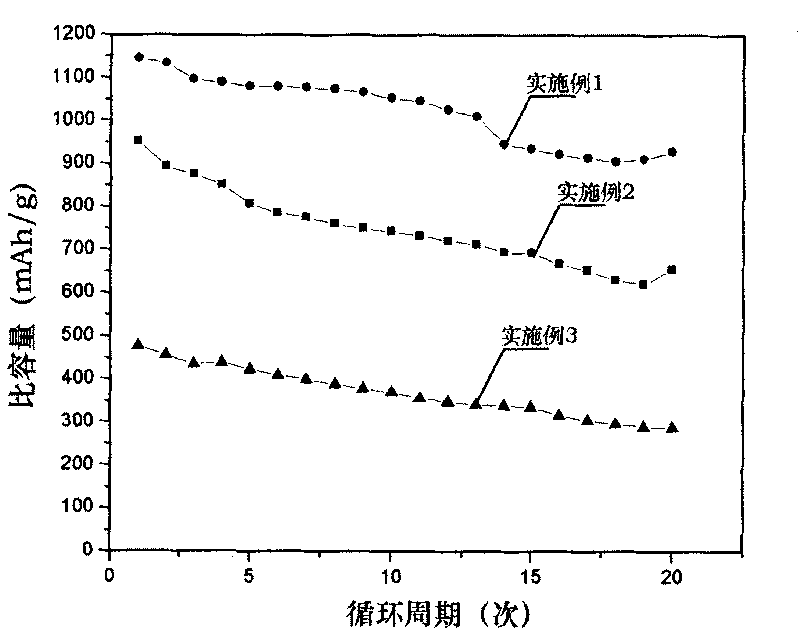

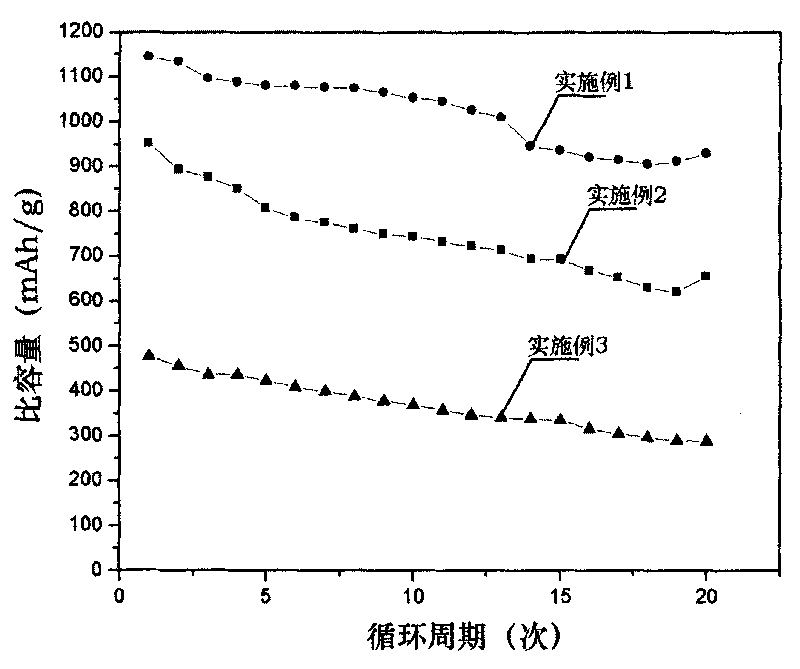

Embodiment 1

[0038] The first step: adding poly(aniline-pyrrole) powder, sublimed sulfur and absolute ethanol into a ball mill and milling for 10 minutes to obtain the first mixed raw material;

[0039] The second step: put the mixed raw materials obtained in the first step into the glass boat of the tube furnace, pass nitrogen into the glass boat to remove the air; and keep it warm for 2 hours; then heat it up to 250° C. at a heating rate of 10° C. / min and hold it for 5 hours to prepare a sulfurized poly(aniline-pyrrole) composite (positive electrode active material).

[0040] The third step: adding the positive electrode active material, conductive agent, binder and n-propanol aqueous solution with a concentration of 20% by mass into a ball mill and milling for 10 minutes to obtain the second mixed raw material;

[0041] Dosage: Add 7.2g of positive electrode active material, 3.6g of conductive agent, and 6g of binder to 100ml of n-propanol aqueous solution;

[0042] The conductive agen...

Embodiment 2

[0052] The first step: adding poly(aniline-pyrrole) powder, sublimed sulfur and absolute ethanol into a ball mill and milling for 5 minutes to obtain the first mixed raw material;

[0053] The second step: put the mixed raw material obtained in the first step into the glass boat of the tube furnace, pass nitrogen into the glass boat to remove the air; Keeping it warm for 2 hours; then raising the temperature to 200° C. and keeping it warm for 5 hours to prepare a sulfurized poly(aniline-pyrrole) composite (positive electrode active material).

[0054] The third step: adding the positive electrode active material, conductive agent, binder and n-propanol aqueous solution with a concentration of 20% by mass into a ball mill and milling for 5 minutes to obtain the second mixed raw material;

[0055] Dosage: Add 8.4g of positive electrode active material, 3g of conductive agent, and 9g of binder to 100ml of n-propanol aqueous solution;

[0056] The conductive agent is carbon black...

Embodiment 3

[0065] The first step: adding poly(aniline-pyrrole) powder, sublimed sulfur and absolute ethanol into a ball mill and milling for 15 minutes to obtain the first mixed raw material;

[0066] The second step: put the mixed raw materials obtained in the first step into the glass boat of the tube furnace, pass nitrogen into the glass boat to remove the air; Keeping it warm for 2 hours; then raising the temperature to 300° C. and keeping it warm for 5 hours to prepare a sulfurized poly(aniline-pyrrole) composite (positive electrode active material).

[0067] The third step: adding the positive electrode active material, conductive agent, binder and n-propanol aqueous solution with a concentration of 20% by mass into a ball mill and milling for 10 minutes to obtain the second mixed raw material;

[0068] Dosage: Add 9.6g of positive electrode active material, 1.8g of conductive agent, and 3g of binder to 100ml of n-propanol aqueous solution;

[0069] The conductive agent is acetyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com