Pipe surface ceramizing treatment process

A treatment process and ceramization technology, which is applied in the field of ceramization treatment process on the surface of pipe fittings, can solve the problems of large thermal influence of the substrate, difficult process, difficult post-processing of the ceramic coating, etc., to achieve uniform high temperature resistance, convenient use, temperature and concentration. Basically constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

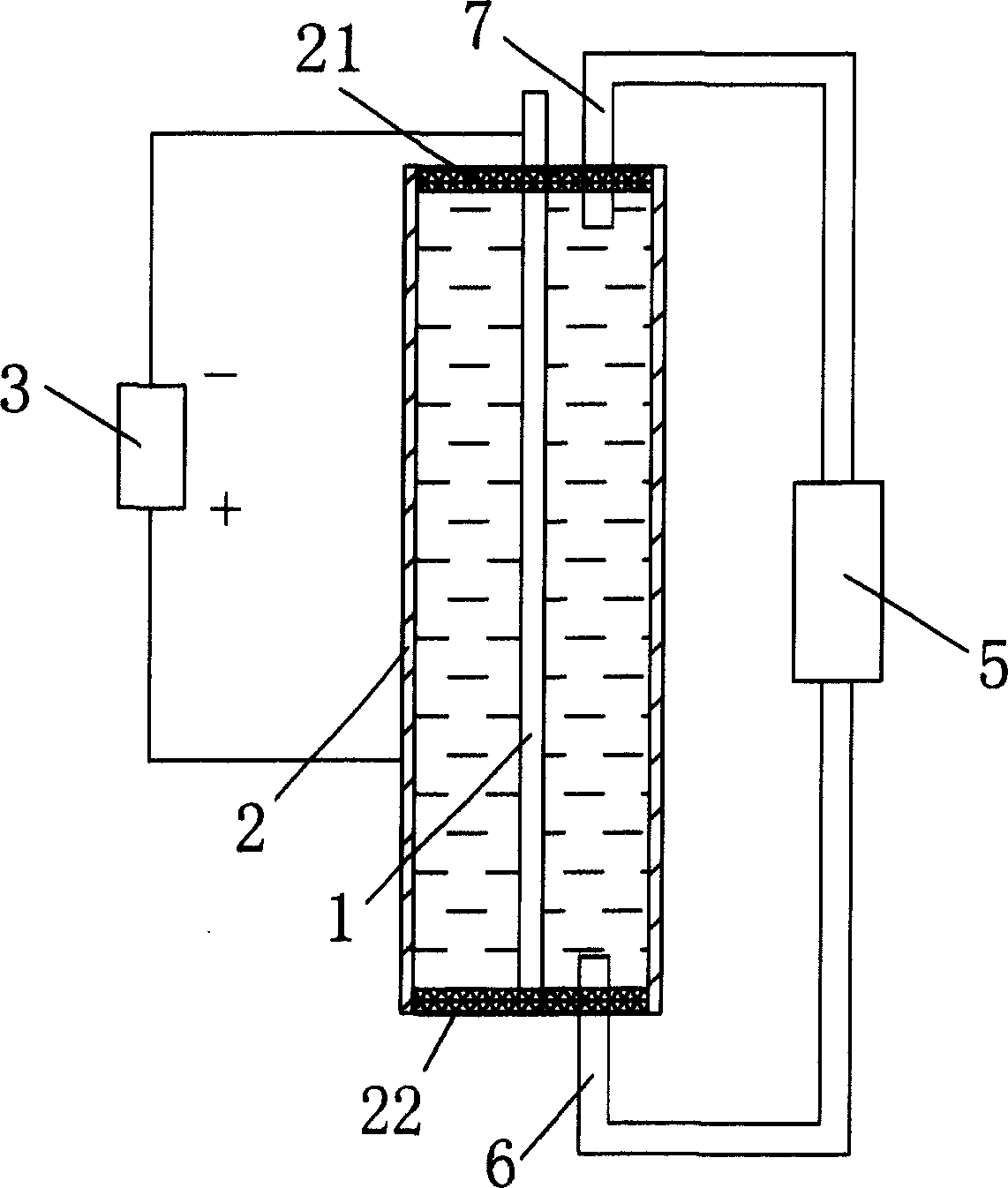

[0026] Example 1: First, hot-dip aluminizing the inner and outer surfaces of 45# steel pipe fitting 2 with an inner diameter of Φ50 mm, immerse the 45# steel pipe fitting 2 in molten aluminum, and control the temperature of the molten aluminum at 690-710°C, and heat-dip the 45# steel pipe Part 2 rotates and moves up and down, and the hot-dip aluminum plating time is about 20 minutes, forming a 75μm Fe-Al alloy layer and an 80μm pure aluminum layer on the surface of the pipe;

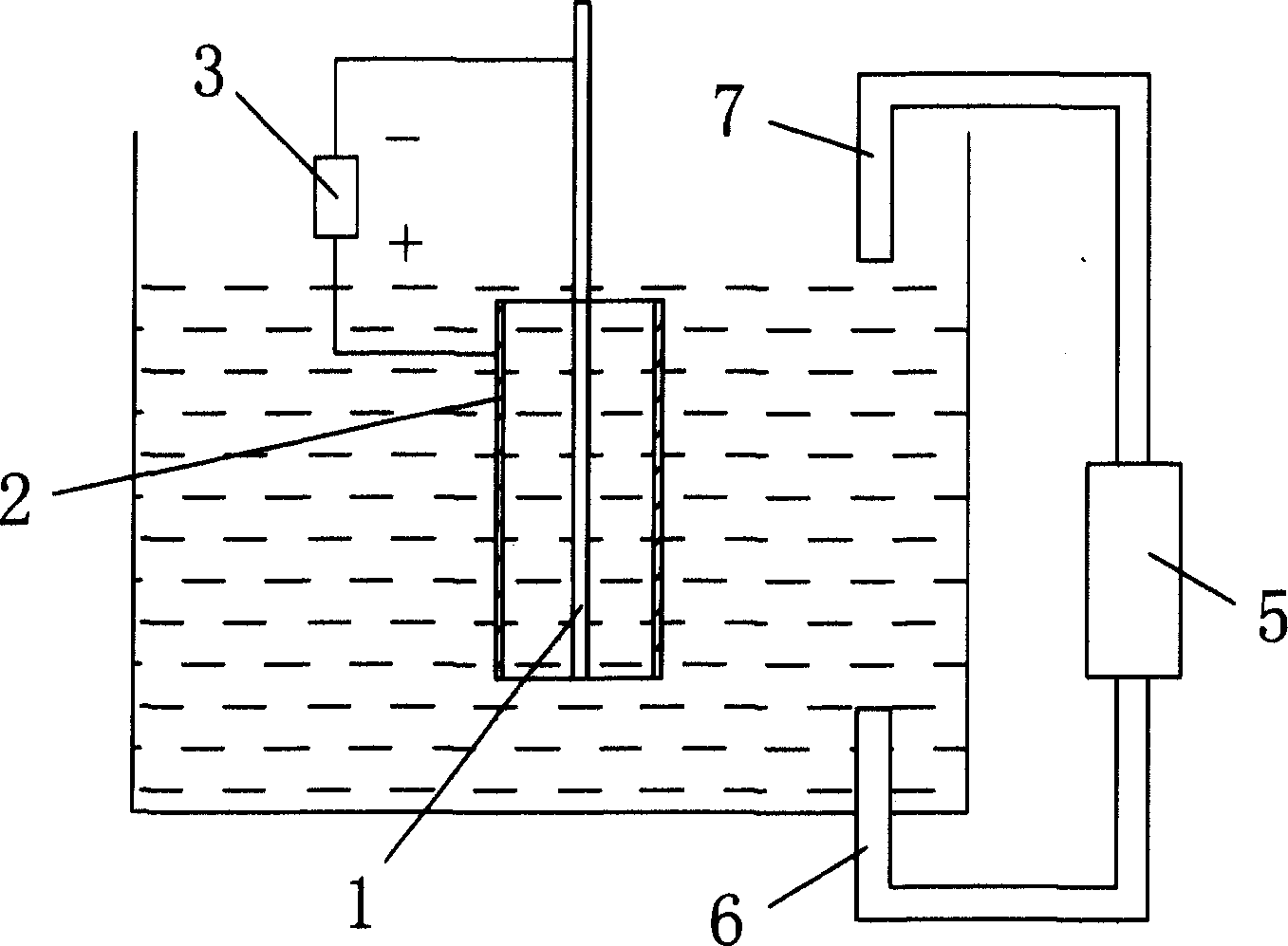

[0027] Then, if figure 2 As shown, the full immersion method is used to vertically fix the 45# steel pipe fitting 2 that has been hot dipped and aluminized, and then immerse it in the treatment liquid in the treatment tank as a whole, place the electrode rod 1 in the center of the inner cavity of the pipe fitting 2, and then put the electrode rod 1 is connected to the negative pole of the pulsed DC power supply 3, and the tube 2 is connected to the positive pole of the pulsed DC power supply 3, and the ...

Embodiment 2

[0029] Embodiment 2: First, the method of PVD is used to pre-deposit a magnesium layer with a thickness of about 50 μm on the inner and outer surfaces of polyvinyl chloride pipe fittings 2 with an inner diameter of Φ50 mm, and then, as figure 2 As shown, using the full immersion method, the PVC pipe fitting 2 prepared with a magnesium valve metal layer is vertically fixed and immersed in the treatment solution in the treatment tank as a whole, the electrode rod 1 is placed in the center of the inner cavity of the pipe fitting 2, and then the electrode Rod 1 is connected to the negative pole of the pulsed DC power supply 3, and the PVC pipe fitting 2 prepared with a magnesium valve metal layer is connected to the positive pole of the pulsed DC power supply 3, and a voltage is applied to the pipe fitting 2 through the pulsed DC power supply 3, and the voltage value is gradually adjusted to maintain a constant current density 0.02A / cm 2 The processing time is 30 to 50 minutes. U...

Embodiment 3

[0031] Embodiment 3: First, hot-dip aluminizing is performed on the inner and outer surfaces of the copper pipe fitting 2 with an inner diameter of Φ20 mm, and a 150 μm pure aluminum layer is formed on the surface of the copper pipe fitting;

[0032] Then, if figure 2 As shown, the full immersion method is used to vertically fix the hot-dip aluminized copper pipe fitting 2 and then immerse it in the treatment solution in the treatment tank as a whole, place the electrode rod 1 in the center of the inner cavity of the pipe fitting 2, and then place the electrode rod 1 Connect the negative pole of the pulsed DC power supply 3, connect the tube 2 to the positive pole of the pulsed DC power supply 3, apply a voltage to the tube 2 through the pulsed DC power supply 3, gradually adjust the voltage value, and maintain a constant current density of 0.02A / cm 2 , the processing time is 30 to 50 minutes. Under the action of the electrode rod 1, a ceramic layer is grown on the inner and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com