Method for recovering and regenerating positive electrode material of lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of recycling and regenerating lithium-ion battery positive electrode materials, can solve the problems of secondary environmental pollution, long processing cycle, and low energy consumption, and achieve short processing cycles, improve overall performance, and reduce energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

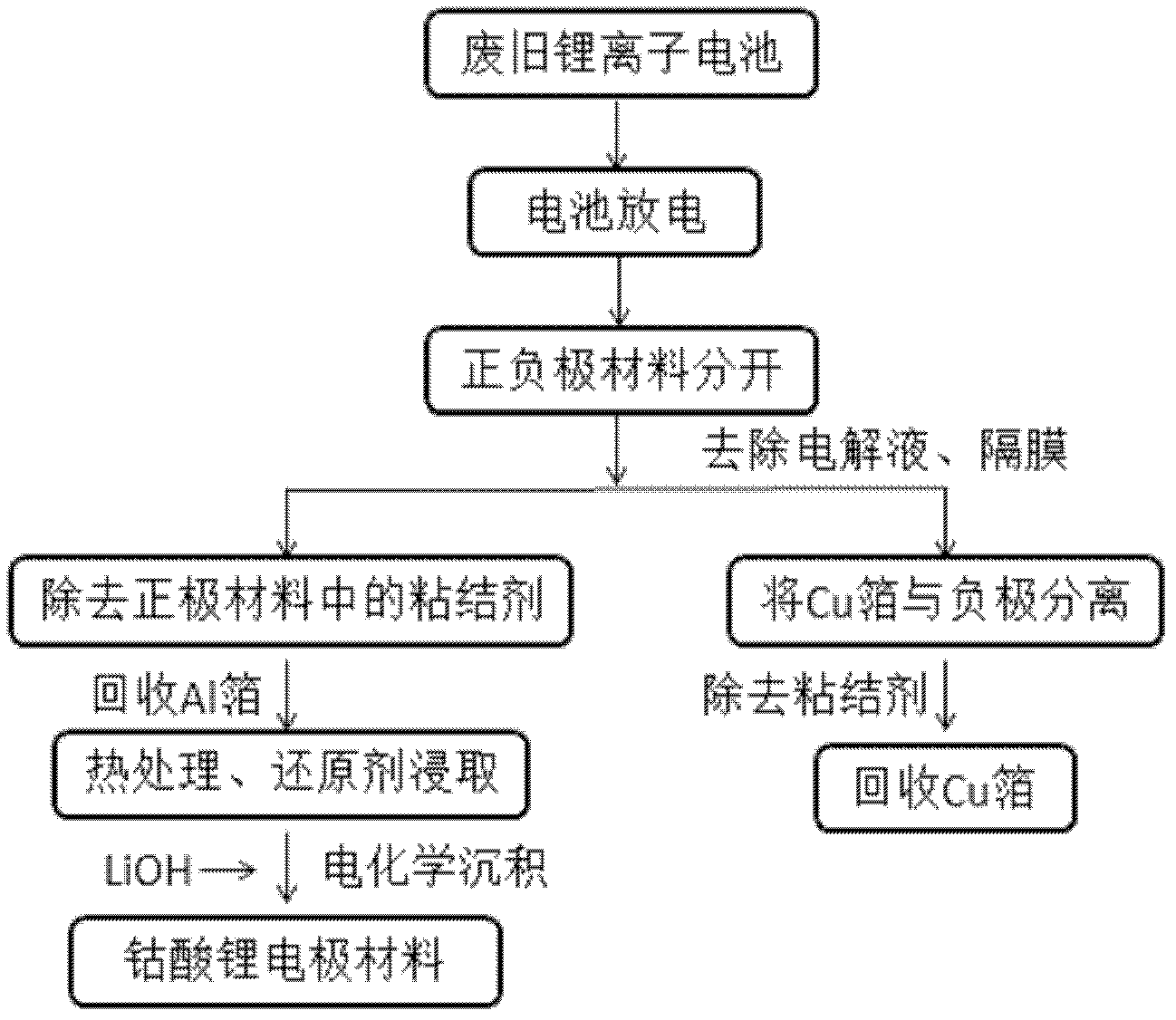

[0026] (1) Discharge the waste lithium-ion battery deeply with Land, then decompose it, separate the positive and negative electrode materials, remove the electrolyte and diaphragm, separate the copper (Cu) foil from the negative electrode, remove the binder and recycle Copper foil; the aluminum (Al) foil with lithium cobaltate in the positive electrode material is cut into strips and then ultrasonically treated with NMP, filtered, and the binder is removed. The above process is carried out in a fume hood to obtain aluminum foil and conductive agent. and the precipitation of lithium cobaltate, and recover the aluminum foil; after drying the precipitate for 12 hours, burn it in a muffle furnace at 600°C for 3 hours to remove the conductive agent therein, and obtain a black solid powder containing lithium cobaltate.

[0027] (2) Weigh 5g of the black solid powder obtained in step (1), put it into a 100ml there-necked bottle, then add 50ml of 2mol / L hydrochloric acid and 10ml of 4...

Embodiment 2

[0032](1) Discharge the waste lithium-ion battery deeply with land, then decompose it, separate the positive and negative materials, remove the electrolyte and diaphragm, separate the copper foil from the negative electrode, and recover the copper foil after removing the binder; The aluminum foil sheet with lithium cobaltate is cut into strips and treated with NMP ultrasonically, filtered, and the binder is removed. The above process is carried out in a fume hood to obtain aluminum foil and a precipitate containing conductive agent and lithium cobaltate, and recycle the aluminum foil; After the precipitate was dried for 12 hours, it was fired in a muffle furnace at 600° C. for 3 hours to remove the conductive agent therein to obtain a black solid powder containing lithium cobaltate.

[0033] (2) Weigh 5g of the black solid powder obtained in step (1), put it into a 100ml there-necked bottle, then add 50ml of 2mol / L hydrochloric acid and 10ml of 40% peracetic acid, stir at 80°C ...

Embodiment 3

[0038] (1) Discharge the waste lithium-ion battery deeply with land, then decompose it, separate the positive and negative materials, remove the electrolyte and diaphragm, separate the copper foil from the negative electrode, and recover the copper foil after removing the binder; The aluminum foil sheet with lithium cobaltate is cut into strips and treated with NMP ultrasonically, filtered, and the binder is removed. The above process is carried out in a fume hood to obtain aluminum foil and a precipitate containing conductive agent and lithium cobaltate, and recycle the aluminum foil; After the precipitate was dried for 12 hours, it was burned in a muffle furnace at 700° C. for 4 hours to remove the conductive agent therein to obtain a black solid powder containing lithium cobaltate.

[0039] (2) Weigh 5g of the black solid powder obtained in step (1), put it into a 100ml there-necked bottle, then add 50ml of 2mol / L hydrochloric acid and 10ml of 40% peracetic acid, stir at 80°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com