Preparation method of aluminium foil bionic nanostructured super-hydrophobic anti-condensation functional surface

A bionic nano, super-hydrophobic technology, applied in surface reaction electrolytic coating, anodizing, electrolytic coating, etc., can solve the problems of high surface energy of hydrophilic foil, lower thermal conductivity of aluminum foil, easy adsorption of pollutants, etc. The effect of easy control, reduced corrosion, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] (1) Clean the 0.04mm thick aluminum foil (30mm*30mm, aluminum element content is 99.5%) with acetone and deionized water ultrasonically and blow dry, then immerse in 1mol / L NaOH aqueous solution for about 30-60s, In this example, the treatment time is 40s to remove the oxide film on the surface of the aluminum foil.

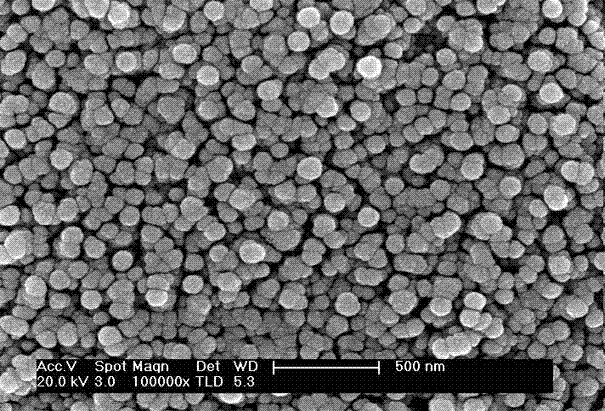

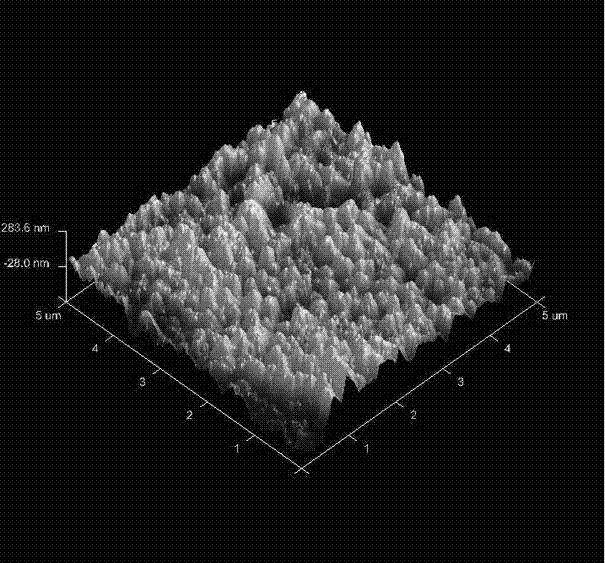

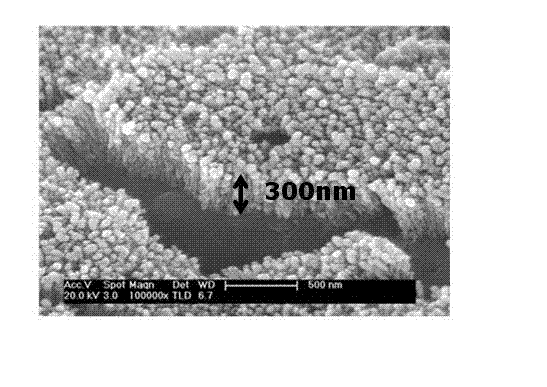

[0030] (2) Use the mixed aqueous solution of phosphoric acid and glycerol as the electrolyte, use the nickel sheet as the cathode, and use the aluminum foil as the anode. The two poles are placed in parallel and facing each other, with an area ratio of 1:1 and a distance of 20 mm. Under room temperature and constant current mode For anodizing, the current density is 3.2mA / cm 2 , oxidation time 120min. After the anodic oxidation is finished, take out the aluminum foil, wash and dry with ethanol and deionized water, and the mixed aqueous solution of phosphoric acid and glycerol is prepared by the following method: add analytically pure phosphoric acid and g...

example 2

[0034] (1) Clean the 0.04mm thick aluminum foil (30mm*30mm, aluminum element content is 99.5%) with acetone and deionized water ultrasonically and blow dry, then immerse in 1mol / L NaOH aqueous solution for about 30-60s, In this example, the treatment time is 60s to remove the oxide film on the surface of the aluminum foil.

[0035] (2) Use the mixed aqueous solution of phosphoric acid and glycerol as the electrolyte, use the nickel sheet as the cathode, and use the aluminum foil as the anode. The two poles are placed in parallel and facing each other, with an area ratio of 1:1 and a distance of 20 mm. Under room temperature and constant current mode For anodizing, the current density is 4.8mA / cm 2 , oxidation time 150min. After the anodic oxidation is finished, take out the aluminum foil, wash and dry with ethanol and deionized water, and the mixed aqueous solution of phosphoric acid and glycerol is prepared by the following method: add analytically pure phosphoric acid and g...

example 3

[0039] (1) Clean the 0.04mm thick aluminum foil (30mm*30mm, aluminum element content is 99.5%) with acetone and deionized water ultrasonically and blow dry, then immerse in 1mol / L NaOH aqueous solution for about 30-60s, In this example, the treatment time is 30s to remove the oxide film on the surface of the aluminum foil.

[0040] (2) Use the mixed aqueous solution of phosphoric acid and glycerol as the electrolyte, use the nickel sheet as the cathode, and use the aluminum foil as the anode. The two poles are placed in parallel and facing each other, with an area ratio of 1:1 and a distance of 20 mm. Under room temperature and constant current mode For anodizing, the current density is 4.2mA / cm 2 , oxidation time 130min. After the anodic oxidation is finished, take out the aluminum foil, wash and dry with ethanol and deionized water, and the mixed aqueous solution of phosphoric acid and glycerol is prepared by the following method: add analytically pure phosphoric acid and g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com