Preparation method of durable underwater ultra oleophobic surface of titanium alloy matrix

An underwater superoleophobic and titanium alloy technology is applied in the field of surface treatment of metal materials, which can solve the problems of environmental pollution of chemical reagents, harmful operators, and the need for special instruments, and achieves simple and easy operation, low cost and little harm. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Pretreatment process: Polish the titanium alloy sheet (20mm×30mm×3mm) with No. 1500 metallographic sandpaper, and then put it into acetone, absolute ethanol, and deionized water for ultrasonic cleaning for 3 minutes;

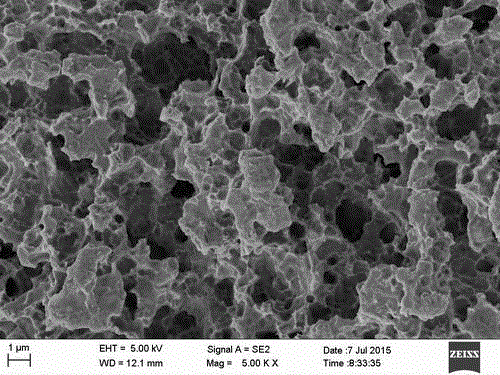

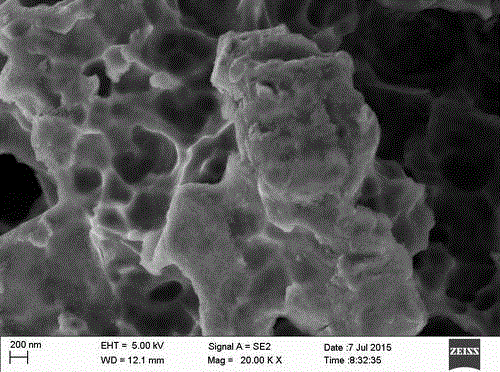

[0021] (2) Electrochemical etching: the pretreated titanium alloy sheet is used as the anode, and the graphite plate with the same area as the titanium alloy sheet is used as the cathode, where the actual effective size (etched area) is 20mm×20mm, and the remaining part is used for mounting Clamp and conduction, two electrodes are placed parallel and symmetrical, the anode is connected to the positive pole of the DC power supply through a wire, the cathode is connected to the negative pole, and the two electrodes are placed in a mixture of 0.5mol / LNaCl and 0.5mol / LH 2 o 2 In the mixed neutral electrolyte solution, turn on the power to start electrochemical etching, and the etching current density is constant at 1A / cm 2 , the etching time is 15min, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com