Preparation method of porous copper full-impregnated film of three-dimensional network structure

A technology of network structure and porous copper, which is applied in the field of preparation of three-dimensional network structure porous copper full-permeable membrane, can solve the problems of inability to peel off the three-dimensional network structure of metal copper membrane, low bonding strength, loose metal membrane structure, etc. Toughness, good filtration separation, uniform pore size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] After mixing the basic plating solution with the additives, stir the electrolyte with a magnetic stirrer to make it uniformly mixed. The additive is 5mmol / LNH 4 Cl, 0g / L polyethylene glycol, appropriate amount of saccharin sodium (C 7 H 4 0 3 NSNaH 2 0) And buffering agent boric acid. The cathode aluminum foil is sequentially put into acetone and absolute ethanol for ultrasonic cleaning to complete the degreasing treatment. Then put it in 10%wt NaOH solution and soak for 15min to remove the oxide layer on the surface of the aluminum foil, and finally polish by electrochemical method. The electrolyte is made of absolute ethanol and perchloric acid in a volume ratio of 4:1, with graphite as the cathode. , The aluminum foil is the anode, polished 15min under 20V voltage. After the preliminary work is completed, put the cathode and anode into the electrolytic cell, ensure that the aluminum foil is on the bottom and the graphite is on the top and the two are parallel and oppo...

Embodiment 2

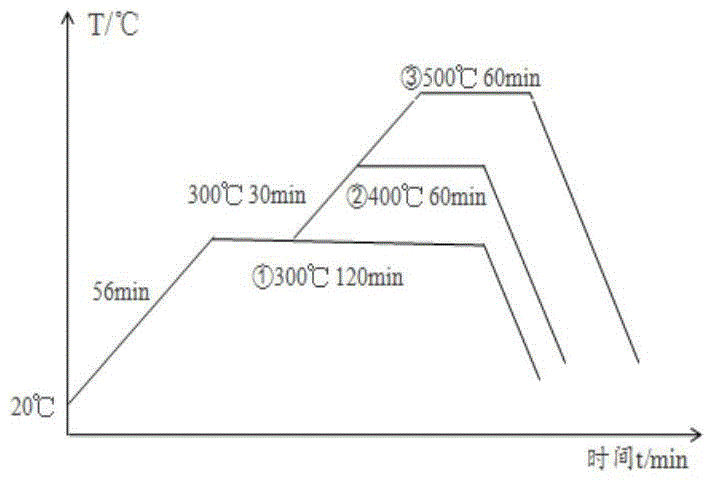

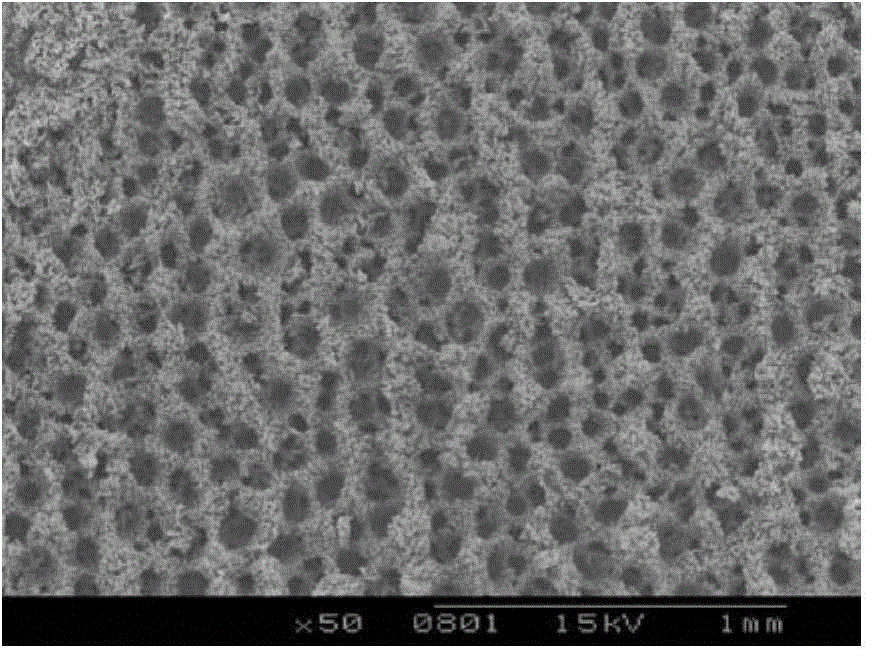

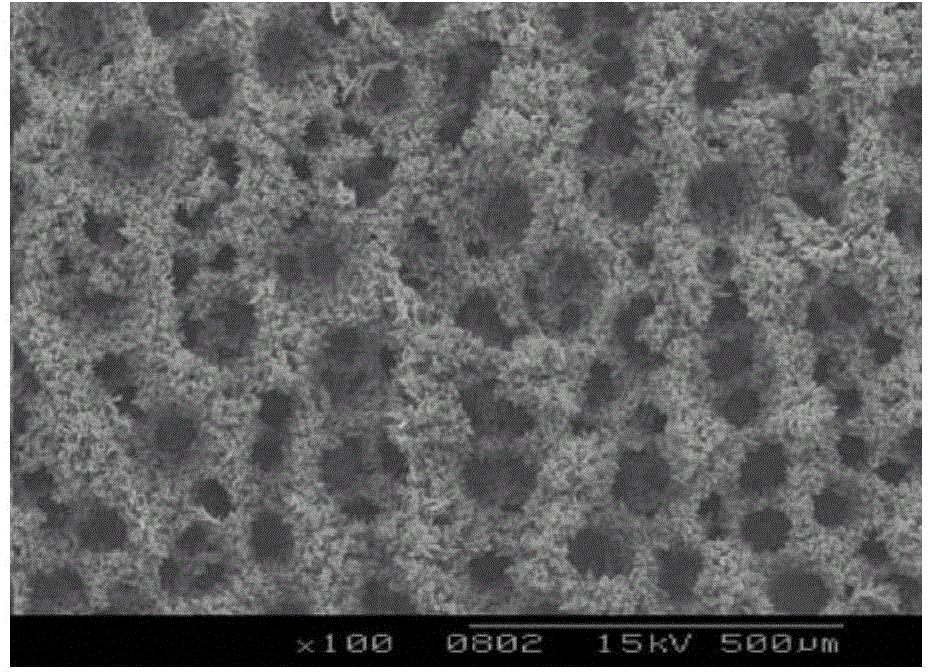

[0025] After mixing the basic plating solution with the additives, stir the electrolyte with a magnetic stirrer to make it uniformly mixed. The additive is 10mmol / LNH 4 Cl, 1g / L polyethylene glycol additive, appropriate amount of saccharin sodium (C 7 H 4 0 3 NSNaH 2 0) And buffering agent boric acid. The electrode was pretreated as in Example 1 and the preparations before electrochemical deposition were completed. The current density in the control loop of the electrochemical workstation is 2A / cm 2 , The deposition time is 30s. After the deposition is completed, take out the aluminum foil, rinse with deionized water and ethanol 3-4 times, and then dry with nitrogen to prepare for the subsequent annealing treatment. First, control the heating rate to 5°C / min to increase the temperature to 300°C, and then keep the temperature at 300°C for 30 minutes to eliminate the internal stress generated during the heating process. After that, continue to heat up to 400℃ for 60 minutes and t...

Embodiment 3

[0027] After mixing the basic plating solution with the additives, stir the electrolyte with a magnetic stirrer to make it uniformly mixed. The additive is 10mmol / LNH 4 Cl, 2g / L polyethylene glycol additive, appropriate amount of saccharin sodium (C 7 H 4 0 3 NSNaH 2 0) And buffering agent boric acid. The electrode was pretreated as in Example 1 and the preparations before electrochemical deposition were completed. The current density in the control loop of the electrochemical workstation is 2.5A / cm2, and the deposition time is 40s. After the deposition is completed, the aluminum foil is taken out, rinsed with deionized water and ethanol 3-4 times, and then dried with nitrogen to prepare for the subsequent annealing treatment. Control the heating rate to 5°C / min to increase the temperature to 300°C, and then keep it at 300°C for 30 minutes to eliminate the internal stress generated during the heating process. After that, continue to heat up to 500℃ for 60 minutes and then cool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com