Anode oxidation method

An anodic oxidation and anodic technology, applied in anodic oxidation and other directions, can solve the problems of poor corrosion resistance and achieve the effect of strong corrosion resistance and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

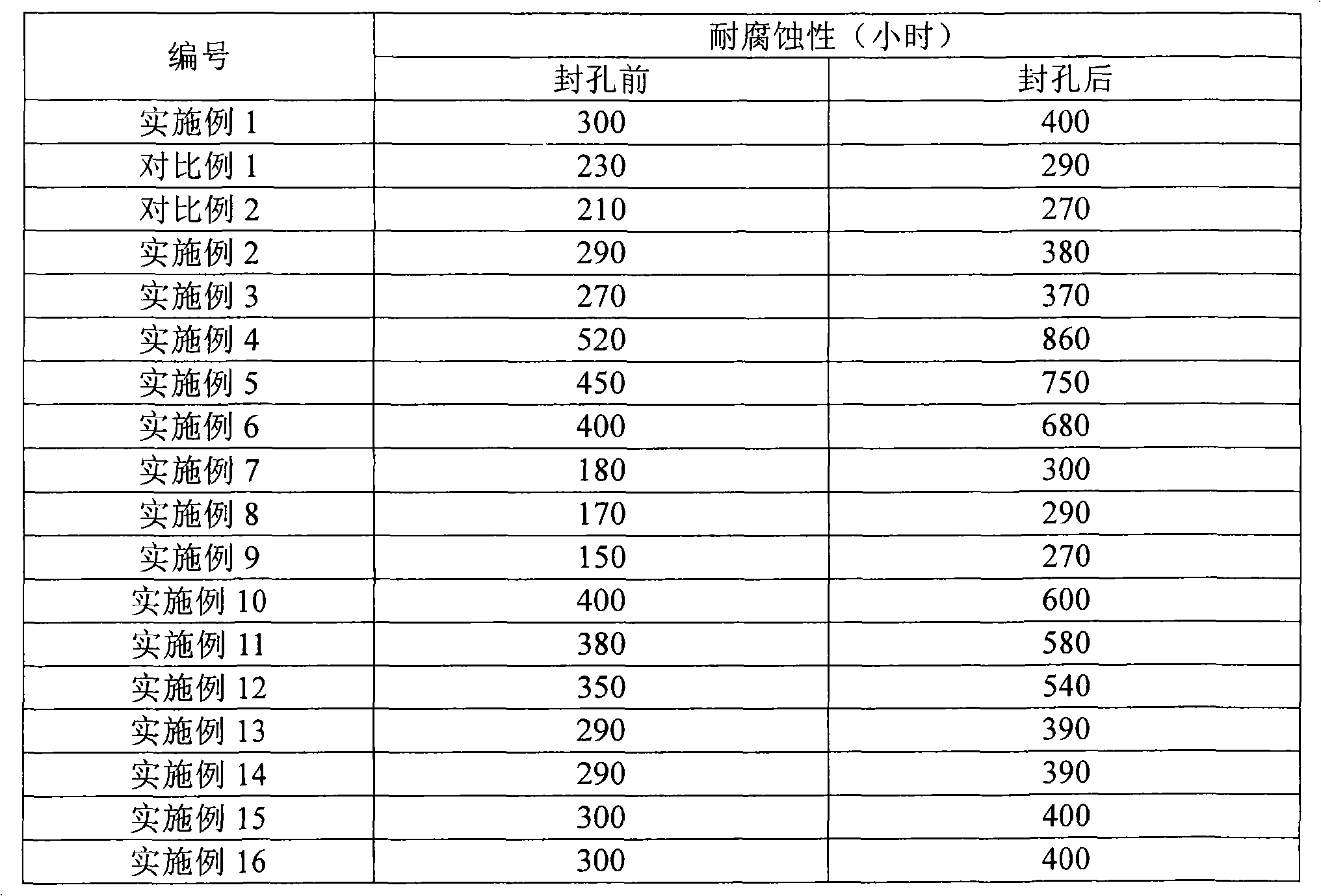

Examples

Embodiment 1

[0026] This example is used to illustrate the anodic oxidation method provided by the present invention.

[0027] 1. Pretreatment

[0028] (1) Grinding

[0029] The AZ91D magnesium alloy substrate (Nanjing Yunhai Special Metal Co., Ltd.) with a size of 80×50×2 mm is polished with sandpaper, and the rough natural oxide film on the surface of the magnesium alloy substrate is removed until the surface of the magnesium alloy substrate shows metal Gloss is enough.

[0030] 2. Anodizing

[0031] The above-mentioned pretreated magnesium alloy substrate is used as an anode and immersed in an electrolyte solution, and at the same time, stainless steel is used as a cathode, and the cathode and anode are respectively electrically connected to the positive and negative electrodes of the power supply. Using 2 g / L sodium hydroxide, 5 g / L sodium fluoroborate, 10 g / L sodium silicate, 0.5 g / L sodium tetraborate, 1 g / L potassium oxalate and 1 mL / L The solution composed of glycerol is used a...

Embodiment 2

[0039] This example is used to illustrate the anodic oxidation method provided by the present invention.

[0040] Prepare the AZ91D magnesium alloy base material (Nanjing Yunhai Special Metals Co., Ltd.) with the same method as Example 1 and carry out pretreatment and anodic oxidation. The difference is that the anodic oxidation adopts the following method:

[0041] The above-mentioned pretreated magnesium alloy substrate is used as an anode and immersed in an electrolyte solution, and at the same time, stainless steel is used as a cathode, and the cathode and anode are respectively electrically connected to the positive and negative electrodes of the power supply. Using 5 g / L of sodium hydroxide, 8 g / L of sodium fluoroborate, 12 g / L of sodium silicate, 1 g / L of sodium tetraborate, 1.5 g / L of potassium oxalate and 2 mL / L The solution composed of isopropylene glycol is used as the electrolyte, the power supply used is a pulse power supply, the adjustment frequency is 400 Hz, th...

Embodiment 3

[0043] This example is used to illustrate the anodic oxidation method provided by the present invention.

[0044] Prepare the AZ91D magnesium alloy base material (Nanjing Yunhai Special Metals Co., Ltd.) with the same method as Example 1 and carry out pretreatment and anodic oxidation. The difference is that the anodic oxidation adopts the following method:

[0045] The above-mentioned pretreated magnesium alloy substrate is used as an anode and immersed in an electrolyte solution, and at the same time, stainless steel is used as a cathode, and the cathode and anode are respectively electrically connected to the positive and negative electrodes of the power supply. Using 7 g / L of sodium hydroxide, 10 g / L of sodium fluoroborate, 15 g / L of sodium silicate, 3 g / L of sodium tetraborate, 2 g / L of potassium oxalate and 3 mL / L The solution composed of glycerin is used as the electrolyte, the power supply used is a pulse power supply, the adjustment frequency is 500 Hz, the duty ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com