Electrosynthesis of nanofibers and nano-composite films

a technology of nanofibers and composite films, applied in the field of electrosynthesis of nanofibers and nanocomposite films, can solve the problems of low selectivity, the inability of most of these methods to apply to organic polymer materials, and the critical issue of instability and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Synthesis of Nanofibers

[0078] A Pt plate about 1 inch by 1 inch in size was washed thoroughly with ethanol and dried in air. The Pt plate was further rinsed in a 1 wt. % sodium dodecyl sulfate (SDS) solution and dried in air to improve the wetting behavior with water. Electrochemical deposition of polyaniline (PANI) was performed by immersing the Pt plate into an aqueous solution containing 0.5 M aniline monomer and 1.0 M perchloric acid (HClO4). The effective area of the immersed Pt plate was 4.5 cm2. Polyaniline was grown from the surface of the Pt plate by redox polymerization of aniline. The electrochemical experiments were performed on an EG & G Princeton Applied Research model 273 potentiostat / galvanostat controlled by a personal computer via EG & G Princeton Applied Research Model 270 electrochemical software. The experiments for PANI film depositions were made in an H-shape two-compartment cell, with another platinum plate used as the counter electrode. A saturated calomel ...

example 2

Synthesis of Composite Films

[0086] A polyaniline nanoporous film was synthesized according to Example 1, except that the second and third constant current density steps were maintained for four hours rather than three. In addition, the working electrode was a glassy carbon disk with a surface area of 0.14 cm2 (commercially available from Bioanalytical Systems) rather than a Pt substrate.

[0087] FeHCF was electrodeposited on the polyaniline-modified electrode by immersing the electrode in a 0.1 M KCl aqueous solution containing a 0.01 M equimolar mixture of FeCl3 and K3Fe(CN)6. The electrode potential was cycled between −0.20 and +0.80 V at 50 mV / s in the mixed solution of 0.1 M KCl, 0.01 M FeCl3 and 0.01 M K3Fe(CN)6.

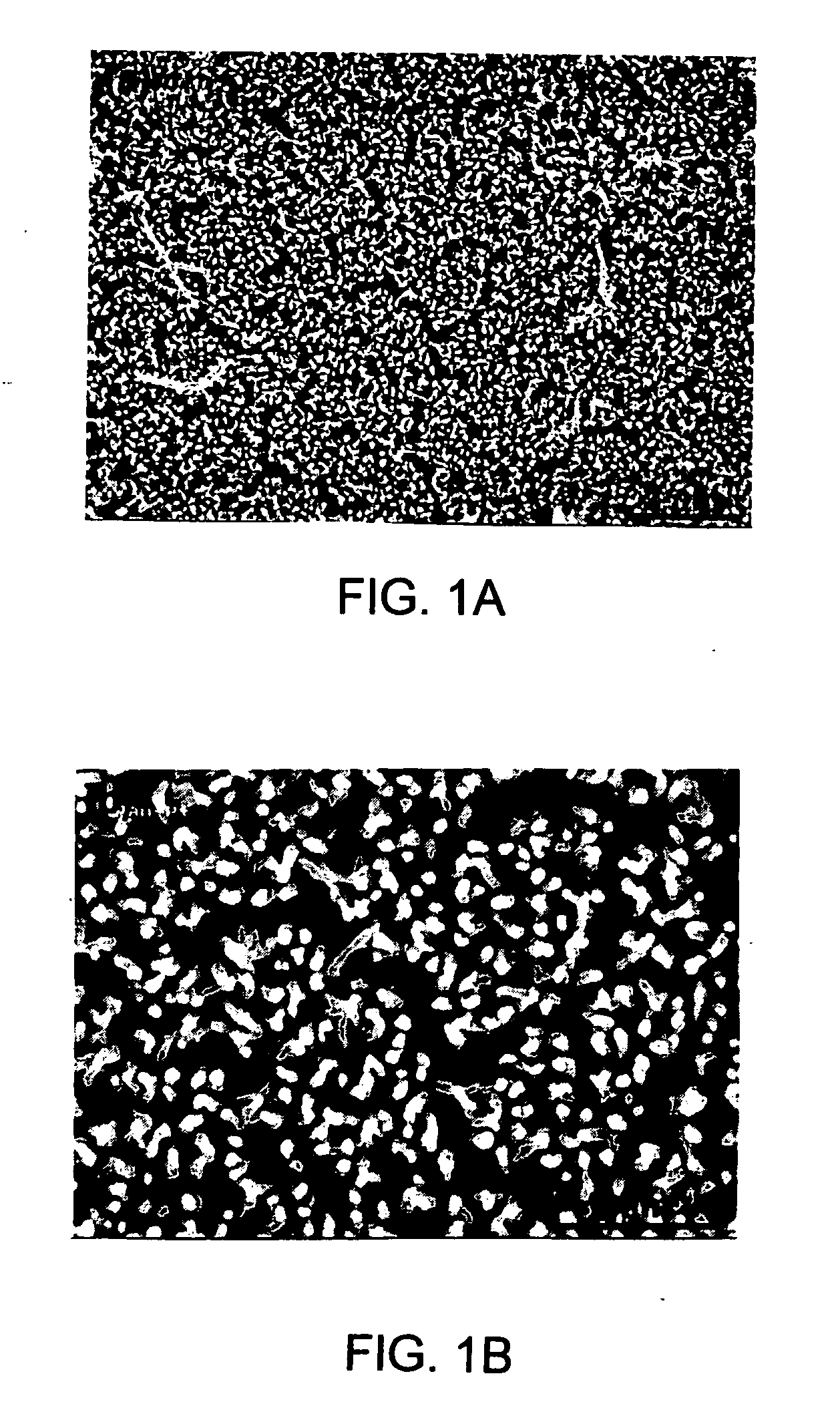

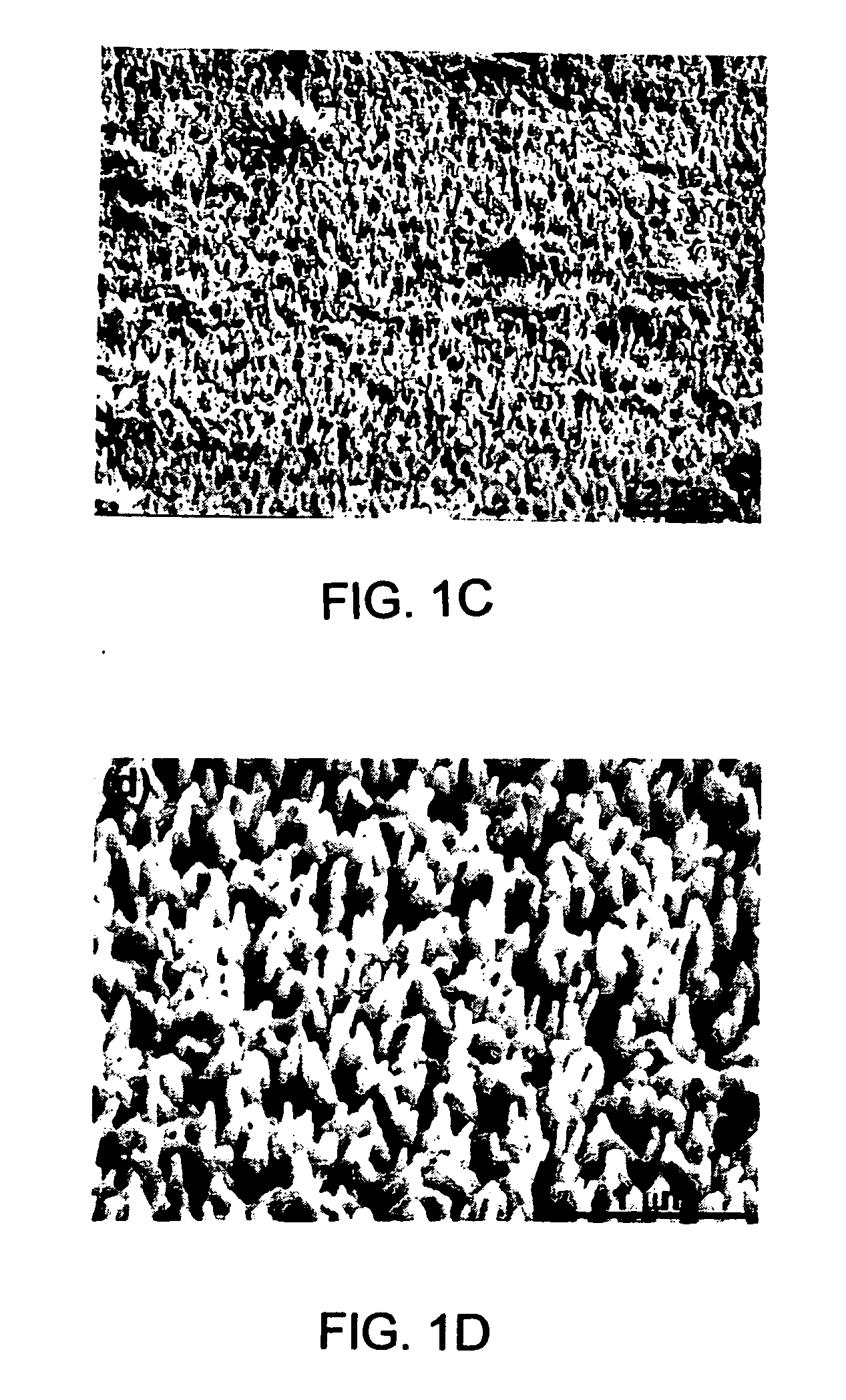

[0088] The surfaces of the polyaniline / FeHCF-modified electrode were investigated with SEM. The SEM micrographs indicated that FeHCF was deposited into the nanoporous polyaniline matrix and at least partially filled the nanopores. The surfaces of the polyaniline / FeHCF-...

example 3

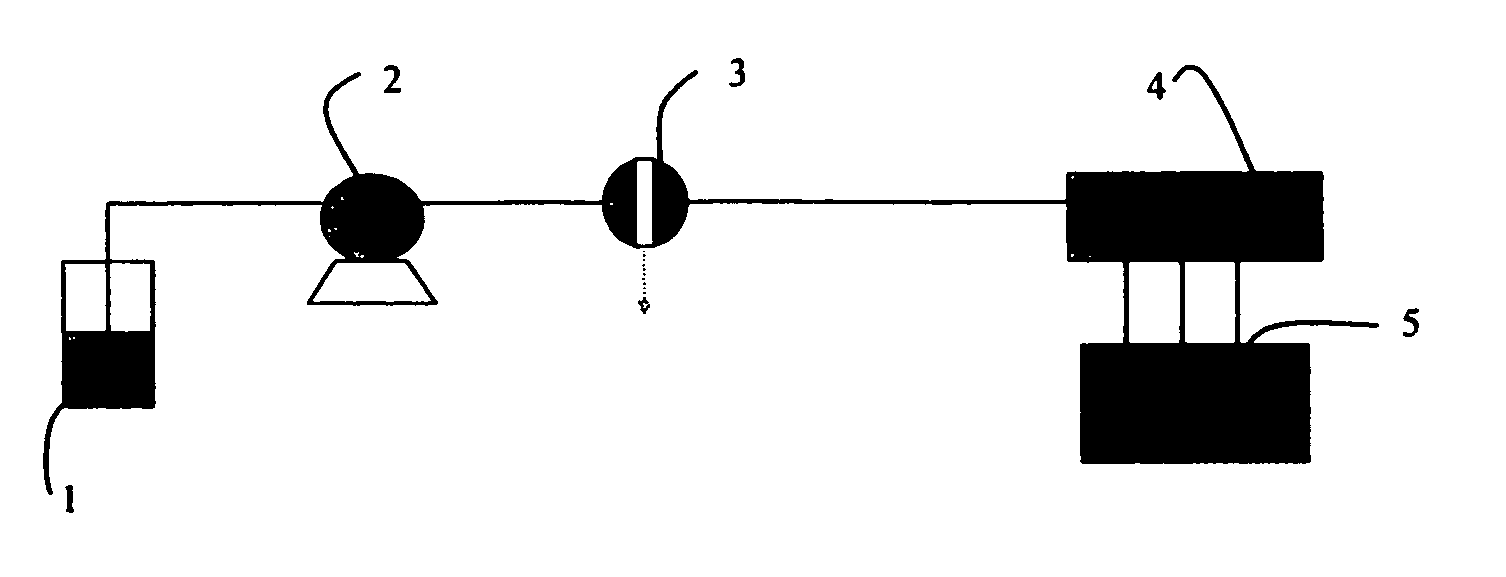

Sensor

[0090] A polyaniline / FeHCF-modified glassy carbon electrode made as described above in Example 2 was used to detect the presence of hydrogen peroxide by sensing catalytic reduction of hydrogen peroxide. The amperometric detection was conducted using the flow injection analysis system shown in FIG. 7. The particular system included a peristaltic pump, a Rheodane 7125 injector with a 50-μL sample loop, an interconnecting polytetrafluorethylene tubing, and a thin-layer electrochemical flow cell. Flow injection / amperometric measurements were conducted with a CH Instruments model CHI 824 electrochemical detector. The working electrode is the glassy carbon electrode embedded in a PEEK plate. A constant potential of 0.1 V was applied to the electrode. The flow rate of the carrier solution (0.1 M KCl, 0.05 M acetate buffer (pH 6.0) was 0.5 mL / min. A 50-uL sample containing hydrogen peroxide was injected from the injection valve into the carrier solution. Hydrogen peroxide was reduced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com