Teflon thin film with high light transmitting and dewatering functions and preparation method and application thereof

A polytetrafluoroethylene and thin film technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of uneven film thickness and poor adhesion to the substrate, improve adhesion, prevent Oxidation, the effect of improving dimming durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

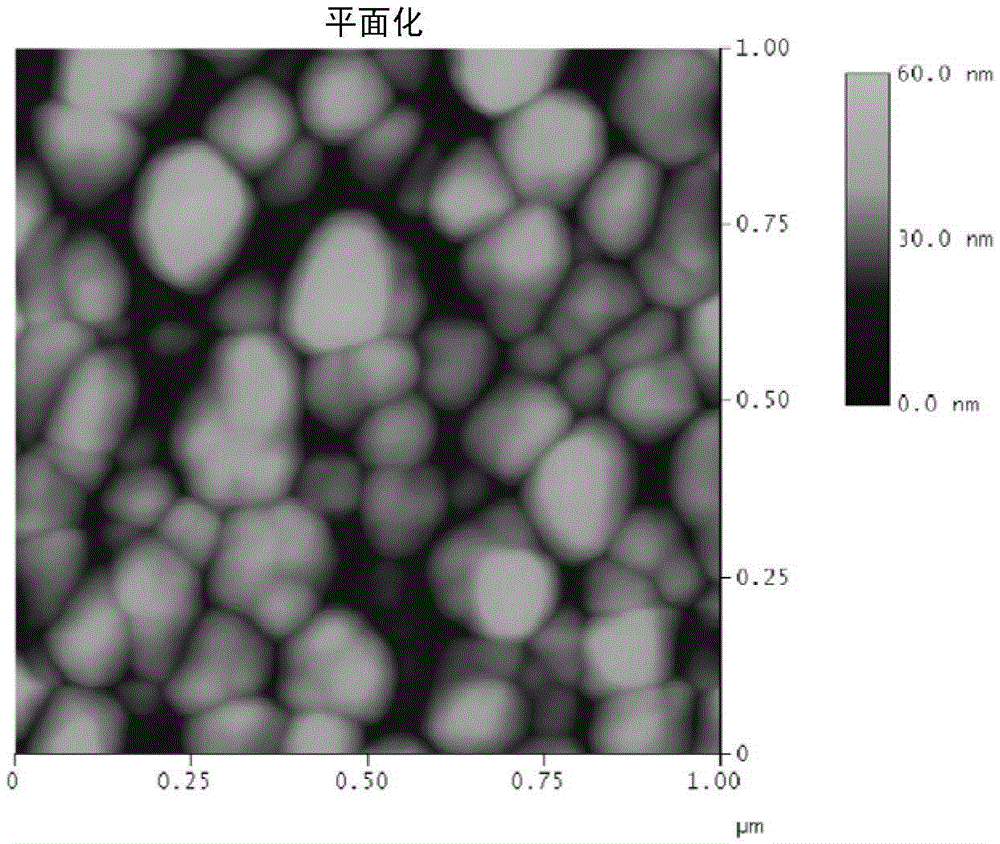

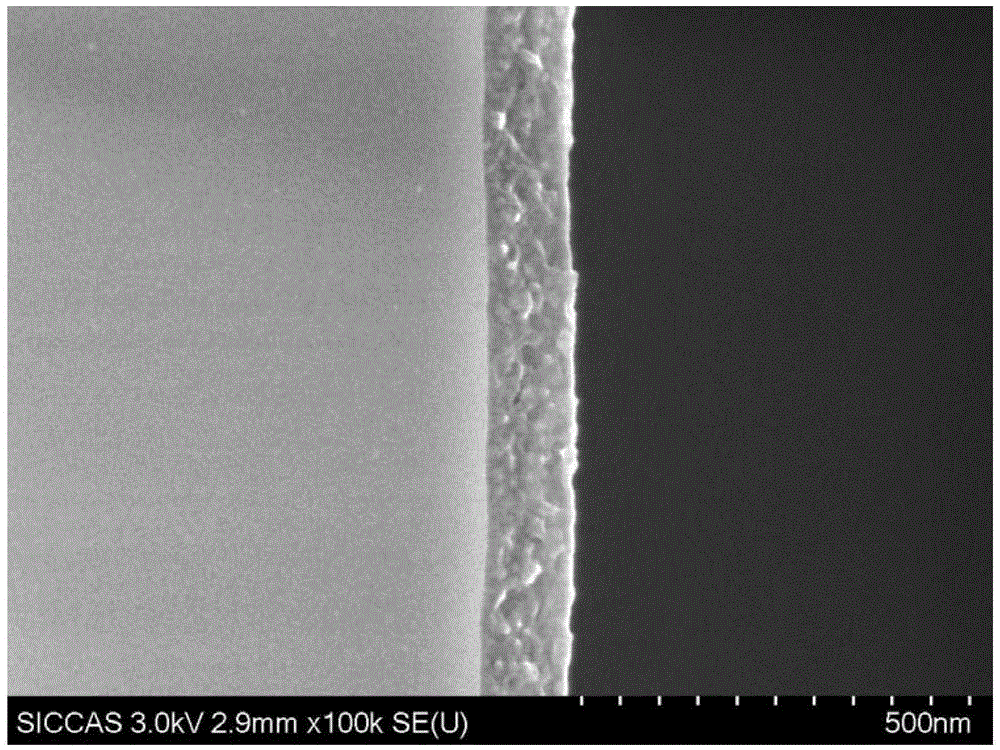

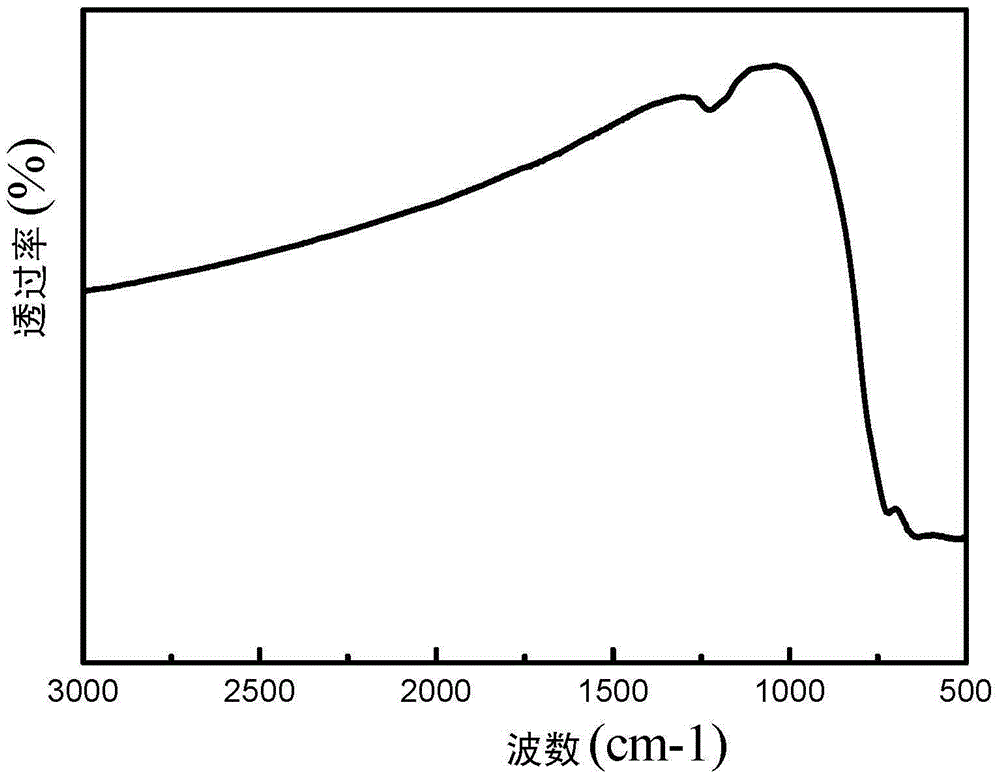

[0031] The invention provides a method for preparing a polytetrafluoroethylene film and its application on a light-adjusting device. The polytetrafluoroethylene film is sputtered on a substrate by using a radio frequency magnetron sputtering method.

[0032] When sputtering PTFE film on the substrate, the preparation conditions are: background vacuum 1*10 -6 ~2*10 -3 Pa, the volume ratio of argon gas to carbon tetrafluoride is 10:1~100:1, the working pressure is 0.5-2.0Pa, the sputtering power is 10-100W, the substrate temperature is 25°C-300°C, and the sputtering time is 15-60min. In a preferred example, the preparation conditions are as follows: background vacuum 2-6*10 -5 Pa, the volume ratio of argon to carbon tetrafluoride is 10:1, the working pressure is 1-1.5Pa, the sputtering power is 10-60W, the substrate temperature is room temperature, and the sputtering time is 15-60min, preferably 30min. By controlling the sputtering time, the thickness of the film can be contr...

Embodiment 1

[0039] The pre-treatment of the glass substrate is ultrasonic washing for 5-10 minutes in the order of 5% sodium hydroxide aqueous solution-deionized water-absolute ethanol-deionized water respectively. The pretreatment of other substrates is boiling with absolute ethanol for 10-60 minutes.

Embodiment 2

[0041] Weigh 20g of polytetrafluoroethylene powder, put it into a mold, heat press and sinter at 310°C, hold heat and pressure for 12h, and obtain a polytetrafluoroethylene target material with a thickness of 3-5mm. Or cut 2-inch targets from Teflon sheets for magnetron sputtering.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com