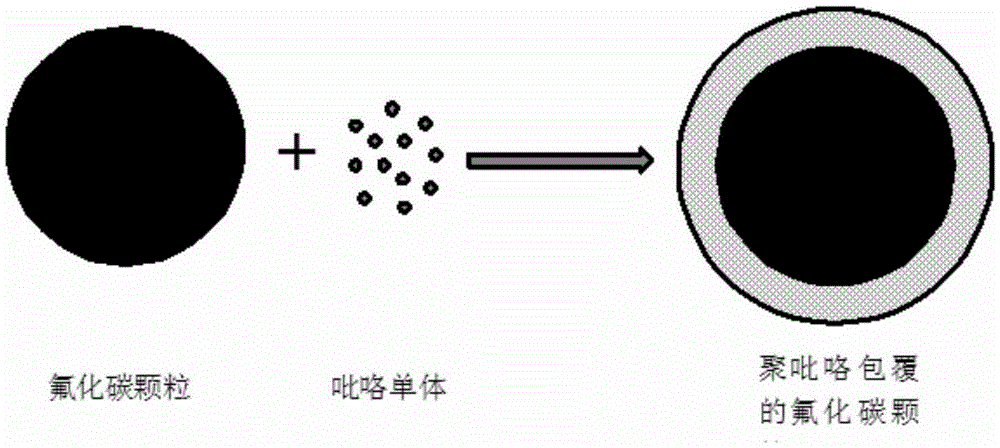

Preparation method and application of polypyrrole-coated carbon fluoride positive electrode material

A technology of coating carbon fluoride and positive electrode material, which is applied to the electrodes of primary batteries, battery electrodes, electrical components, etc., can solve the problems of low efficiency and difficult industrialization, and achieve the improvement of energy density and power density, conductivity improvement, Realize the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

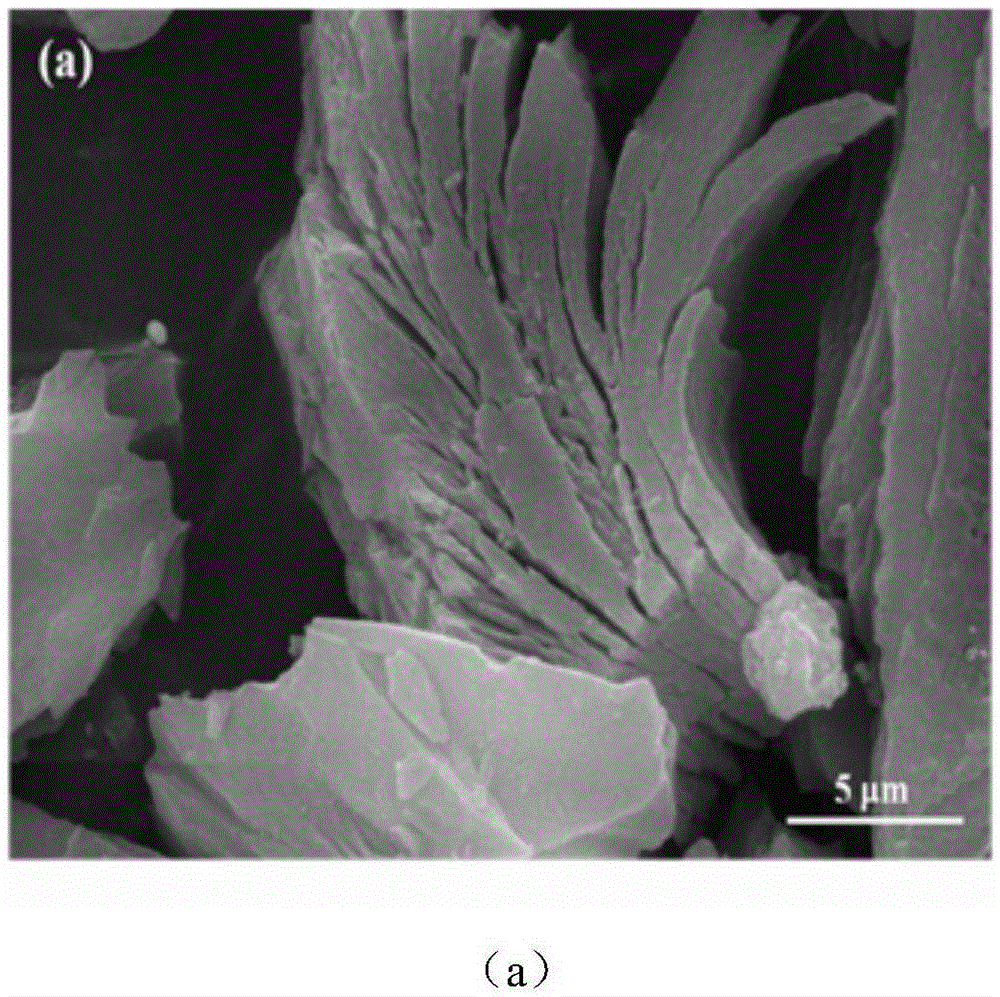

Examples

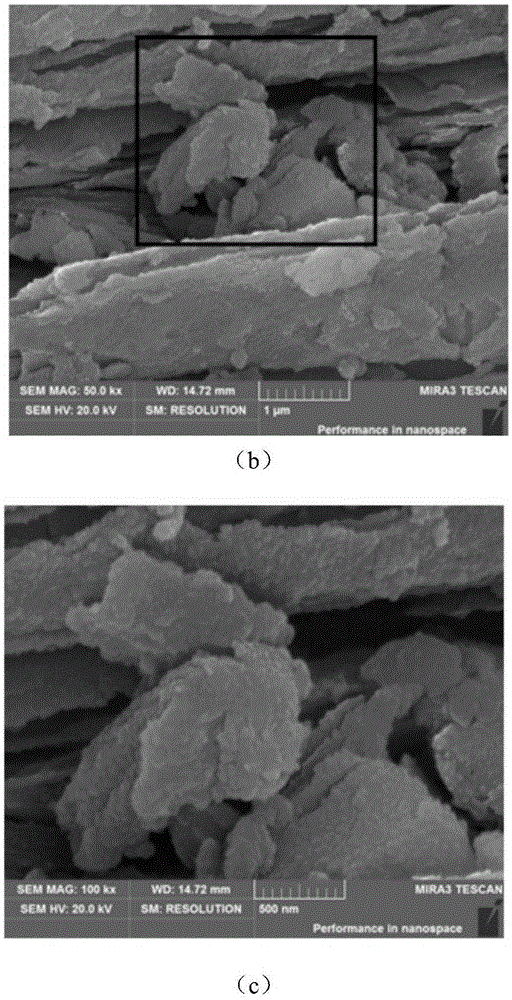

Embodiment 1

[0038] (1) Weigh 1 g of carbon fluoride, pour it into 10 mL of deionized water dissolved in a dispersant, and make a 0.1 g / mL carbon fluoride suspension by magnetic stirring, and stir for 30 minutes to make the agglomerated large particles of carbon fluoride fully Dispersion: ultrasonically disperse the above-mentioned carbon fluoride suspension for 30 minutes to fully disperse the agglomerated carbon fluoride particles. Under the condition of 0°C, in the three-neck round-bottomed flask containing the carbon fluoride suspension, magnetic stirring is carried out, and argon gas is introduced while passing through, and 0.125g of pyrrole monomer is added to the above-mentioned carbon fluoride suspension, and continue Stir for 30 minutes to disperse the pyrrole monomer evenly. Thus, a mixed suspension of carbon fluoride / pyrrole was prepared.

[0039] (2) Weigh 0.5g (NH 4 ) 2 S 2 o 8 , was added to 20mL2mol / L HCl solution, and the concentration was 0.025g / mL (NH 4 )S 2 o 4 s...

Embodiment 2

[0047] (1) Weigh 1 g of carbon fluoride, pour it into 10 mL of deionized water dissolved in a dispersant, and make a 0.1 g / mL carbon fluoride suspension by magnetic stirring, and stir for 30 minutes to make the agglomerated large particles of carbon fluoride fully Dispersion: ultrasonically disperse the above-mentioned carbon fluoride suspension for 30 minutes to fully disperse the agglomerated carbon fluoride particles. Under the condition of 0°C, in the three-necked round-bottomed flask containing the carbon fluoride suspension, magnetic stirring is carried out, and argon gas is introduced while passing through, and 0.0625g of pyrrole monomer is added to the above carbon fluoride suspension, and continue Stir for 30 minutes to disperse the pyrrole monomer evenly. Thus, a mixed suspension of carbon fluoride / pyrrole was prepared.

[0048] (2) Weigh 0.25g (NH 4 ) 2 S 2 o 8 , was added to 10mL2mol / L HCl solution, and the concentration was 0.025g / mL (NH 4 )S 2 o 4 solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com