Ruthenium-modified carbon fluoride material, and preparation method and application thereof

A technology of carbon fluoride and positive electrode material, applied in the direction of organic electrolyte battery, electrical components, battery electrodes, etc., can solve the problem of insignificant effect, achieve high-rate performance improvement, large industrial and commercial value, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

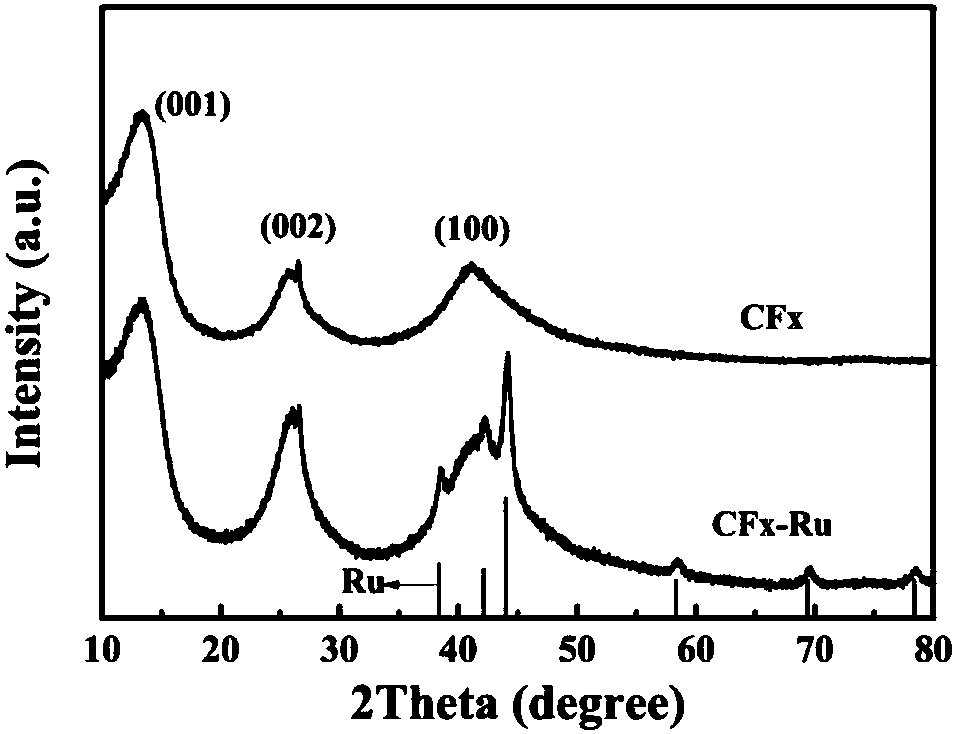

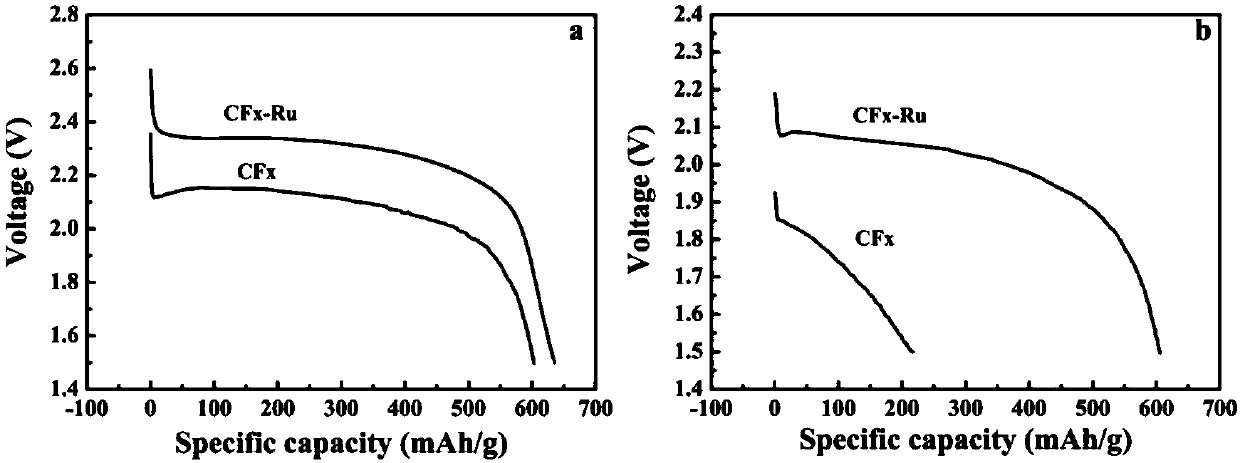

Method used

Image

Examples

Embodiment 1

[0024] (1) the CF X The cathode material was dispersed in a mixed solution of deionized water and ethanol (volume ratio 1:1), and stirred evenly.

[0025] (2) RuCl 3 Add to the suspension obtained in step (1) in a certain proportion with carbon fluoride, then add NaOH solution to adjust the pH, keep the pH at 8-9, and continue stirring for 6 hours.

[0026] (3) Suction filter the suspension obtained in step (2), and wash with deionized water and ethanol several times to form a mixture.

[0027] (4) Drying the mixture in step (3) to obtain a mixture powder.

[0028] (5) The mixture powder obtained in step (4) is placed in an atmosphere furnace, subjected to high-temperature treatment, and lowered to room temperature to obtain ruthenium-modified carbon fluoride.

[0029] The ratio of deionized water and ethanol in step 1 is 1:1, 15mL respectively

[0030] The NaOH concentration in step 2 is 0.1mol / L

[0031] The drying temperature in step 4 is 80°C

[0032] The high temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com