Modified polyvinyl alcohol resins and adhesive, polarizer, and display device containing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

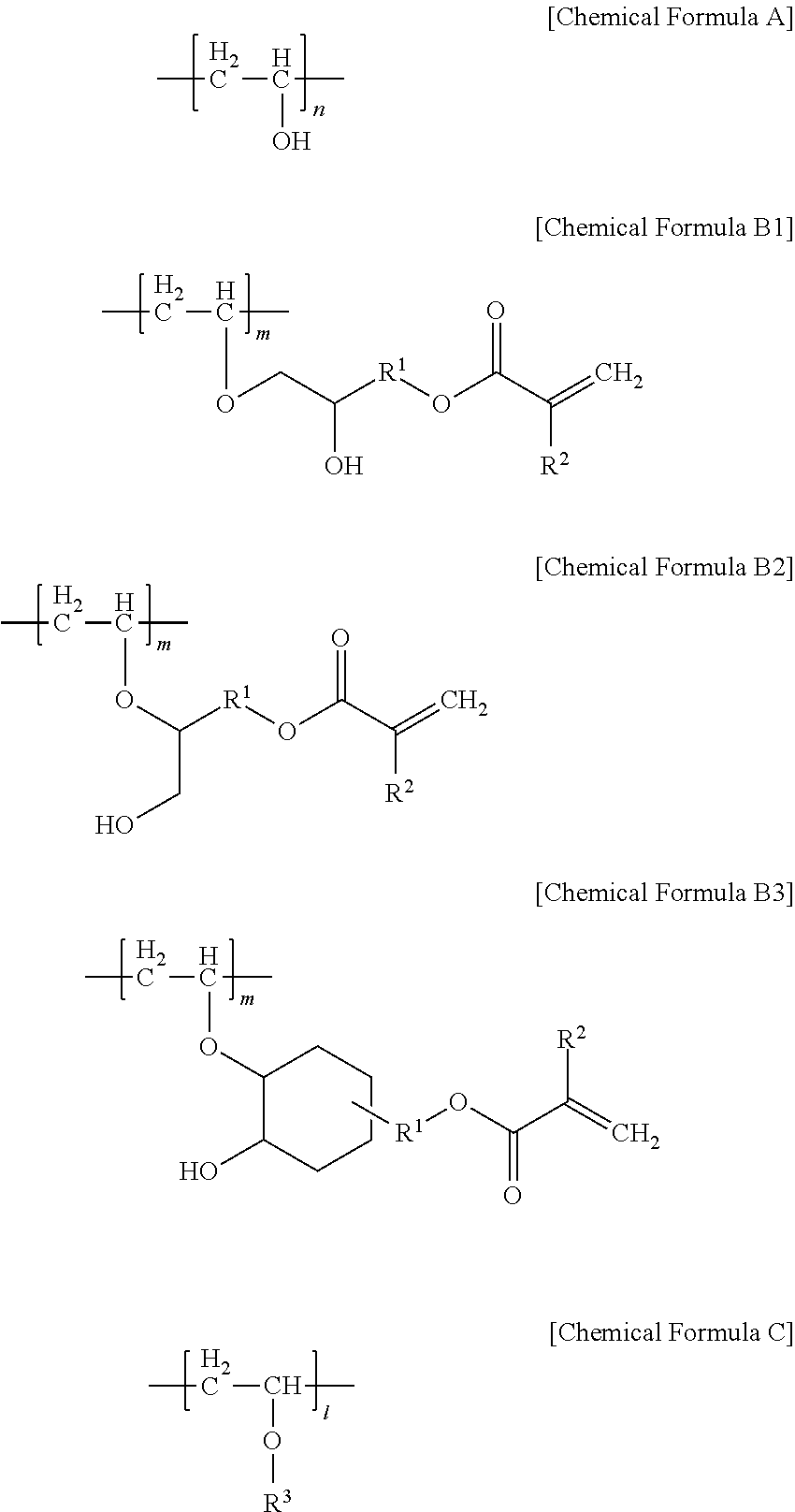

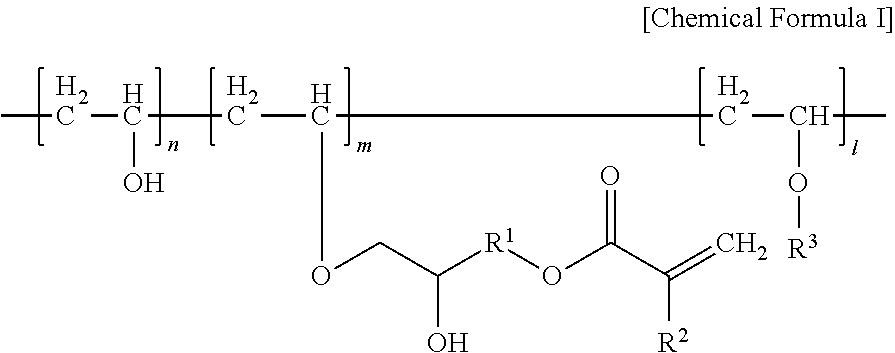

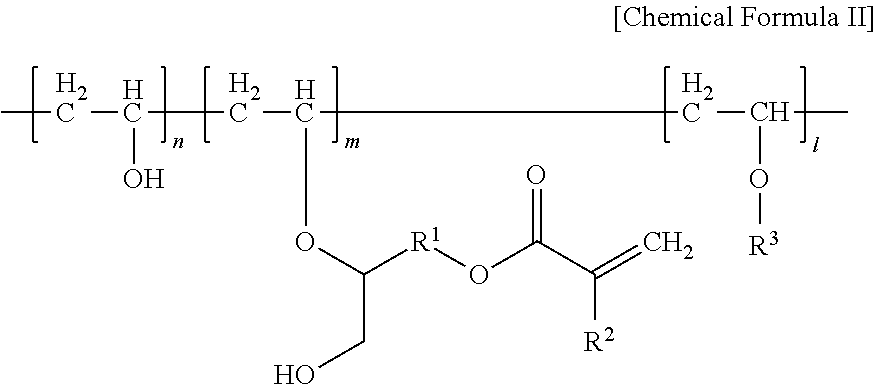

Method used

Image

Examples

example 2

[0058]A polyvinyl alcohol resin (average degree of polymerization of 1700, degree of saponification of 95% to 97%, Nippon Synthetic Chemical Industry Co., Ltd., product Z320) was dissolved in pure water at 80° C. for 1 hour, and then 40 parts by weight of glycidylmethacrylate (GMA) was added with respect to 100 parts by weight of the polyvinyl alcohol resin and stirred overnight at room temperature. As a result, GMA was chemically combined with the polyvinyl alcohol resin according to Reaction Formula 1. Meanwhile, a pH level was controlled to about 13 to 14 by adding 1N NaOH during the reaction.

[0059]Thereafter, an AH-PVA resin was analyzed by FT-IR and the presences of the introduced acrylate and formed OH-functional group were confirmed. Also, a content of the introduced GMA was calculated by using NMR and a polyvinyl alcohol resin was obtained in which 2.0 mol % of GMA was introduced.

[0060]A water-based adhesive was prepared by dissolving the prepared AH-PVA resin (average degre...

example 3

[0062]A polyvinyl alcohol resin (average degree of polymerization of 1100, degree of saponification of 99%, Nippon Synthetic Chemical Industry Co., Ltd., product Z210) was dissolved in pure water at 80° C. for 1 hour, and then 5 parts by weight of glycidylmethacrylate (GMA) was added with respect to 100 parts by weight of the polyvinyl alcohol resin and stirred overnight at room temperature. As a result, GMA was chemically combined with the polyvinyl alcohol resin according to Reaction Formula 1. Meanwhile, a pH level was controlled to about 1 to 2 by adding concentrated HCl during the reaction.

[0063]Thereafter, an AH-PVA resin was analyzed by FT-IR and the presences of the introduced acrylate and formed OH— functional group were confirmed. Also, a content of the introduced GMA was calculated by using NMR and a polyvinyl alcohol resin was obtained in which 0.15 mol % of GMA was introduced.

[0064]A water-based adhesive was prepared by dissolving the prepared AH-PVA resin (average degr...

example 4

[0066]A polyvinyl alcohol resin (average degree of polymerization of 600, degree of saponification of 95% to 97%, Nippon Synthetic Chemical Industry Co., Ltd., product Z100) was dissolved in pure water at 80° C. for 1 hour, and then 60 parts by weight of glycidylmethacrylate (GMA) was added with respect to 100 parts by weight of the polyvinyl alcohol resin and stirred at 70° C. for 24 hours. As a result, GMA was chemically combined with the polyvinyl alcohol resin according to Reaction Formula 1. Meanwhile, a pH level was controlled to about 13 to 14 by adding 1N NaOH during the reaction.

[0067]Thereafter, an AH-PVA resin was analyzed by FT-IR and the presences of the introduced acrylate and formed OH-functional group were confirmed. Also, a content of the introduced GMA was calculated by using NMR and a polyvinyl alcohol resin was obtained in which 10.0 mol % of GMA was introduced.

[0068]A water-based adhesive was prepared by dissolving the prepared AH-PVA resin (average degree of po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com