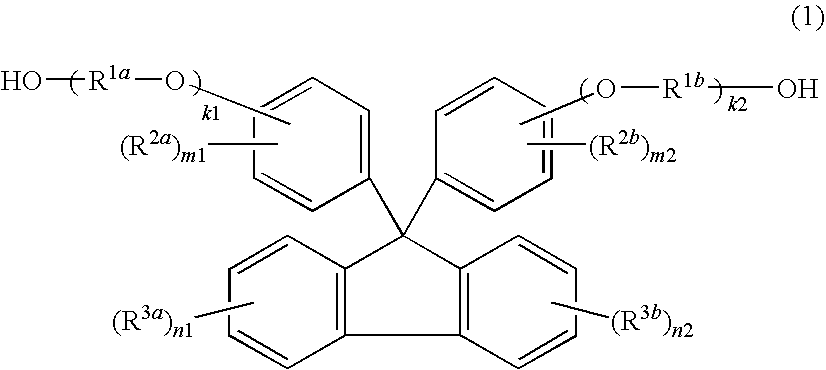

Resin composition and molded articles thereof

a technology of resin composition and molded articles, applied in the field of resin composition, can solve the problems of poor compatibility of polyester resin with polycarbonate resin, inability to maintain transparency of resin composition obtained, and sometimes difficult moldability of polyester resin, etc., and achieve excellent moldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0385]This invention will be more specifically explained with reference to Examples hereinafter, while this invention shall not be limited in any way by these Examples. In Examples, “part” stands for “part by weight”.

[0386]Polyester resins, polycarbonate resins, resin compositions, plates, lenses or infrared absorbing filters obtained in Synthesis Examples A-1 to A-4 and B-1 to B-5, Examples 1 to 16 or Comparative Examples 1 to 5 were evaluated by the following methods.

[0387](1) Measurement of number average molecular weight (Mn): Size exclusion chromatography was carried out with HLC-8220GPC supplied by Tosoh Corporation using a chloroform eluting solution and a UV detector, and a number average molecular weight was measured as a standard polystyrene.

[0388](2) Tg measurement: Measured with a differential scanning calorimeter DSC-2910 supplied by T. A. Instruments Japan K.K. according to JIS K-7121 at a temperature elevation rate of 20° C. / minute in a nitrogen atmosphere.

[0389](3) M...

examples 1 to 9

[0414]The polyester resins and polycarbonate resins obtained in the above Synthesis Examples were dry-blended in compositional ratios shown in Table 4, and each dry blend was separately melt-kneaded with a 15Φ twin-screw extrusion kneading machine supplied by TECHNOVEL CORPORATION at a resin temperature of 240 to 280° C. The thus-kneaded products were cooled and pelletized to give transparent resin compositions.

[0415]Pellets of each of the thus-obtained resin compositions were separately injection-molded with a 30-ton injection molding machine supplied by Toshiba Machine Co., Ltd. to obtain plates. All the plates had low refractive indices and were optically uniform.

[0416]Further, when pellets of each of the above resin compositions were separately injection-molded under the conditions of a cylinder temperature of 250 to 280° C. and a mold temperature of 100° C., the resin compositions were excellent in moldability and gave colorless transparent plastic lenses. The above lenses in a...

examples 10 to 15

[0426]The polyester resins and the polycarbonate resins obtained in the above Synthesis examples and infrared absorbents in compositional ratios shown in Table 5 were added to 341 parts of cyclopentanone, and each mixture was separately stirred at room temperature for 10 hours to give coating liquids. In any one of the coating liquids, the dispersion state of a dye was excellent. The coating liquids were separately applied onto glass plates by a spin coating method to form coatings that would have a dry film thickness of 4.0 μm each, and the coatings were dried in an oven at 80° C. for 30 minutes to give coating films (near infrared absorbing filters). In any one of these Examples, the appearance of the film was in an excellent state free of non-uniformity, etc., and when the films were observed for aggregates of dyes, no aggregates, etc., were found.

[0427]

TABLE 5Resin compositionPoly-Phthalo-PolyestercarbonatecyanineDiimmoniumresinpartresinpartDithiol dyepartdyepartdyepartExample 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mol % | aaaaa | aaaaa |

| mol % | aaaaa | aaaaa |

| mol % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com