Blast furnace slag flushing technology by pneumatic lifting runner and its flushing device

A blast furnace slag and hub technology, which is applied in the field of blast furnace slag punching process and its punching device by the air-lifting hub method, can solve the problems of high frequency of dry slag, high slag content in circulating water, and low equipment operation rate, etc. problems, to achieve the effects of long equipment life, water and energy saving in slag water content, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

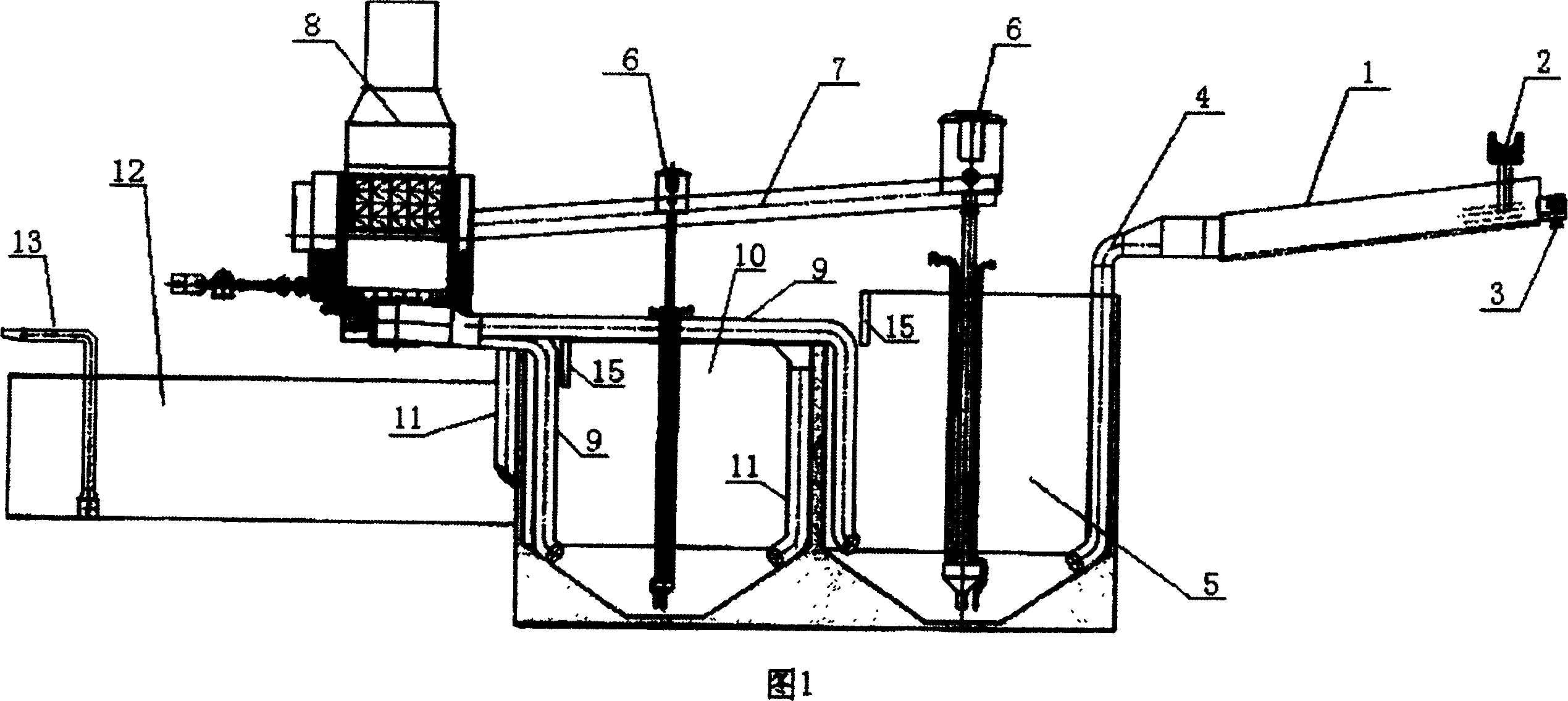

[0027] Below in conjunction with accompanying drawing and concrete example for further description:

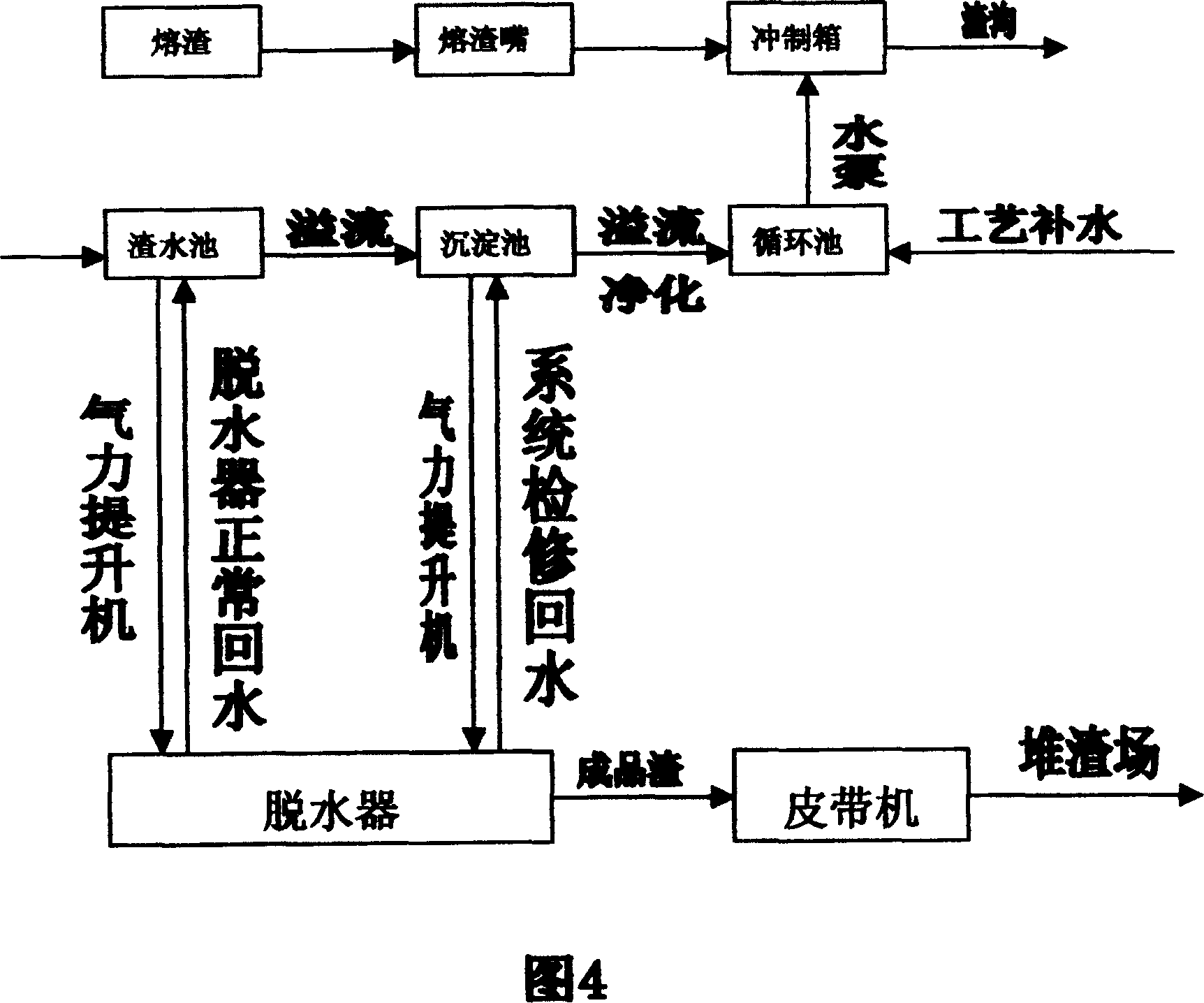

[0028] As shown in Figure 4, the blast furnace slag punching process of the present invention includes the following steps in turn:

[0029] A. The slag separated by the skimmer flows to the slag nozzle through the slag ditch;

[0030] B. The slag discharged from the slag nozzle is mixed with the water sprayed from the punching box, and then discharged into the bottom of the slag pool through the slag flushing ditch and the water diversion pipe;

[0031] C. The pneumatic lift pump transports the slag water at the bottom of the slag pool to the hub type dehydrator for dehydration. The dehydrated slag is sent to the slag dump by the belt conveyor. The bottom of the slag water tank is transported to the bottom of the sedimentation tank through the return pipe during system maintenance; the overflow water from the slag water tank is led to the bottom of the sedimentation tank;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com