Shoe midsole cloth scraping rubber latex paste, preparation method and application thereof

A technology for latex pulp and shoes, which is applied in the field of rubber processing, can solve the problems of complex pulping process, reduced production efficiency, long time consumption, etc., and achieves the effects of wide source of materials, improved production quality and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

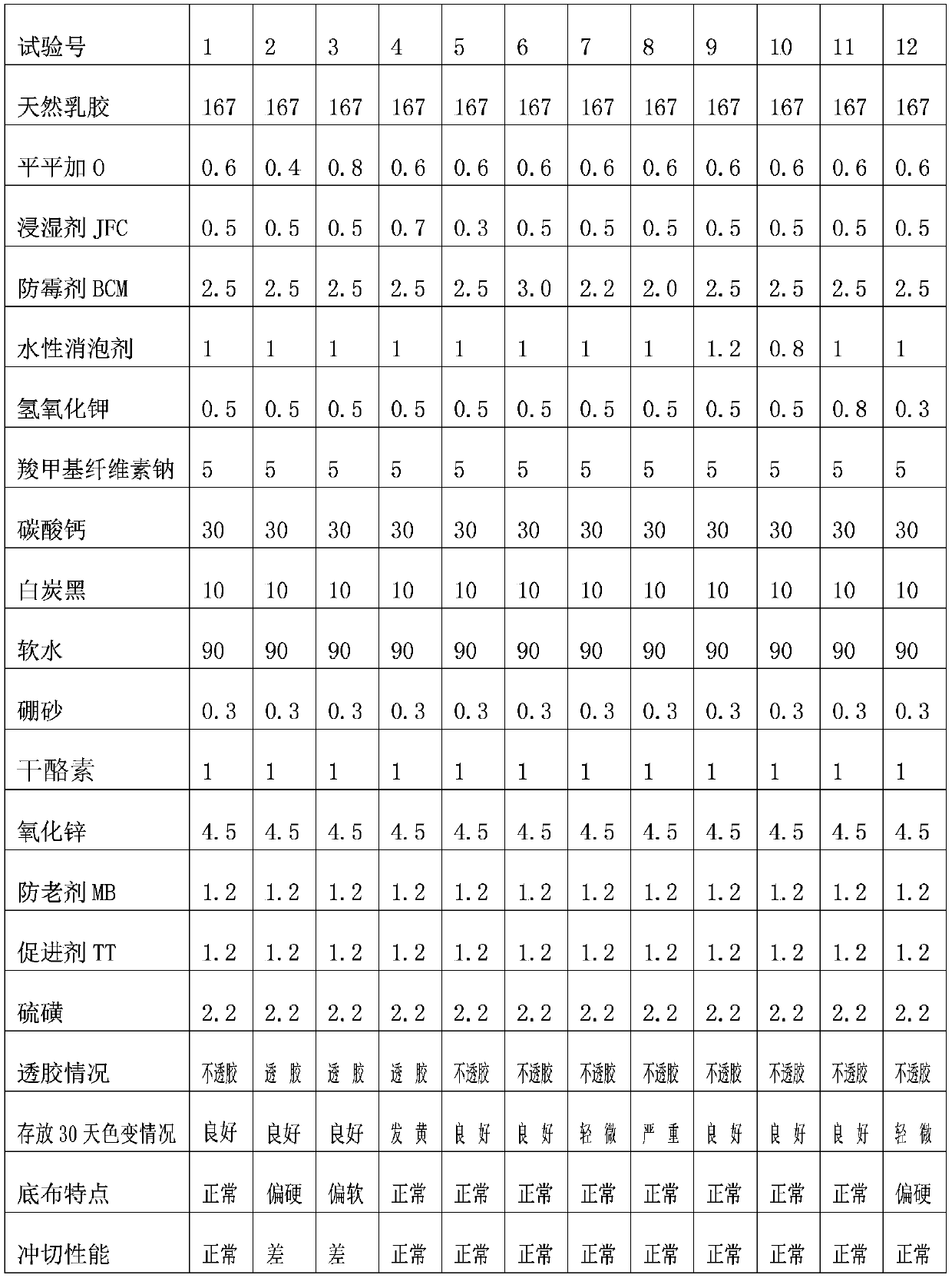

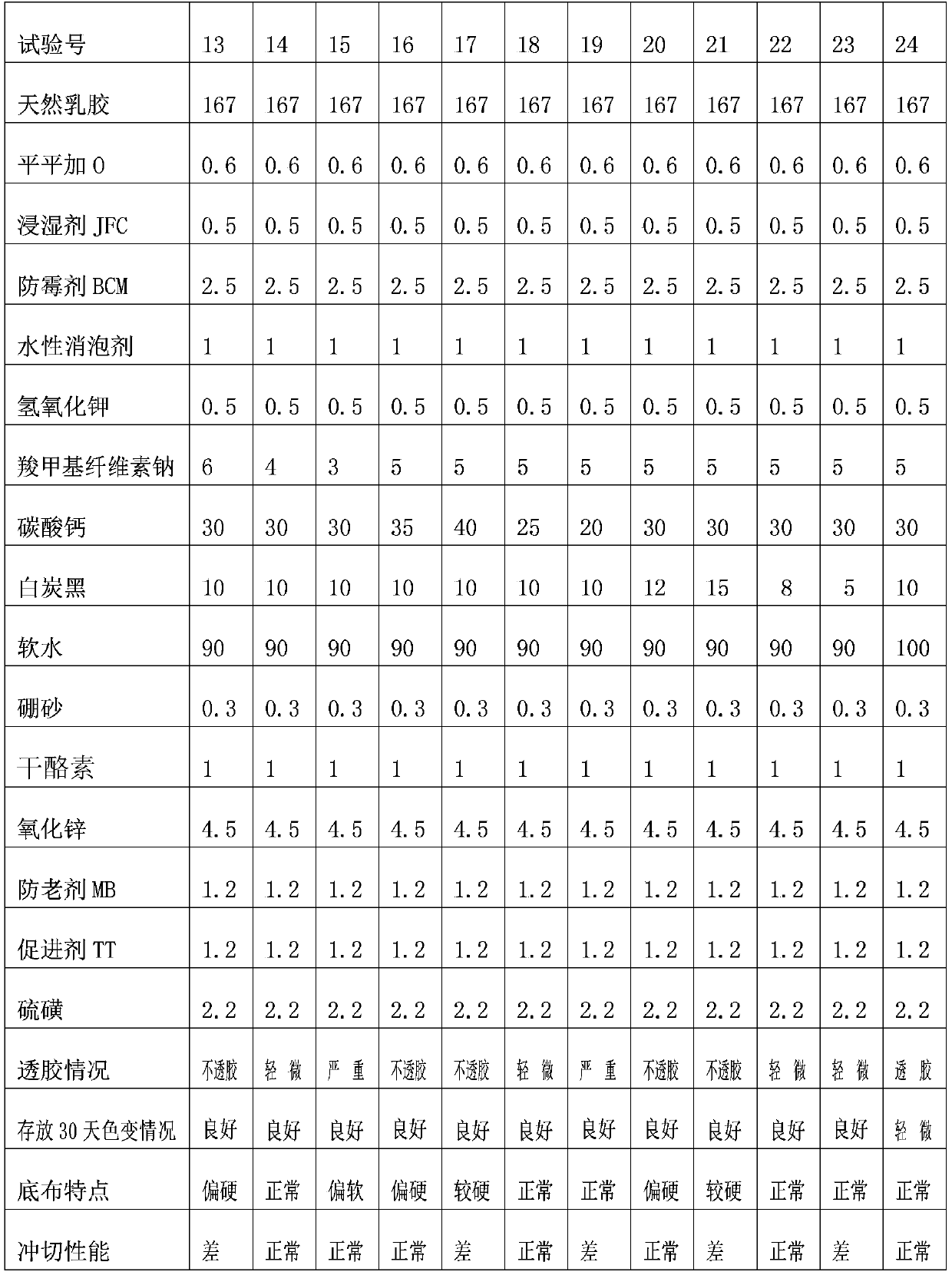

Examples

Embodiment 1

[0042] Embodiment 1 of the present invention: Scraping latex latex for midsole cloth for shoes, calculated in parts by weight, including 167 parts of natural latex, 10 parts of white carbon black, 30 parts of calcium carbonate, 0.6 part of flat plus O, 0.5 part of wetting agent JFC, 1 part of water-based defoamer, 90 parts of soft water, 2.5 parts of antifungal agent BCM, 1.2 parts of antiaging agent MB, 4.5 parts of zinc oxide, 0.5 parts of potassium hydroxide, 5 parts of sodium carboxymethylcellulose, 0.3 parts of borax, 1 part casein, 1.2 parts accelerator and 2.2 parts sulfur.

[0043] The preparation method of latex latex for midsole cloth for shoes is to get each component according to the above weight fraction; 1) prepare CMC swelling body: add 65 parts of soft water, 5 parts of sodium carboxymethyl cellulose and 2.5 parts of antifungal agent in the mixer Mix BCM, stir slowly and add 0.5 parts of potassium hydroxide, stir until the sodium carboxymethyl cellulose is unif...

Embodiment 2

[0045]Embodiment 2 of the present invention: Scraping latex latex for midsole cloth for shoes, calculated in parts by weight, including 167 parts of natural latex, 15 parts of white carbon black, 25 parts of calcium carbonate, 0.6 part of Pingping plus O, 0.5 part of wetting agent JFC, 1 part of water-based defoamer, 100 parts of soft water, 2.0 parts of antifungal agent BCM, 1.2 parts of antiaging agent MB, 4.5 parts of zinc oxide, 0.5 parts of potassium hydroxide, 4 parts of sodium carboxymethylcellulose, 0.3 parts of borax, 1 part casein, 1.2 parts accelerator, 2.2 parts sulfur.

[0046] The preparation method and application are the same as in Example 1.

Embodiment 3

[0047] Embodiment 3 of the present invention: Scraping latex latex for midsole cloth for shoes, calculated in parts by weight, including 167 parts of natural latex, 10 parts of white carbon black, 30 parts of calcium carbonate, 0.6 part of Pingping plus O, 0.5 part of wetting agent JFC, 1 part of water-based defoamer, 85 parts of soft water, 3 parts of antifungal agent BCM, 1.2 parts of antiaging agent MB, 4.5 parts of zinc oxide, 0.7 parts of potassium hydroxide, 5 parts of sodium carboxymethylcellulose, 0.3 parts of borax, 1.5 parts casein, 1.2 parts accelerator, 2.0 parts sulfur.

[0048] The preparation method and application are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com