Release film for use in producing green sheet

A technology of printed circuit board and peeling film, which is applied in the direction of manufacturing tools, synthetic resin layered products, transportation and packaging, etc. It can solve the problems of poor winding, thinning of printed circuit board, adhesion, etc., and prevent local uneven thickness , Excellent peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

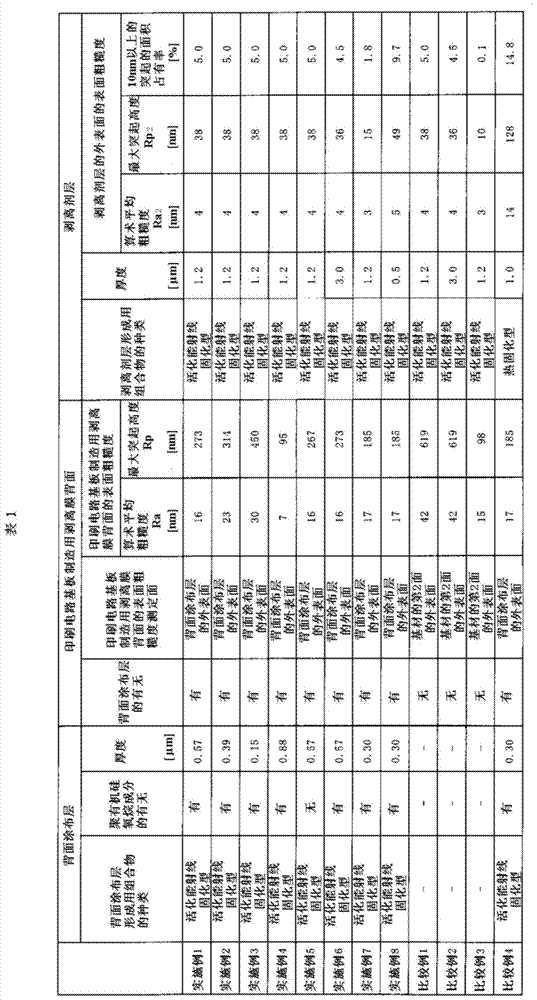

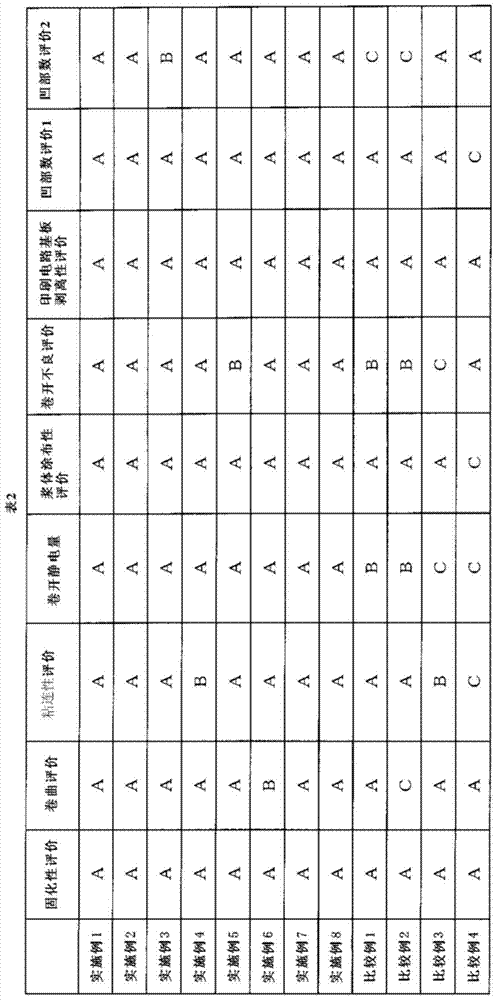

[0145] First, prepare a biaxially stretched polyethylene terephthalate film as a substrate [thickness: 38 μm, arithmetic average roughness Ra of the first surface 1 : 42nm, the maximum protrusion height Rp of the first surface 1 : 619nm, the arithmetic mean roughness Ra of the second surface 0 : 42nm, the maximum protrusion height Rp of the second surface 0 : 619nm].

[0146] Then, 94 parts by mass of dipentaerythritol hexaacrylate [solid content 100% by mass] as the active energy ray-curable compound (a1), and 1 part by mass as A polyether-modified acryloyl group-containing polydimethylsiloxane of polyorganosiloxane (b1) [Big Chemical Japan Co., Ltd., trade name "BYK-3500", solid content 100 mass %], and 5 mass As the photopolymerization initiator (c1), α-aminoalkylphenone photopolymerization initiator [made by BASF Corporation, trade name "IRGACURE907", 2-methyl-1[4-(methylthio)phenyl ]-2-morpholinopropan-1-one, solid content 100% by mass] to obtain a release agent layer...

Embodiment 2~4

[0151] Except having changed the thickness of the back surface coating layer and the surface roughness of the back surface of the release film for printed circuit board manufacture as shown in Table 1, it carried out similarly to Example 1, and prepared the release film for printed circuit board manufacture.

Embodiment 5

[0153] Except that the material for forming the back coating layer in Example 1 was changed to 95 parts by mass of dipentaerythritol hexaacrylate as the active energy ray compound (a2) was diluted with isopropyl alcohol / methyl ethyl ketone mixed solvent (mass ratio 3 / 1)[ Solid content 100% by mass], and 5 parts by mass of an α-aminoalkylphenone-based photopolymerization initiator [BASF, trade name "IRGACURE907" as a photopolymerization initiator (c2), 2-methyl-1 [4-(methylthio) phenyl]-2-morpholinopropan-1-one, solid content 100 mass %] the material for forming the back coating layer with a solid content of 20 mass % obtained, and as shown in Table 1 Except having changed the surface roughness of the back surface of the release film for printed circuit board manufacture, it carried out similarly to Example 1, and prepared the release film for printed circuit board manufacture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com