Manufacturing method of photovoltaic welding strip and tin coating machine thereof

A manufacturing method and technology of a tin coating machine, which are applied in the field of welding ribbon manufacturing, can solve problems such as low production efficiency, pinhole defects, and silicon wafer rupture, and achieve the effects of improving quality, reducing the generation of tin oxide, and reducing the fragmentation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

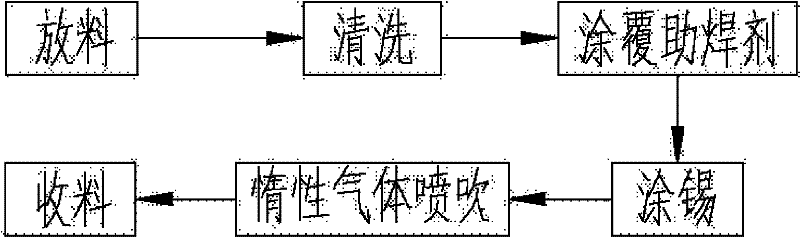

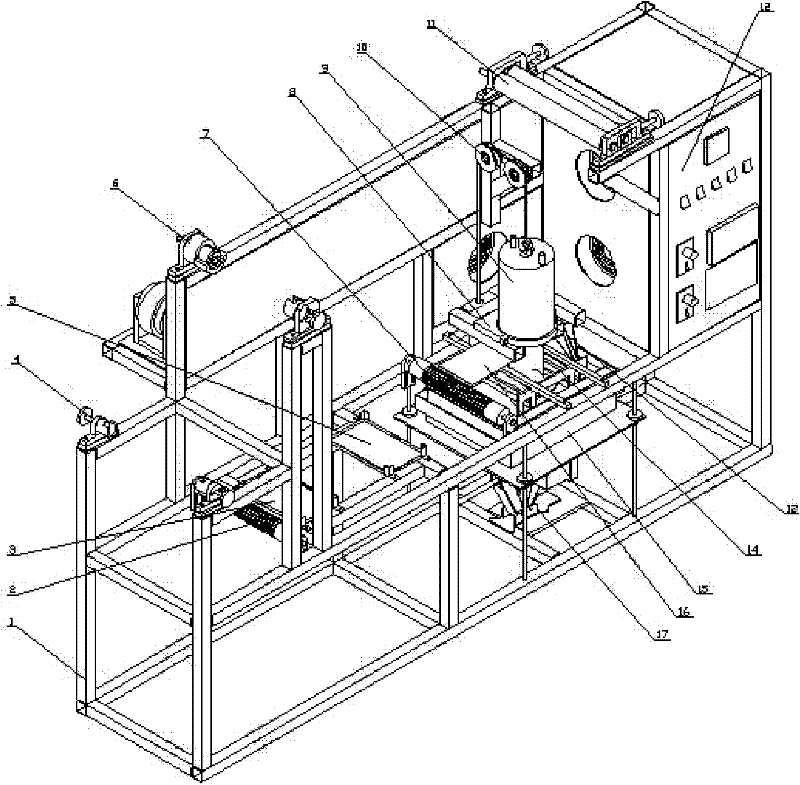

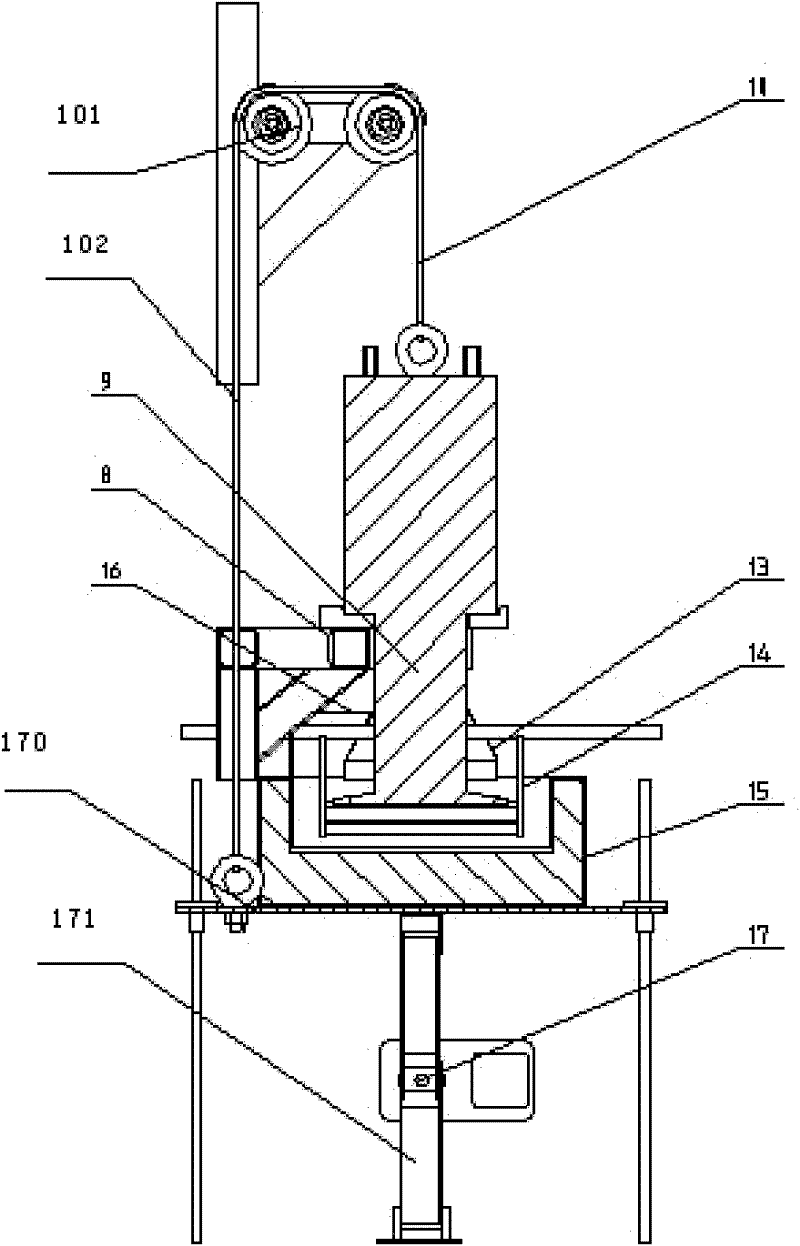

[0037] Clean the copper strip through a cleaning agent at a speed of 10m / min. The cleaning agent can be a chemical agent such as alcohol or dilute hydrochloric acid, and then drag the copper strip in a sponge or wool felt containing flux to make the welding strip Flux is evenly coated on the periphery, and the flux is not limited. NCF can be used to clean the environmentally friendly flux. The copper strip that has been treated above is sent to the plating solution of the tin furnace for tin coating. The transducer emits ultrasonic waves to ultrasonically treat the copper strip. The temperature of the tin furnace is 220 degrees, the ultrasonic frequency is 20KHz, the power is 500W, and the tape running speed is 10m / min; the copper strip passes through the tin furnace after being coated with tin. There is an air outlet device for blowing inert gas on it to blow tin, and blow excess tin liquid back to the tin furnace. The gas pressure of the gas is 0.4Mpa, the flow rate is 8m / s,...

Embodiment 2

[0040]Clean the copper strip through a cleaning agent at a speed of 20m / min. The cleaning agent can be a chemical agent such as alcohol or dilute hydrochloric acid, and then drag the copper strip in a sponge or wool felt containing flux to make the welding strip Flux is evenly coated on the periphery, and the flux is not limited. NCF can be used to clean the environmentally friendly flux. The copper strip that has been treated above is sent to the plating solution of the tin furnace for tin coating. The transducer emits ultrasonic waves to ultrasonically treat the copper strip. The temperature of the tin furnace is 225 degrees, the ultrasonic frequency is 20KHz, the power is 1200W, and the tape speed is 20m / min; the copper strip passes through the tin furnace after being coated with tin. There is an air outlet device for blowing inert gas on it to blow tin, and blow excess tin liquid back to the tin furnace. The gas pressure of the gas is 0.45Mpa, the flow rate is 10m / s, and t...

Embodiment 3

[0043] Clean the copper strip through a cleaning agent at a speed of 35m / min. The cleaning agent can be a chemical agent such as alcohol or dilute hydrochloric acid, and then drag the copper strip in a sponge or wool felt containing flux to make the welding strip Flux is evenly coated on the periphery, and the flux is not limited. NCF can be used to clean the environmentally friendly flux. The copper strip that has been treated above is sent to the plating solution of the tin furnace for tin coating. The transducer emits ultrasonic waves to ultrasonically treat the copper strip. The temperature of the tin furnace is 235 degrees, the ultrasonic frequency is 20KHz, the power is 1200W, and the tape speed is 35m / min; the copper strip passes through the tin furnace after being coated with tin. There is an air outlet device for blowing inert gas on it to blow tin, and blow excess tin liquid back to the tin furnace. The gas pressure of the gas is 0.5Mpa, the flow rate is 11m / s, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com