Waterproof base plate of fabricated integral bathroom

A prefabricated and integral technology, applied in the direction of bathtubs, showers, sanitary equipment, etc., can solve the problems of empty noise when stepping on it, plastic appearance, non-recyclable, etc., and achieve good waterproof effect, fast production, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Describe in detail below in conjunction with accompanying drawing and specific embodiment:

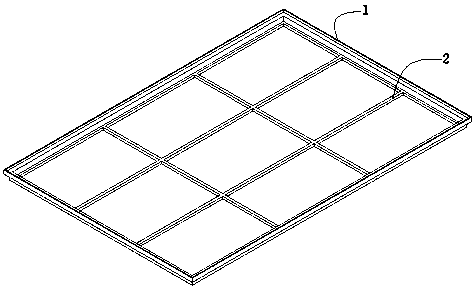

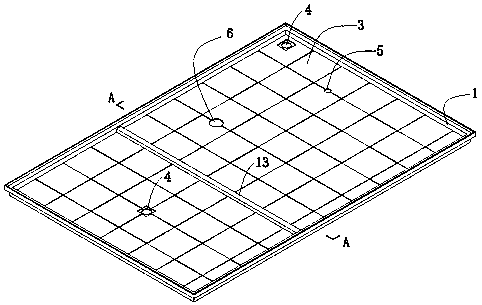

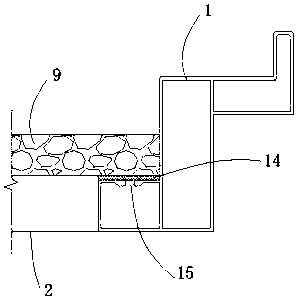

[0025] Such as figure 1 To such as Figure 7 The waterproof chassis of the prefabricated integral bathroom shown is an aluminum outer frame formed by welding aluminum profiles 1 and aluminum square tubes 2. The body of the pan can be formed of two materials: cement fiber board 9 and honeycomb core 11, and both materials need to be laid The ceramic tile 3 is the surface layer, and the round hole 4 on the chassis is the floor drain in the dry and wet area, which is used to connect the sewer pipe for drainage; the round hole 5 is the connection port for washing basin drainage, and the round hole 6 is the connection port for the toilet sewage pipe; the long strip Artificial stone 13 is used for dry and wet partitions.

[0026] figure 1 For multiple professionally designed aluminum profiles 1, the quadrilateral frame is synthesized by aluminum welding, and the corner connection of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com