Electric brush plating device of flat plate type metal component

A brush plating and parts technology, applied in jewelry and other directions, can solve the problems of high labor intensity of operators, unstable coating quality, short service life, etc., to improve the liquid phase mass transfer process, speed up electrodeposition, improve The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

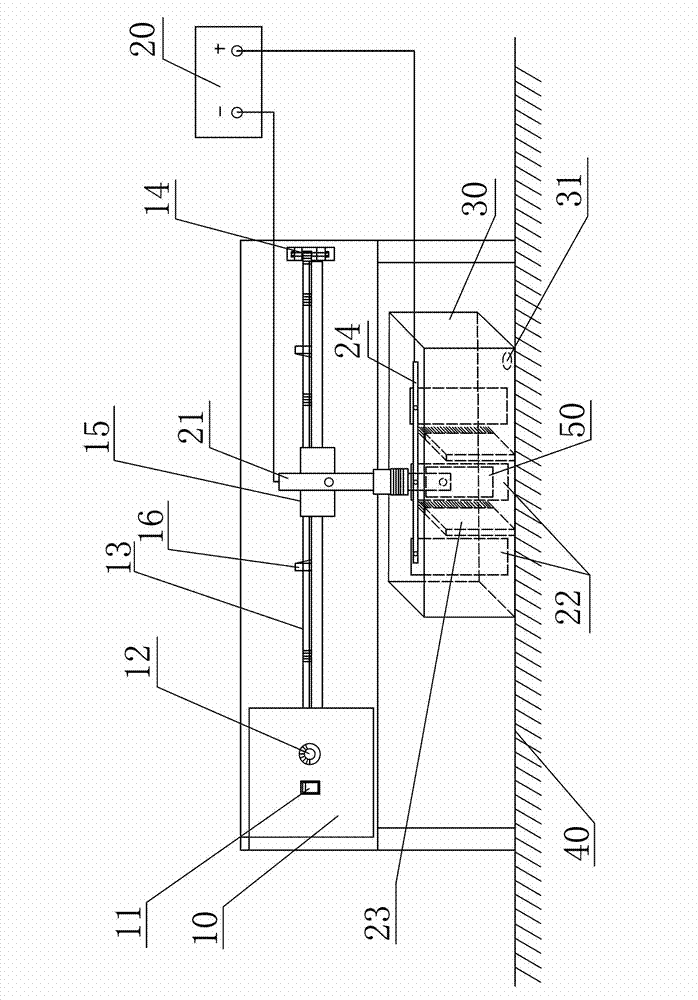

[0020] like figure 1 As shown, the brush plating device for flat metal parts of the present invention includes a motion control device, a brush 23, an anode plate 22 and a brush plating tank 30, wherein: the brush 23 and the anode plate 22 are fixedly mounted on the brush In the plating tank 30, the plating piece (ie, the flat metal part) 50 is installed on the motion control device via the insulating handle 21. In practice, the plating piece 50 can be fixed via the conductive block and the conductive rod (not shown in the figure). Installed on the insulating handle 21, the plating member 50 is located in the brush plating tank 30, the plated surface of the plating member 50 is arranged opposite to the anode plate 22 (referring to the plate surface of the anode plate 22), and the plating member 50 is opposite to the anode plate 22. The negative pole of the DC power supply 20 is connected. In practice, the plating member 50 is connected to the negative pole of the DC power supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com