Roll-to-roll vertical type magnetic control film plating device

A coating device, roll-to-roll technology, applied in the direction of sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems of film layer influence, coating layer scratches, single sputtering material, etc., to achieve guaranteed quality, the effect of avoiding pinholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

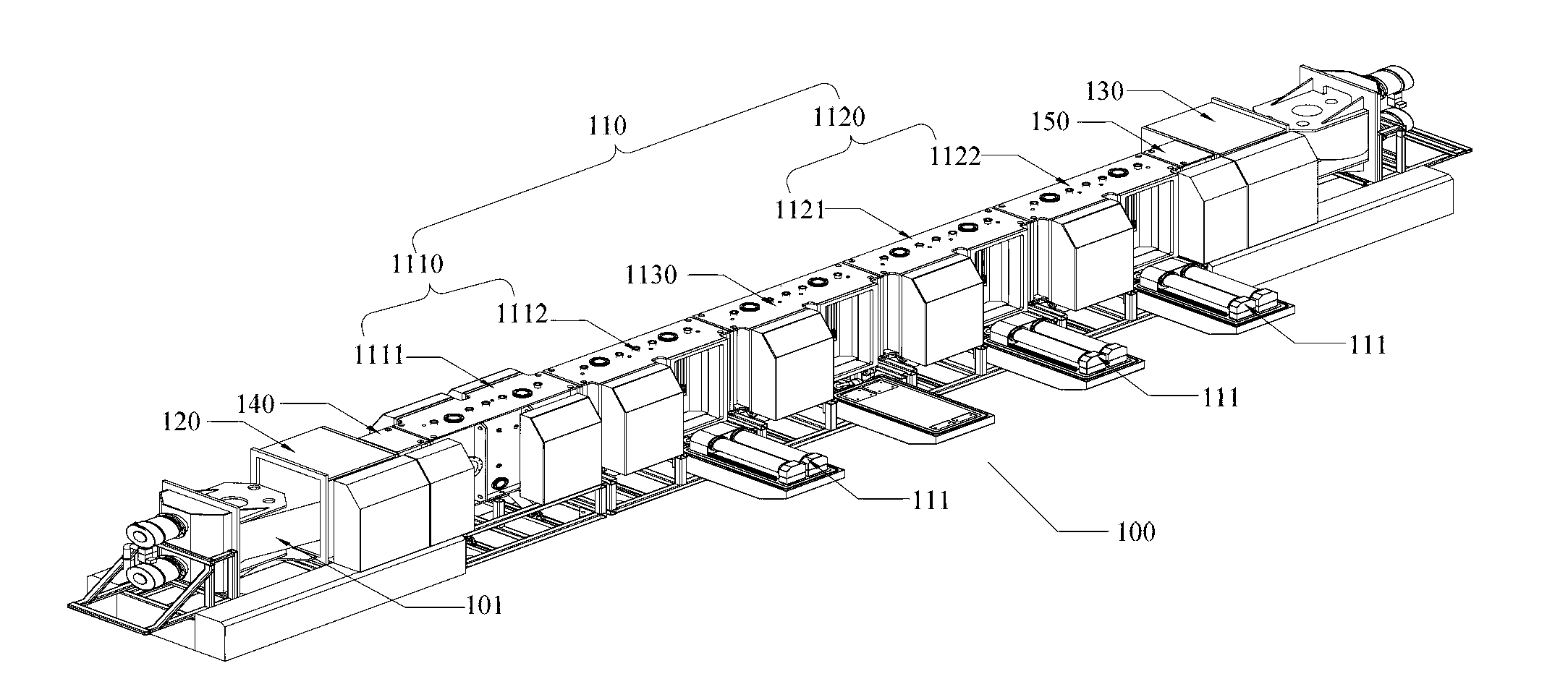

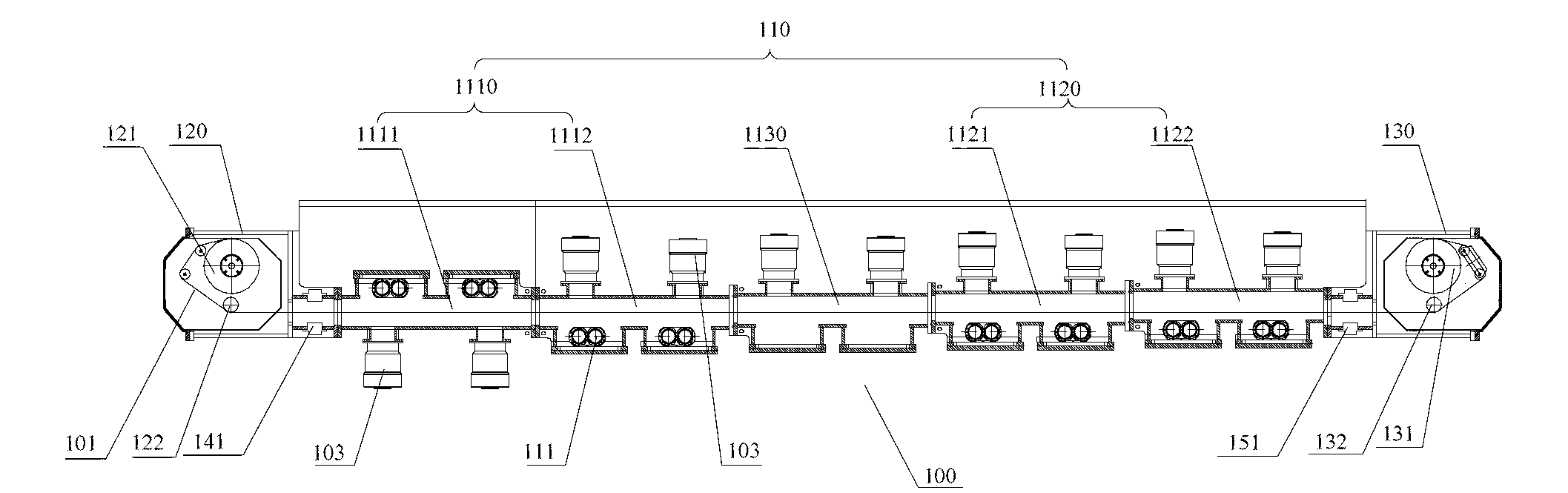

[0026] see figure 1 and figure 2 , an embodiment of a roll-to-roll vertical magnetron coating device 100 of the present invention is proposed, which includes: a coating chamber 110, one end of the coating chamber 110 is connected with an unwinding chamber 120, and the unwinding chamber 120 is provided with The unwinding roller 121 and the guide roller 122 with the roller axis arranged in the vertical direction; the other end of the coating chamber 110 is connected with a winding chamber 130, and the winding chamber 130 is provided with the winding roller 131 whose roller axis is arranged in the vertical direction and the first guide roller 132; the side wall of the coating chamber 110 is provided with a magnetron sputtering target 111, and the target surface of the magnetron sputtering target 111 is set in a vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com