Method for extracting oil and gas by convection heating of oil shale

A convective heating and oil shale technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve problems such as high cost, low efficiency, heat loss, etc., and achieve improved oil and gas recovery and low cost. , the effect of uniform temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

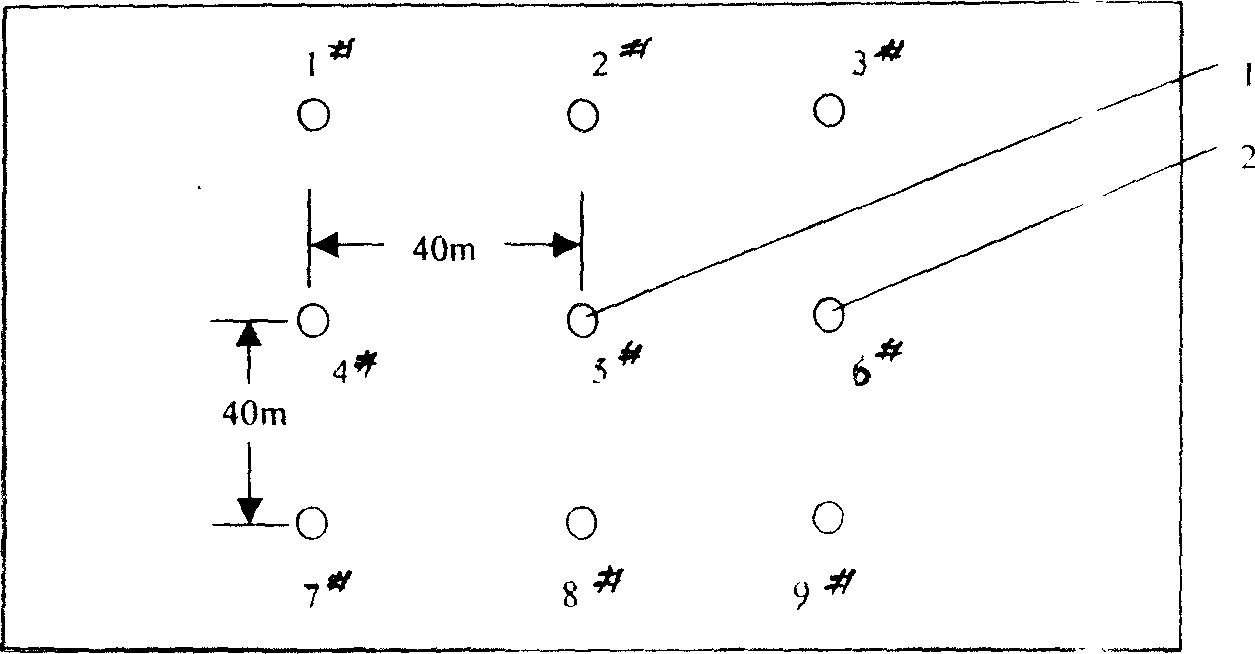

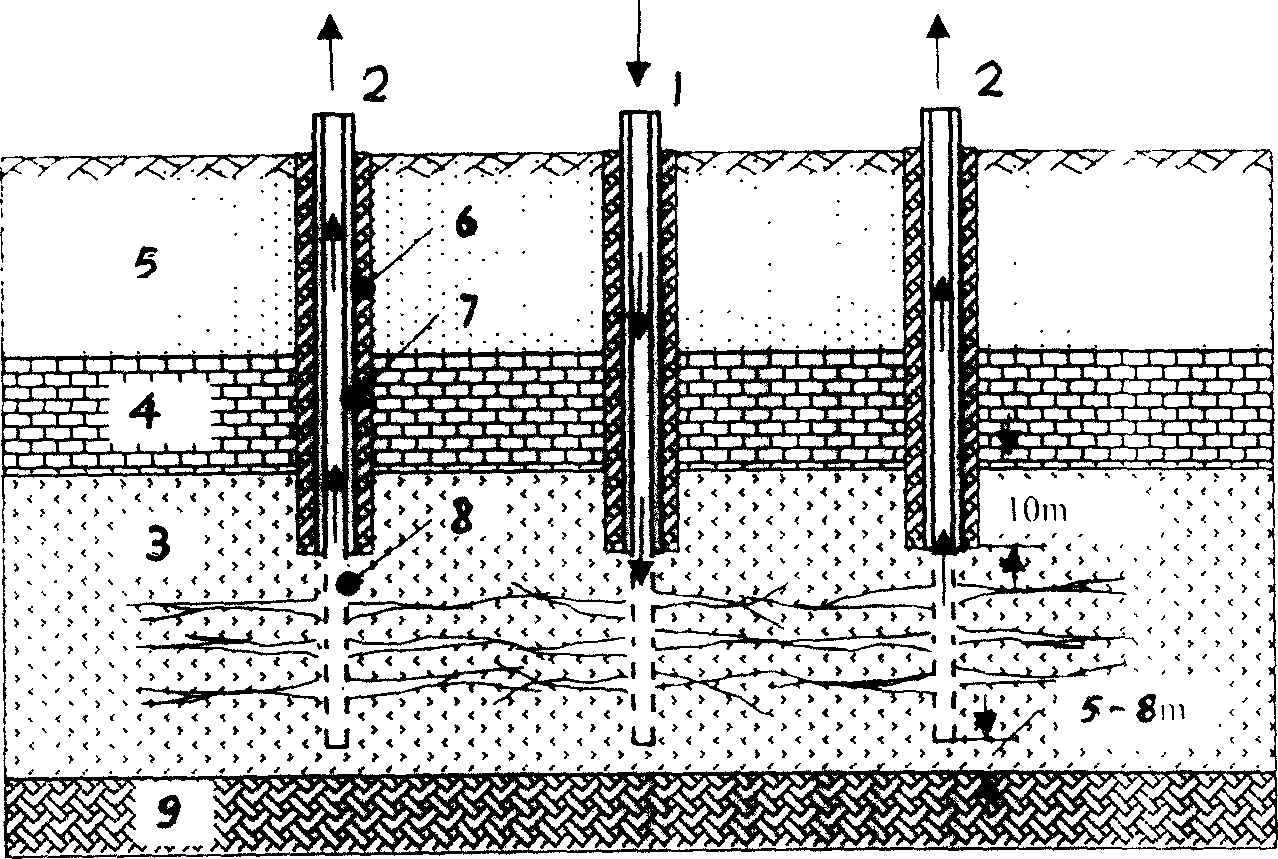

[0035] Such as figure 1 , 2 As shown, a method for convection heating oil shale to extract oil and gas, in a single oil shale layer with a thickness of 30m and a buried depth of 100m, 9 wells are arranged by the present invention, with a well spacing of 40m and a square shape Grid distribution, each well is located at the intersection of the square grid, each well is drilled into the ore layer 3, and then lowered into the double-layer annular pipe 7, the double-layer annular pipe 7 is made of high-temperature-resistant seamless steel pipe with an inner diameter of 150mm, and The top of floral tube 8 is connected, and the length of floral tube is 15m, and it is 5~8m apart from bottom plate 9 when going down into ore layer, and leaves about 10m apart from ore layer top plate 4. The flower tube and the double-layer annular pipe are still in the elastic state of the material under the continuous action of the high temperature of 700°C and the horizontal thermal expansion stress 2...

Embodiment 2

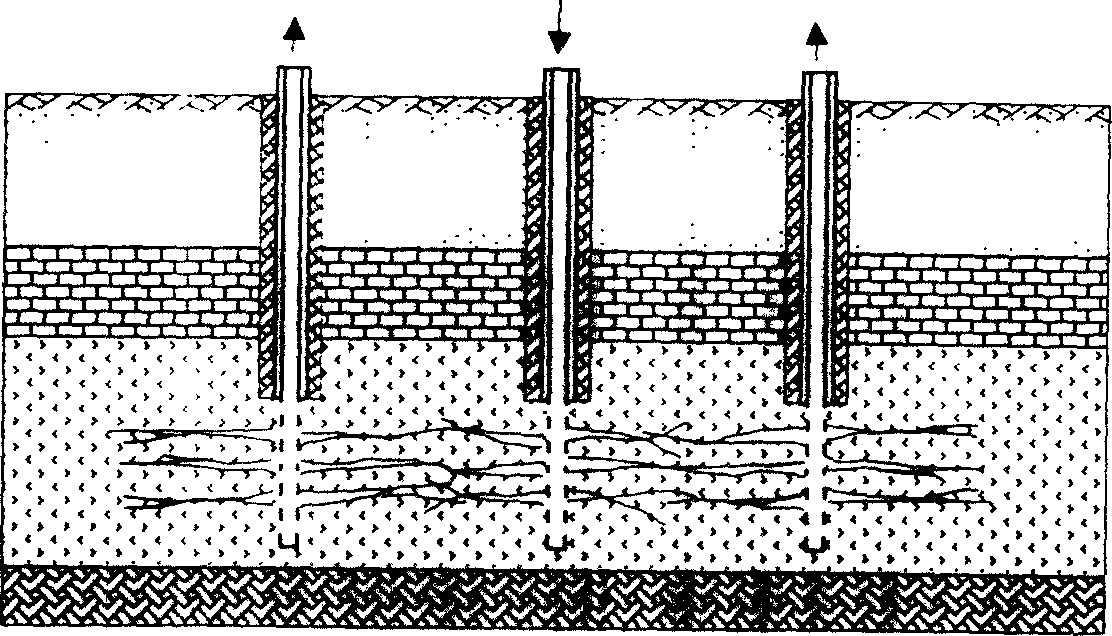

[0045] Such as Figure 4 , 5 As shown, a method for convectively heating oil shale to exploit oil and gas, a certain oil shale layer group contains three layers of oil shale layer 3, the thickness of the oil shale layer from bottom to top is 10m, 25m, 8m respectively, and the interlayer is The thickness of sandstone is 3m and 4m respectively. The accumulative thickness of this ore layer group is 43m, and the ore-bearing coefficient is 86%. The wells are arranged in equilateral triangle with the spacing of 50m and 11 wells are arranged.

[0046] Drill wells with the method of embodiment 1, each well is drilled into the ore layer 3, and then lowered into the double-layer annular pipe 7, the inner diameter of the double-layer annular pipe is 150mm, connected with the top of the flower pipe 8, the length of the flower pipe is 15m, and lowered into The ore seam is 5-8m away from the bottom plate 9, and 5-10m is reserved from the ore seam roof 4.

[0047] Specific steps are as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com