Patents

Literature

58results about How to "Guaranteed Error Accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

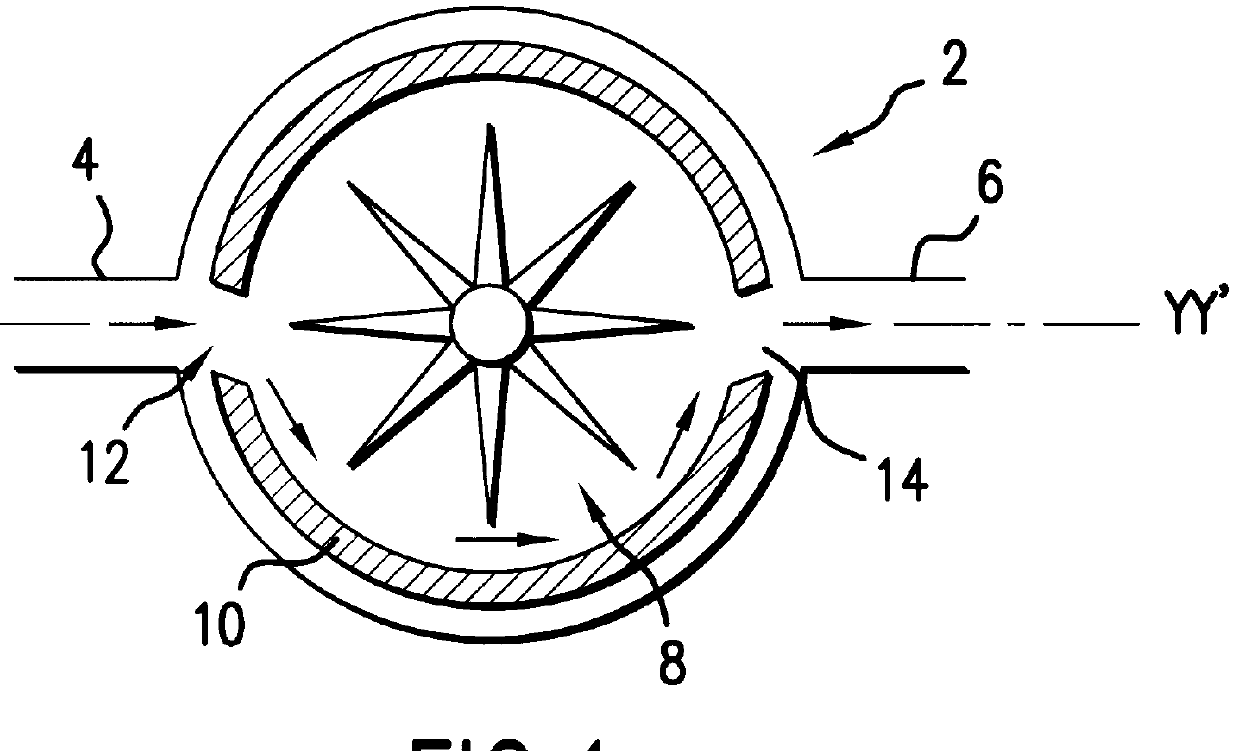

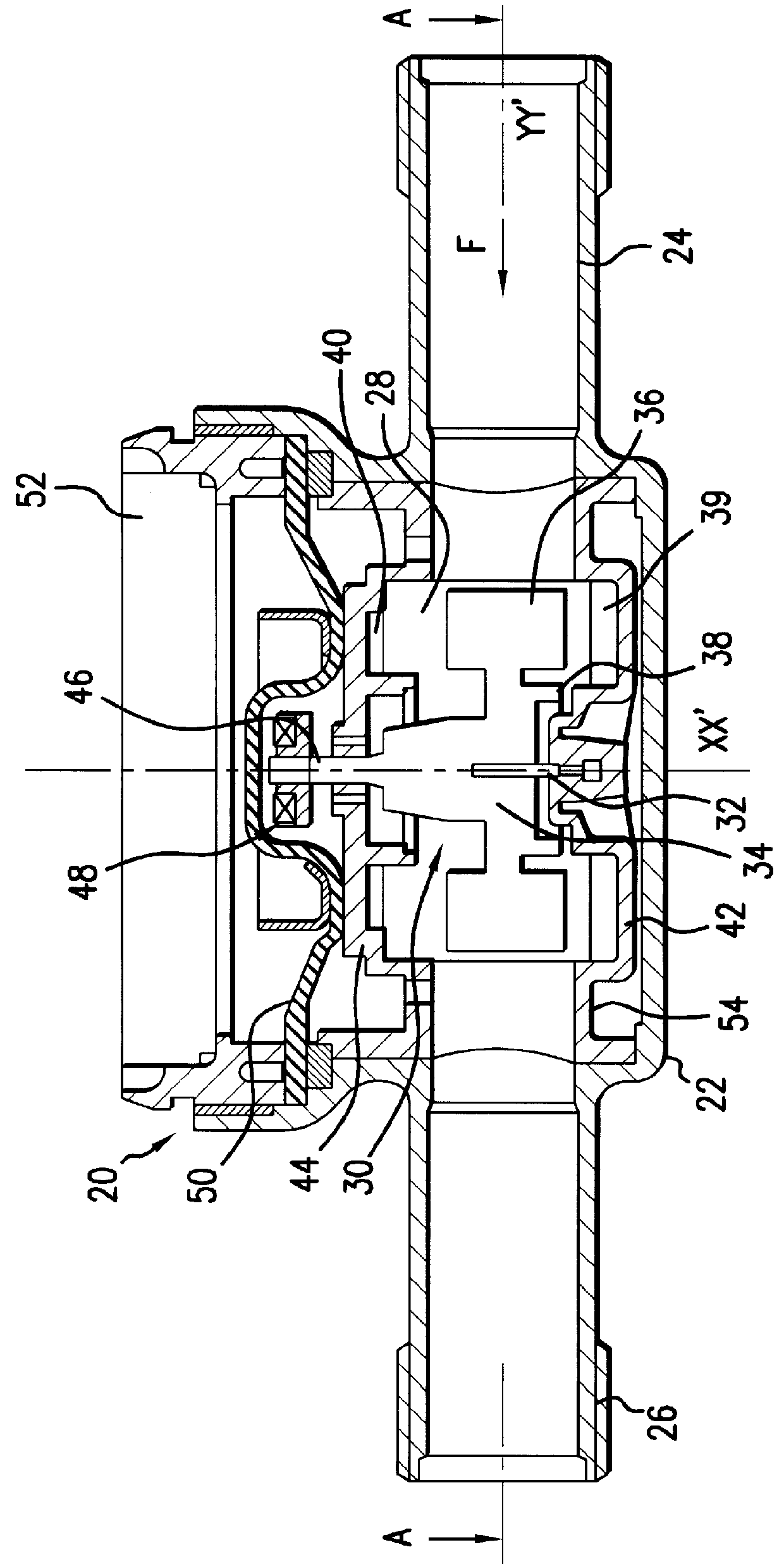

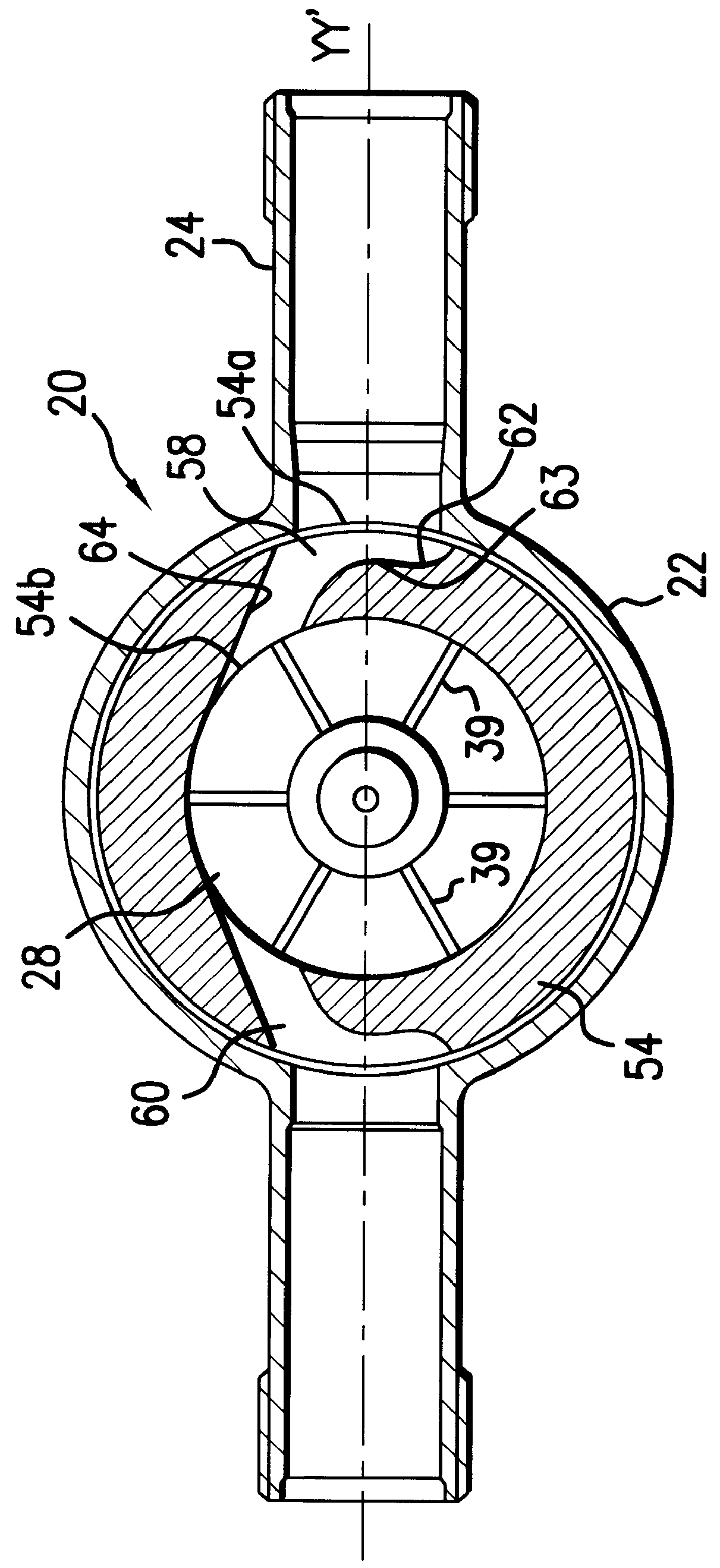

Single-jet liquid meter with improved driving torque

InactiveUS6079281AHigh measurement accuracyError on measurement accuracyVolume/mass flow by mechanical effectsMechanical engineeringFeeding tube

A single-jet liquid meter comprises a body in which a measurement chamber of substantially cylindrical shape is disposed. The chamber is fitted with a spinner having a longitudinal axis XX' and provided with blades, a liquid feed tube and a liquid discharge tube connected to the body and in alignment on an axis YY' that intersects axis XX' perpendicularly. A housing is disposed in the body around the periphery of the spinner and includes at least two slots respectively facing the feed tube and the discharge tube. The slots are designed to inject and eject the liquid flow in an inclined manner relative to the alignment axis of the tubes. At least one slot faces the feed tube and presents, to the flow of liquid coming from said tube, a shaped surface that progressively increases the speed of the flow.

Owner:ACTARIS SAS

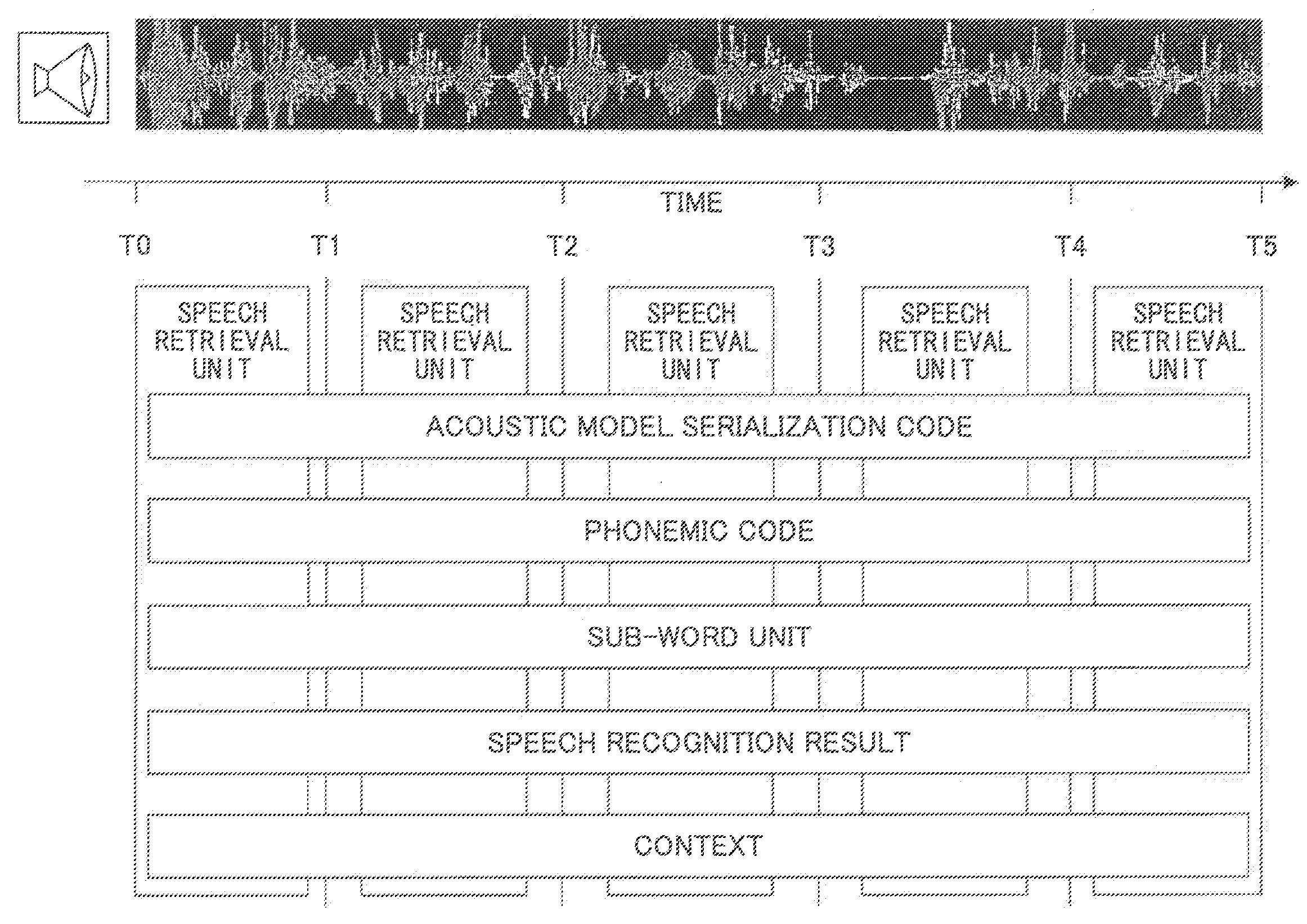

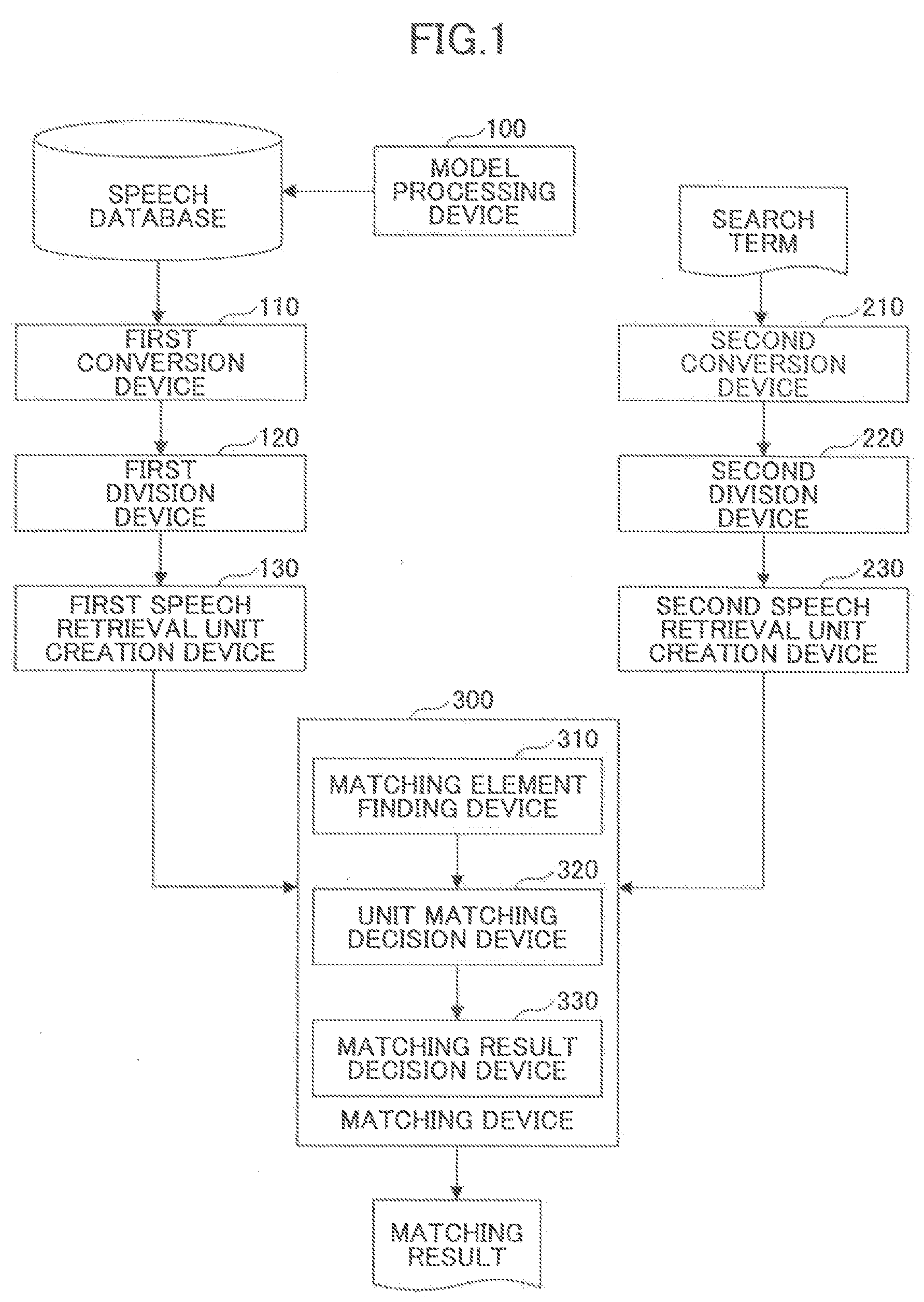

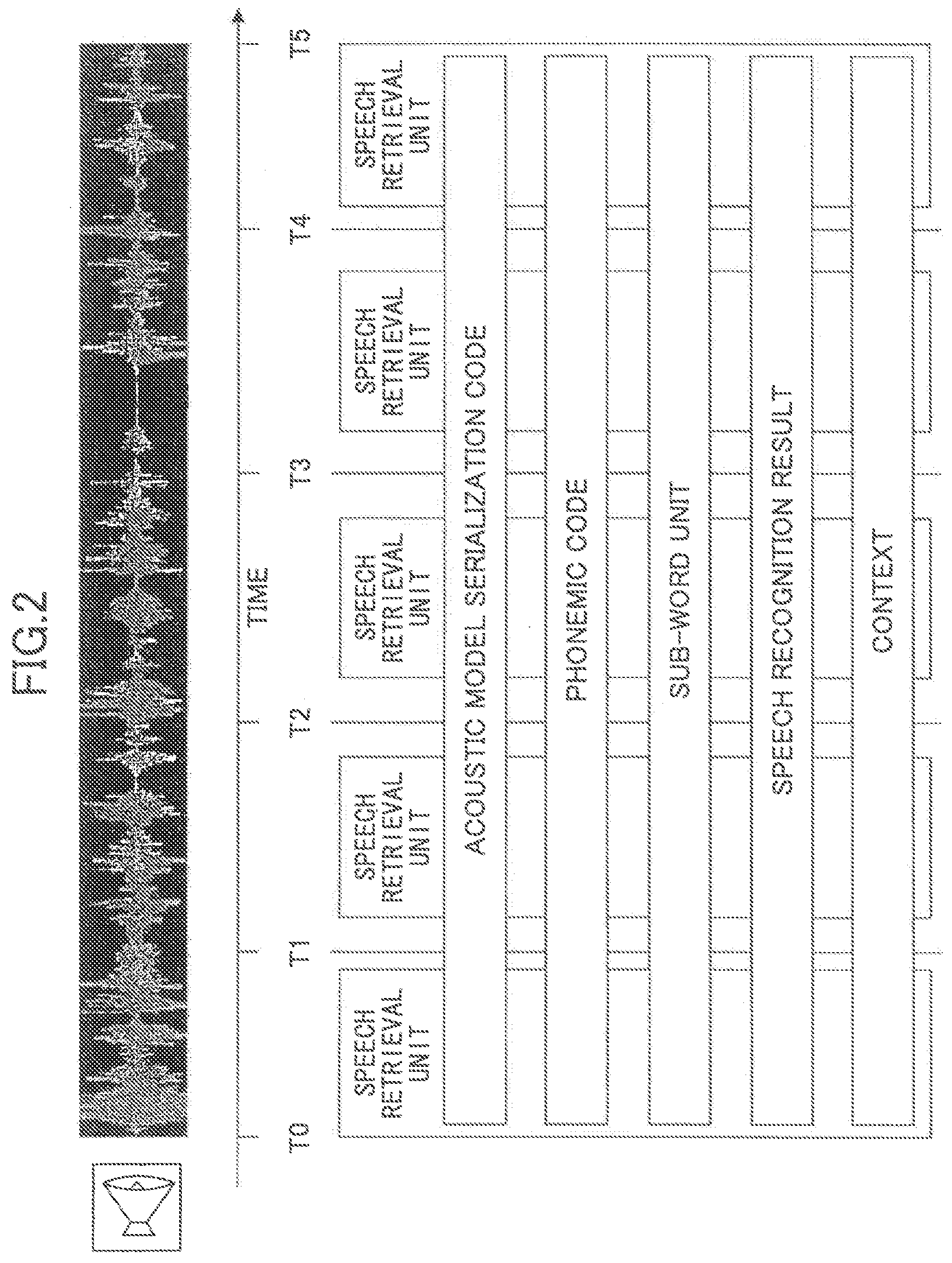

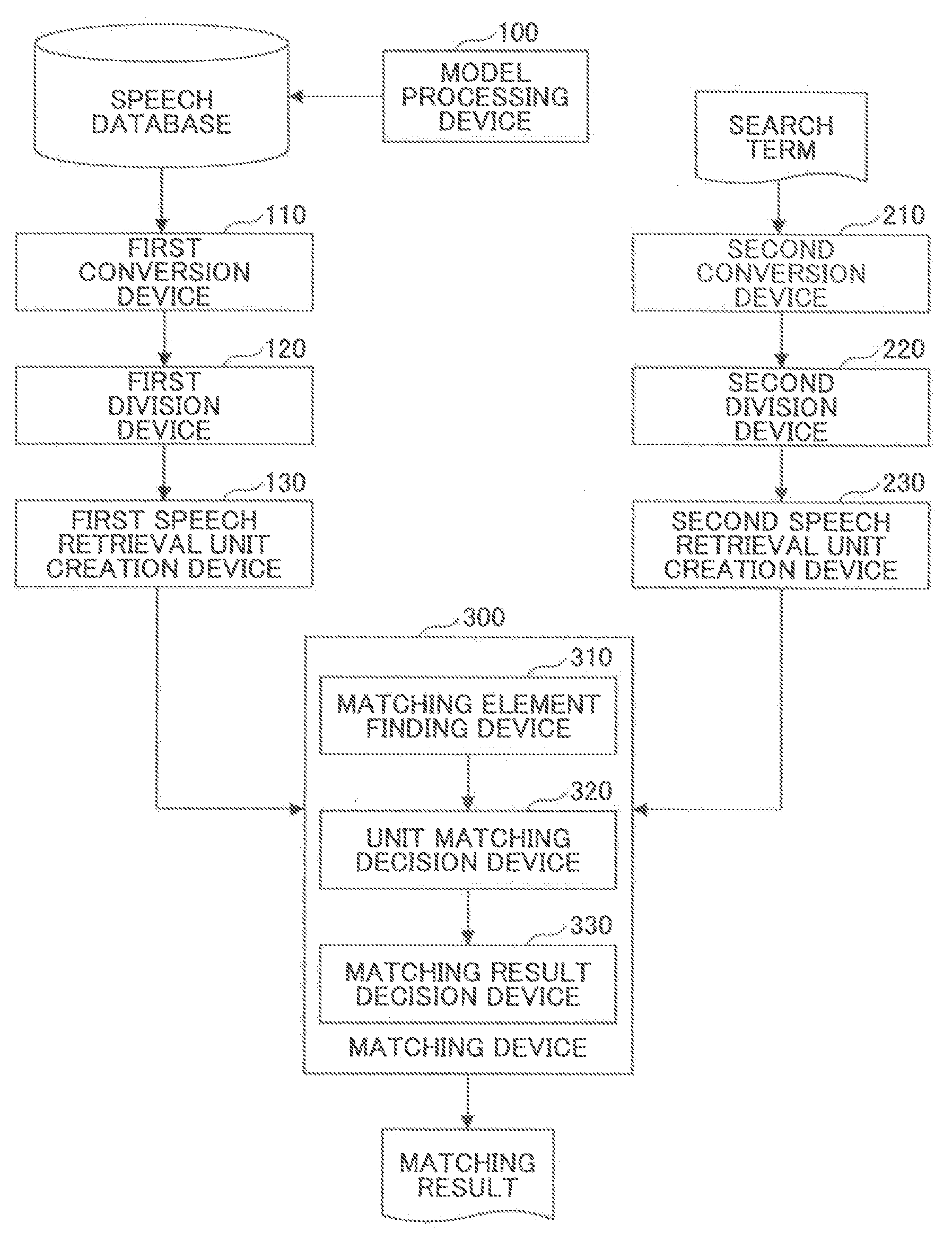

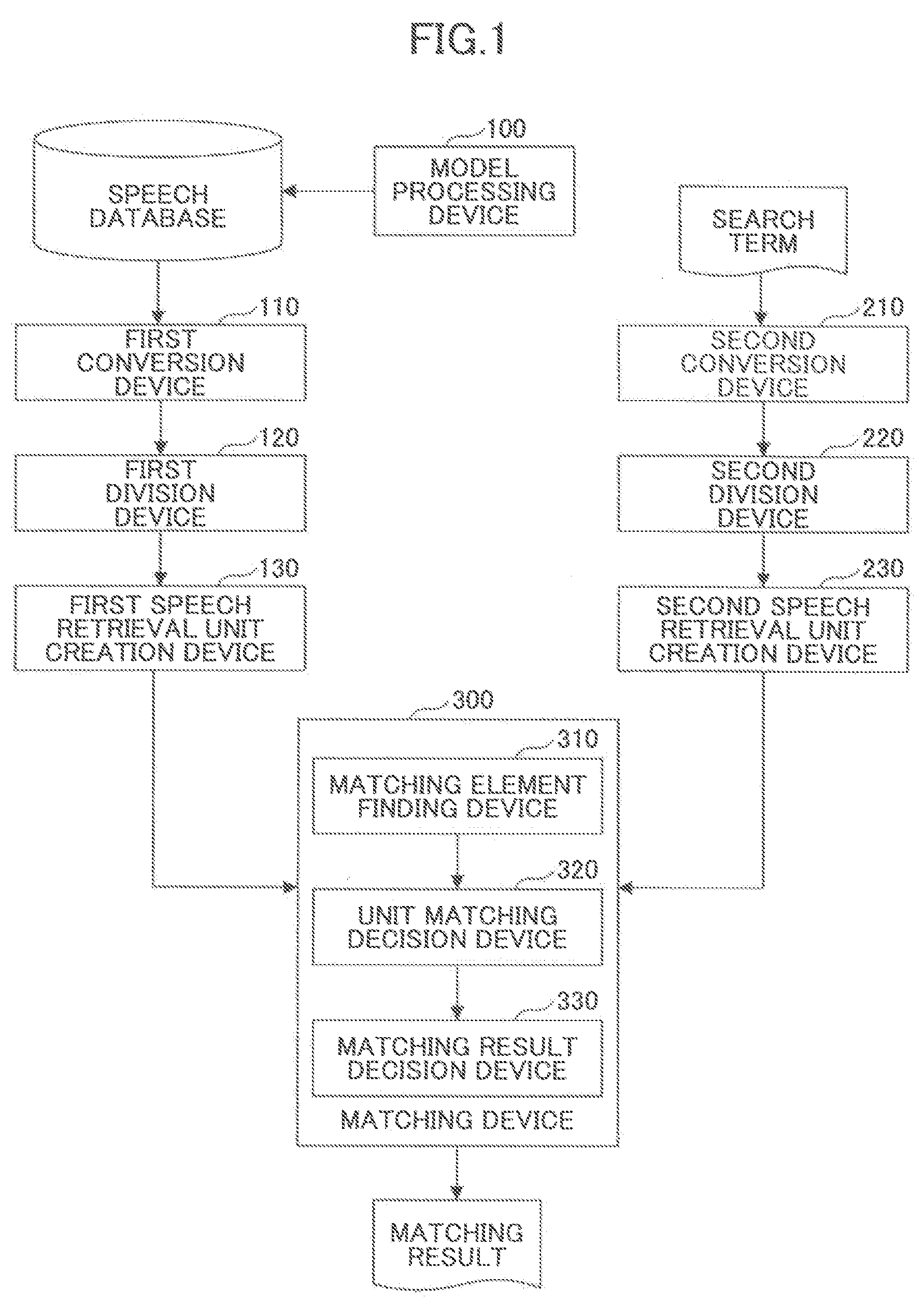

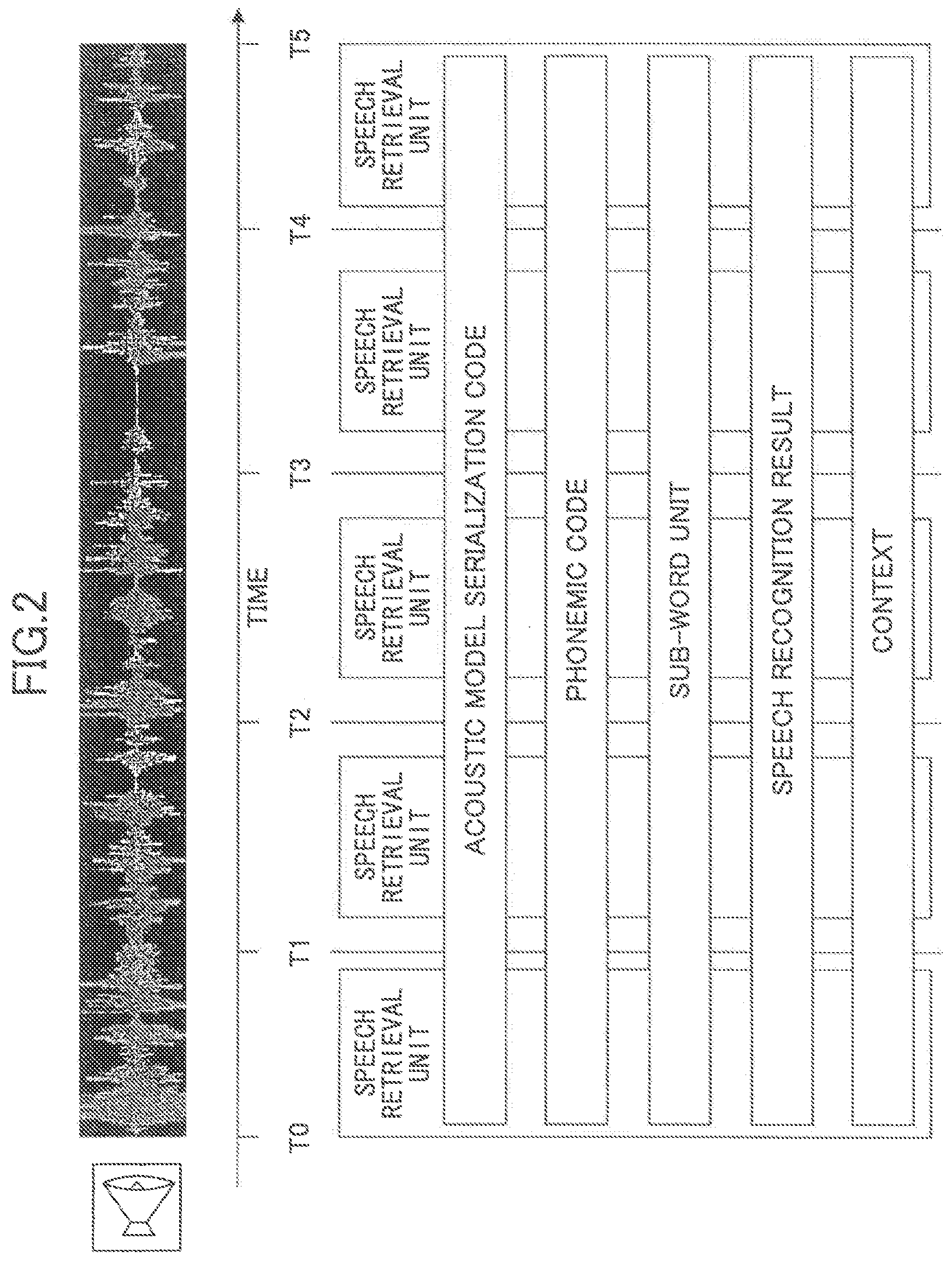

Speech retrieval apparatus and speech retrieval method

InactiveUS20110071833A1Error robustnessError speech recognition accuracyAudio data retrievalSpeech recognitionSerializationAcoustic model

Disclosed are a speech retrieval apparatus and a speech retrieval method for searching, in a speech database, for an audio file matching an input search term by using an acoustic model serialization code, a phonemic code, a sub-word unit, and a speech recognition result of speech. The speech retrieval apparatus comprises a first conversion device, a first division device, a first speech retrieval unit creation device, a second conversion device, a second division device, a second speech retrieval unit creation device, and a matching device. The speech retrieval method comprises a first conversion step, a first division step, a first speech retrieval unit creation step, a second conversion step, a second division step, a second speech retrieval unit creation step, and a matching step.

Owner:RICOH KK

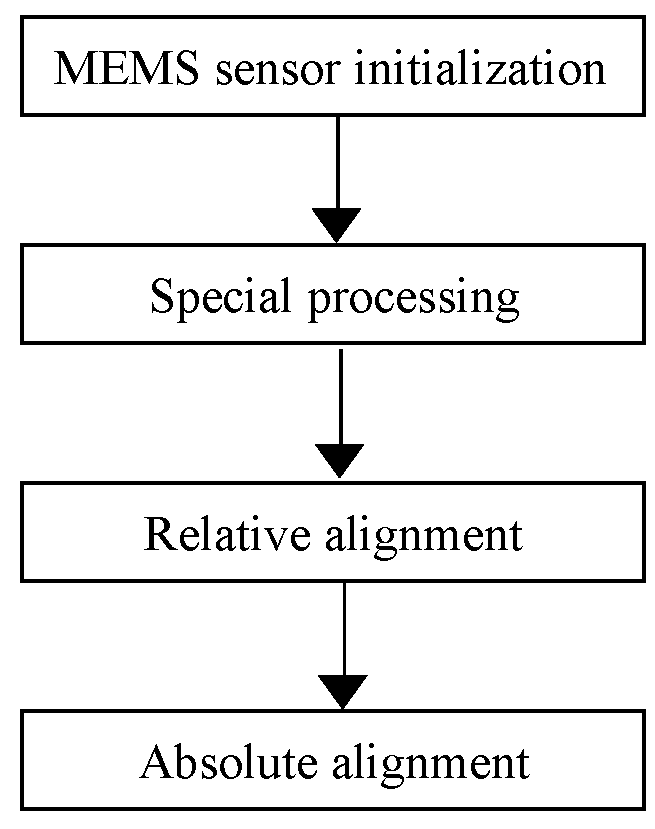

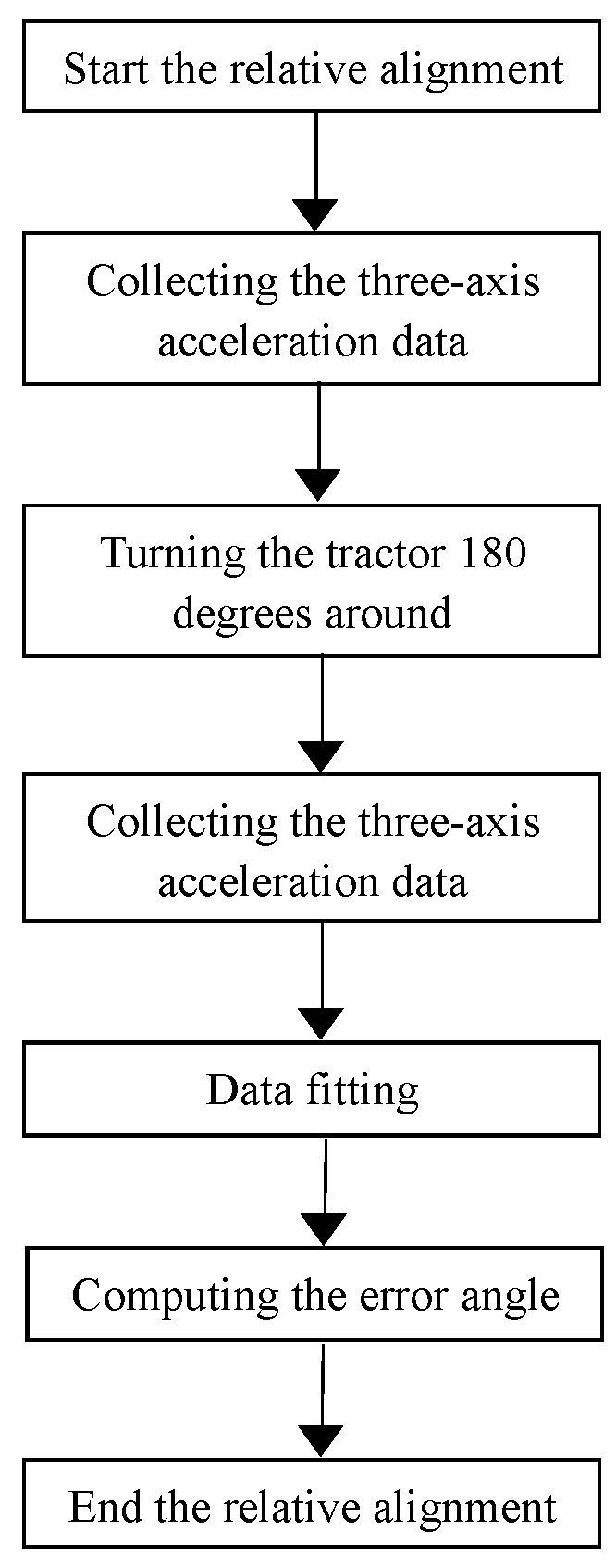

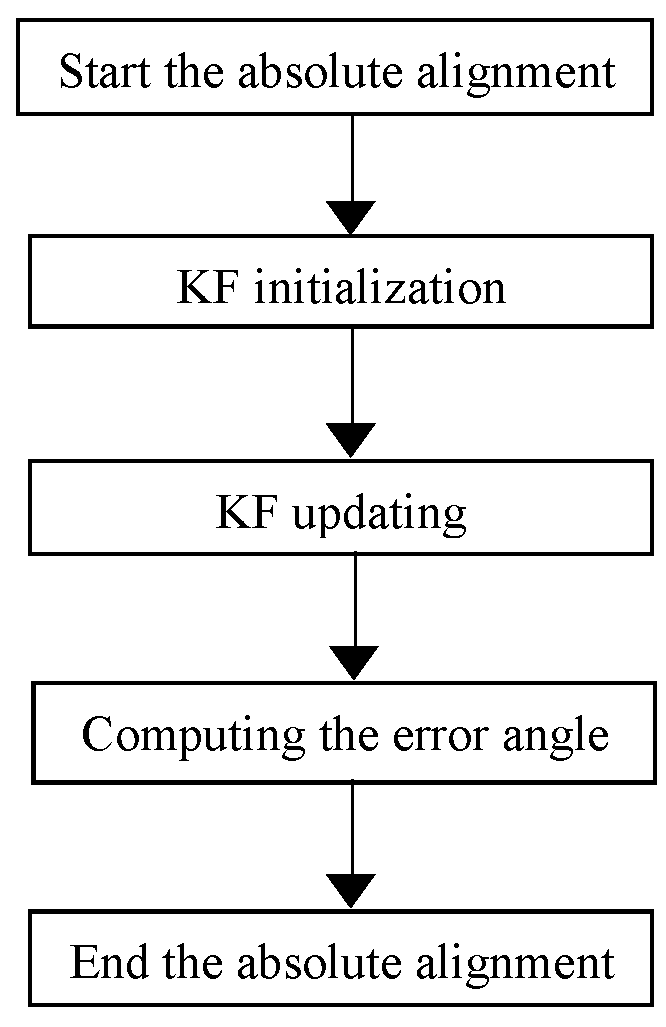

A method for initial alignment of an inertial navigation apparatus

ActiveUS20180274940A1Convergence can be speededImprove accuracyNavigation by speed/acceleration measurementsKaiman filterComputer vision

A method for initial alignment of an inertial navigation apparatus, comprising the following steps: providing an apparatus loaded with a sensor, and preprocessing the sensor; carrying out relative alignment to calculate an installation error angle of the sensor; carrying out absolute alignment to calculate an installation attitude angle error of the sensor to increase an accuracy of an error attitude angle calculated during the relative alignment. The relative alignment process calculates a relative error attitude angle, the relative error attitude angle being used as the initial value for attitude error in a stat vector in the absolute alignment process, thereby accelerating convergence of the Kalman filter. Alignment precision is further enhanced by the absolute alignment process.

Owner:SHANGHAI HUACE NAVIGATION TECH

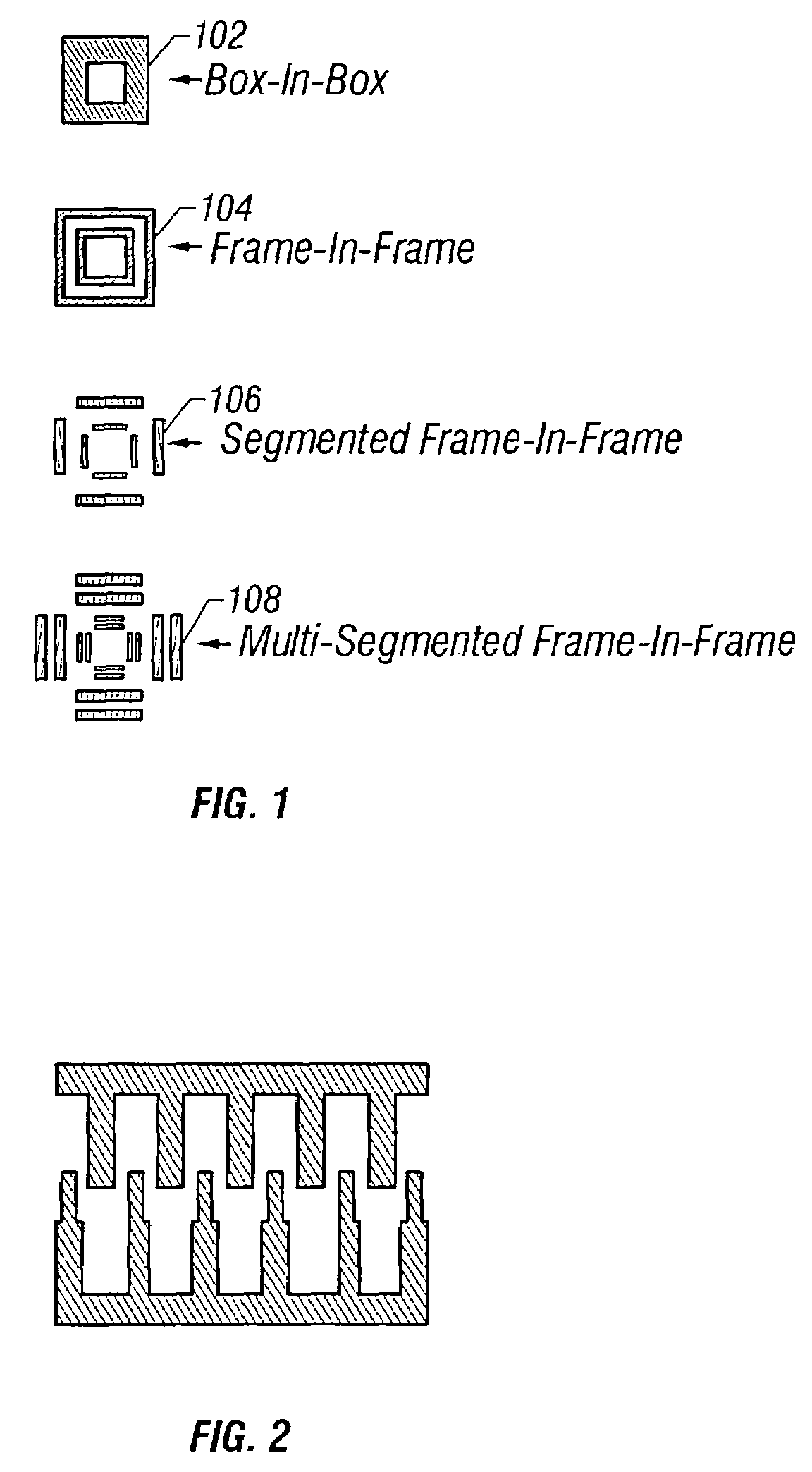

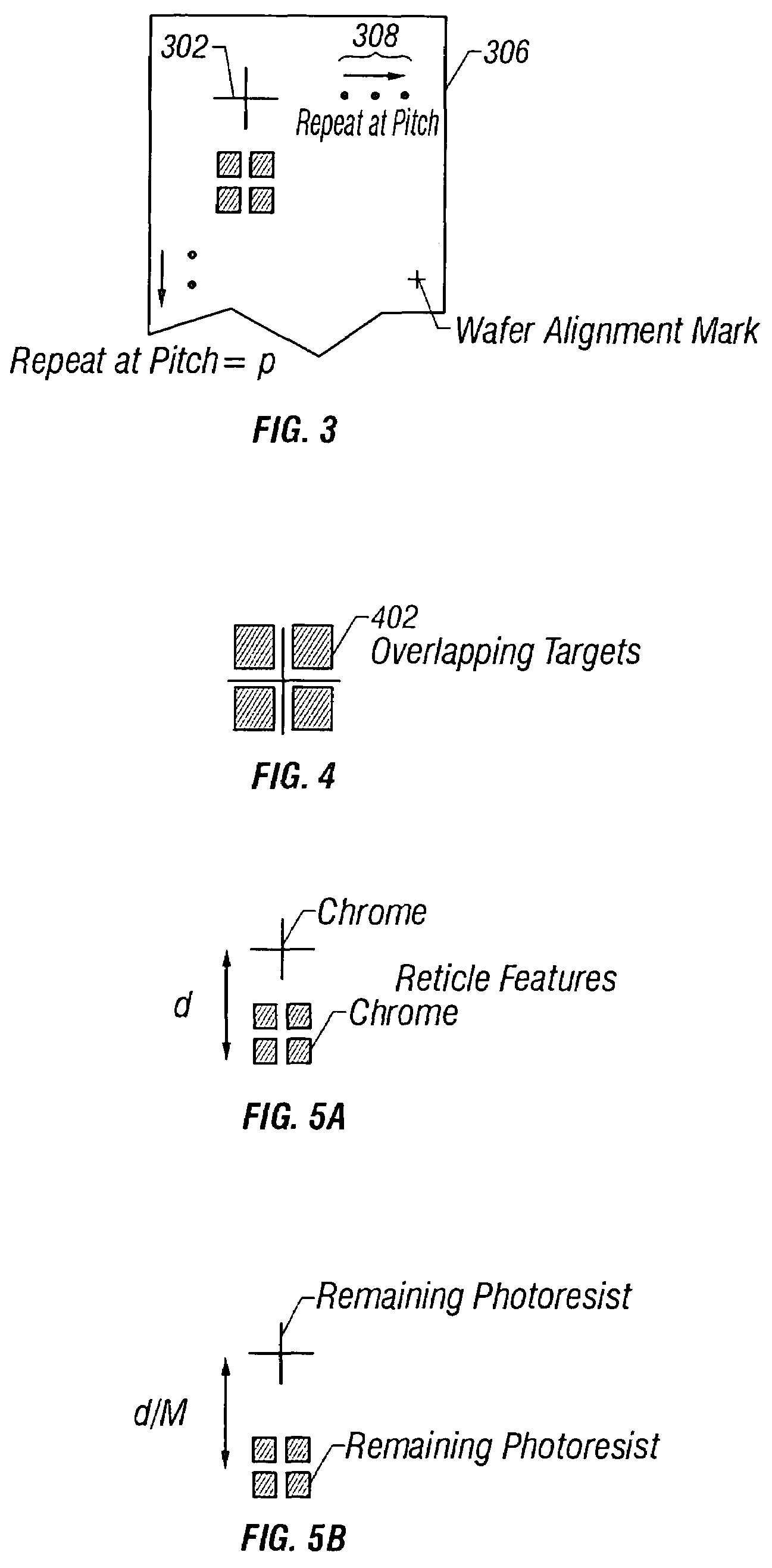

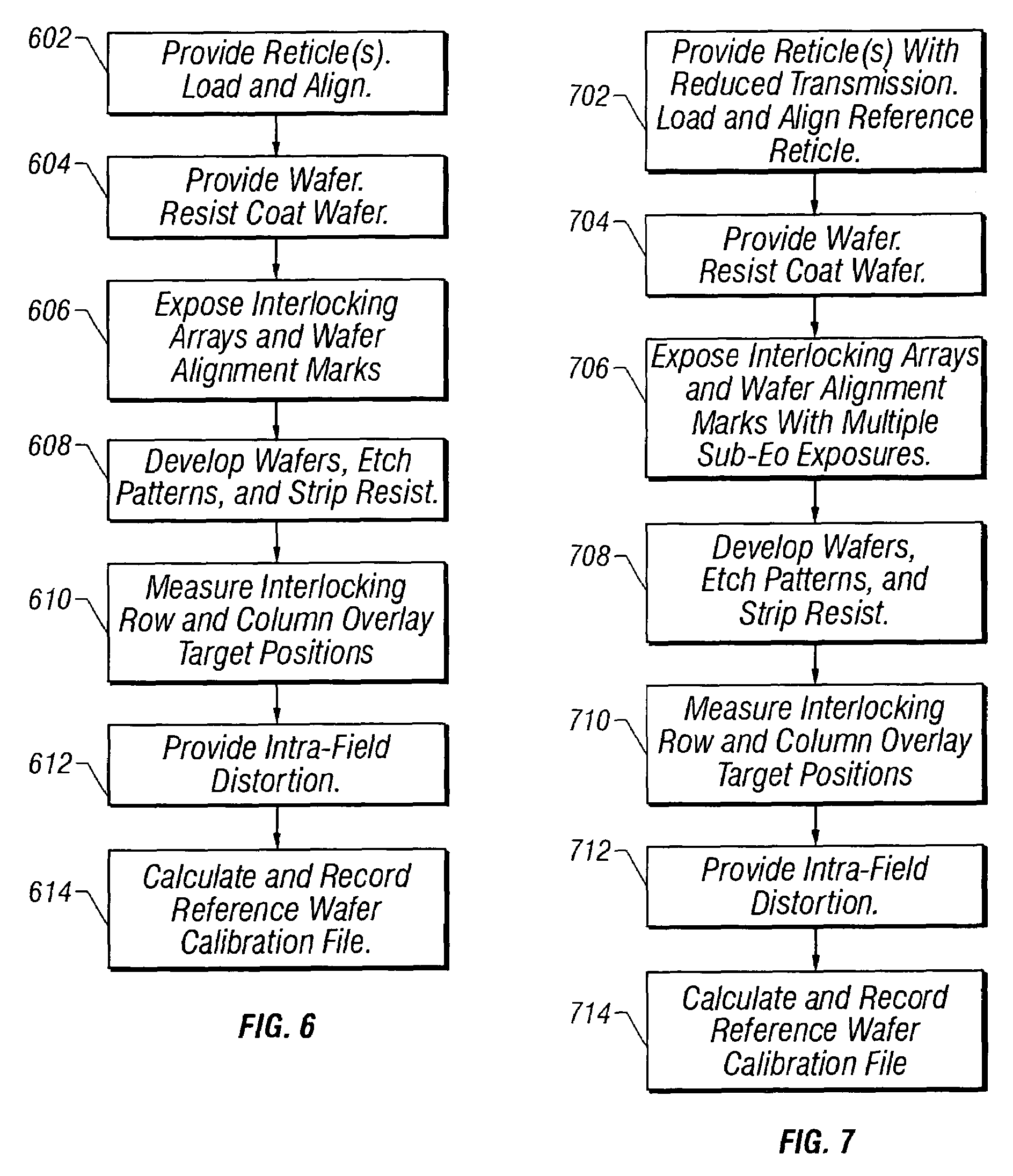

Reference wafer and process for manufacturing same

InactiveUS7160657B2Accurately determinePrecise positioningElectric discharge tubesRadiation applicationsResistMetrology

An apparatus and method for manufacturing and using a calibrated registration reference wafer in a semiconductor manufacturing facility. A reference reticle consisting of a 2-dimensional array of standard alignment attributes is exposed several times onto a photoresist coated semiconductor wafer using a photolithographic exposure tool. After the final steps of the lithographic development process the resist patterned wafer is physically etched using standard techniques to create a permanent record of the alignment attribute exposure pattern. The permanently recorded alignment attributes are measured for placement error using a conventional overlay metrology tool. The resulting overlay error data is used to generate a calibration file that contains the positions of the alignment attributes on the reference wafer. The reference wafer and calibration file can be used to determine the wafer stage registration performance for any photolithographic exposure tool.

Owner:LITEL INSTR

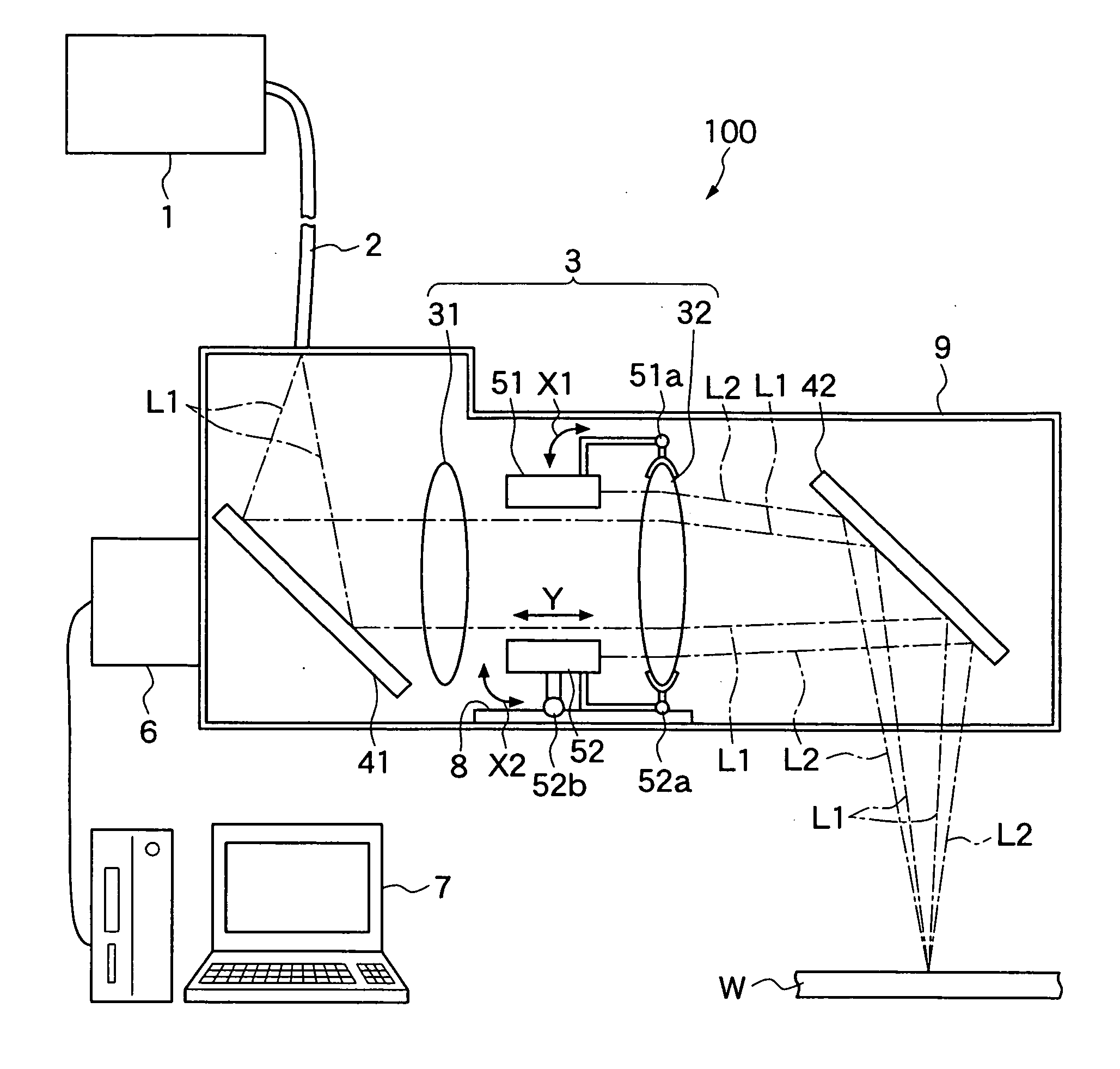

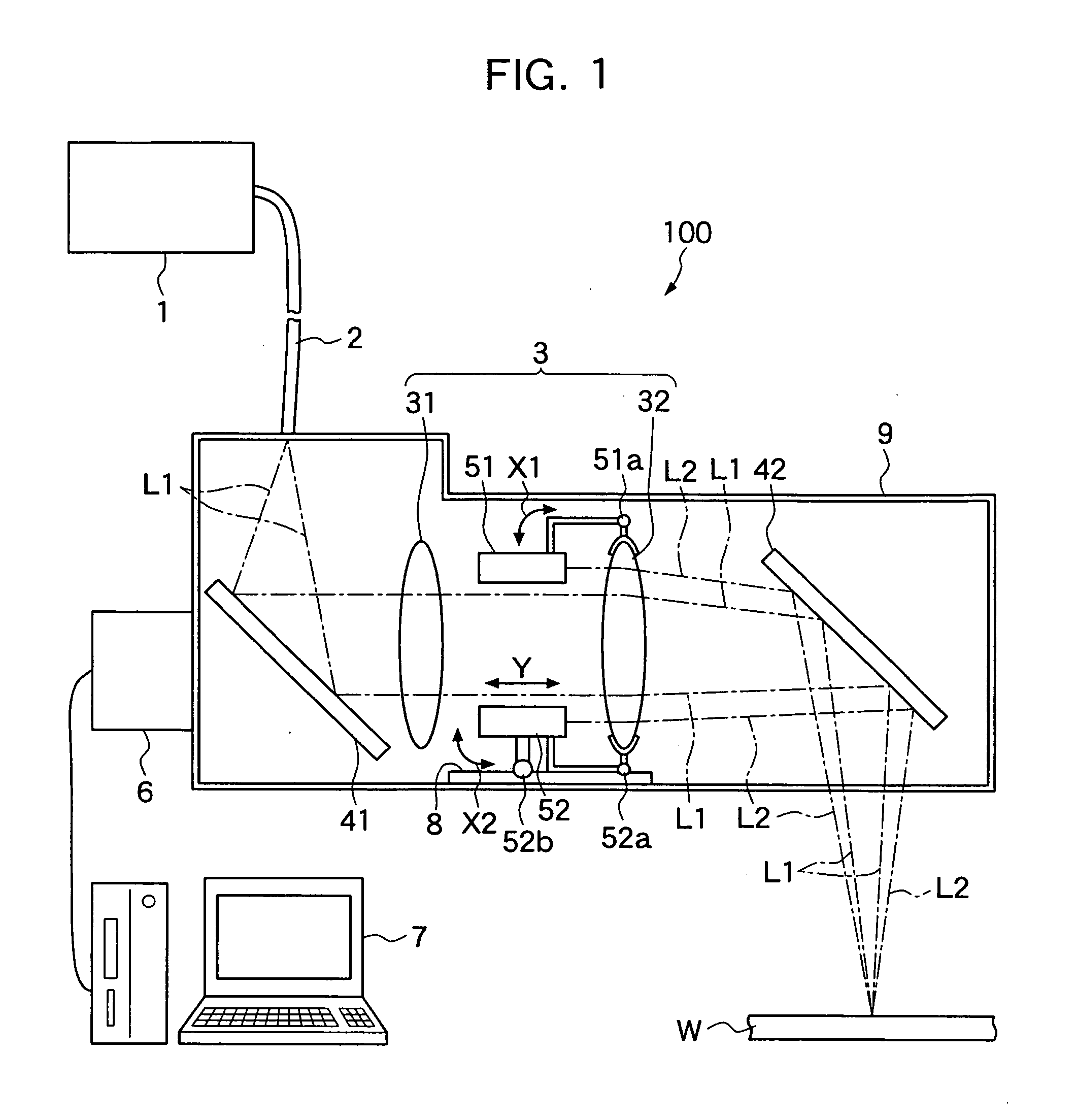

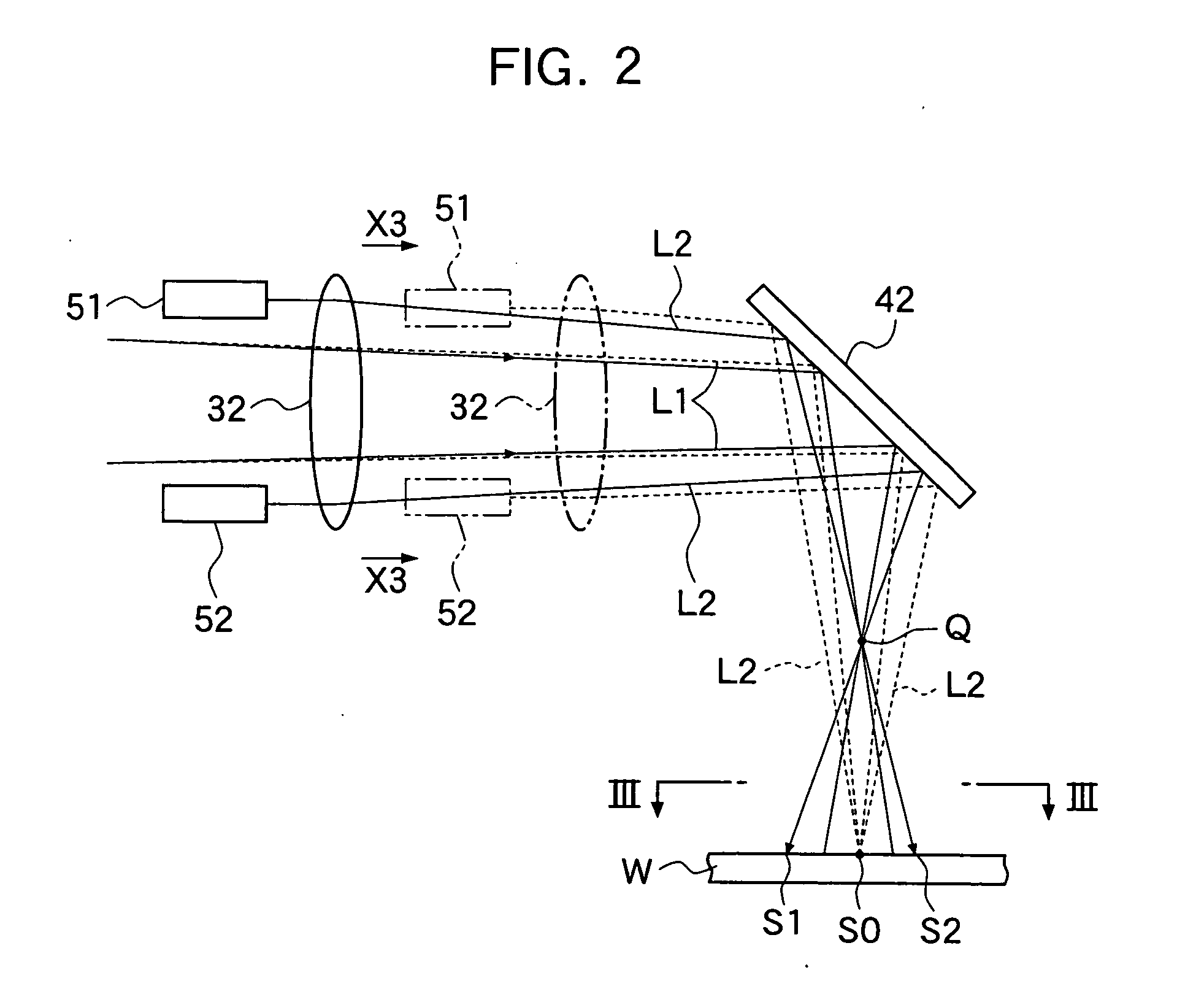

Laser Processing System and laser Processing Method

InactiveUS20100219171A1Highly accurately and efficiently performHighly accurately and efficiently perform laser processingLaser detailsLaser beam welding apparatusLaser processingImaging processing

A laser processing system and a laser processing method that can highly accurately and efficiently specify a focus position of a processing laser using visible lasers are provided. For that purpose, a laser processing system includes a processing laser oscillator, a condensing optical system including a condenser lens, two visible laser oscillators and, a movement adjusting unit that adjusts the condenser lens and the visible laser oscillators and to move forward and backward in synchronization with each other, an imaging unit that images spot lights of the visible lasers on a workpiece, an image processing unit that subjects an imaged video to image processing and displays an image after the processing, a calculating unit that calculates, in a state in which the respective visible lasers are focused on a focus position of the processing laser, center of gravity positions of spot lights of the respective visible lasers formed on the surface of the workpiece according to the movement of the condenser lens and calculates a distance between centers of gravity, and a control unit that controls the movement adjusting unit such that the distance between centers of gravity is adjusted to zero or substantially zero.

Owner:TOYOTA JIDOSHA KK +1

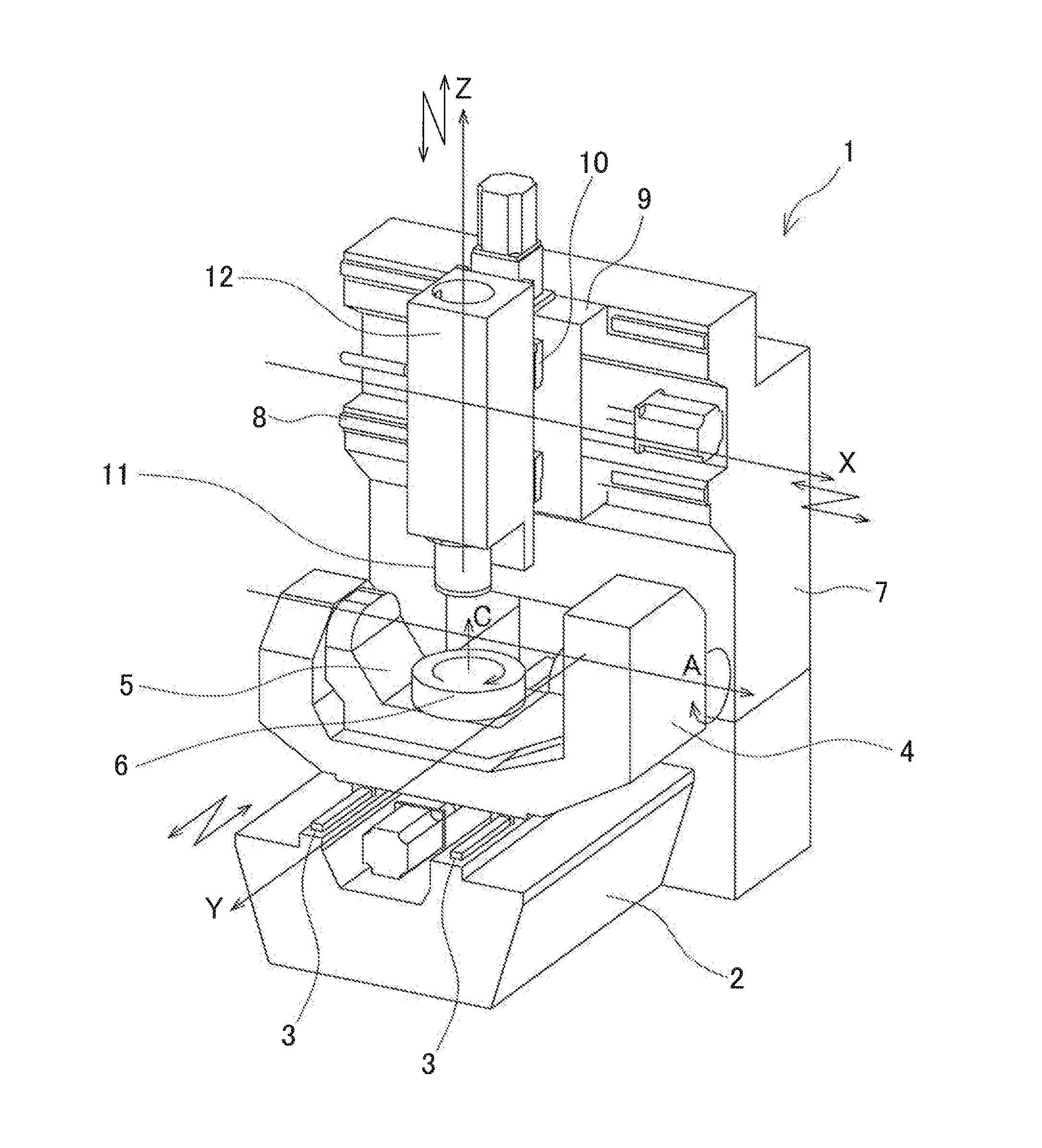

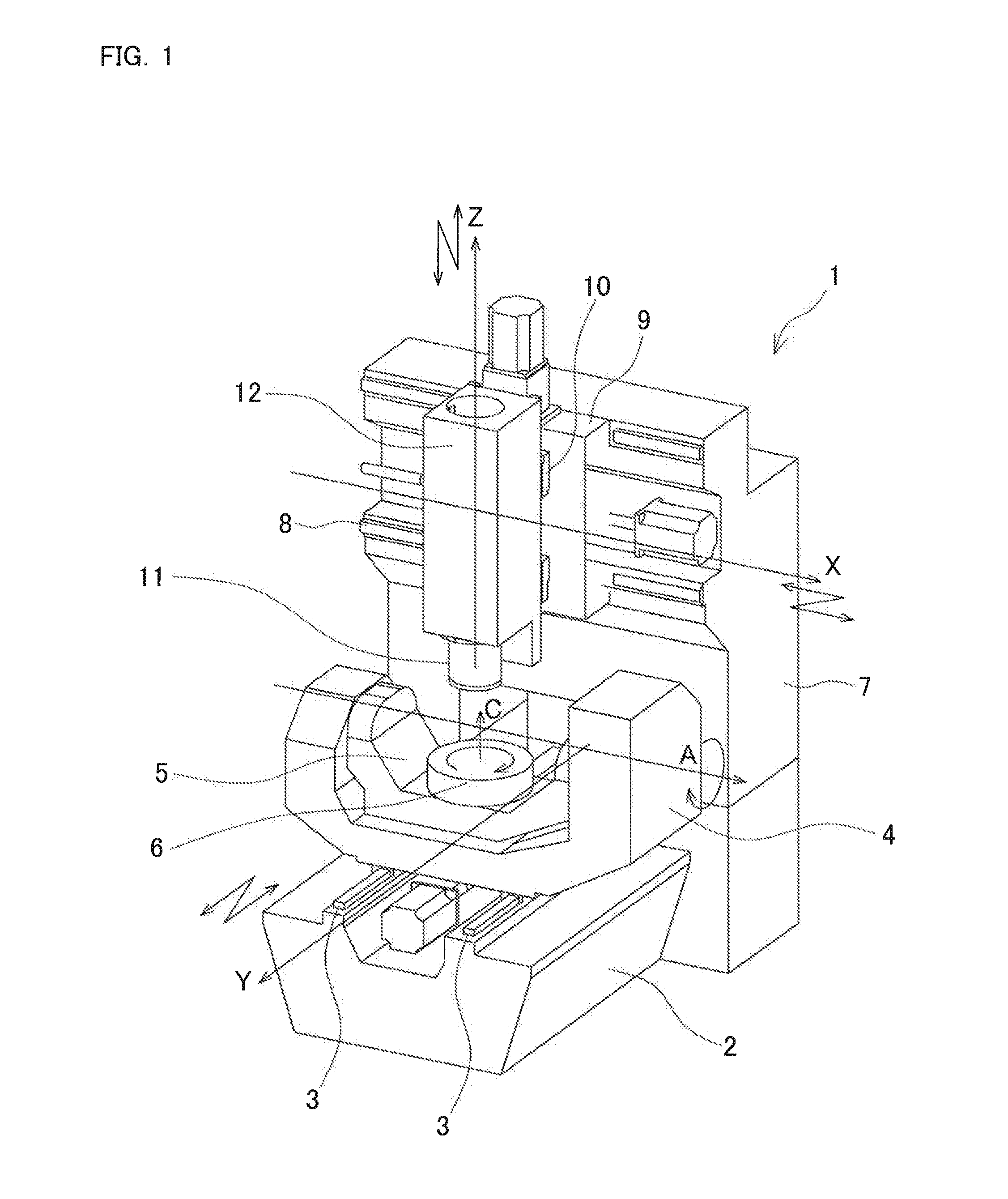

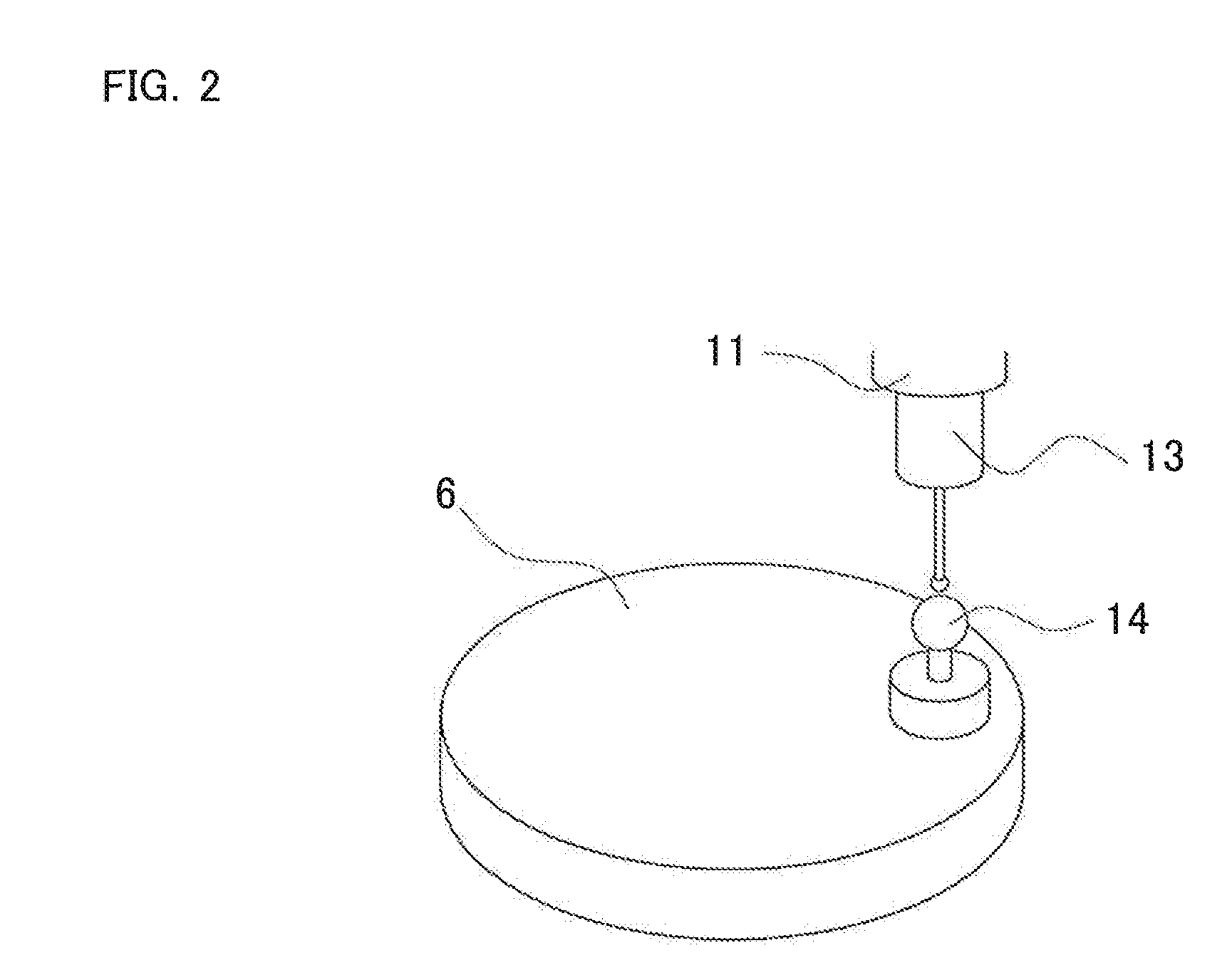

Geometric-error identification system and geometric-error identification method

InactiveUS20160116275A1Easy CalibrationHigh positioning accuracyTesting/calibration of speed/acceleration/shock measurement devicesSpecial data processing applicationsGeometric errorMachine control

A geometric-error identification system includes a control unit configured to identify geometric errors in a machine. The machine controls three or more translational axes and one or more rotation axes so as to perform positioning for a positional relationship between a main spindle and an object. The control unit controls the rotation axis so as to index a measurement object jig, measures an indexed position of the indexed measurement object jig on a three-dimensional space using a position measurement sensor attached to the main spindle so as to acquire a measurement value, and identifies geometric errors of the machine related to the translational axis and / or the rotation axis based on the measurement values in a plurality of positions. The control unit measures an initial position of the measurement object jig and performs calibration of the position measurement sensor using an initial measurement value acquired for measuring the initial position.

Owner:OKUMA CORP

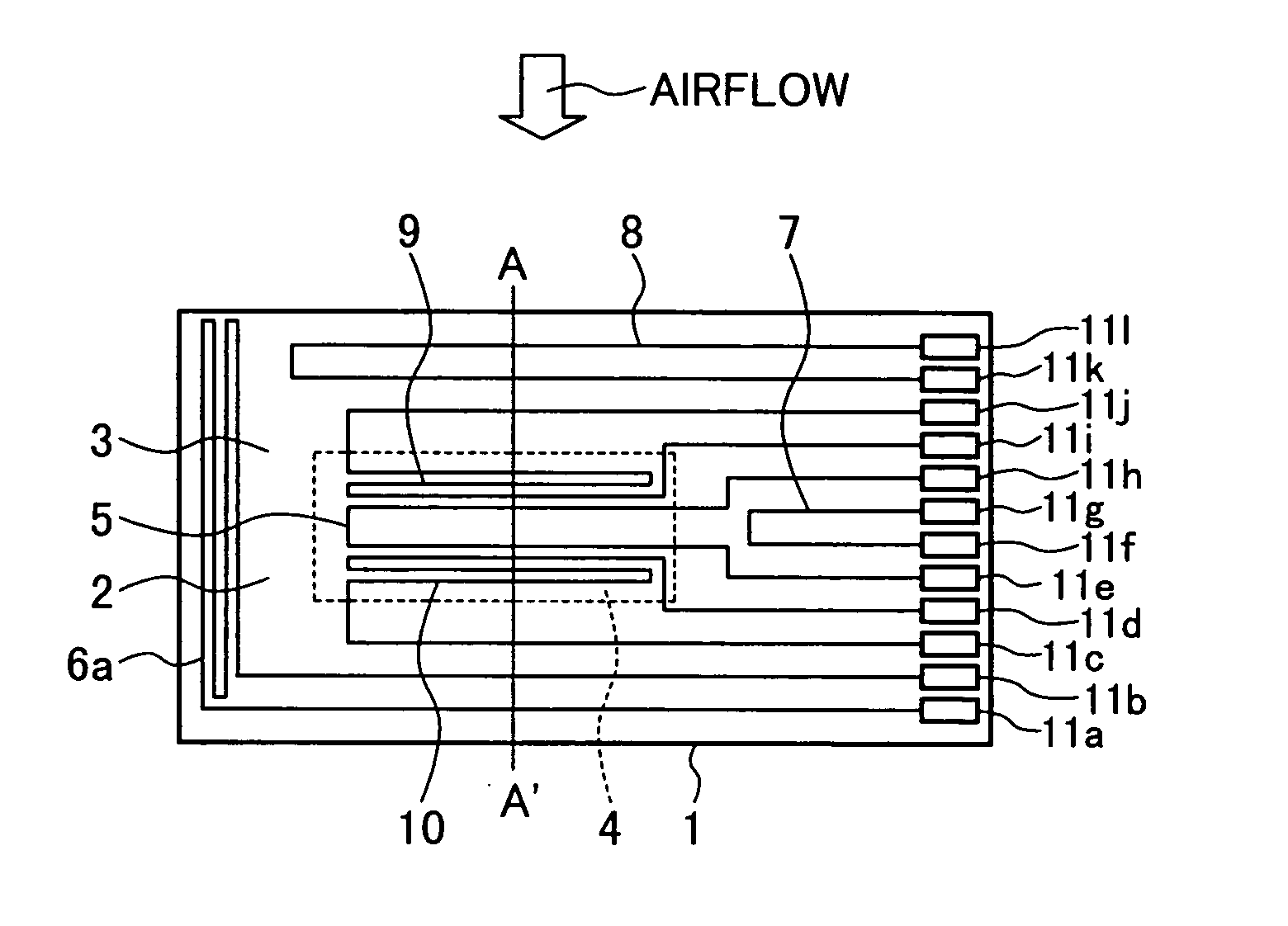

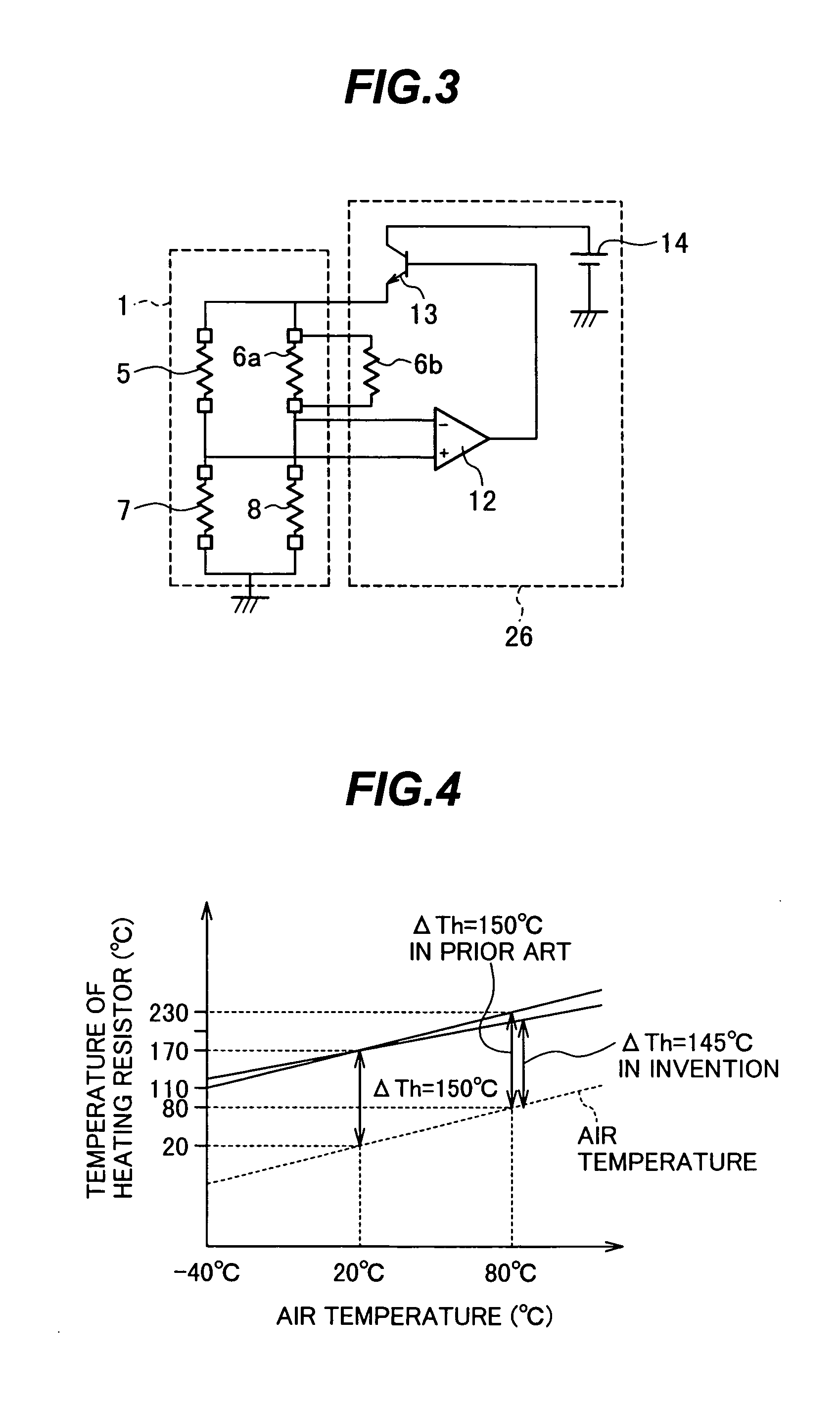

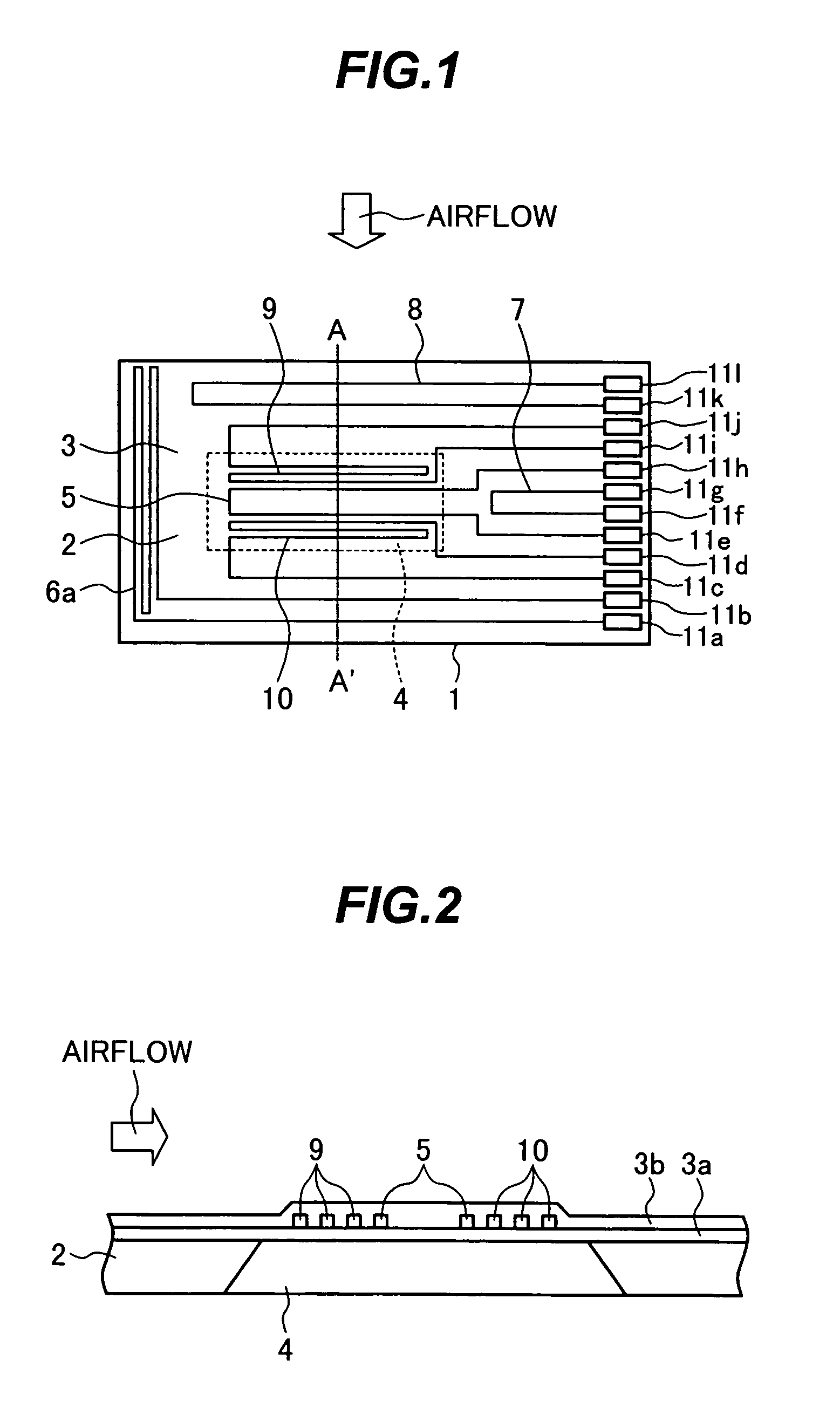

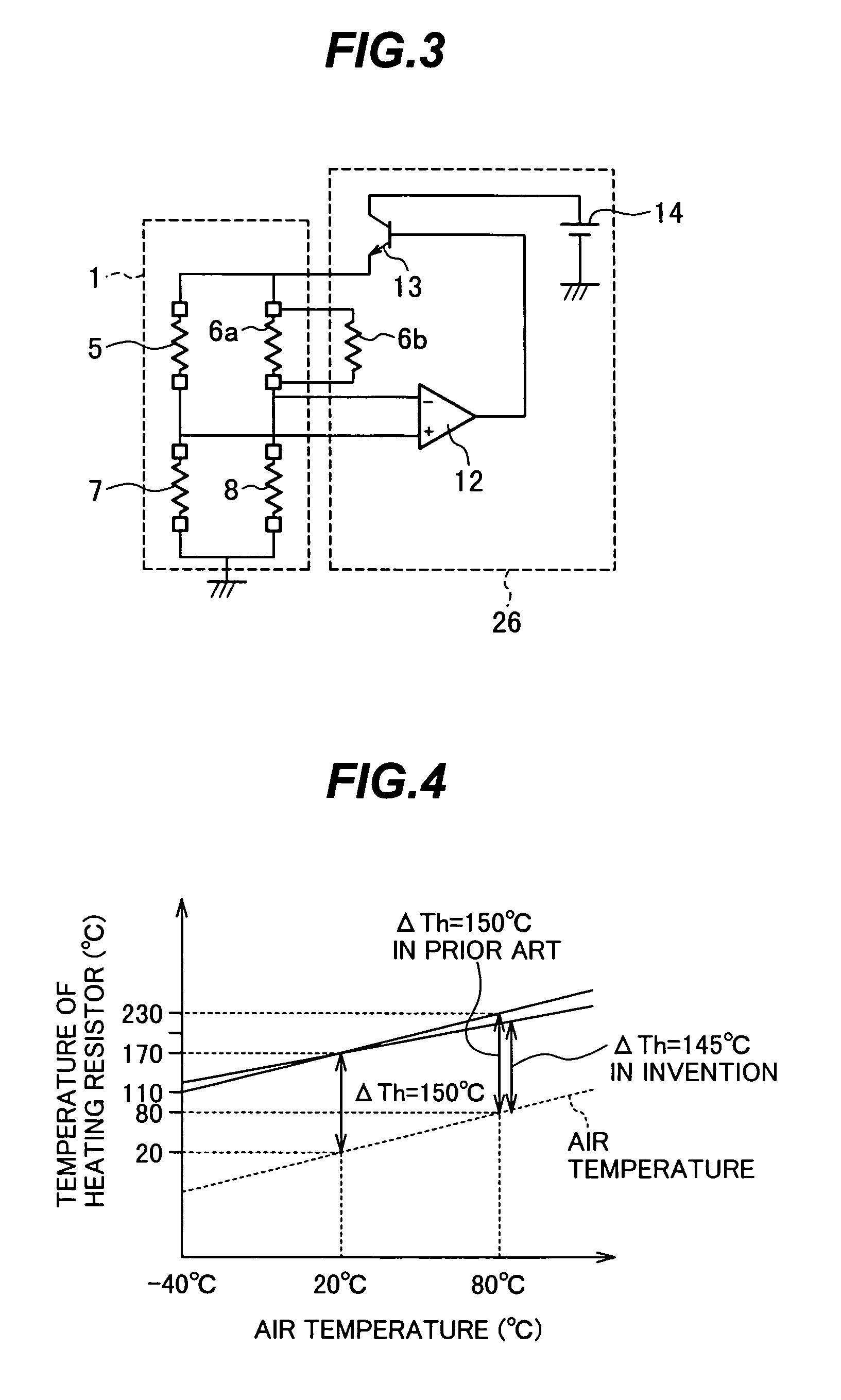

Thermal flowmeter of fluid

InactiveUS20070125169A1Reduce error in measurement accuracyImprove accuracyVolume/mass flow by thermal effectsTemperature controlEngineering

A thermal air flowmeter having excellent temperature characteristics and improved measurement accuracy. The thermal air flowmeter comprises a temperature sensor disposed in a casing of the air flowmeter, a computing unit for correcting a flow rate detection voltage from a measuring element by using the temperature sensor, and heating temperature control means disposed in a temperature control circuit for performing temperature control of a heating resistor to vary a temperature rise of the heating resistor relative to an air temperature depending on the air temperature. Flow rate detection errors of the thermal air flowmeter caused by an overall temperature change and a temperature change on an intake passage wall surface can be corrected simultaneously and a thermal air flowmeter having superior measurement accuracy can be realized.

Owner:HITACHI LTD +1

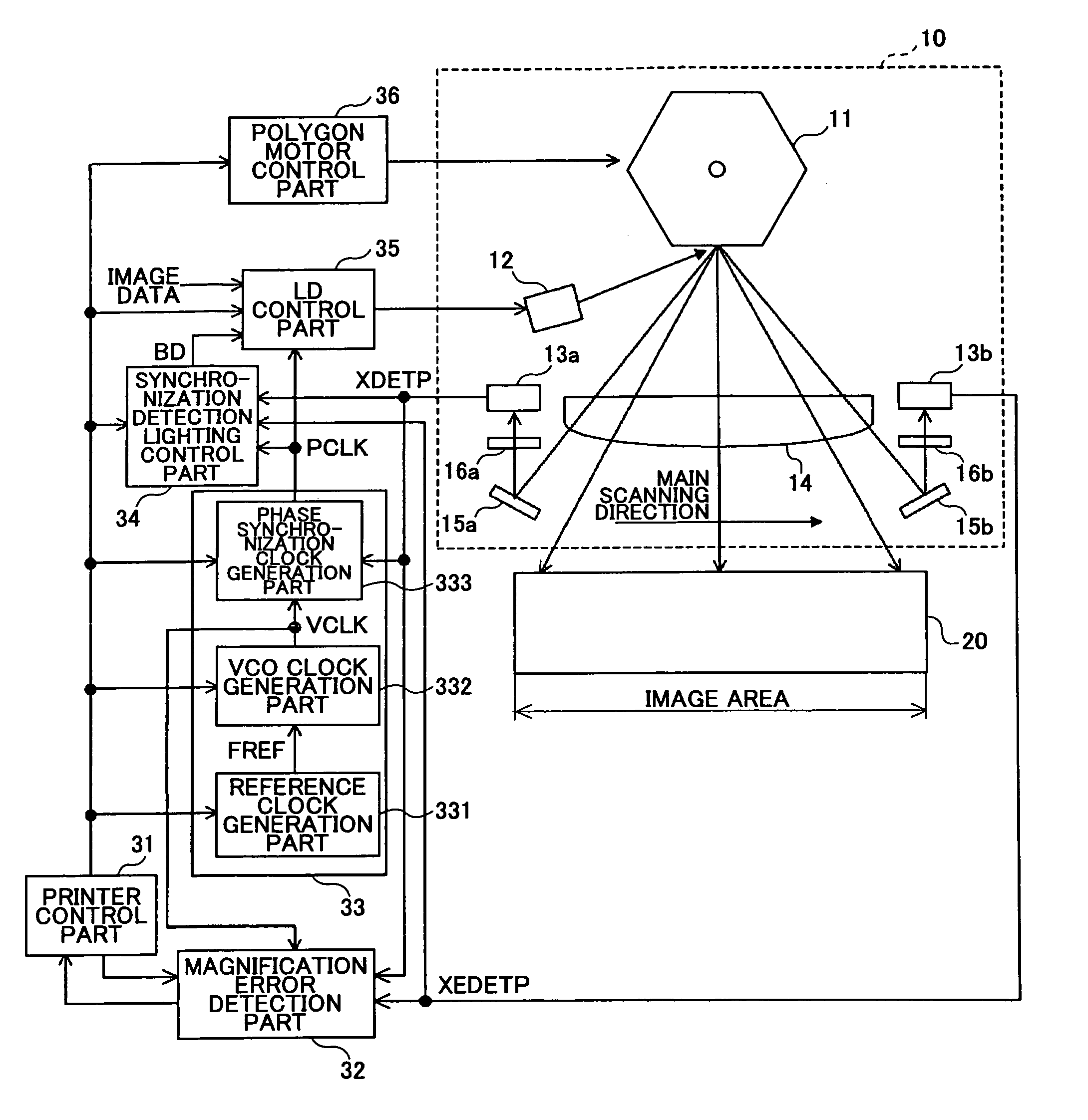

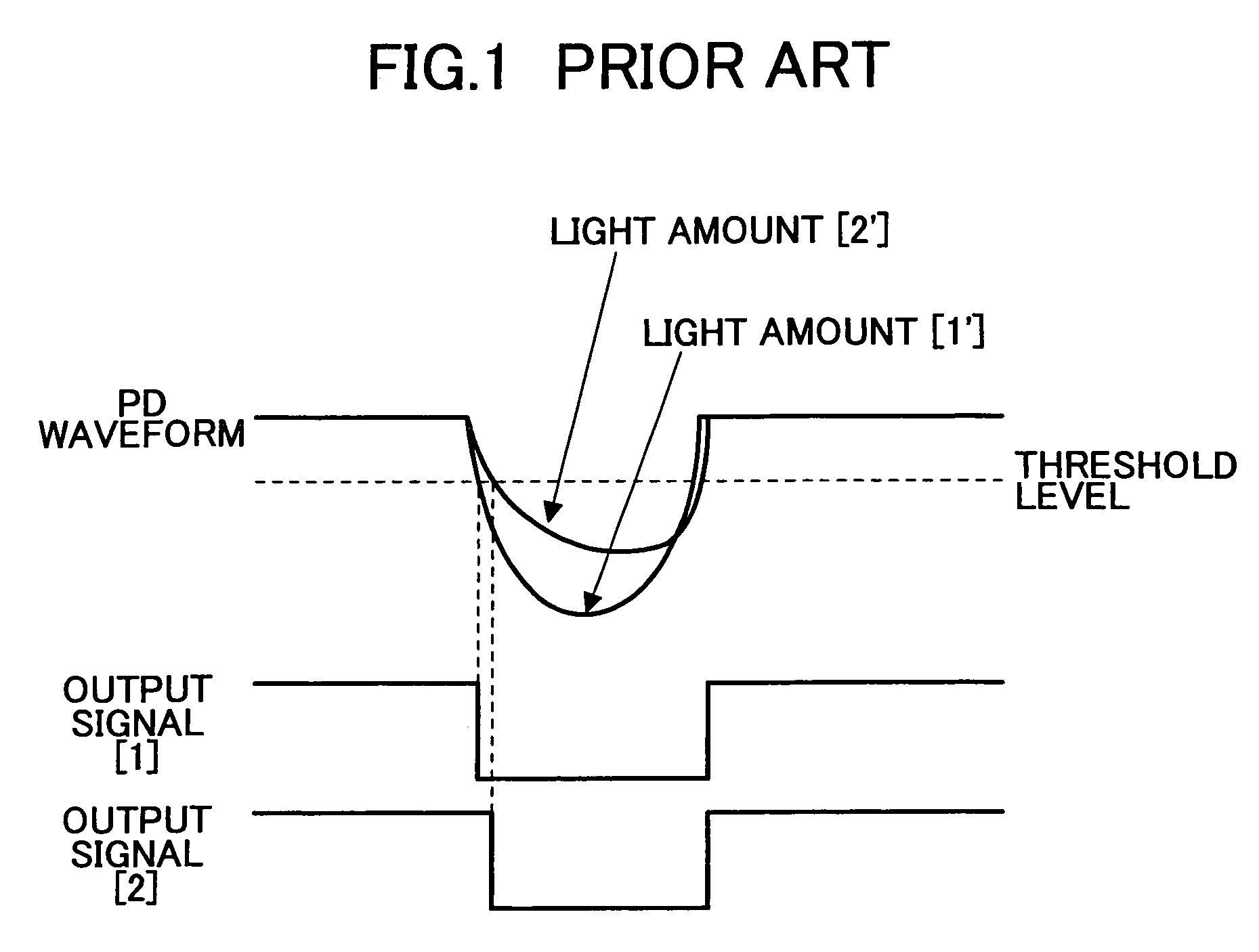

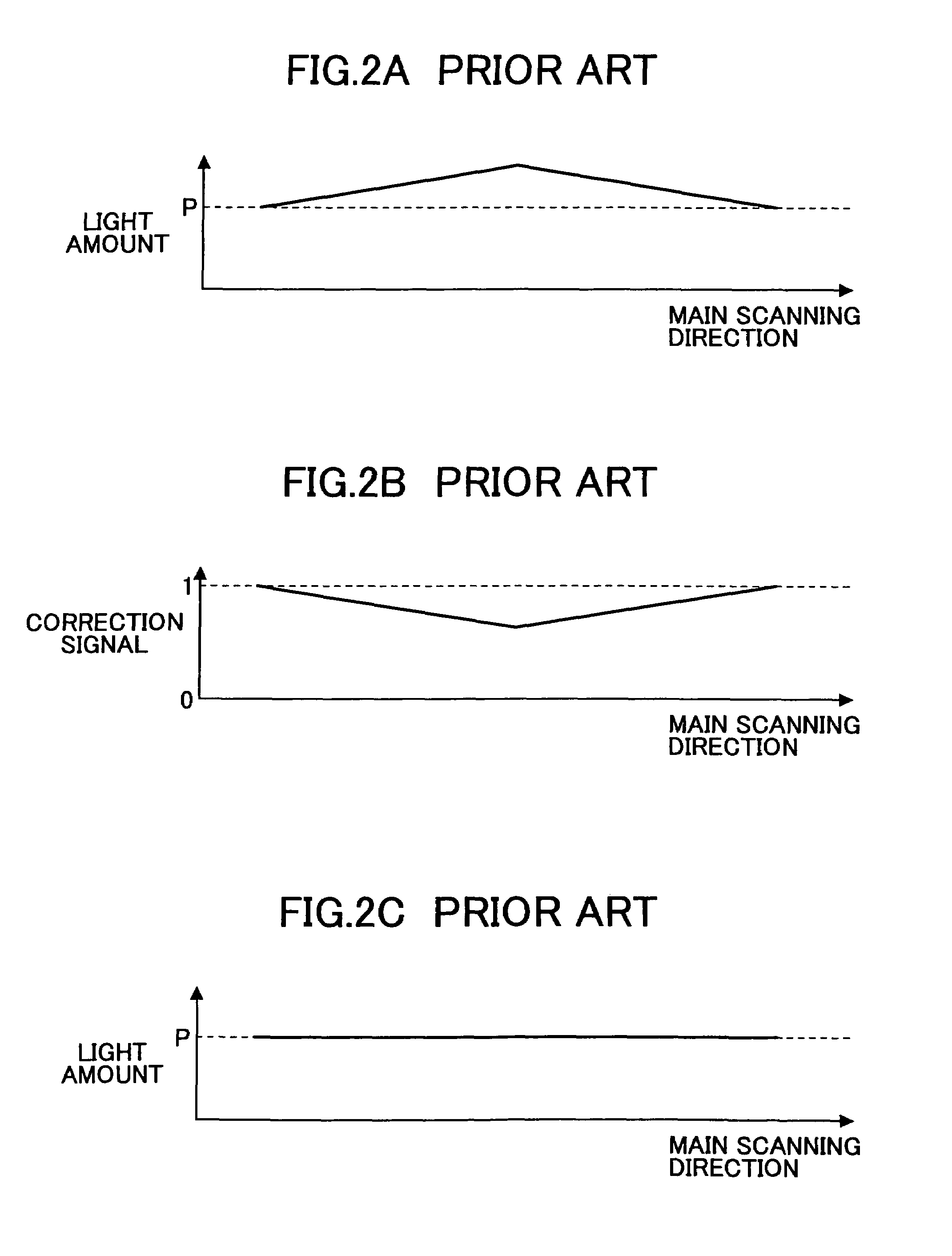

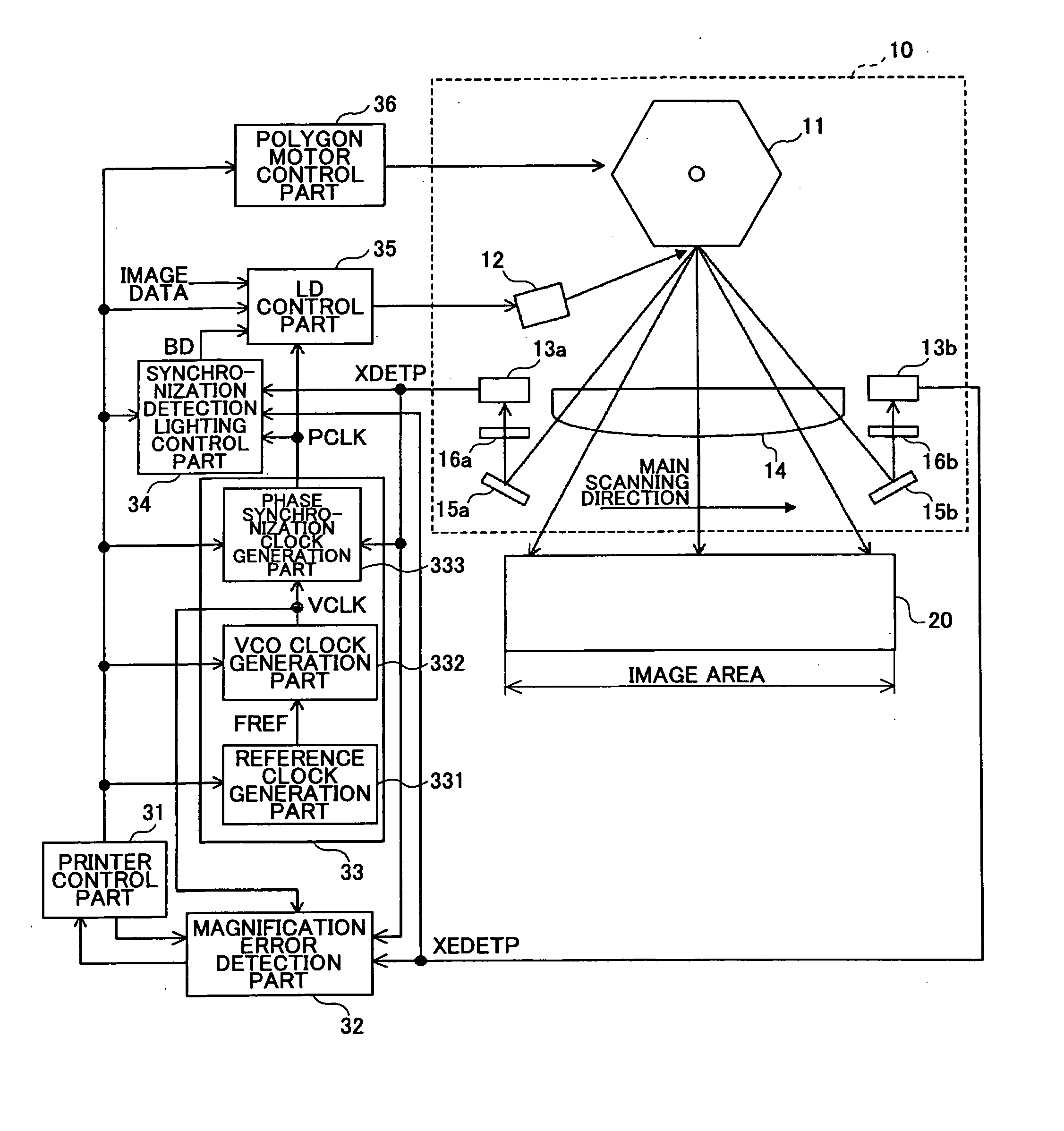

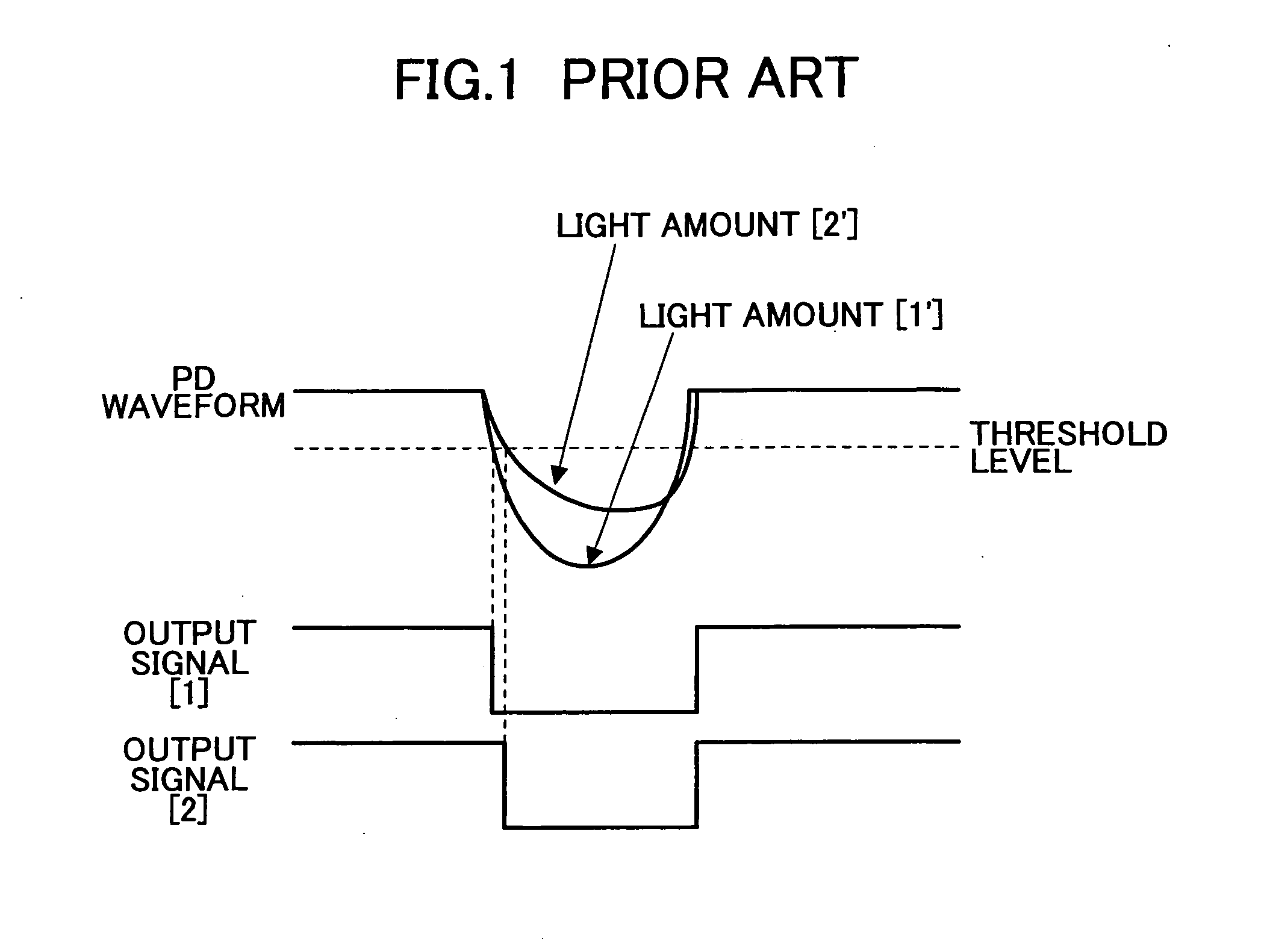

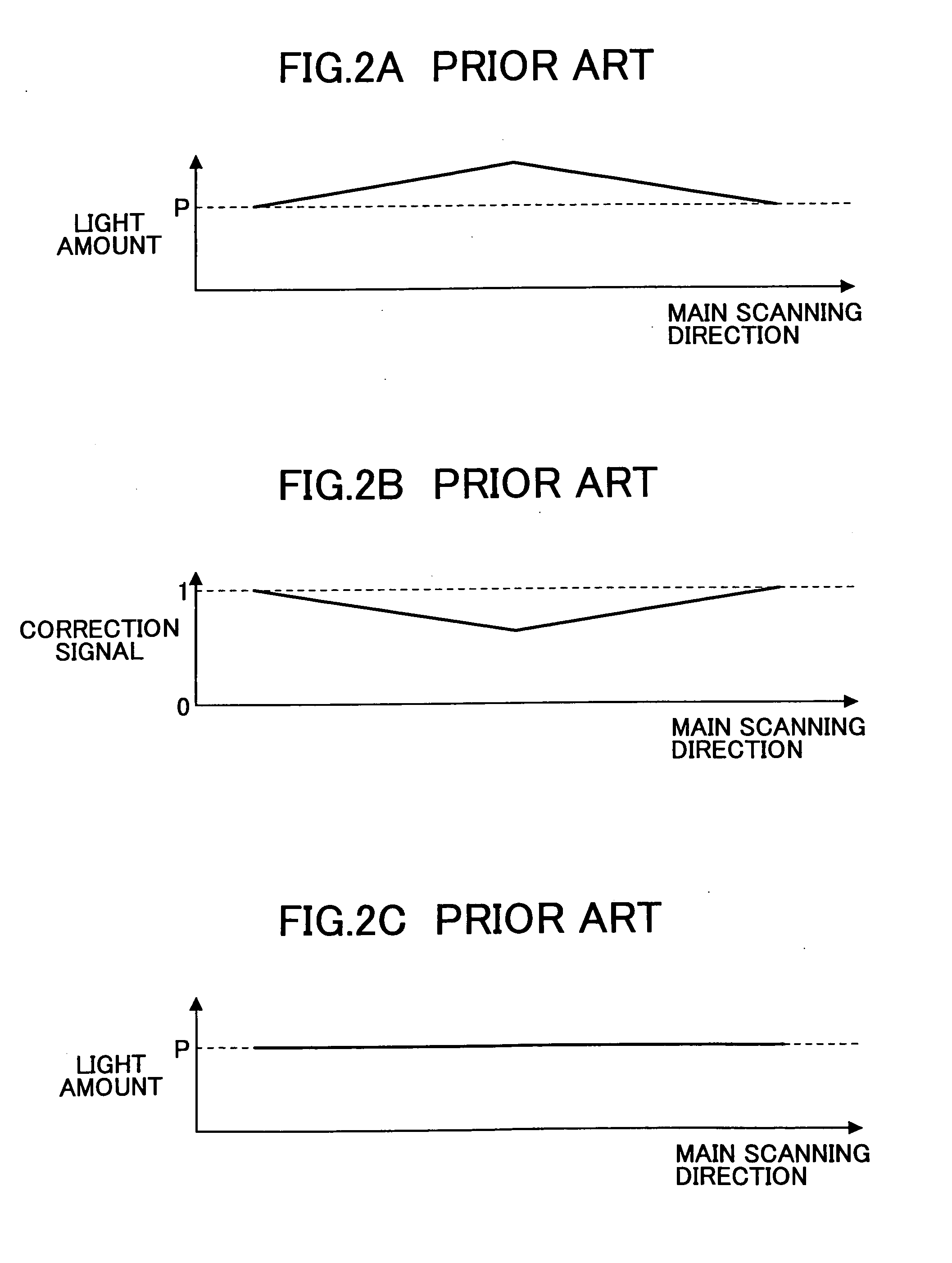

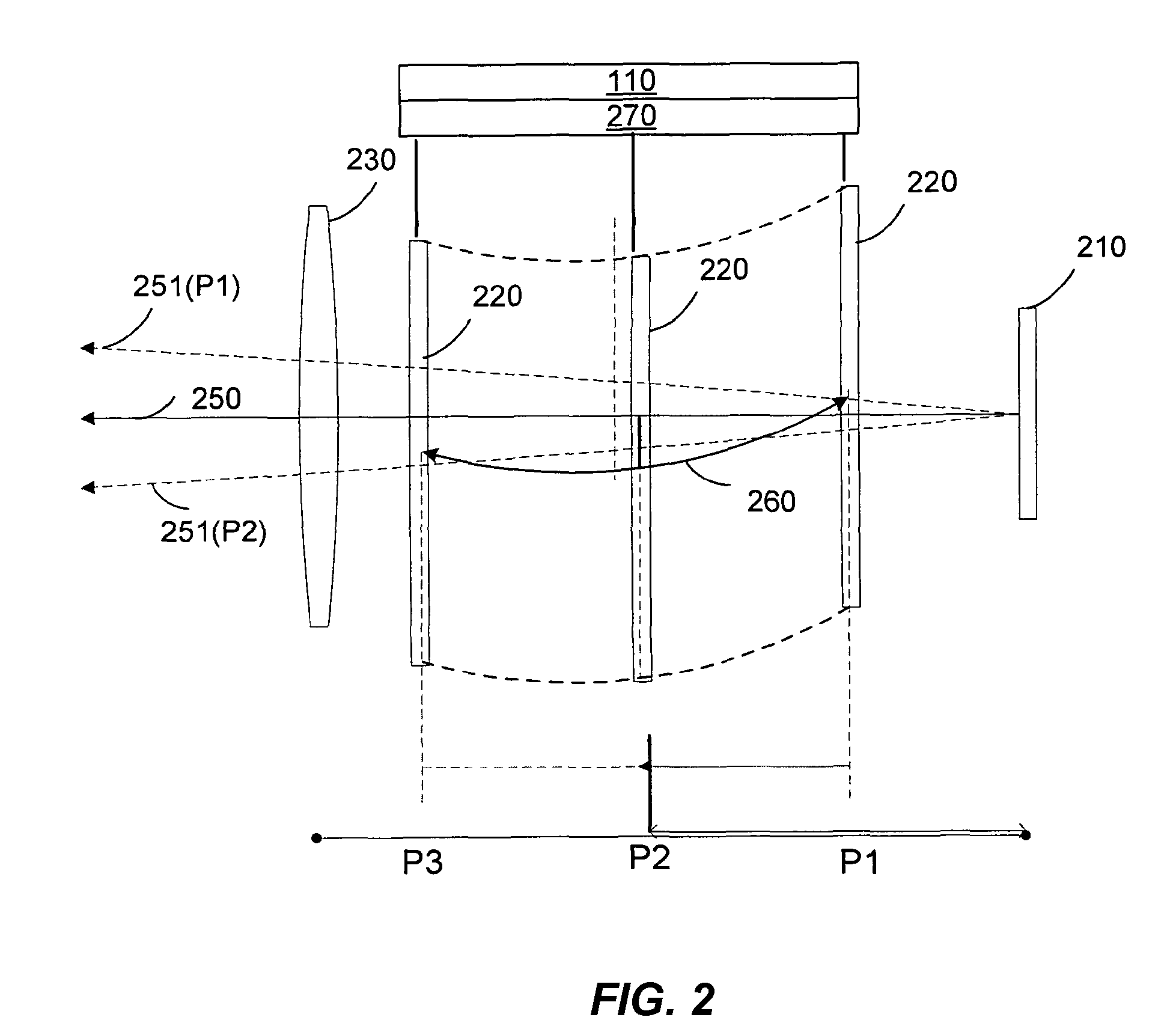

Light beam scanning device, image forming apparatus, and light beam scanning method

InactiveUS7294824B2Guaranteed Error AccuracyBeam/ray focussing/reflecting arrangementsMaterial analysis by optical meansImage formationLight beam

A light beam scanning device is disclosed that includes a light emission source to emit a light beam, a deflection part to deflect the emitted light beam in the main scanning direction, first and second light beam detection parts to detect the deflected light beam at first and second positions, respectively, outside an image area on the opposite sides thereof in the main scanning direction, a time difference measurement part to measure the time difference between the light beam detections by the first and second light beam detection parts, and a control part to perform control so as to correct image magnification in the main scanning direction in the image area from the measured time difference. The control part performs control so that the condition of the amount of light at the time of detecting the light beam by the first and second light beam detection parts is constant.

Owner:RICOH KK

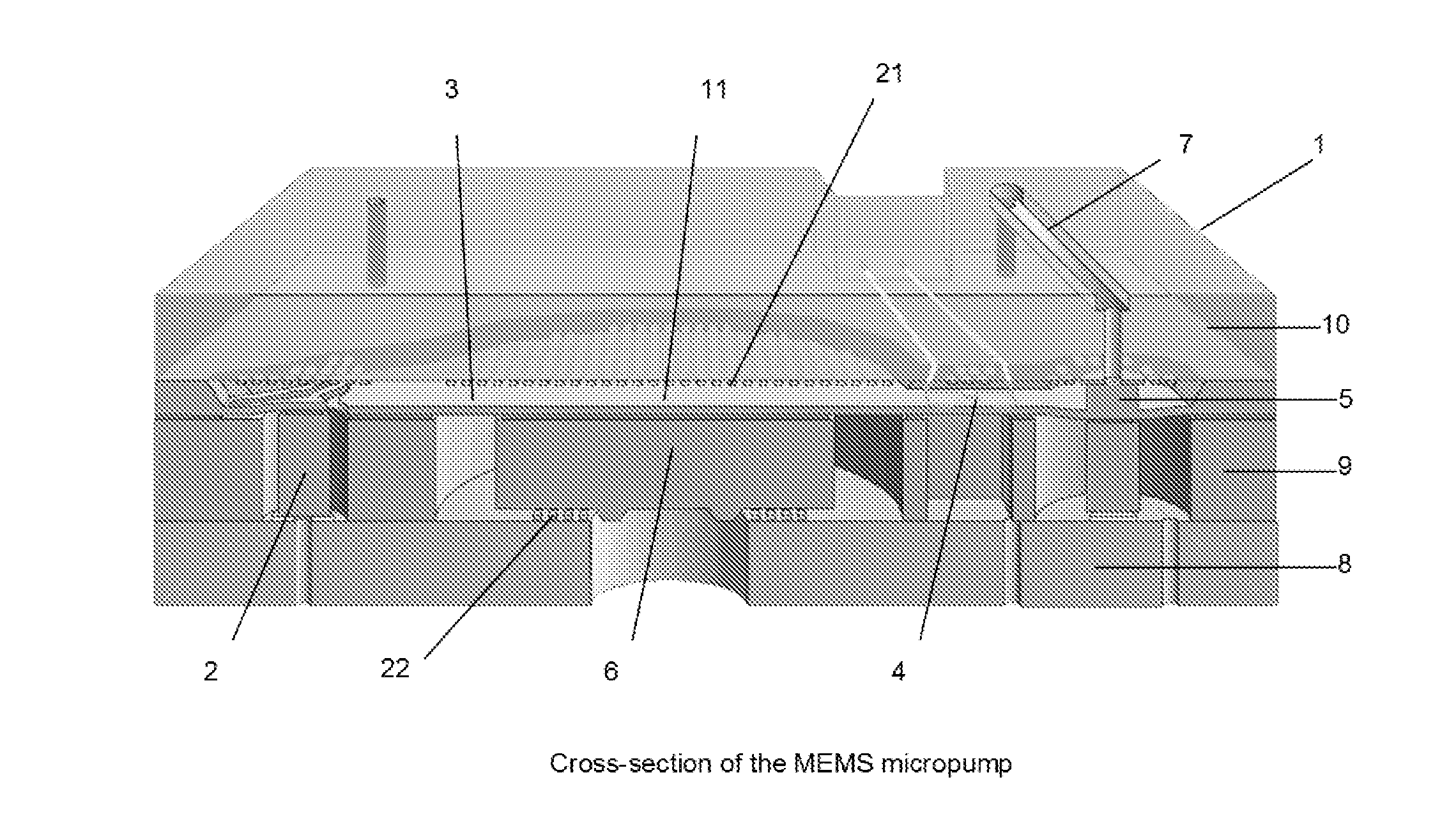

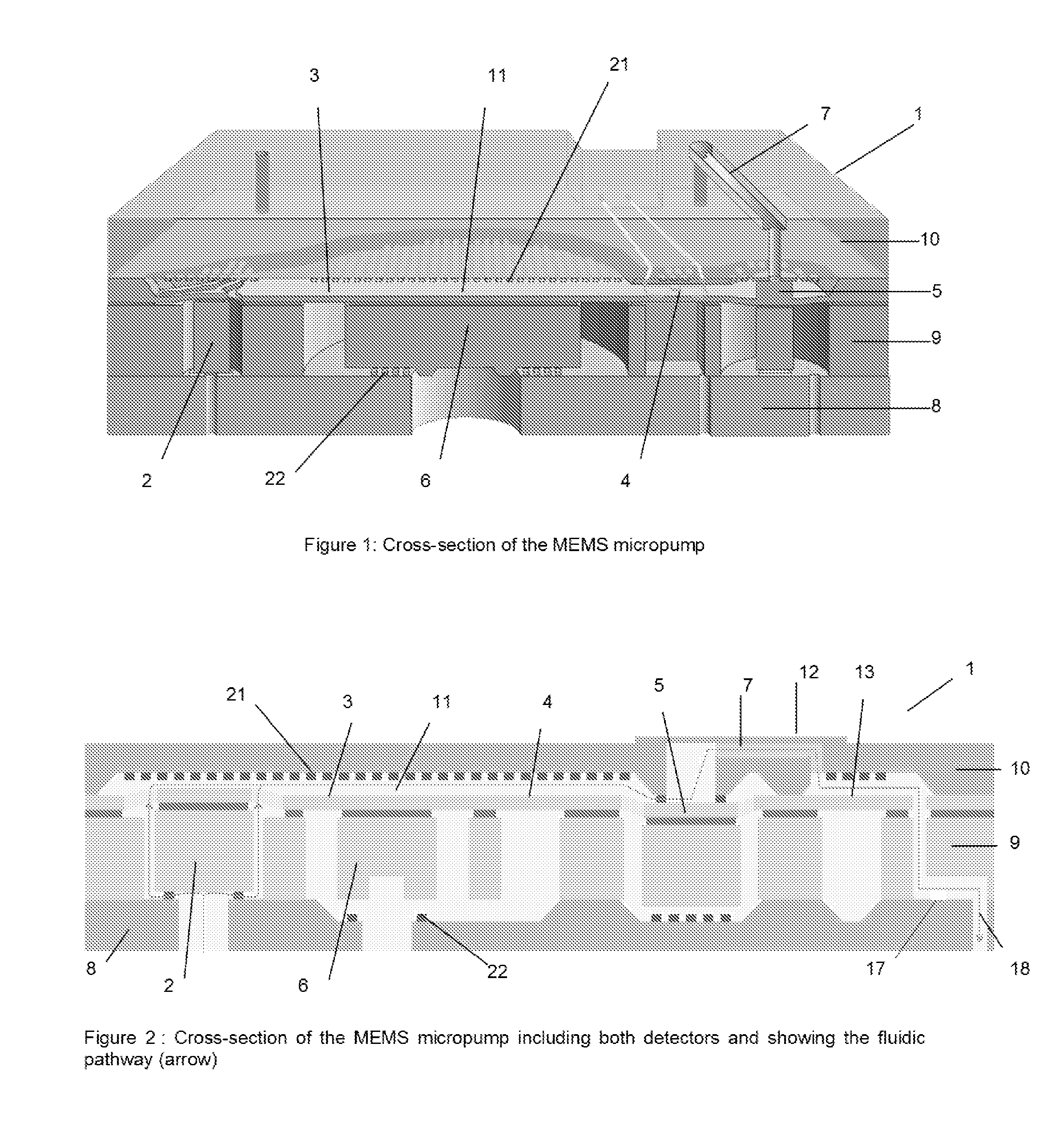

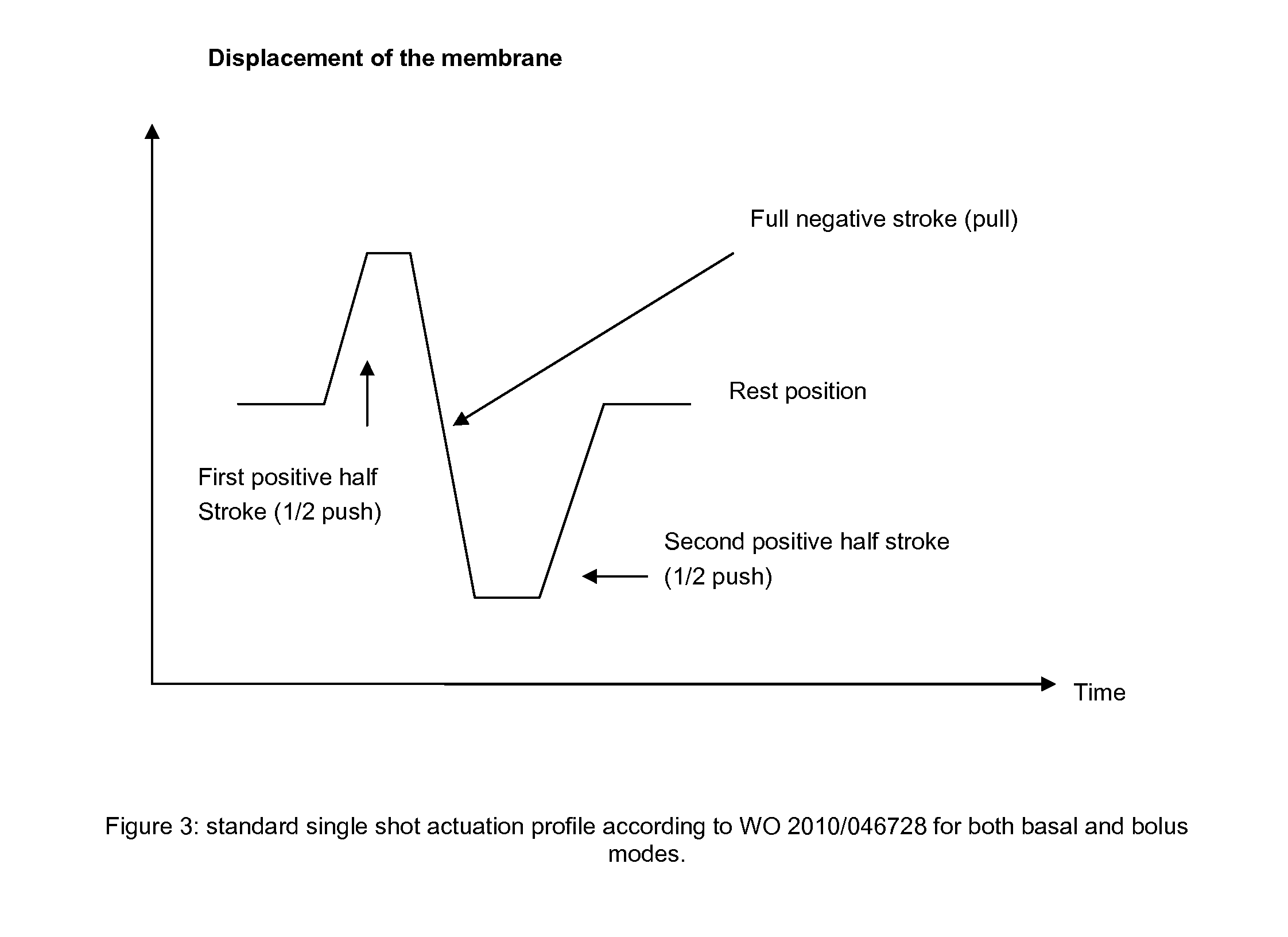

Method for accurate and low-consumption MEMS micropump actuation and device for carrying out said method

InactiveUS20140199181A1Avoid mistakesMinimize delivery errorFlexible member pumpsIntravenous devicesHysteresisPump chamber

The present invention describes the improvements due to alternated actuation cycles to reduce the delivery errors related to the pumping chamber elasticity, the actuator relaxation or hysteresis. The method actuates a pumping device with an optimal driving voltage profile, wherein the pumping device comprises a pumping chamber including a pumping membrane and a voltage controlled actuator connected to said membrane; the movement of said membrane being defined by three positions, namely a rest, a bottom and a top position. The method includes the actuation of the membrane with a pumping pattern including at least two different cycles: Cycle A: rest-bottom-rest-top-rest Cycle B: rest-top-rest-bottom-rest. The invention also relates to a device to carry out the method.

Owner:DEBIOTECH SA

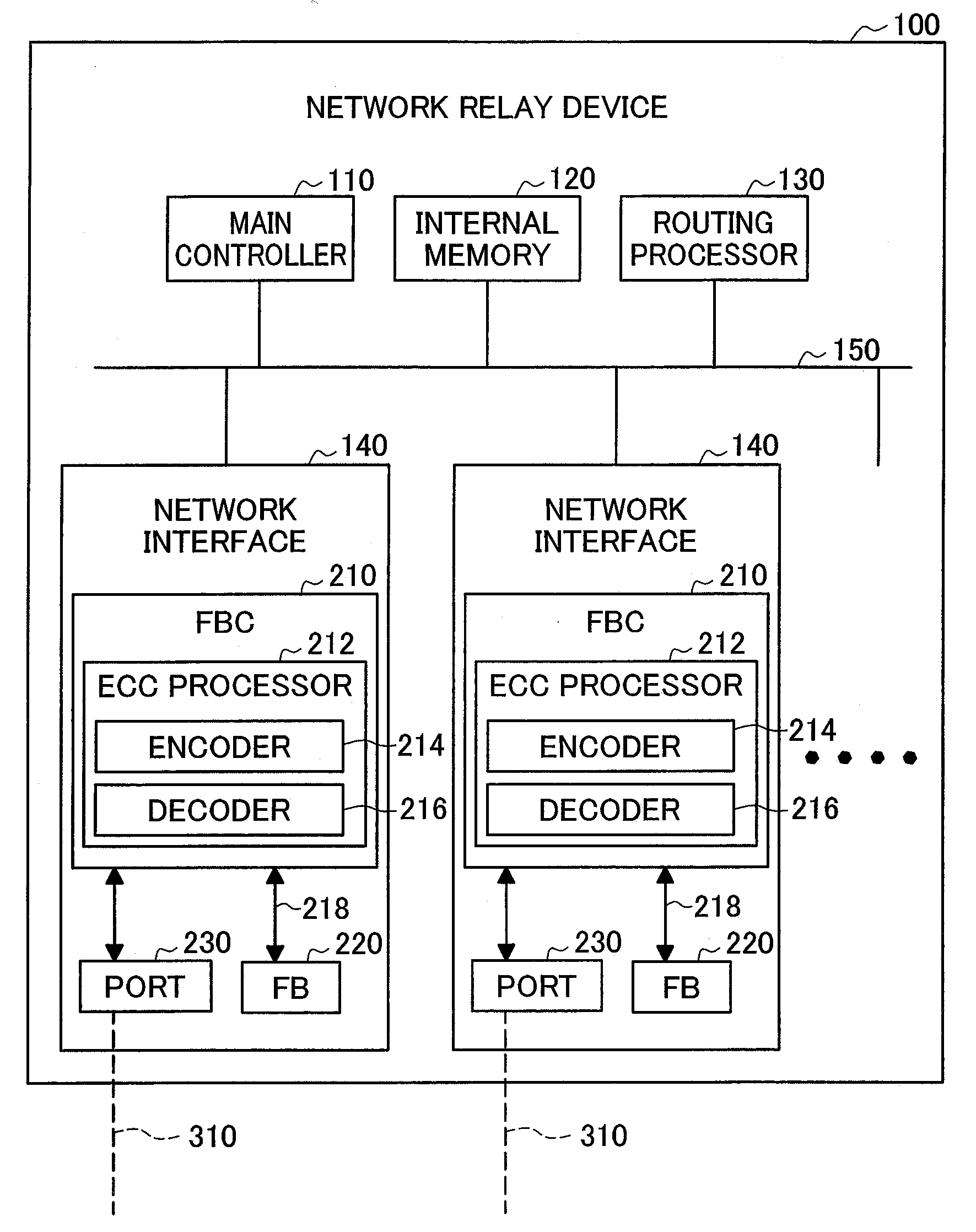

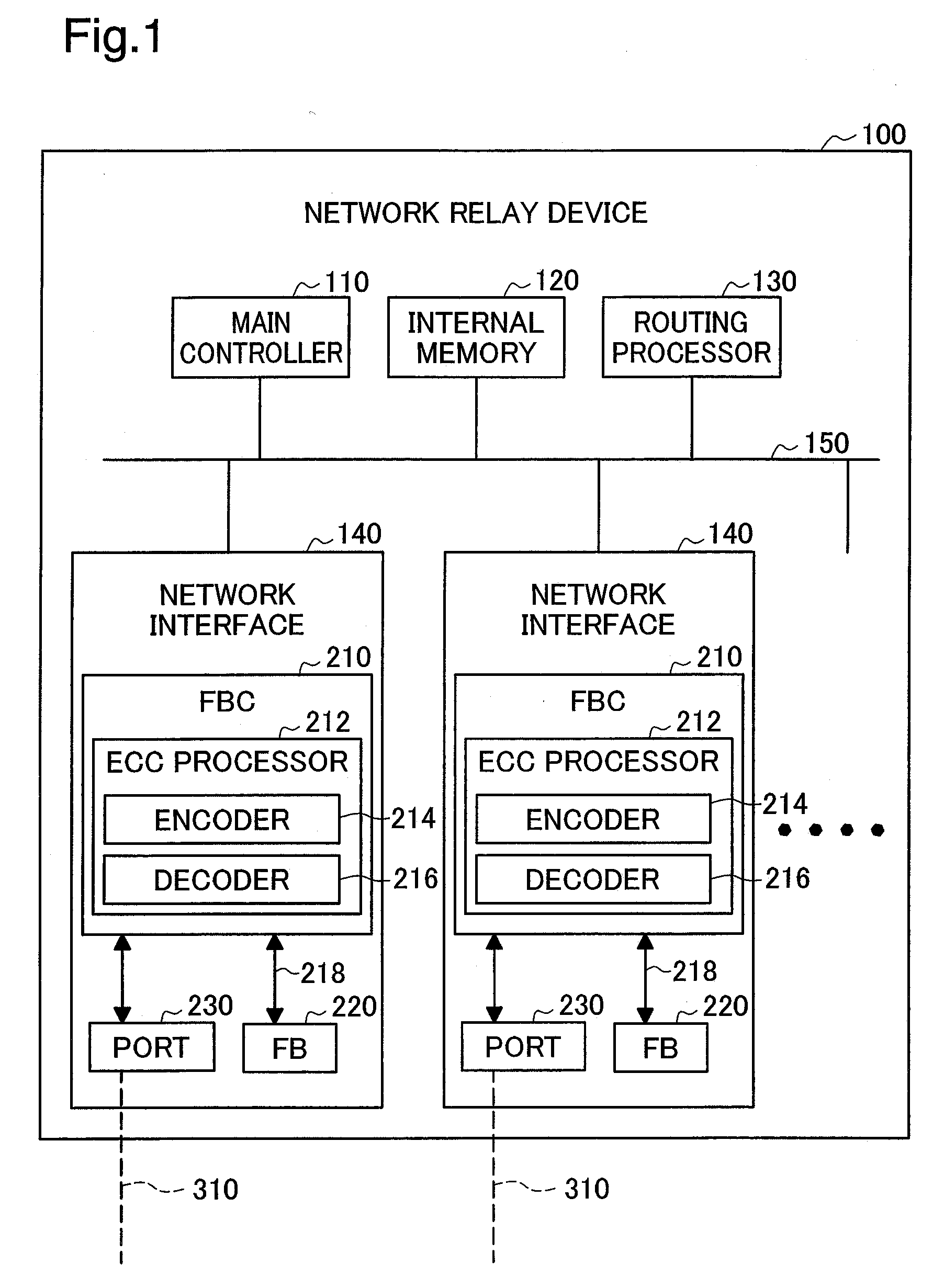

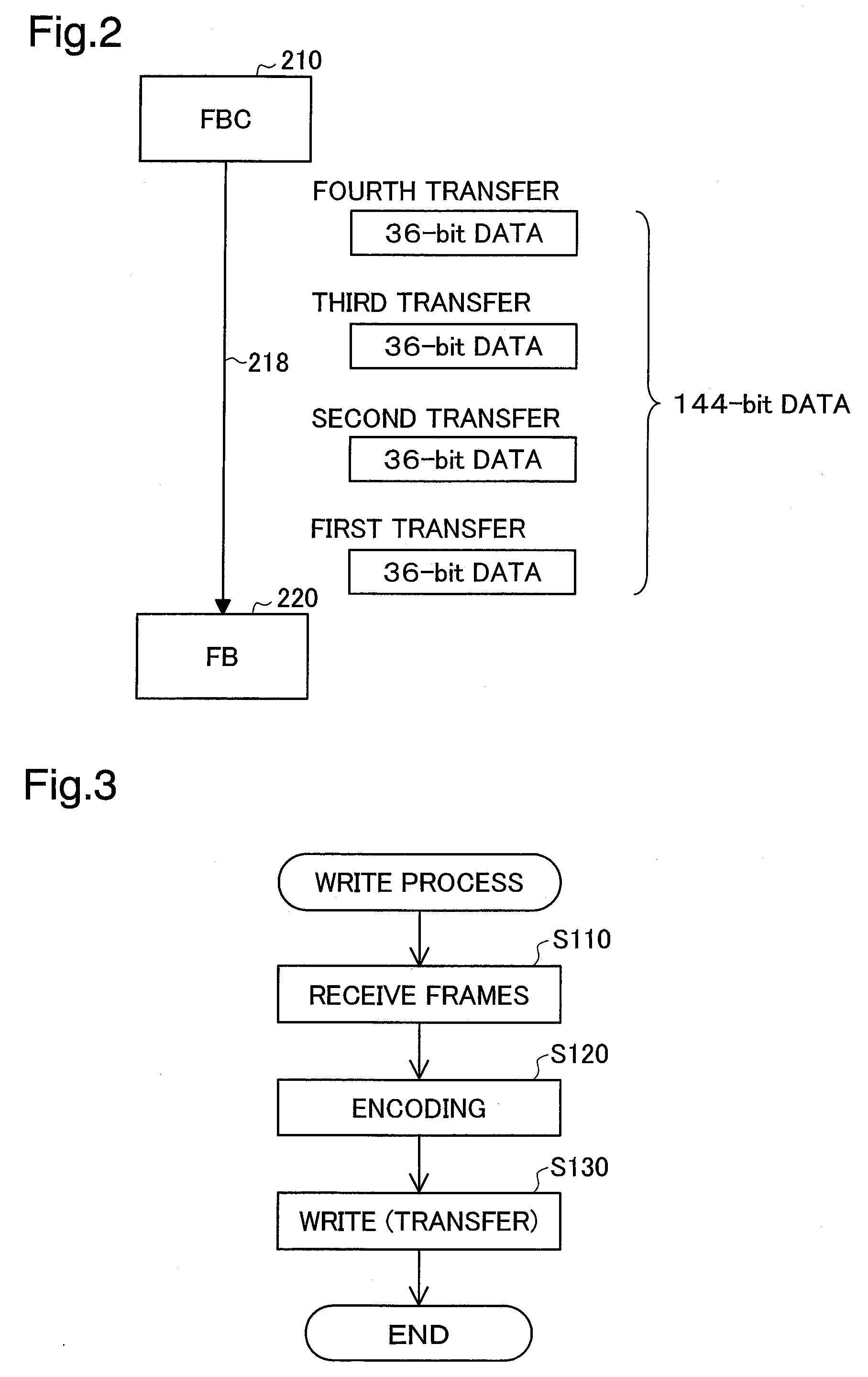

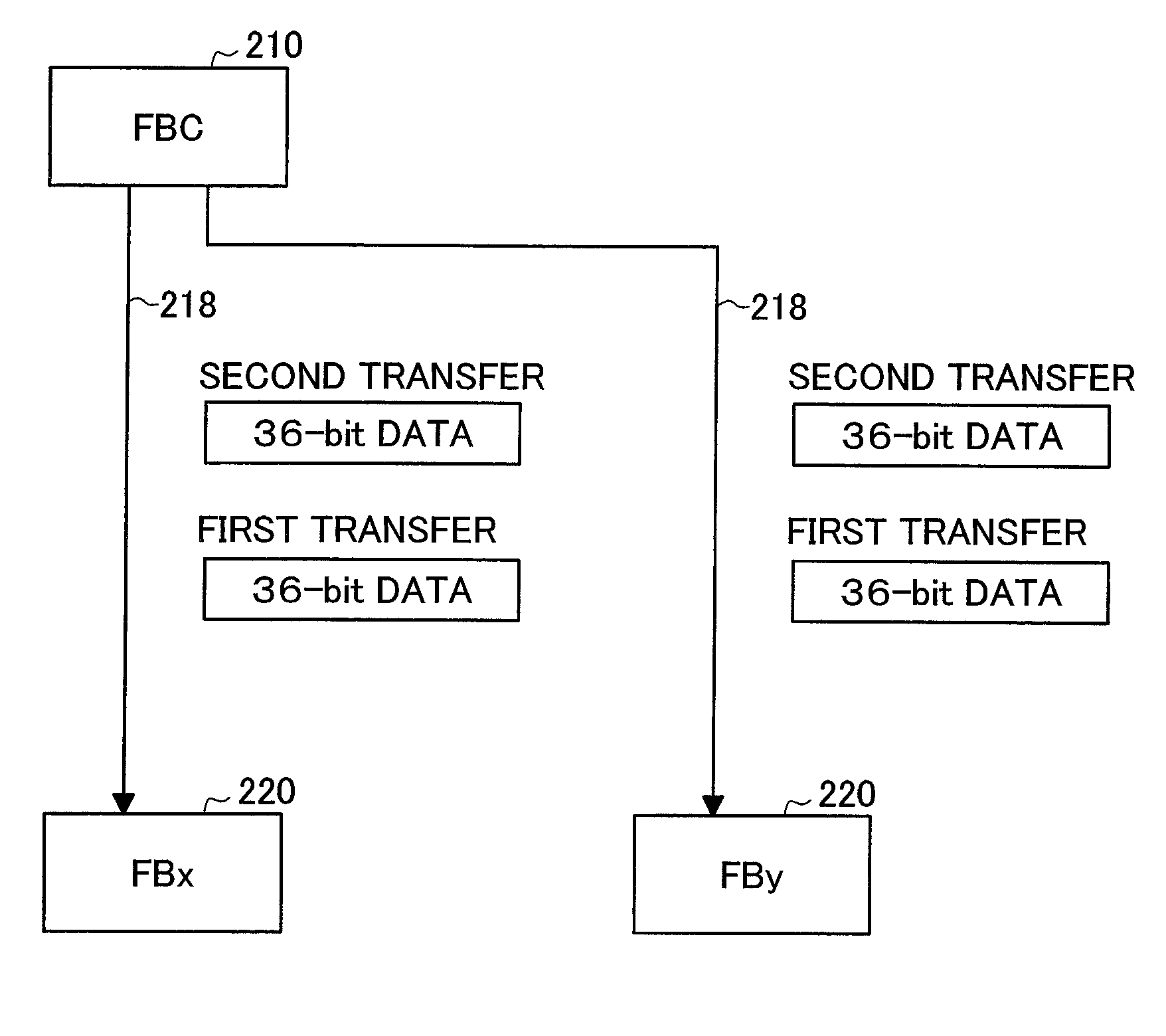

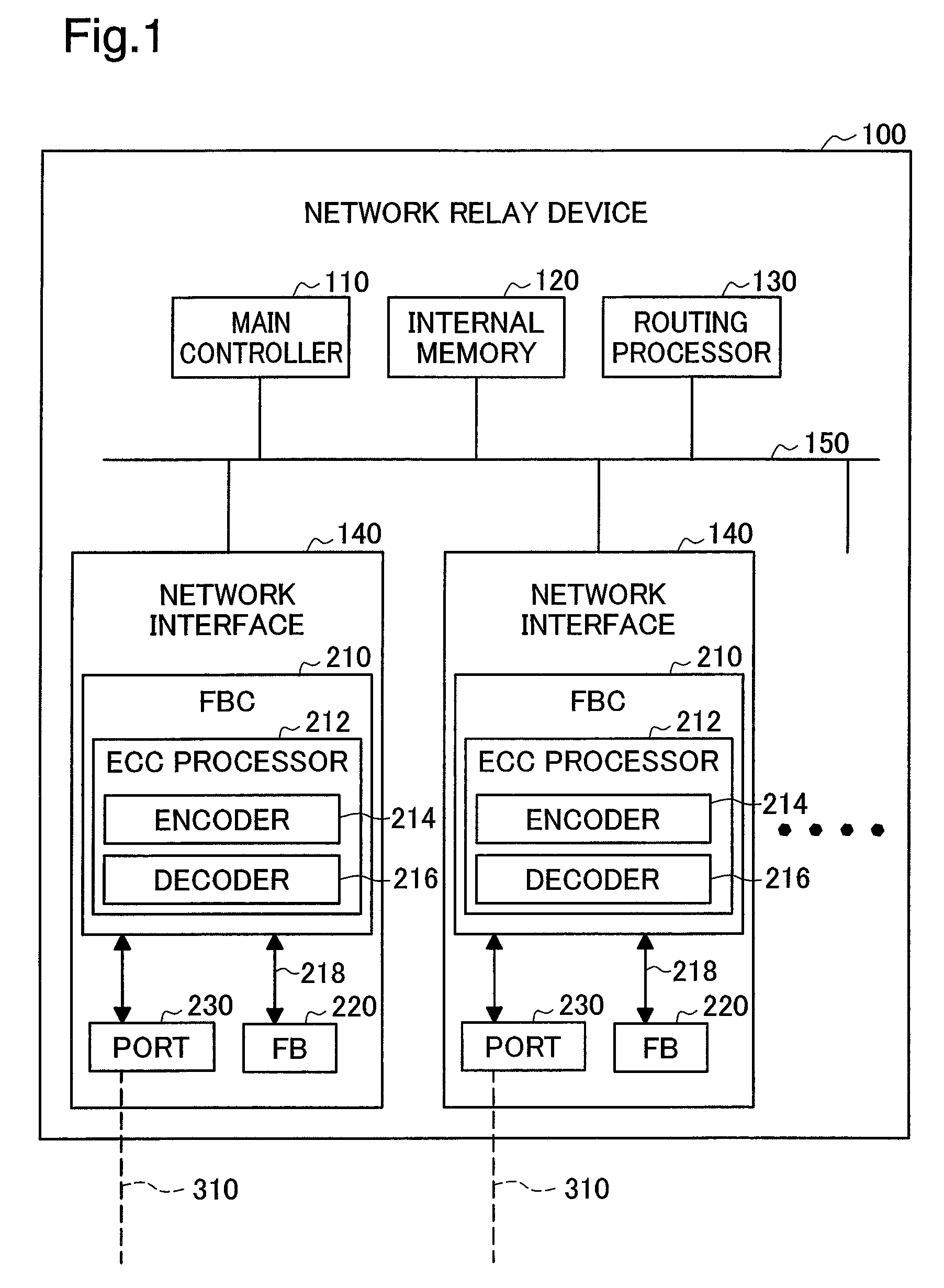

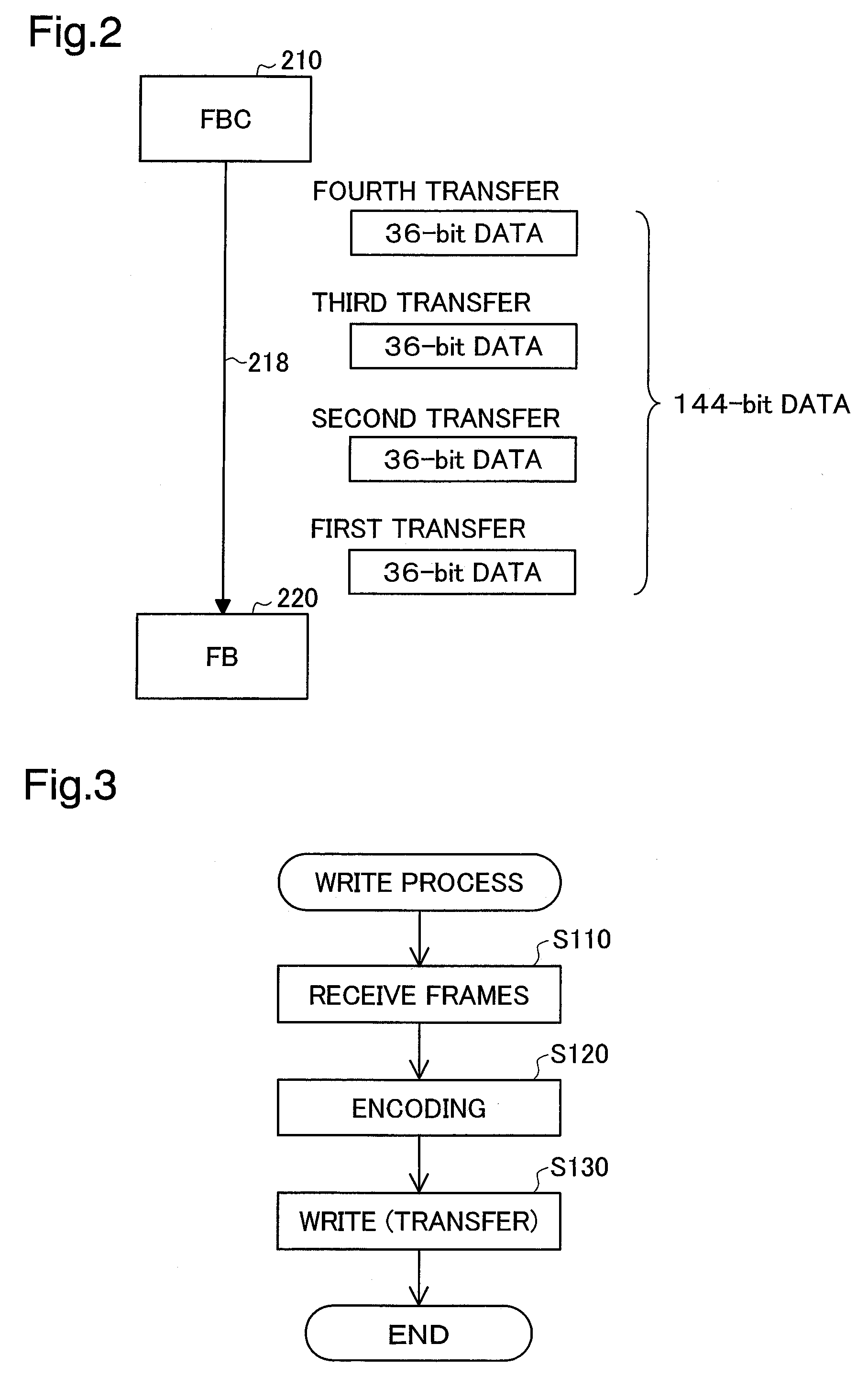

Information processing device and information processing method

ActiveUS20070300126A1Improve accuracyMinimizing increase in bit length of bitCode conversionError detection onlyInformation processingComputer science

An information processing device implements error control including at least one of error detection and error correction. The device comprises an information bit sequence acquiring unit and an encoder. The information bit sequence acquiring unit acquires an information bit sequence. The encoder generates a redundant bit sequence enabling execution of error control of the entire information bit sequence, the redundant bit sequence being generated through encoding by a predetermined code based on the information bit sequence and generates a codeword that includes the information bit sequence and the redundant bit sequence. The encoder generates the redundant bit sequence in such a way that one or more bits contained in the redundant bit sequence each functions as a parity bit for one of a plurality of divided information bit sequences produced by dividing the information bit sequence.

Owner:ALAXALA NETWORKS

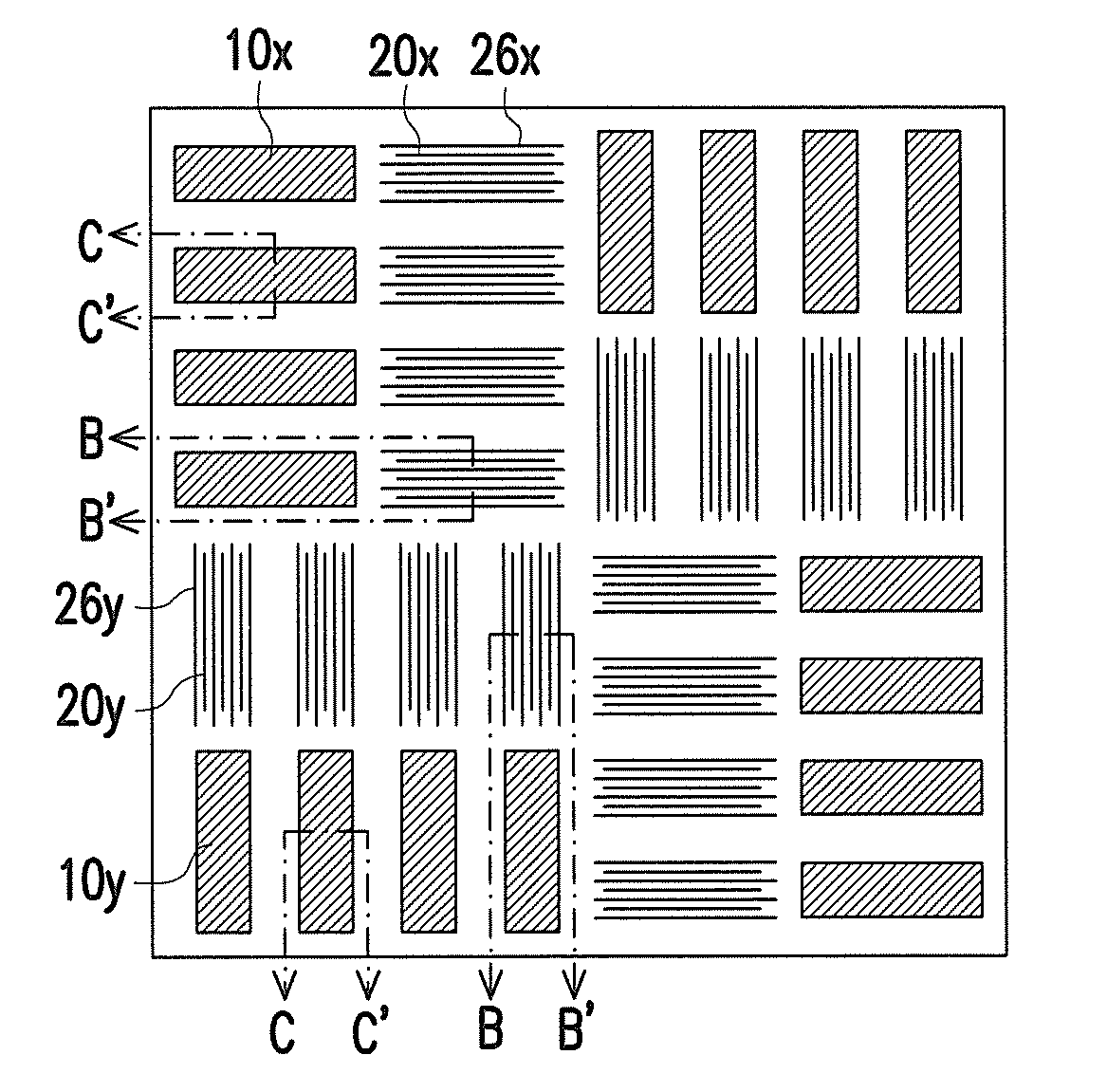

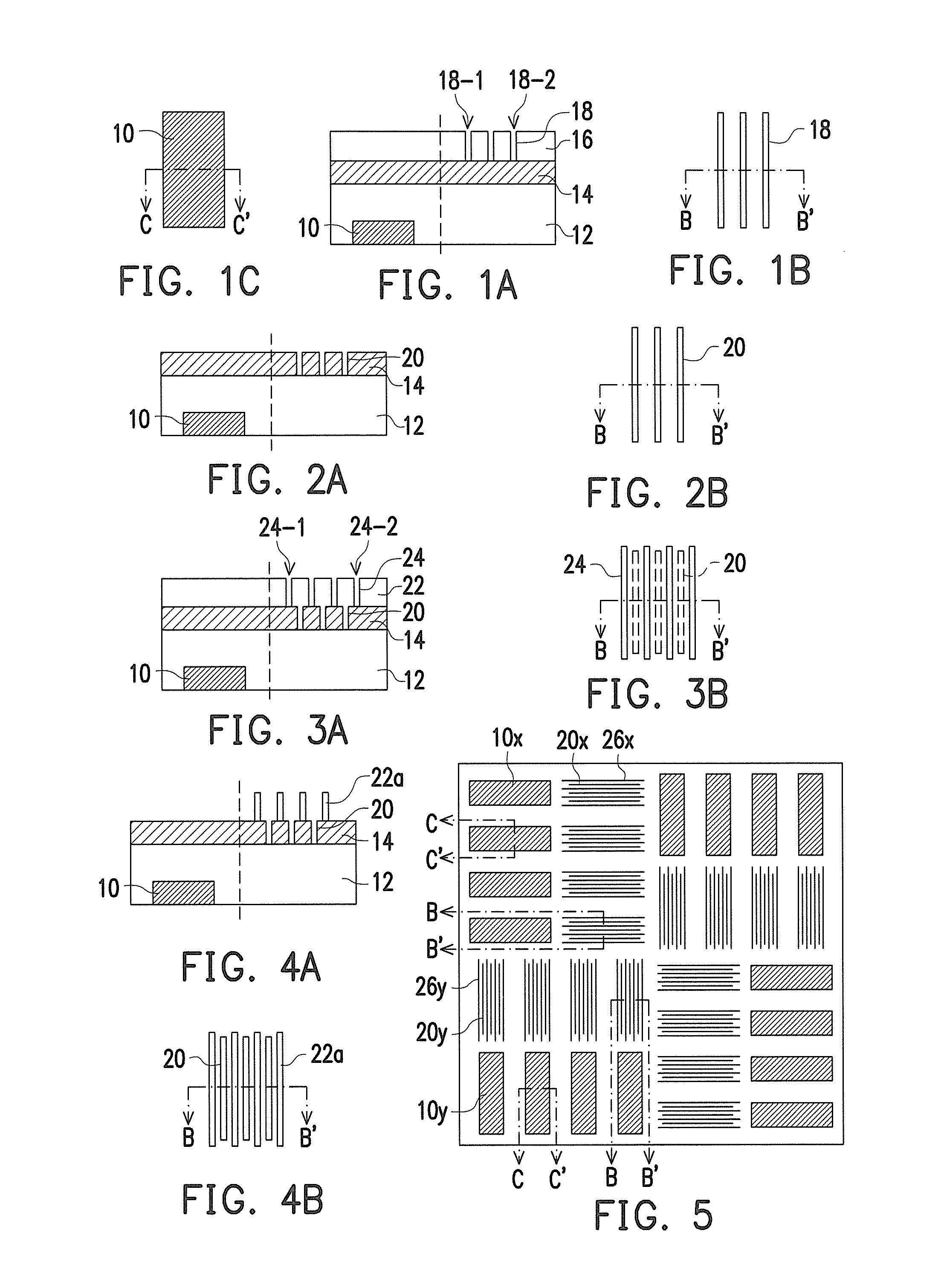

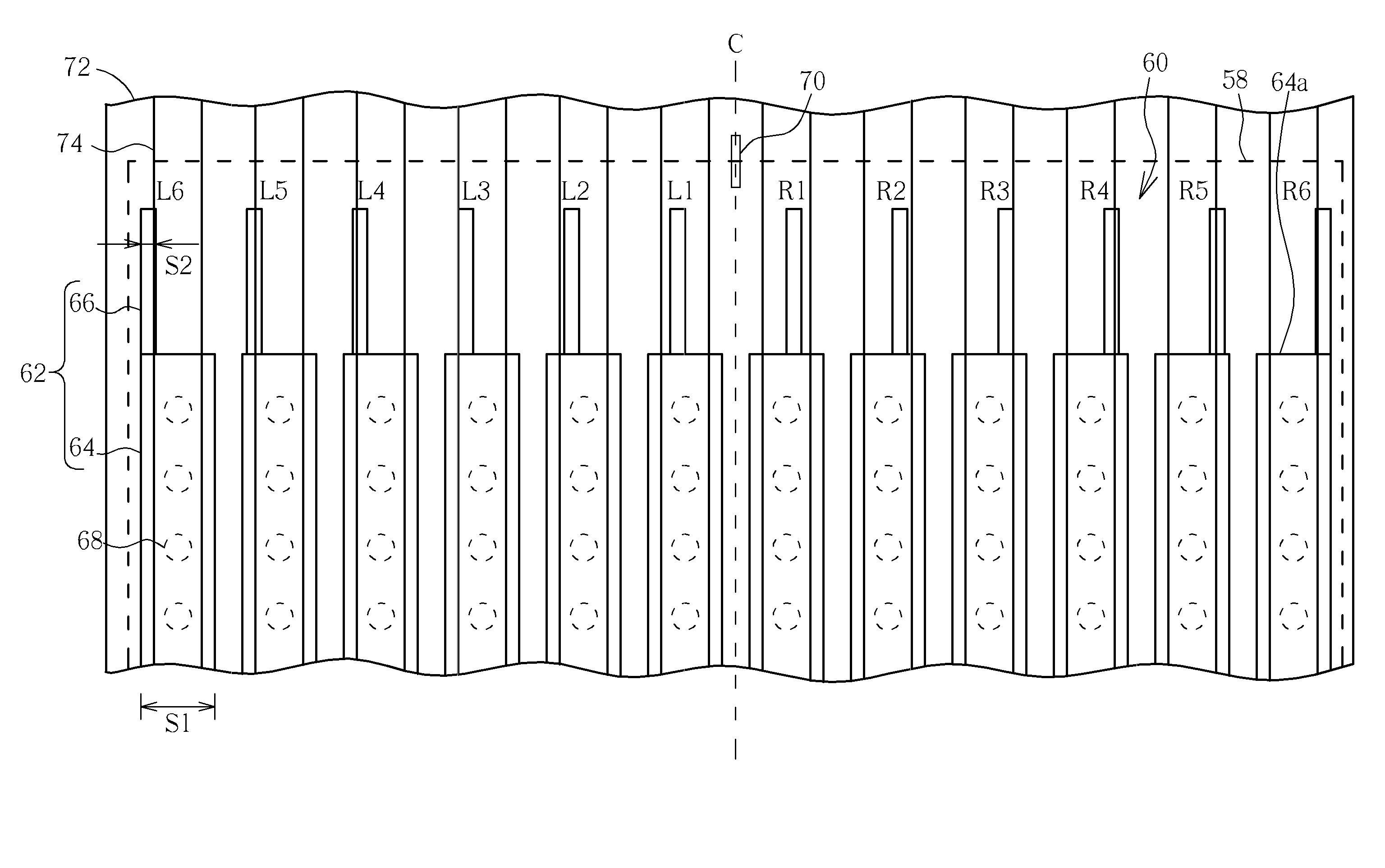

Overlay mark and method for forming the same

ActiveUS20160093573A1Wafer Area ReductionImprove accuracySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringLithography

An overlay mark applied to a LELE-type double patterning lithography (DPL) process including a first lithography step, a first etching step, a second lithography step and a second etching step in sequence is described. The overlay mark includes a first x-directional pattern and a first y-directional pattern of a previous layer, second x-directional and y-directional patterns of a current layer defined by the first lithography step, and third x-directional and y-directional patterns of the current layer defined by the second lithography step. The second x-directional patterns and the third x-directional patterns are arranged alternately beside the first x-directional pattern. The second y-directional patterns and the third y-directional patterns are arranged alternately beside the first y-directional pattern.

Owner:UNITED MICROELECTRONICS CORP

Light beam scanning device, image forming apparatus, and light beam scanning method

InactiveUS20050184229A1Correction errorPrevent unnecessary difficultyBeam/ray focussing/reflecting arrangementsMaterial analysis by optical meansLight beamImage formation

A light beam scanning device is disclosed that includes a light emission source to emit a light beam, a deflection part to deflect the emitted light beam in the main scanning direction, first and second light beam detection parts to detect the deflected light beam at first and second positions, respectively, outside an image area on the opposite sides thereof in the main scanning direction, a time difference measurement part to measure the time difference between the light beam detections by the first and second light beam detection parts, and a control part to perform control so as to correct image magnification in the main scanning direction in the image area from the measured time difference. The control part performs control so that the condition of the amount of light at the time of detecting the light beam by the first and second light beam detection parts is constant.

Owner:RICOH KK

Method for accurate and low-consumption MEMS micropump actuation and device for carrying out said method

InactiveUS10041483B2Improve accuracyGuaranteed Error AccuracyFlexible member pumpsPressure infusionHysteresisPump chamber

Owner:DEBIOTECH SA

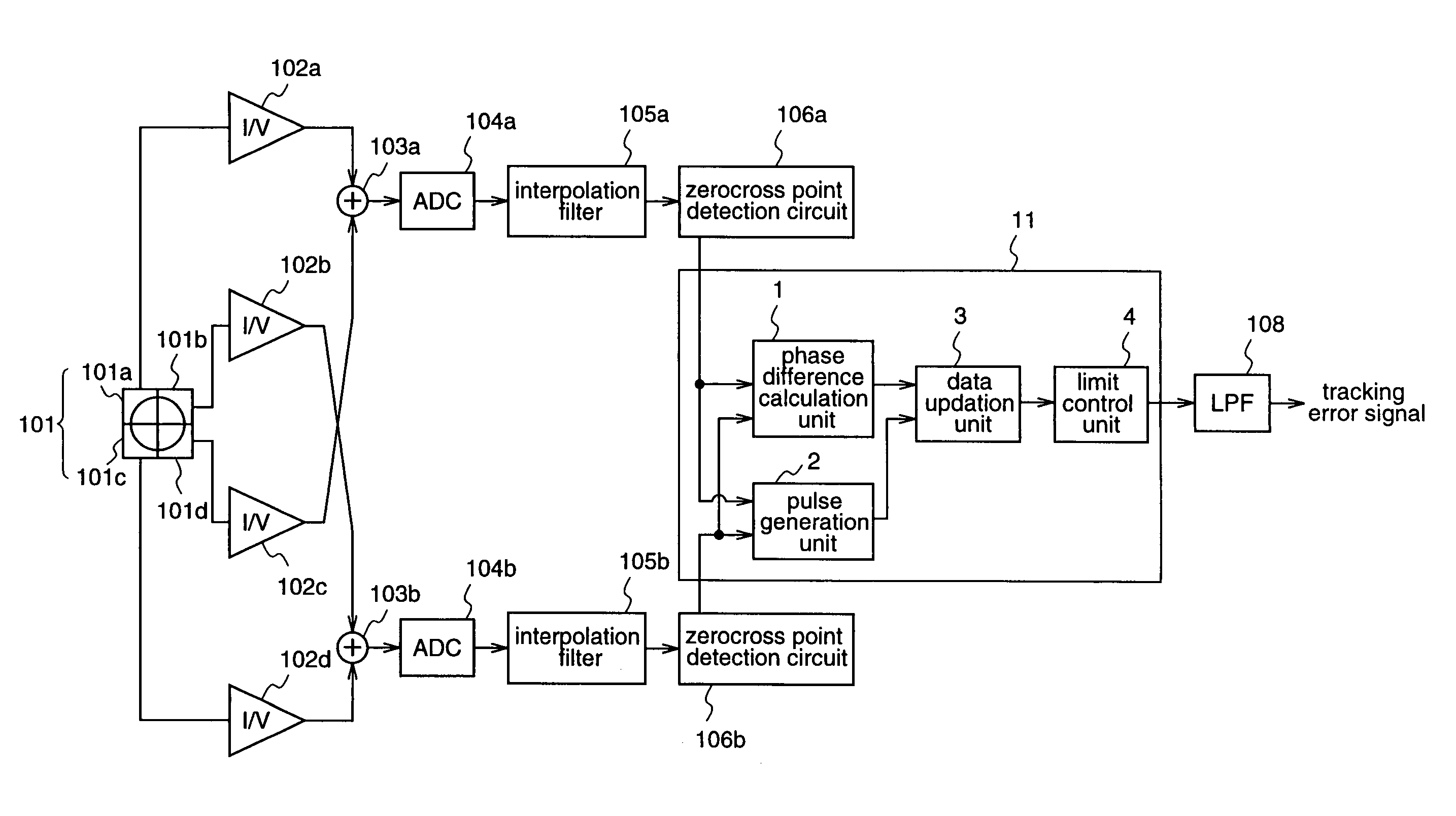

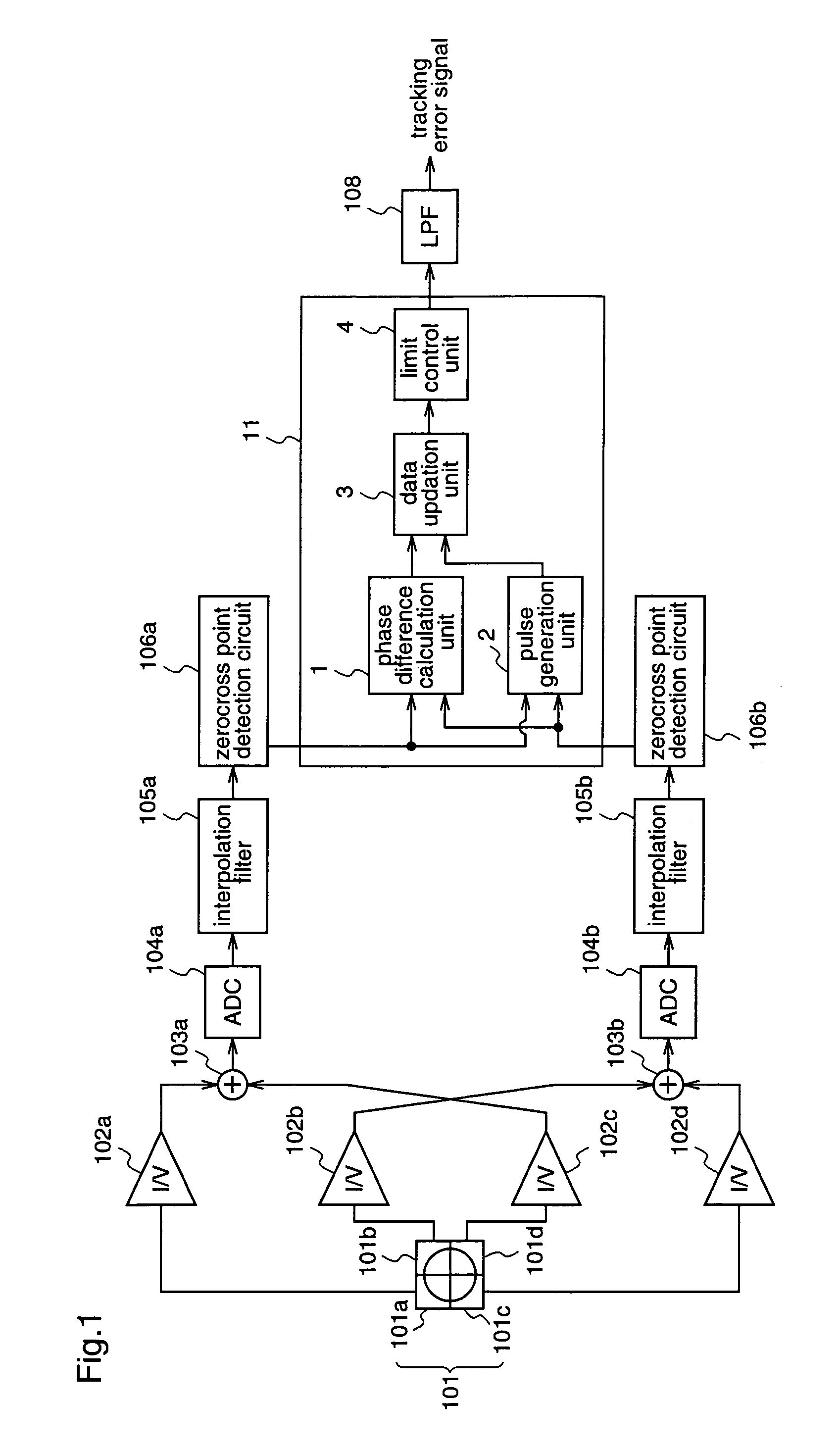

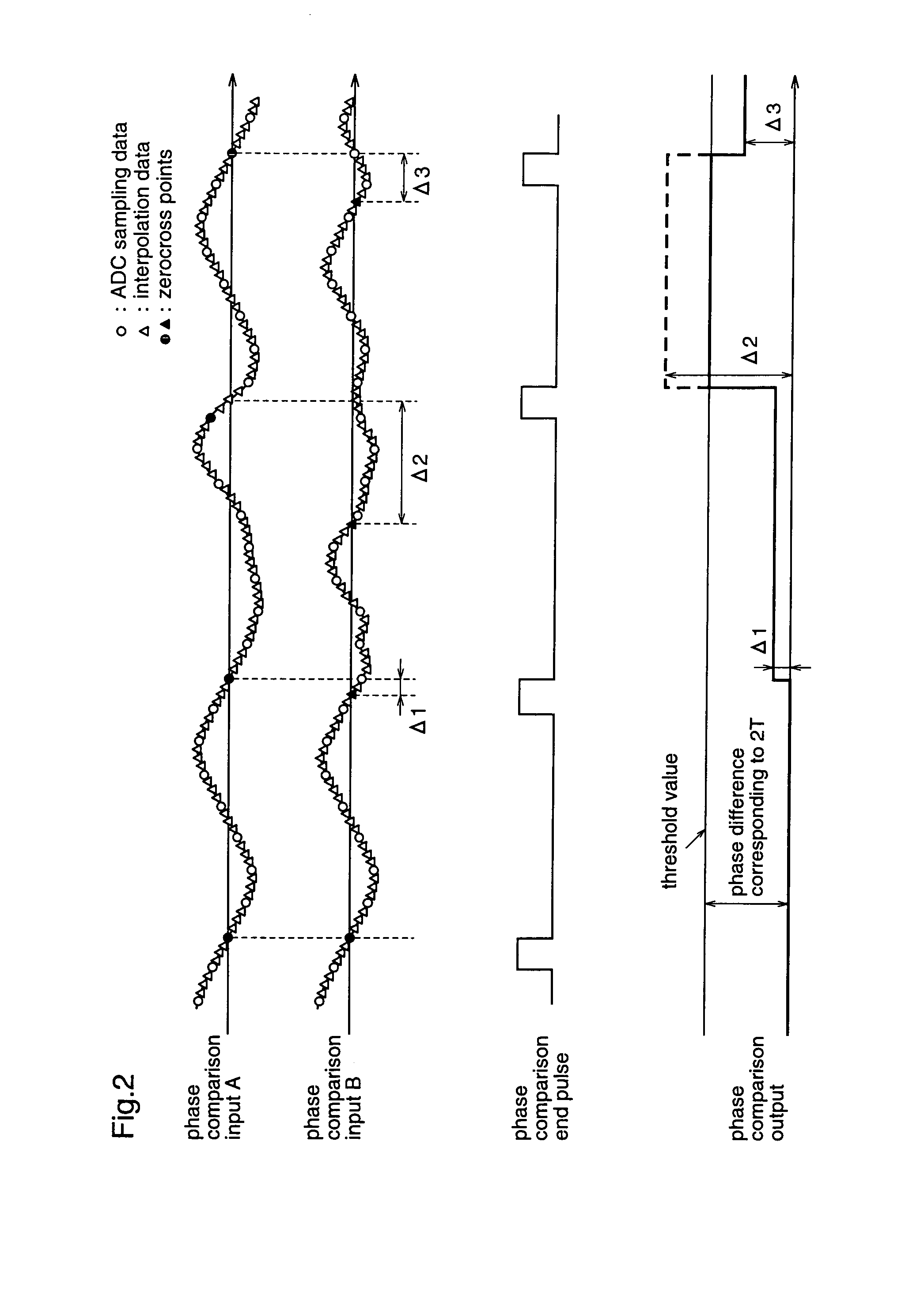

Tracking error detection apparatus including reduction in false tracking error detection during phase error detection

InactiveUS7289399B2Reduce impactImprove accuracyRecord information storageDisposition/mounting of headsLow-pass filterPhase difference

A tracking error detection apparatus comprises a photodetector comprising plural photoreceptor elements; zerocross detection circuits for detecting zerocross points at which two sequences of digital signals intersect the center levels of the respective digital signals, which digital signals are generated according to the amounts of light received by the respective photoreceptor elements and are outputted from the photodetector; a phase difference detection circuit for performing phase comparison using a distance between zerocross points of the two sequences of digital signals, and outputting a result of phase comparison; and a low-pass filter for performing band restriction to a signal outputted from the phase difference detection circuit. When a phase difference between the two sequences of digital signals, which is detected by the phase difference detection circuit, is larger than a maximum value of a theoretical tracking error signal, the output from the phase difference detection circuit is limited.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

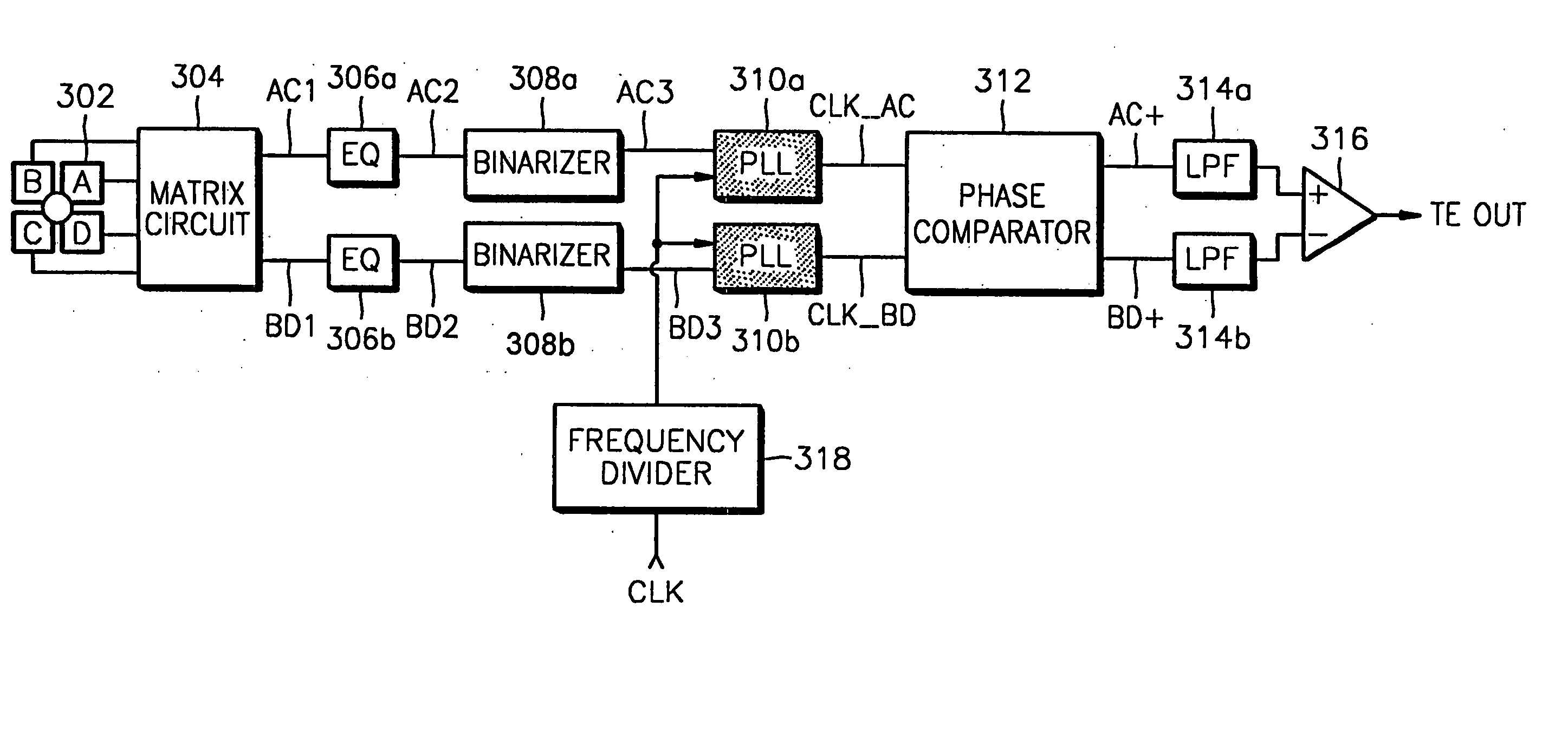

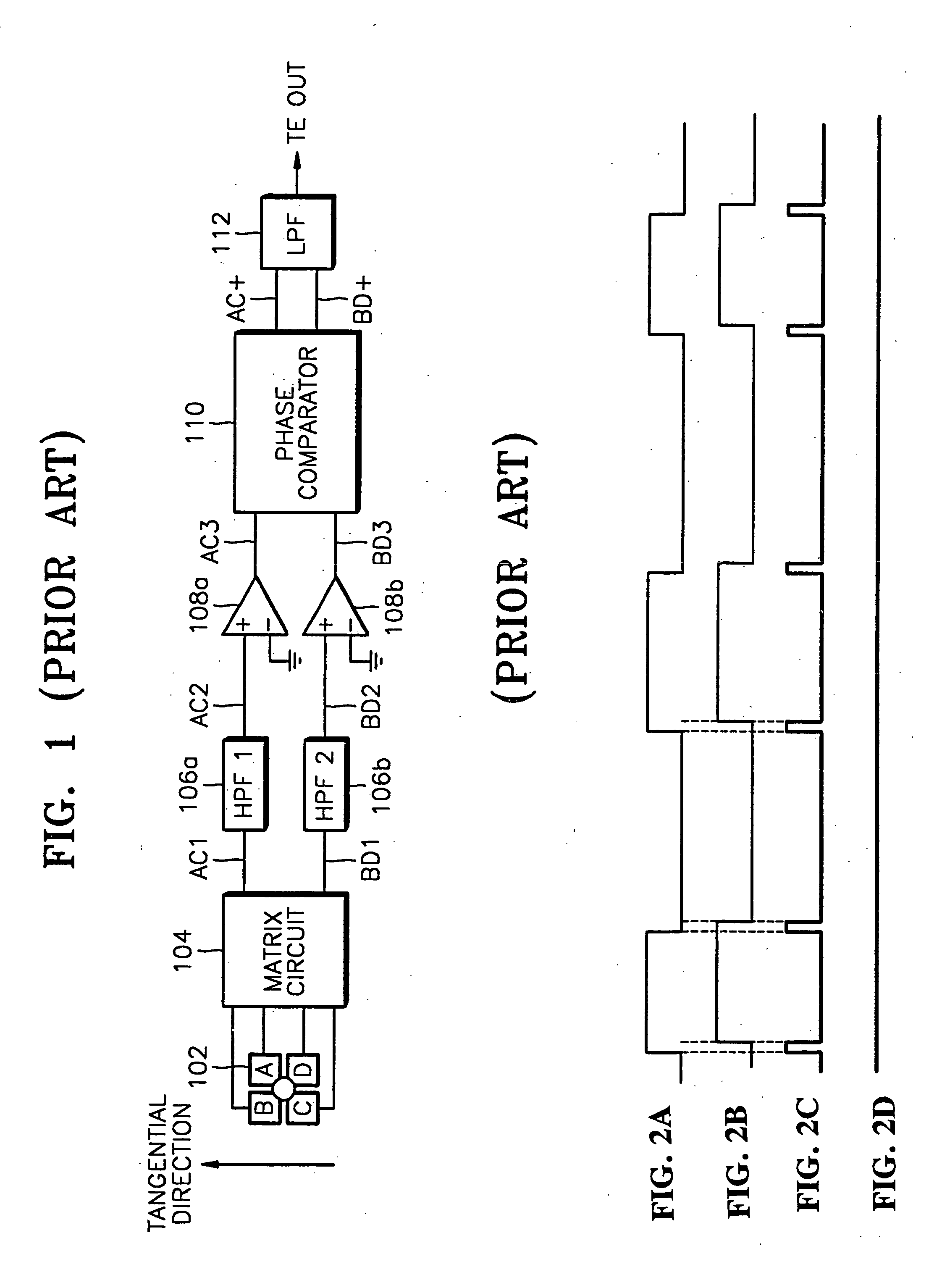

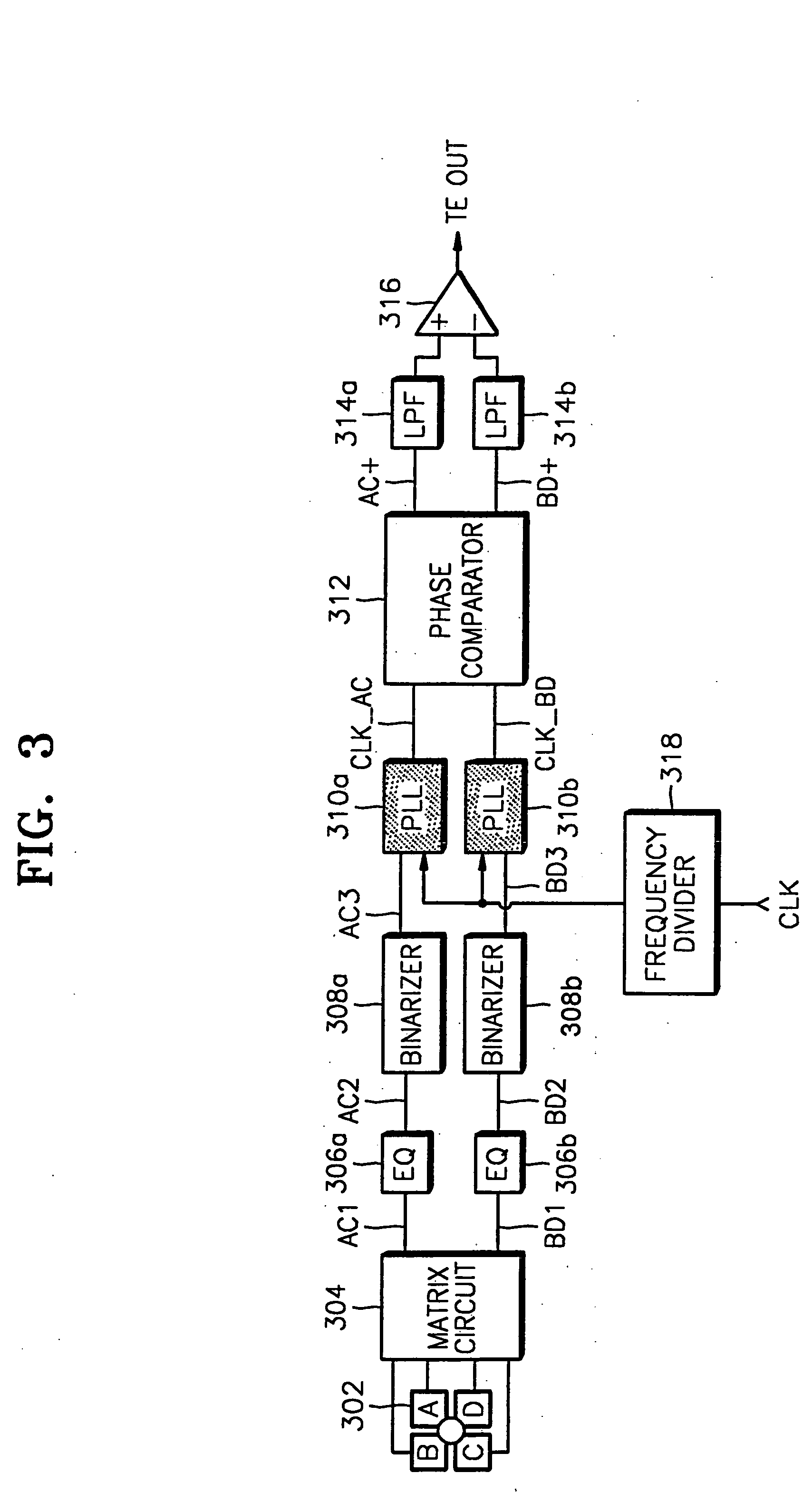

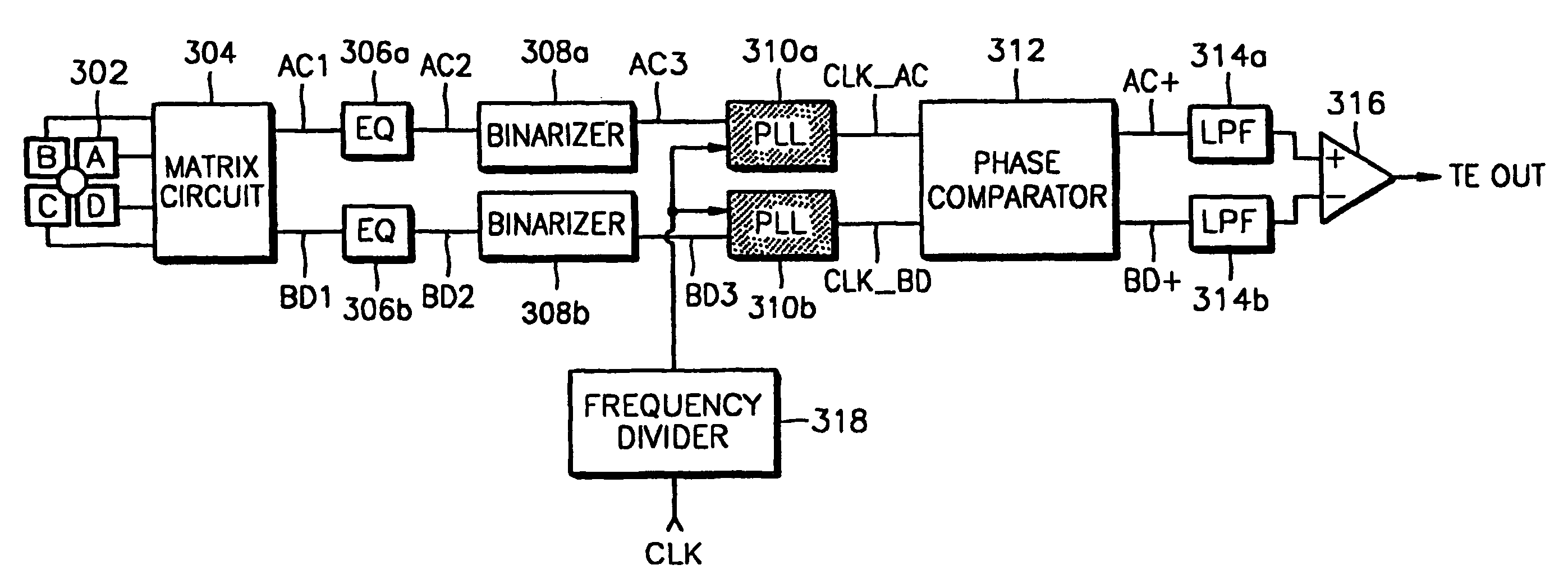

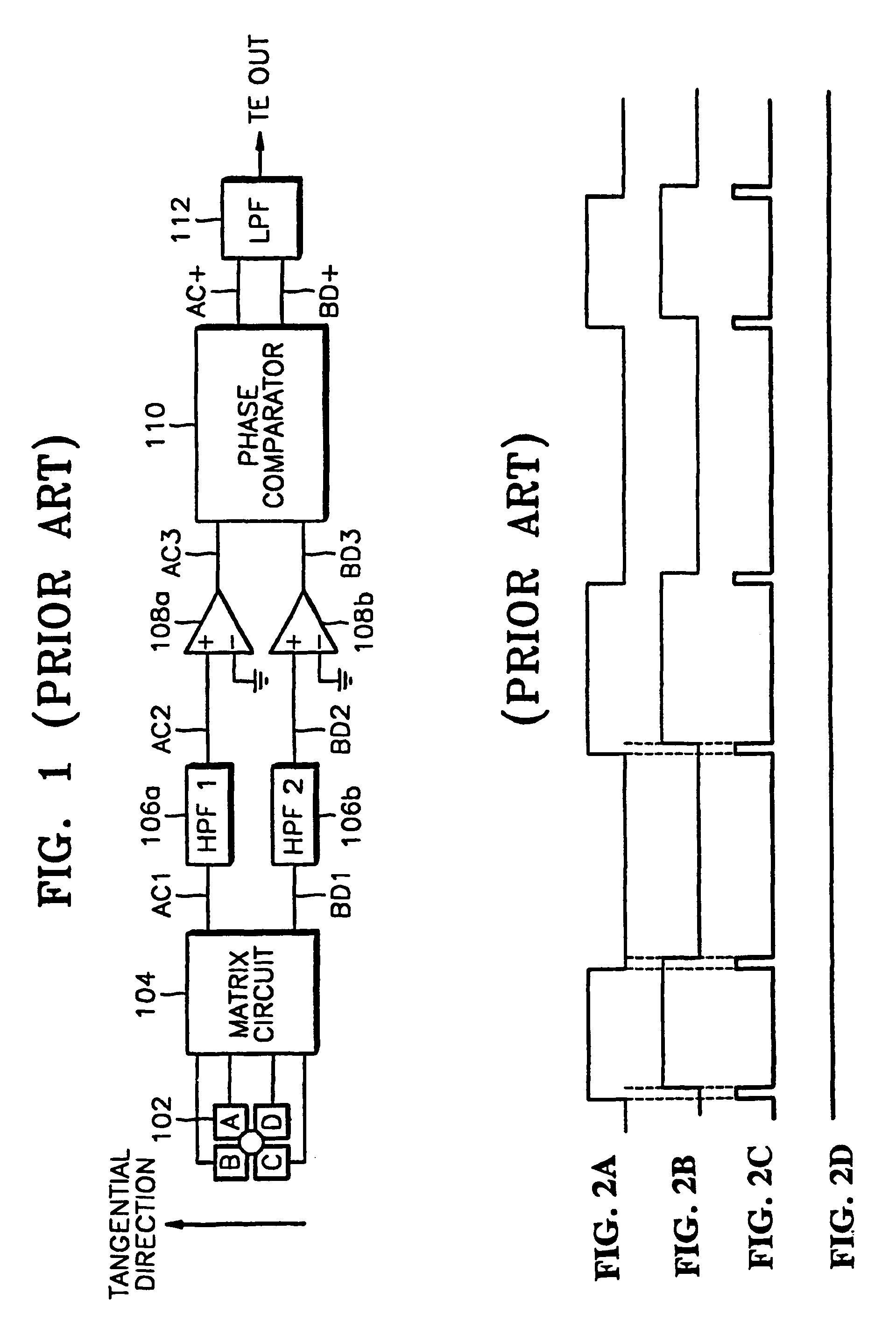

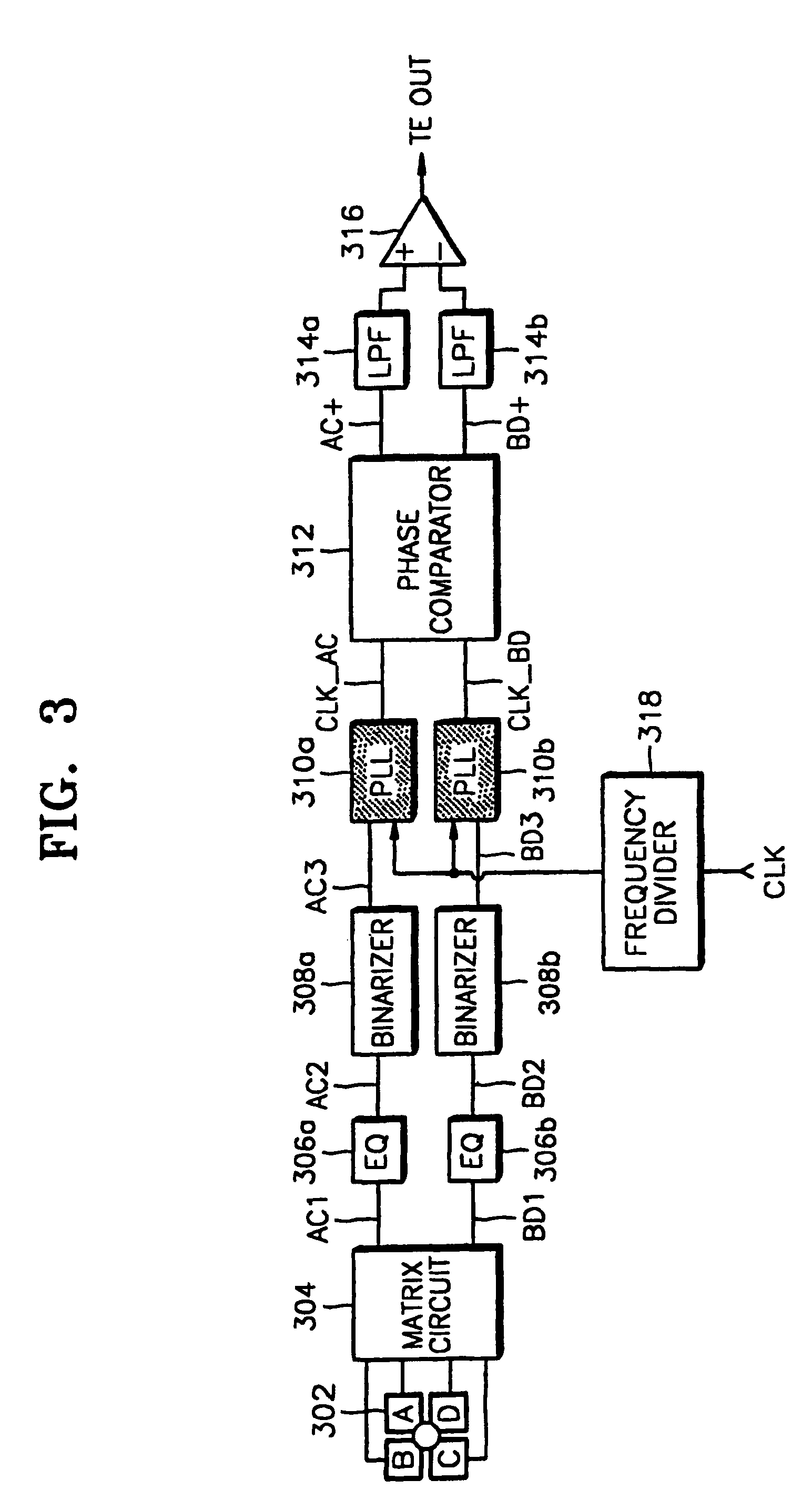

Method and apparatus for tracking error detection in optical disk driver

InactiveUS20050068864A1Additional drawbackGuaranteed Error AccuracyRecord information storageDisposition/mounting of headsPhase differenceLow-pass filter

A method and apparatus for tracking error detection in an optical disk reproduction system. The tracking error detecting apparatus generates a tracking error signal as a difference signal of optical detection signals generated by more than two optical detectors positioned along a diagonal line from a track center and includes binarizers which binarize each output of the optical detectors, phase locked loops (PLLs) which generate respective clock signals synchronized with the outputs of each of the binarizers, a phase difference detector which detects a phase difference between the synchronized signals output from the PLLs, and low-pass filters which filter the output of the phase difference detector to output the result as the tracking error signal. The tracking error detecting apparatus generates a tracking error signal which is not dependent on the lengths of pits or marks recorded on an optical disk, enhancing the reliability of the tracking error signal.

Owner:SAMSUNG ELECTRONICS CO LTD

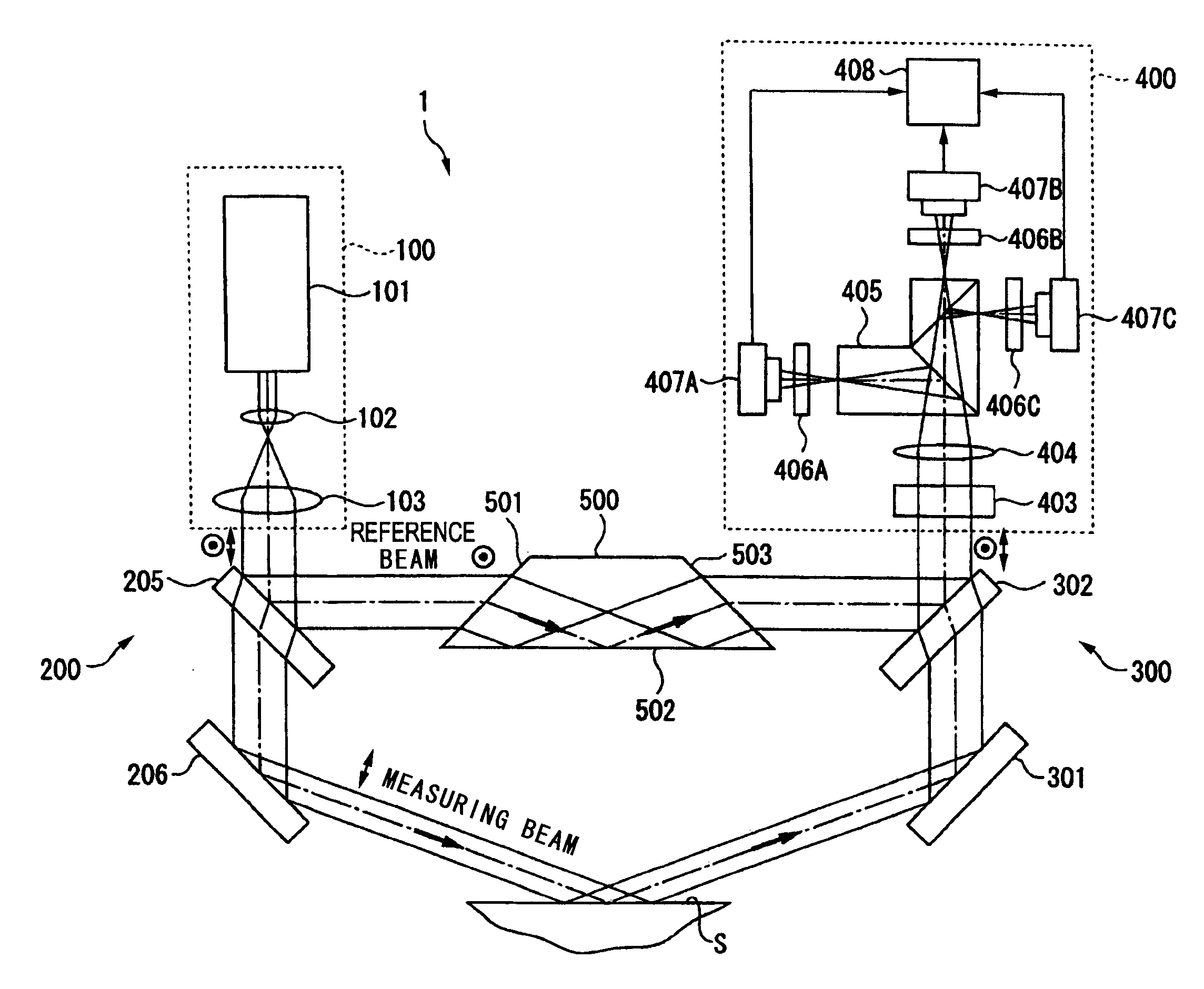

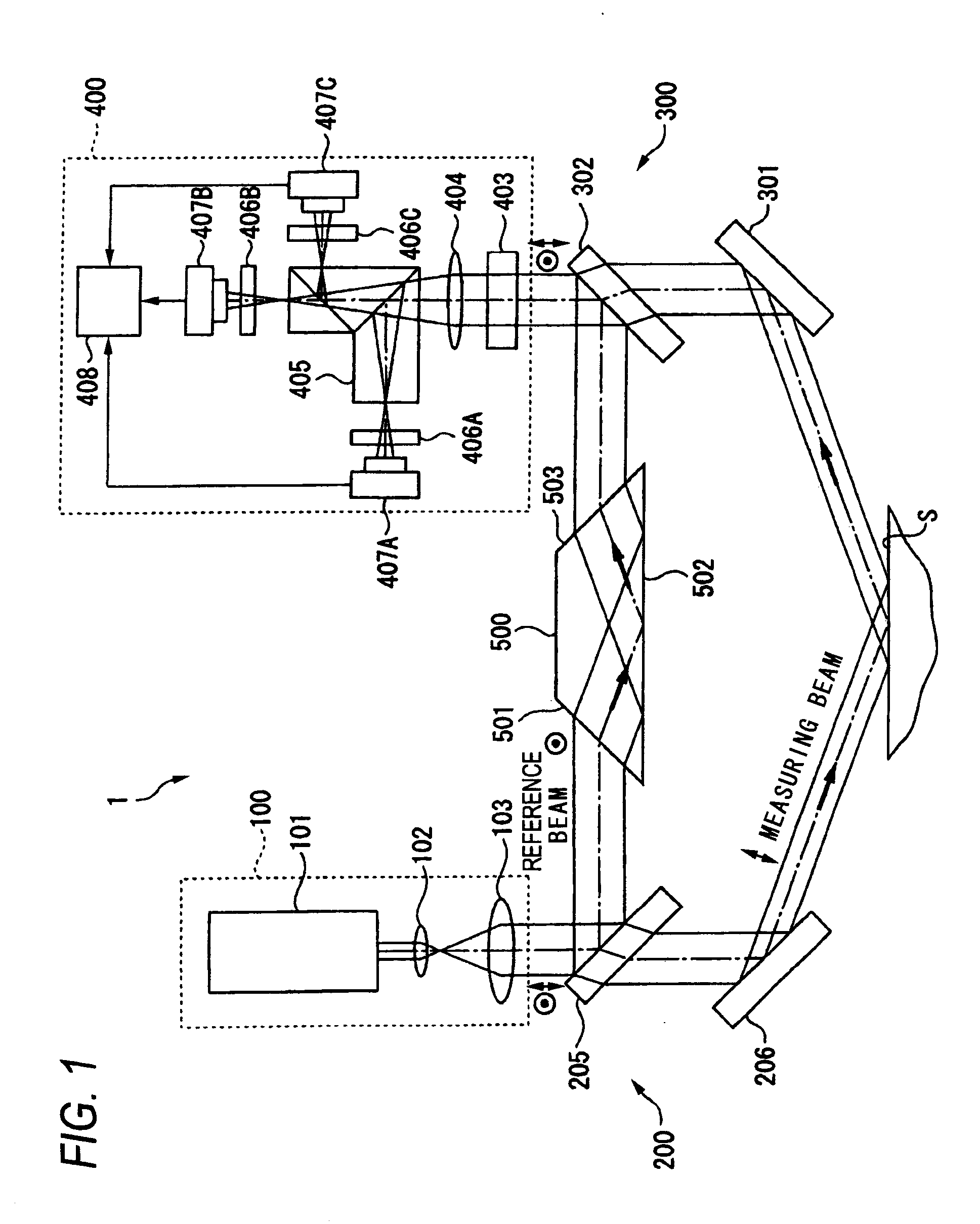

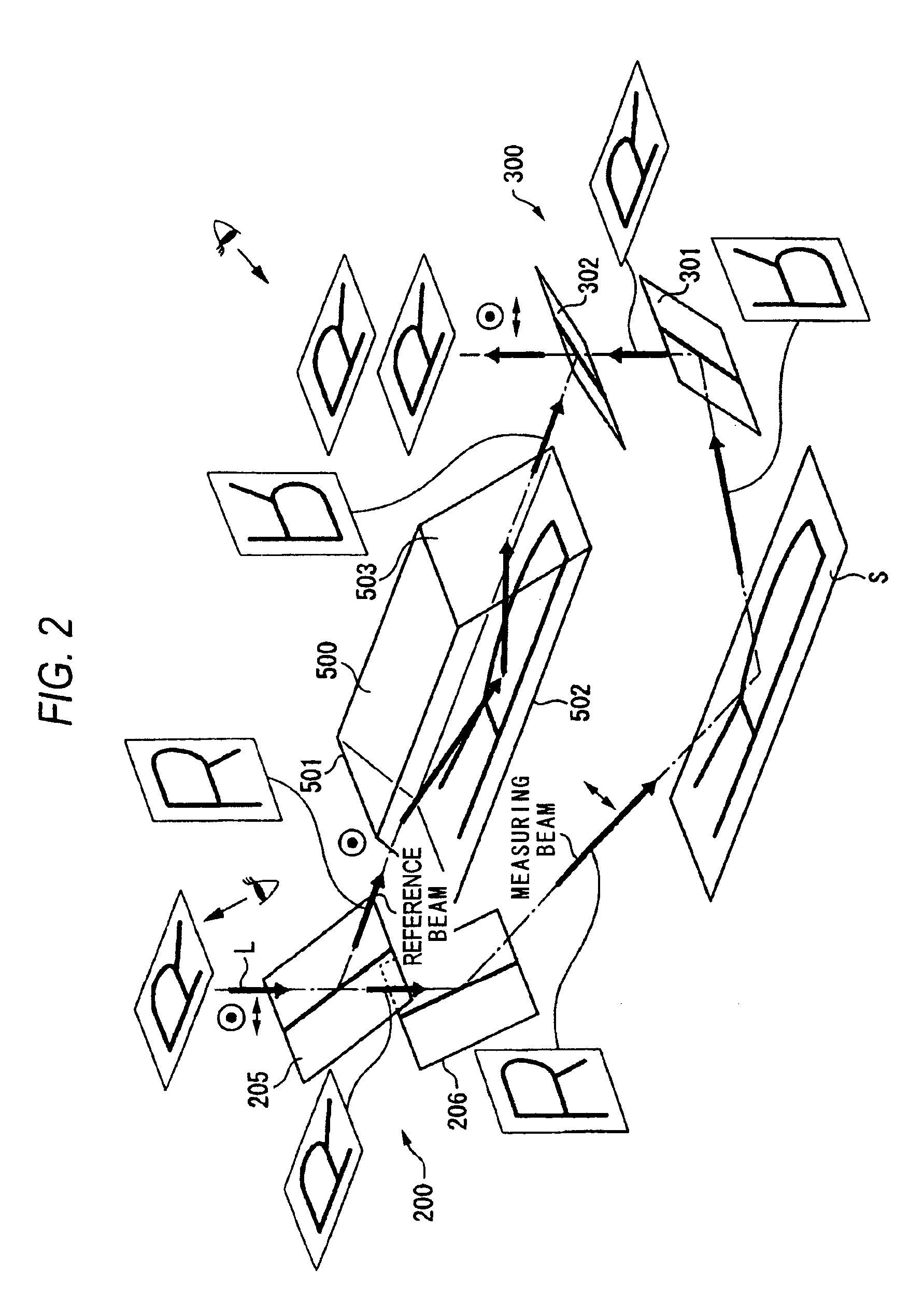

Grazing incidence interferometer

ActiveUS20110032536A1Easy to changeExcellent ease of useInterferometersUsing optical meansBeam splittingBeam source

A grazing incidence interferometer includes: a beam splitting section configured to split a beam from a beam source section into a measuring beam emergent to a measurement surface and a reference beam serving as a measurement reference, and configured to cause the measuring beam to emerge obliquely to the measurement surface; a beam combining part configured to combine the reference beam and the measuring beam reflected at the measurement surface, to obtain a combined beam; a detecting section configured to detect a profile of the measurement surface based on an interference fringe formed by the combined beam; and an image inverting part configured to invert an orientation of a wave front of the measuring beam or the reference beam, the image inverting part being provided in an optical path of the measuring beam or the reference beam leading from the beam splitting section to the beam combining section.

Owner:MITUTOYO CORP

Method and apparatus for tracking error detection in optical disk driver

InactiveUS7102967B1Additional drawbackGuaranteed Error AccuracyRecord information storageOptical recording/reproducingPhase differenceLow-pass filter

A method and apparatus for tracking error detection in an optical disk reproduction system. The tracking error detecting apparatus generates a tracking error signal as a difference signal of optical detection signals generated by more than two optical detectors positioned along a diagonal line from a track center and includes binarizers which binarize each output of the optical detectors, phase locked loops (PLLs) which generate respective clock signals synchronized with the outputs of each of the binarizers, a phase difference detector which detects a phase difference between the synchronized signals output from the PLLs, and low-pass filters which filter the output of the phase difference detector to output the result as the tracking error signal. The tracking error detecting apparatus generates a tracking error signal which is not dependent on the lengths of pits or marks recorded on an optical disk, enhancing the reliability of the tracking error signal.

Owner:SAMSUNG ELECTRONICS CO LTD

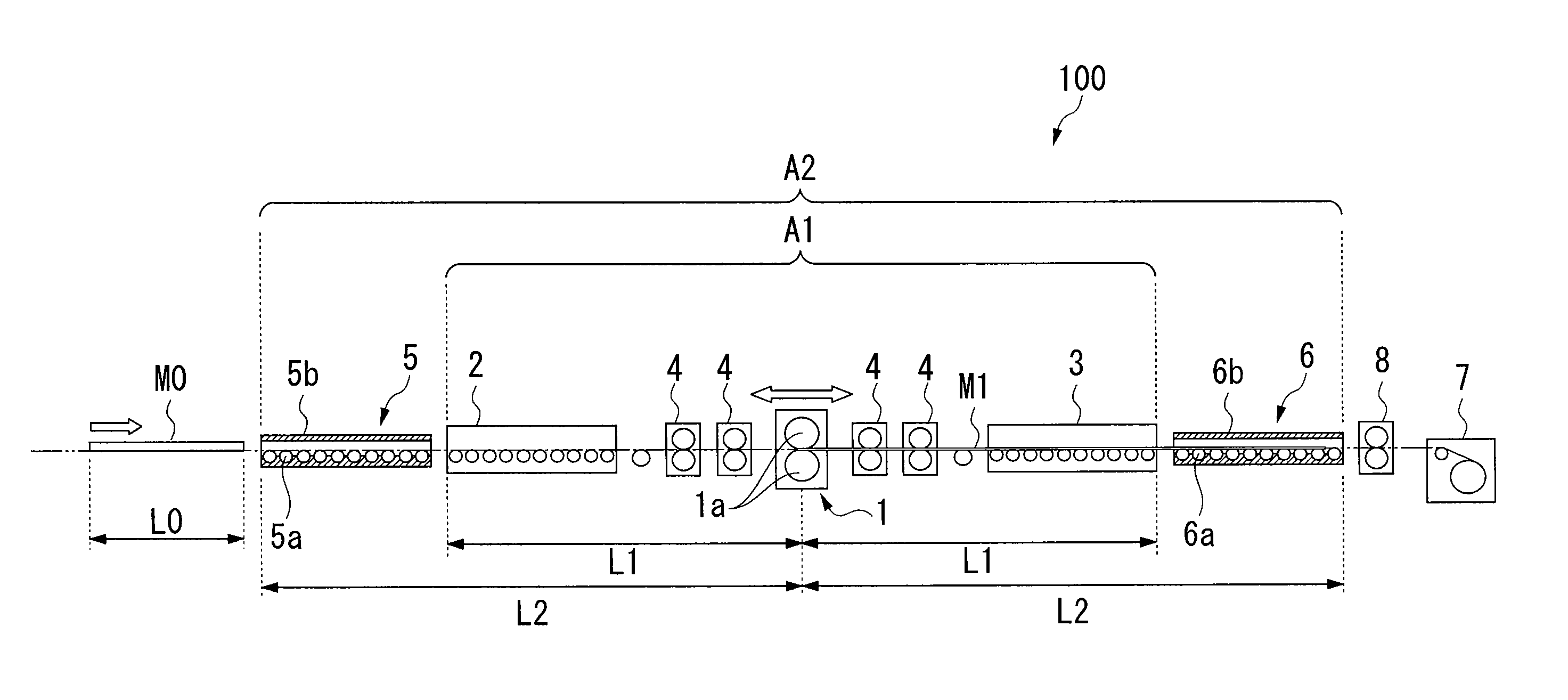

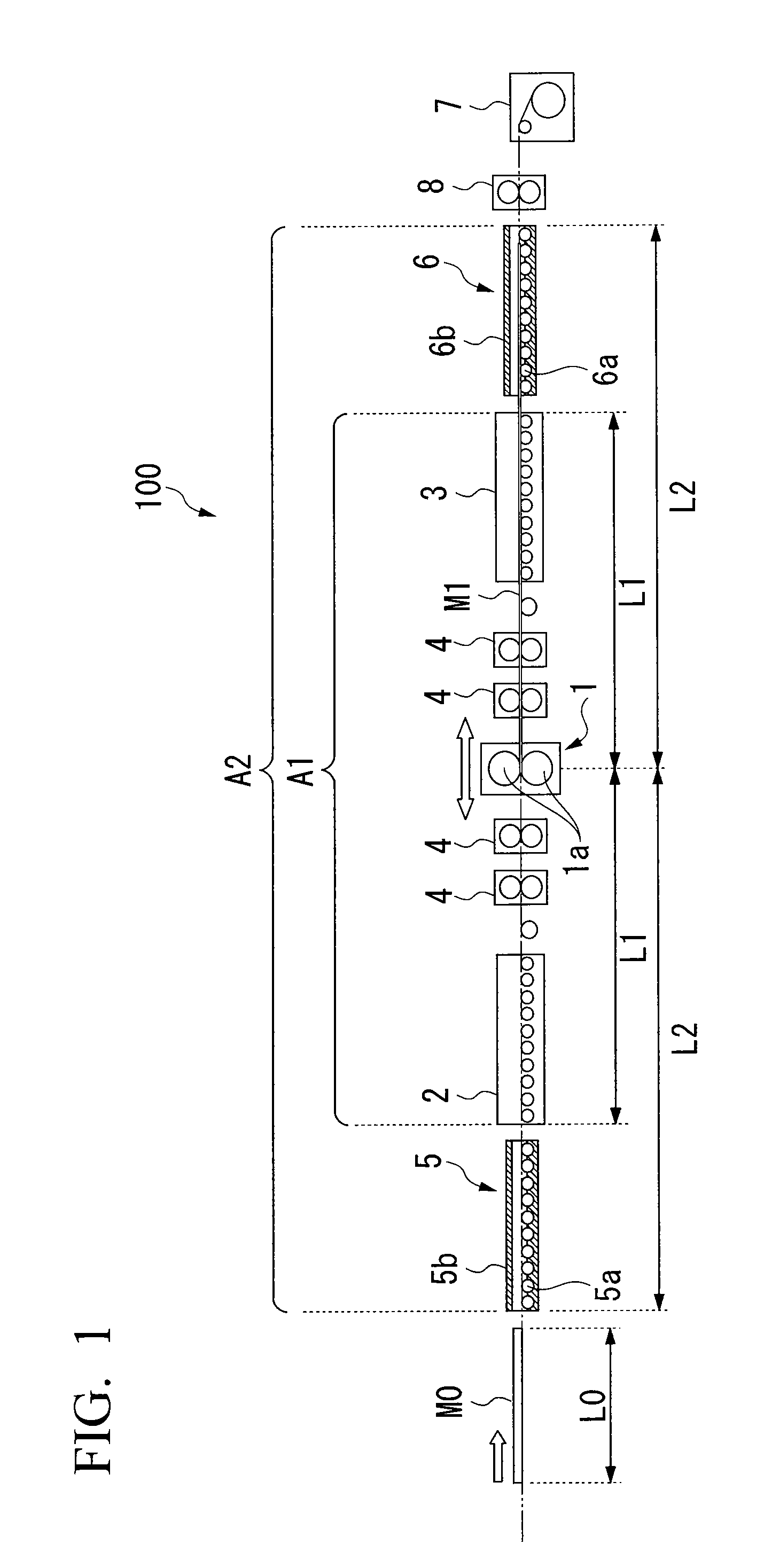

Magnesium hot rolling method and apparatus

InactiveUS20110100083A1Temperature dropSuperior qualityTemperature control deviceRollsHeating furnaceHot rolled

A magnesium alloy hot rolling method includes: a first rolling step in which a magnesium plate (M0, M1) is rolled reciprocatingly between an upstream heating furnace (2) which is located on an upstream side of a rolling mill (1) and which heats the magnesium plate (M0, M1), and a upstream heating furnace (3) which is located on a downstream side of the rolling mill (1) and which heats the magnesium plate (M0, M1); and a second rolling step in which the temperature of respective end portions of the magnesium plate (M0, M1) on both the upstream and downstream sides is maintained while the magnesium plate (M0, M1) is being rolled reciprocatingly between an upstream temperature maintaining apparatus (5) which transports the heated magnesium plate (M0, M1) while maintaining the temperature thereof, and a downstream temperature maintaining apparatus (6) which transports the heated magnesium plate (M0, M1) while maintaining the temperature thereof. According to the magnesium hot rolling apparatus of the present invention and to the magnesium hot rolling method of the present invention which uses this apparatus, it is possible to prevent any deterioration in the quality of a product which is due to temperature variations during the hot rolling of magnesium alloy.

Owner:IHI METALTECH CO LTD +1

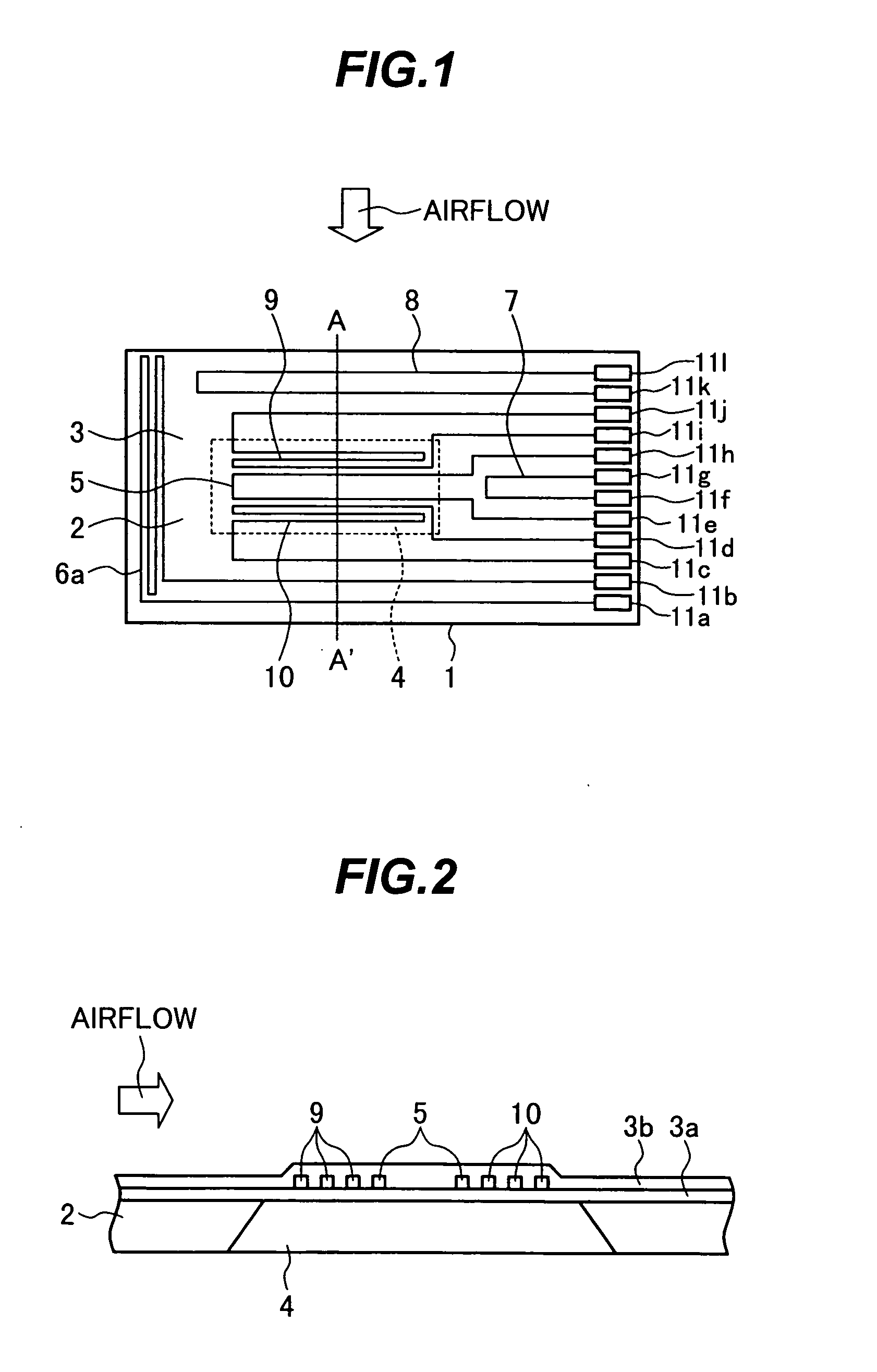

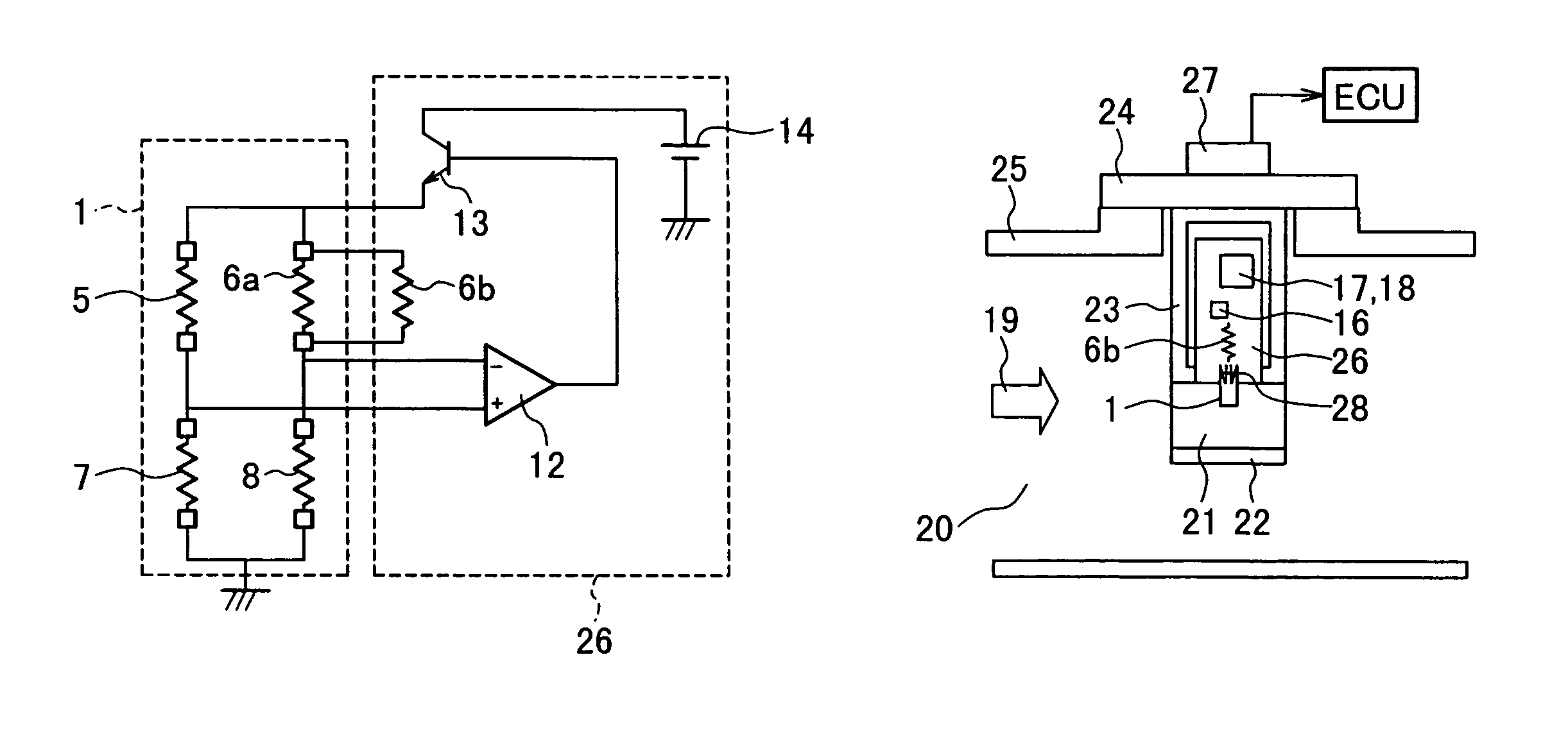

Thermal flowmeter for measuring a flow rate of fluid

InactiveUS7631555B2Guaranteed Error AccuracyImprove accuracyVolume/mass flow by thermal effectsTemperature controlEngineering

A thermal air flowmeter having excellent temperature characteristics and improved measurement accuracy. The thermal air flowmeter includes a temperature sensor disposed in a casing of the air flowmeter, a computing unit for correcting a flow rate detection voltage from a measuring element by using the temperature sensor, and a heating temperature control disposed in a temperature control circuit for performing temperature control of a heating resistor to vary a temperature rise of the heating resistor relative to an air temperature depending on the air temperature. Flow rate detection errors of the thermal air flowmeter caused by an overall temperature change and a temperature change on an intake passage wall surface can be corrected simultaneously and a thermal air flowmeter having superior measurement accuracy can be realized.

Owner:HITACHI LTD +1

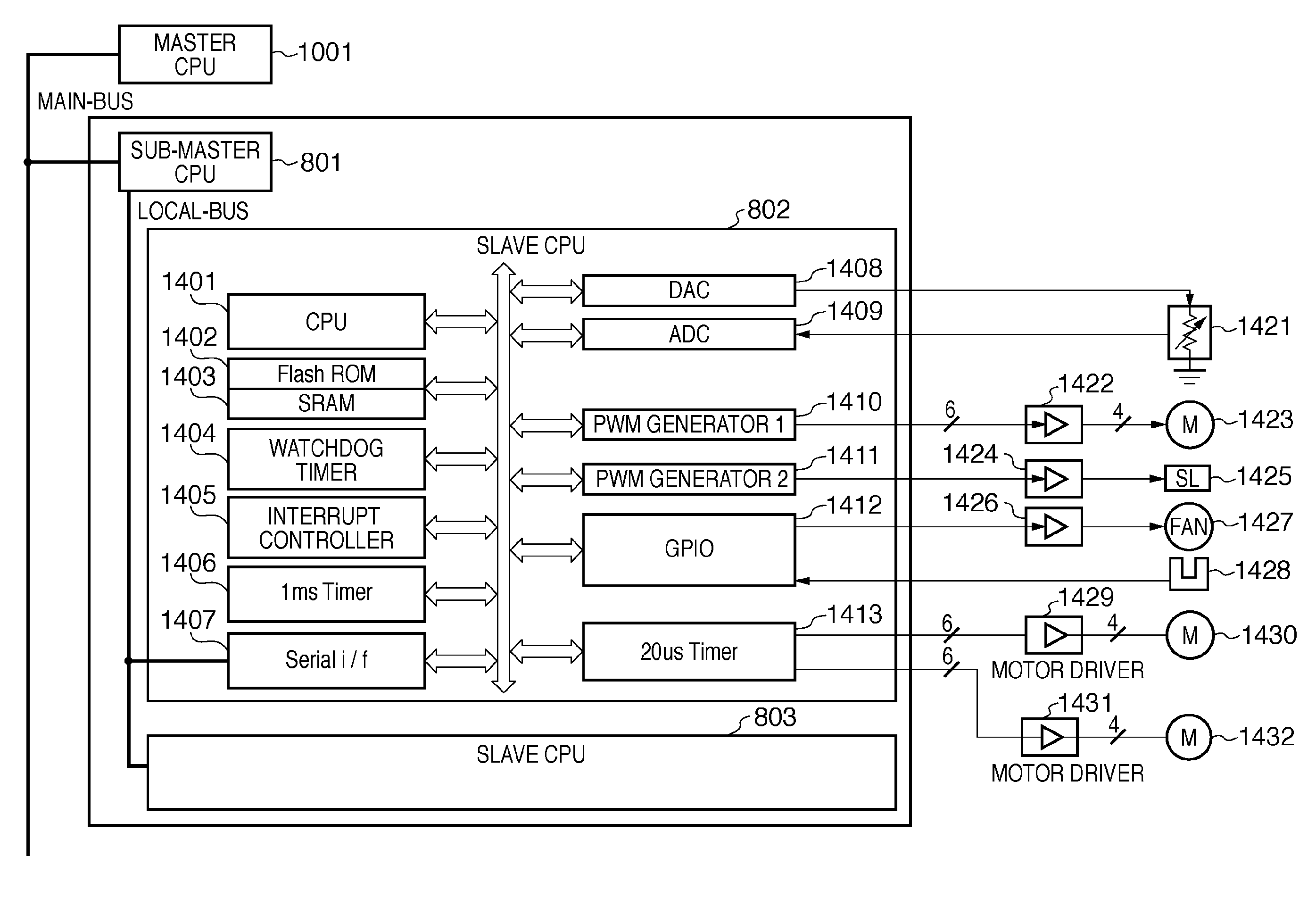

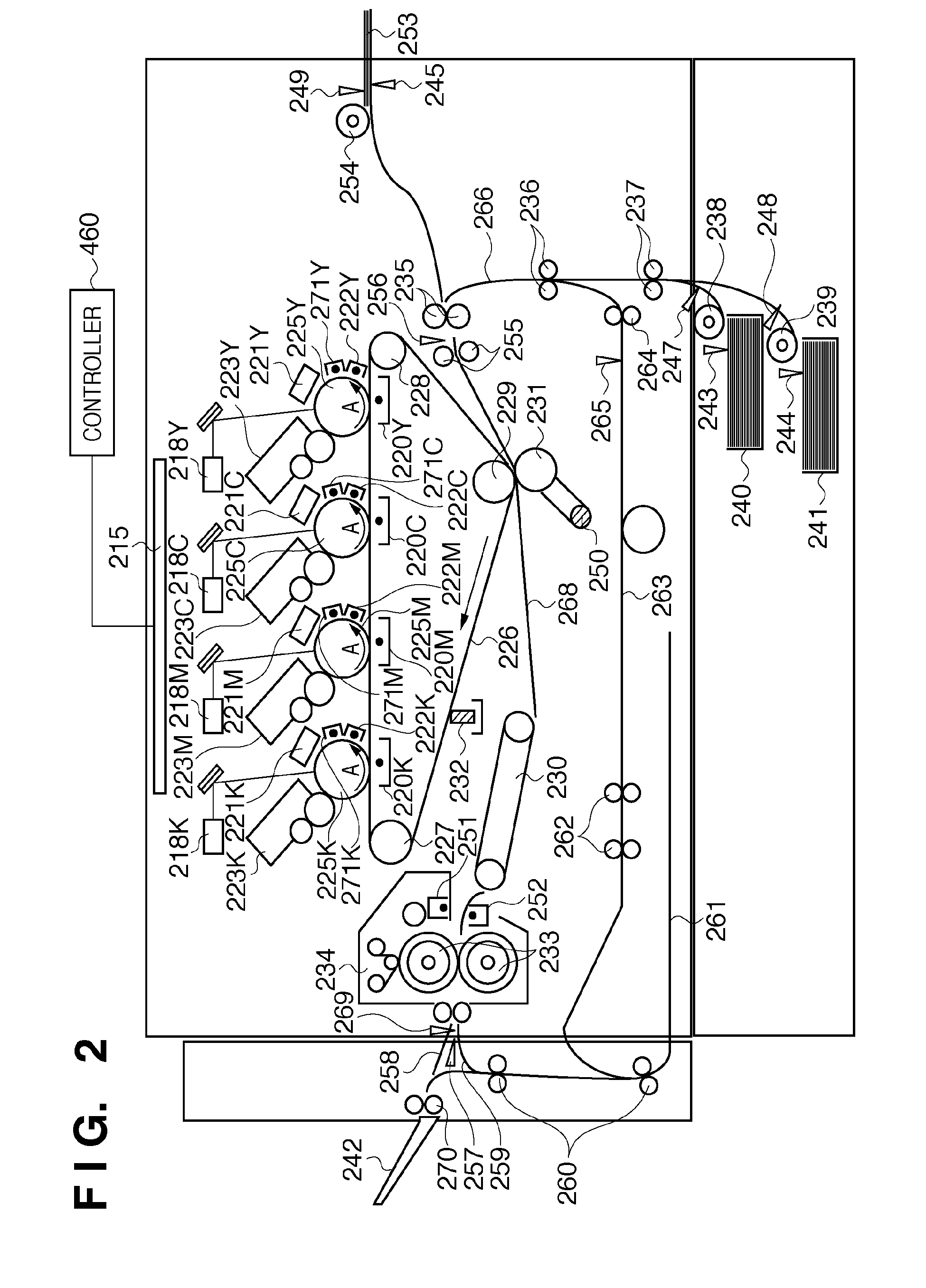

Image forming apparatus

InactiveUS20100268989A1Guaranteed Error AccuracyFault responseElectrographic process apparatusImage formationDistributed control system

There is provided an image forming apparatus which adopts a distributed control system and increases the error detection accuracy of each control unit. To accomplish this, the image forming apparatus includes a master control unit that controls the overall image forming apparatus, a plurality of sub-master control units that control a plurality of functions for performing image formation, and a plurality of salve control units that control loads for implementing a plurality of functions. The master control unit determines a diagnosis path for performing a diagnosis process for an error using the signal lines and connection bridge connected to the respective control units. The master control unit performs the diagnosis process for an error in accordance with the determined diagnosis path.

Owner:CANON KK

Information processing device and information processing method

ActiveUS8527834B2Improve accuracyIncrease the lengthCode conversionError correction/detection using block codesInformation processingComputer science

Owner:ALAXALA NETWORKS

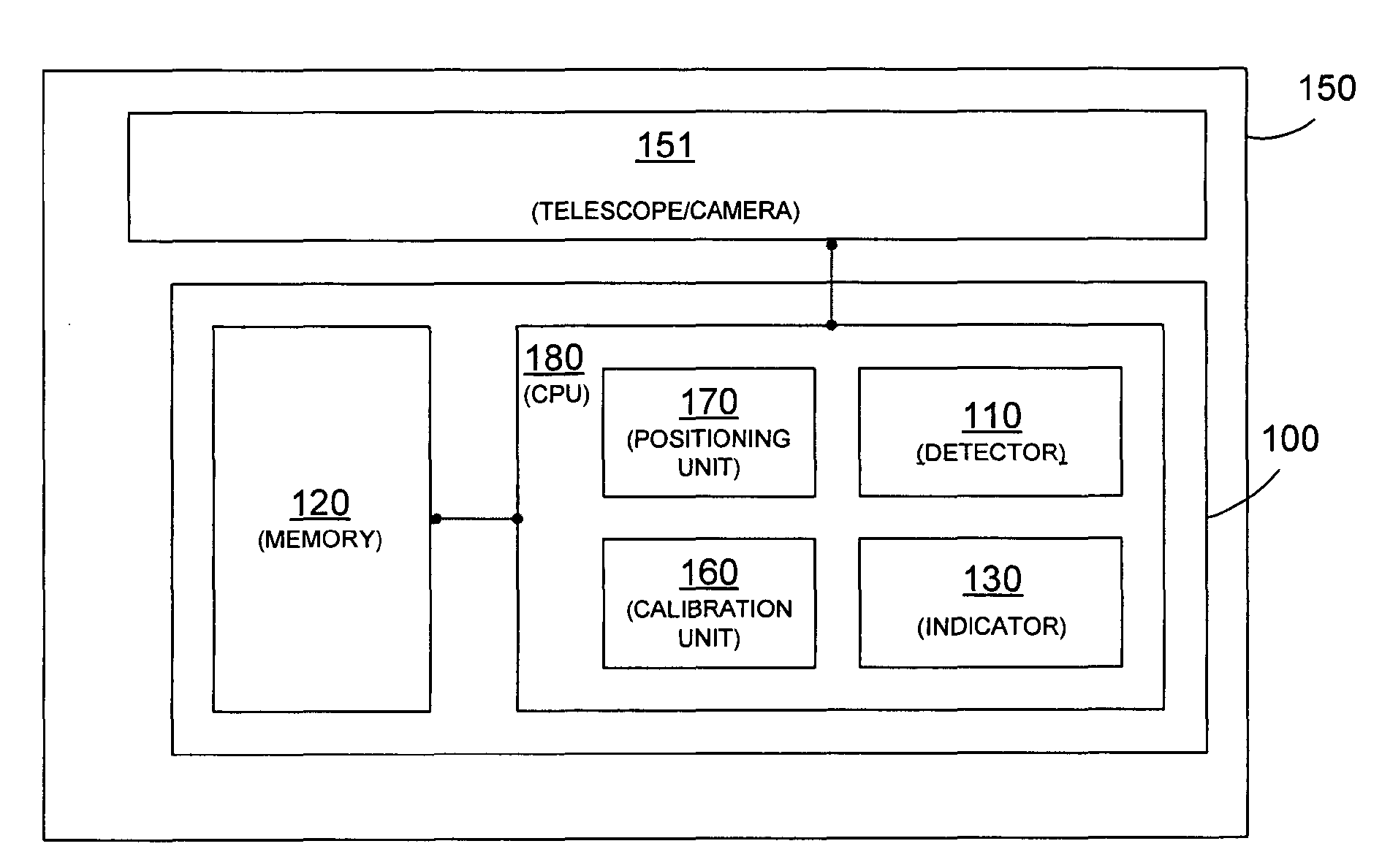

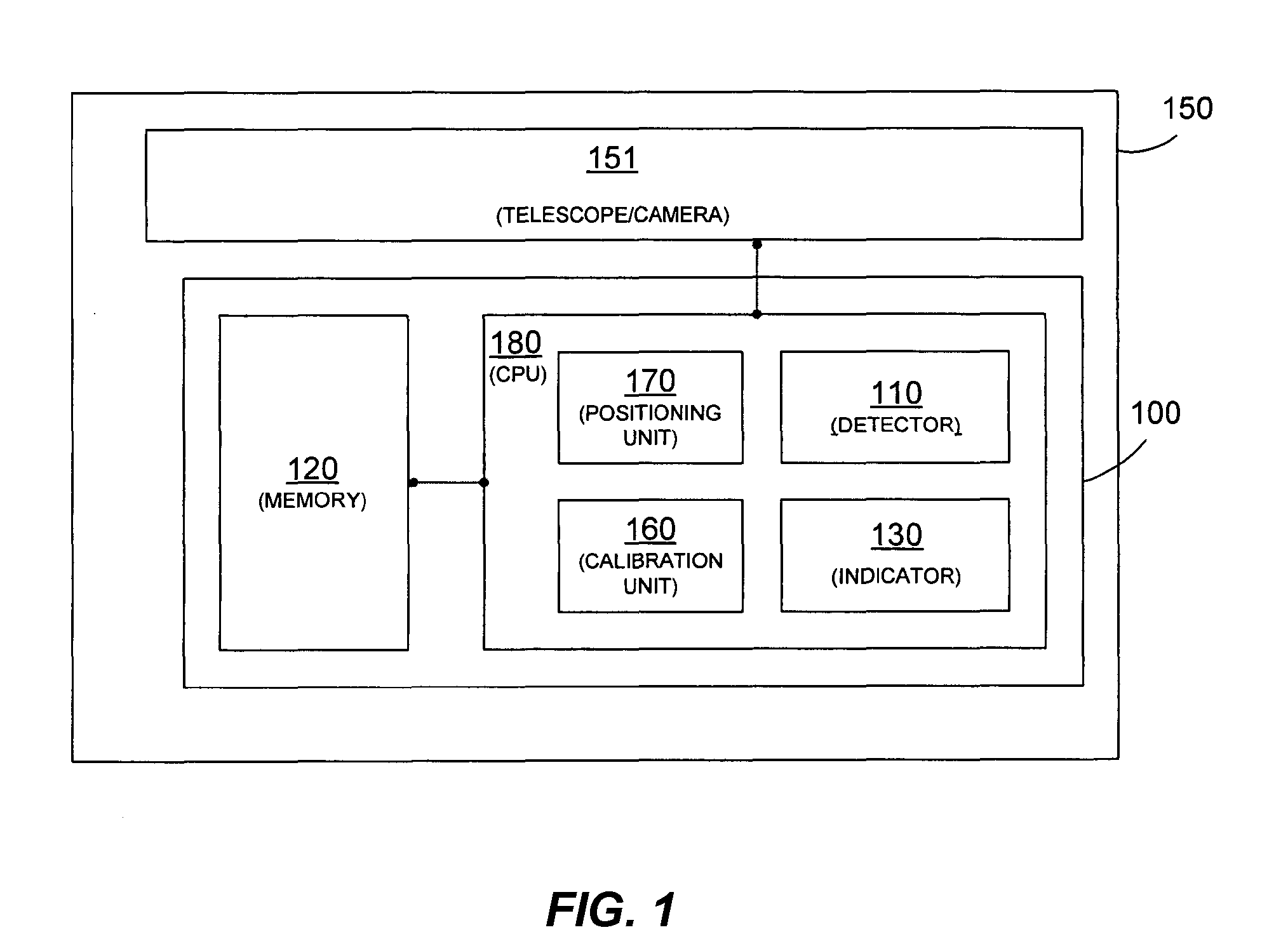

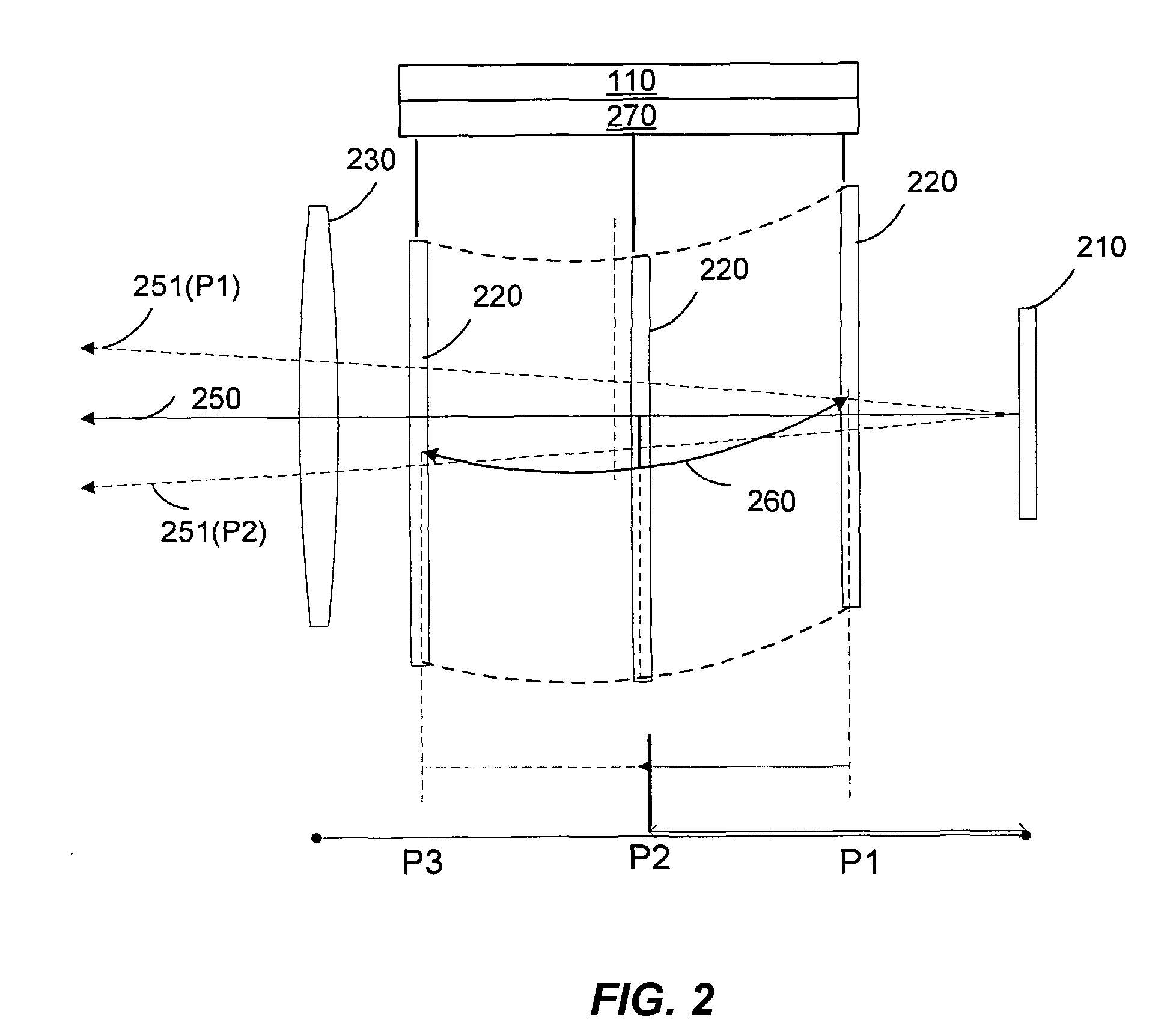

Correction of calibration errors in an optical instrument

ActiveUS20090216476A1Improves accuracy of errorImprove productivitySurveying instrumentsHeight/levelling measurementOptical instrumentImage plane

A calibration error correction device for an optical instrument includes a detector operable to detect a position of a focusing lens of an optical instrument along a mechanical path of the focusing lens. A line of sight through an image plane of the optical instrument and the focusing lens at a present position defines an actual viewing direction. The device also includes a memory configured to store viewing direction errors specifying a deviation between a known theoretical viewing direction and the actual viewing direction associated with a plurality of different positions of the focusing lens along the mechanical path and an indicator of at least one value indicative of the actual viewing direction based on the theoretical viewing direction and the viewing direction errors at each of the different positions of the focusing lens along the mechanical path.

Owner:TRIMBLE JENA

Correction of calibration errors in an optical instrument

ActiveUS8049780B2Guaranteed Error AccuracyImprove productivitySurveying instrumentsHeight/levelling measurementOptical instrumentImage plane

A calibration error correction device for an optical instrument includes a detector operable to detect a position of a focusing lens of an optical instrument along a mechanical path of the focusing lens. A line of sight through an image plane of the optical instrument and the focusing lens at a present position defines an actual viewing direction. The device also includes a memory configured to store viewing direction errors specifying a deviation between a known theoretical viewing direction and the actual viewing direction associated with a plurality of different positions of the focusing lens along the mechanical path and an indicator of at least one value indicative of the actual viewing direction based on the theoretical viewing direction and the viewing direction errors at each of the different positions of the focusing lens along the mechanical path.

Owner:TRIMBLE JENA

Speech retrieval apparatus and speech retrieval method

InactiveUS8504367B2Guaranteed Error AccuracyError robustnessAudio data retrievalSpeech recognitionAcoustic modelSerialization

Owner:RICOH KK

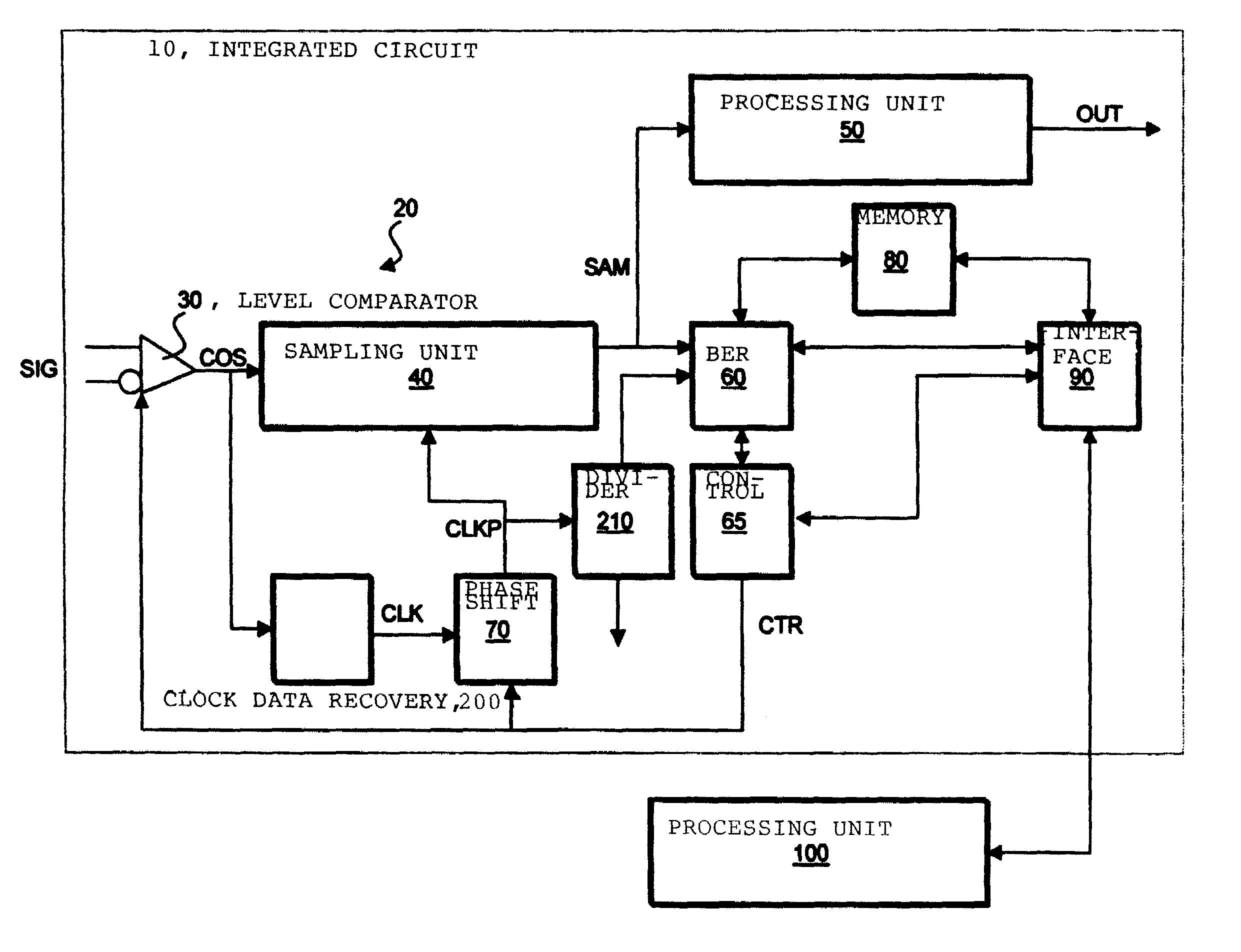

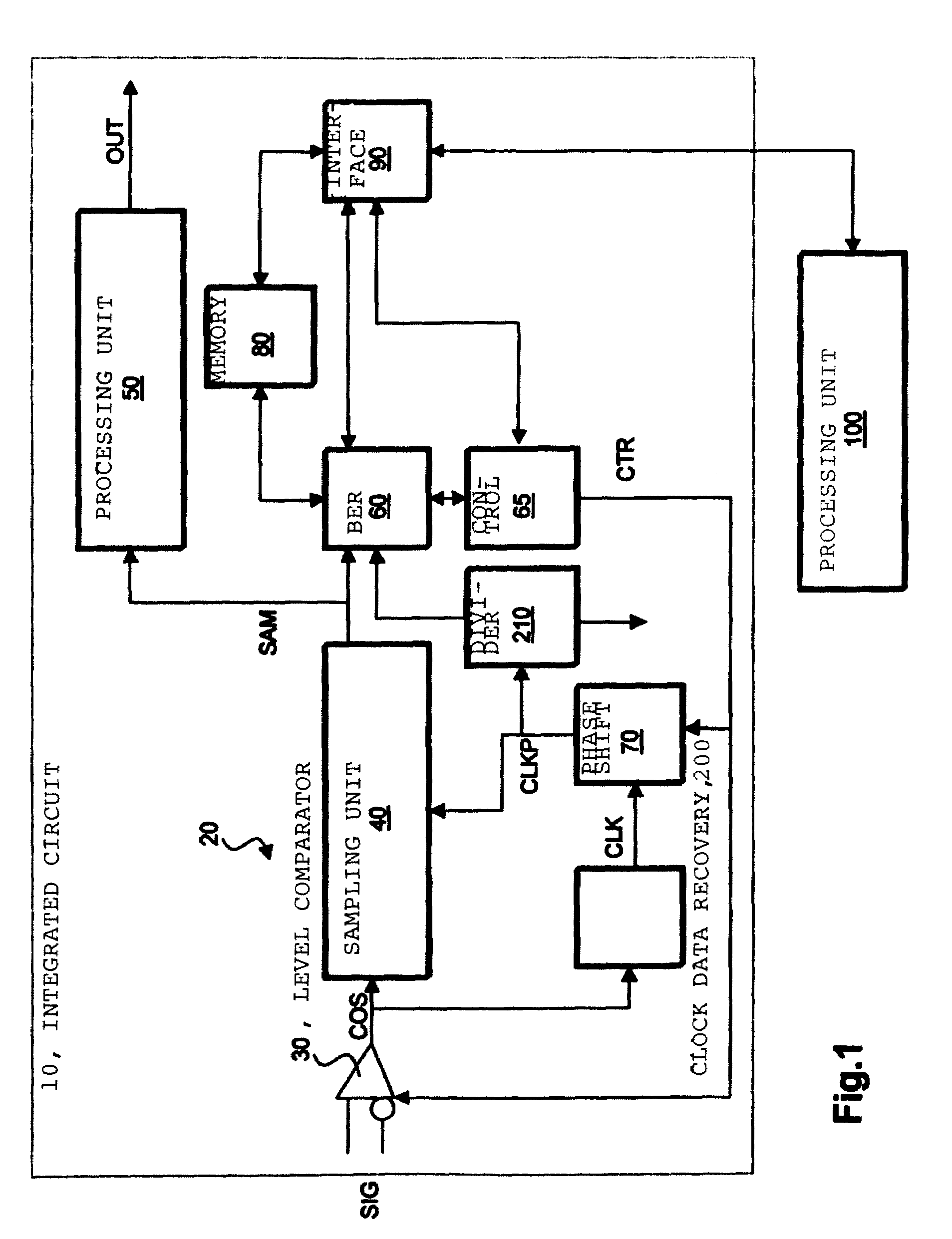

Integrated circuit with bit error test capability

InactiveUS7620515B2Guaranteed Error AccuracyReduce impactError detection/prevention using signal quality detectorDigital circuit testingApplication-specific integrated circuitField-programmable gate array

An integrated circuit (10), preferably a field programmable gate array—FPGA or an application specific integrated circuit—ASIC—, comprises a level comparator (30) for comparing a level of a comparator input signal and correspondingly providing a comparator output signal (COS). A sampling unit (40) is coupled to the level comparator (30) for sampling (SAM) the comparator output signal (COS). A bit error test unit (60) receives the sampled comparator output signal (SAM) and determine therefrom an indication of a bit error in a sequence of the sampled comparator output signal (SAM).

Owner:KEYSIGHT TECH

Installation measurement method of multi-leg pole modular deck sheet

InactiveCN102175109AHigh precisionGuaranteed sizeMechanical measuring arrangementsMeasurement deviceMeasurement point

The invention discloses an installation measurement method of a multi-leg pole modular deck sheet. The method comprises the following steps of: (1) building a reference coordinate system of the deck sheet; (2) selecting a modular key measurement point for measuring a space position coordinate of each leg pole, and taking the modular key measurement point as a coordinate original point to build a relative coordinate system; and measuring the coordinate position of each modular key measurement point in the reference coordinate system of the deck sheet; (3) measuring the space position relative coordinate of each leg pole of the deck sheet which is measured by a measurement device at each modular key measurement point through the measurement device; and (4) converting the space position relative coordinate of each leg pole of the deck sheet into the coordinate in the reference coordinate system of the deck sheet through the coordinate converting relation determined in the step (2), so as to obtain a leg pole installation position. By adopting the method, the high-precision leg pole measurement data can be obtained; the size and the deformation precision of the structure can be guaranteed during the construction process; and the fitting precision and whole error precision of the structure during the final installation process can be guaranteed.

Owner:TIANJIN UNIV

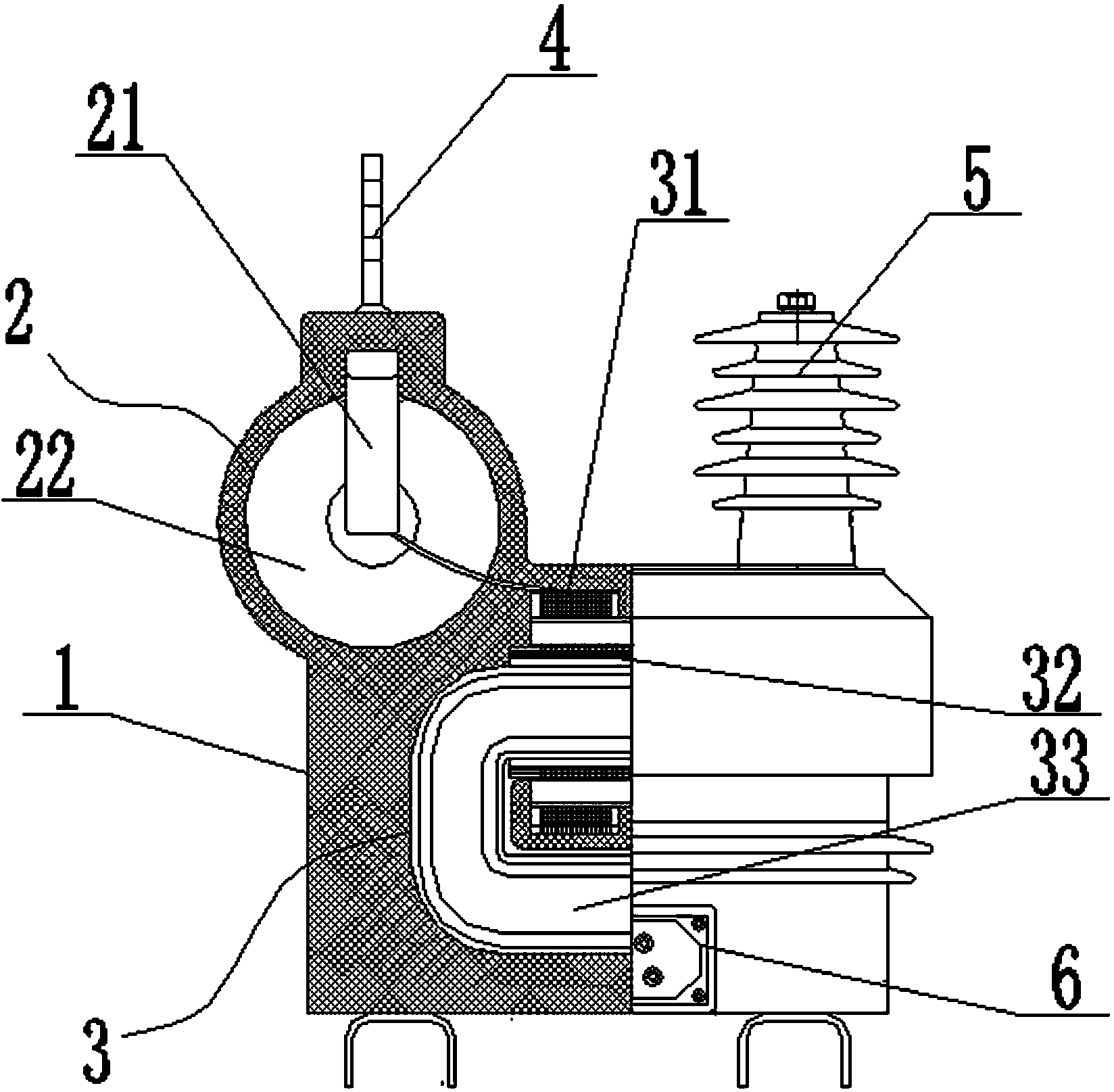

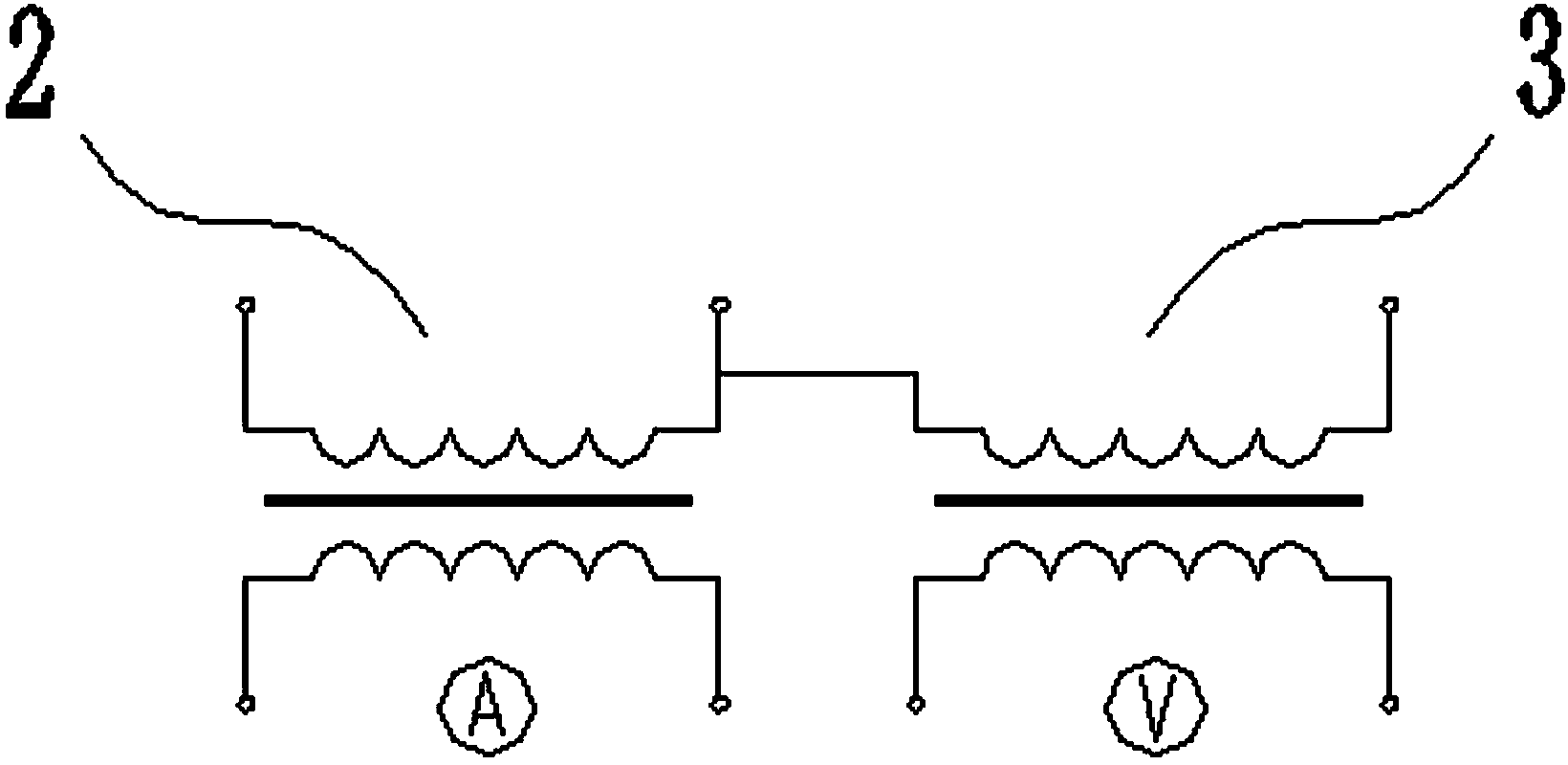

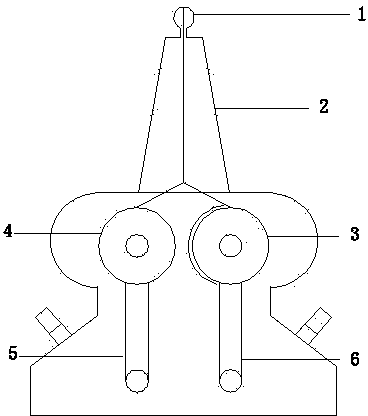

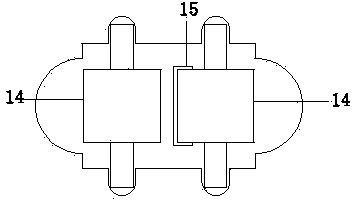

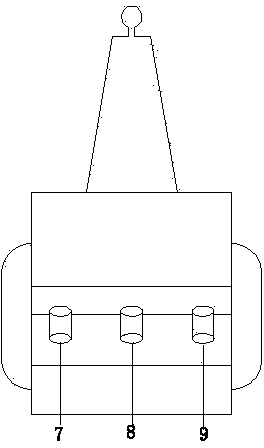

Single-phase pouring type combination measuring dry transformer

InactiveCN104240929AReinforced internal and external insulationMoisture-proofTransformersTransformers/inductances casingsEngineeringThermal stability

The invention relates to a single-phase pouring type combination measuring dry transformer. The single-phase pouring type combination measuring dry transformer comprises a resin case, a current transformer and a voltage transformer, wherein the current transformer is arranged at the upper part of the left end of the resin case; the two terminals of the primary coil of the current transformer are respectively connected to two conducting rods vertically arranged at the left end of the resin case; the voltage transformer is arranged at the lower part of the right end of the resin case; the primary winding of the voltage transformer is connected to any terminal of the primary coil of the current transformer in the resin case; the secondary winding of the voltage transformer is connected to a plug column vertically arranged at the upper part of the right end of the resin case; the winding direction of the primary coil of the current transformer is parallel to the winding direction of the primary winding of the voltage transformer. The single-phase pouring type combination measuring dry transformer is simple in structure, convenient to produce, small in occupied space, large in creep distance, uniform in electric field distribution and high in measuring accuracy, has higher dynamic thermal stability and better overcurrent resistance, and can be suitable for being used in a high-pollution and high-altitude environment.

Owner:江苏科兴电器有限公司

Conductive wire pattern and method of monitoring the bonding error of a film

InactiveUS8144472B2Guaranteed Error AccuracyEfficiency of errorStatic indicating devicesUsing optical meansElectrical conductorEngineering

Owner:CHUNGHWA PICTURE TUBES LTD

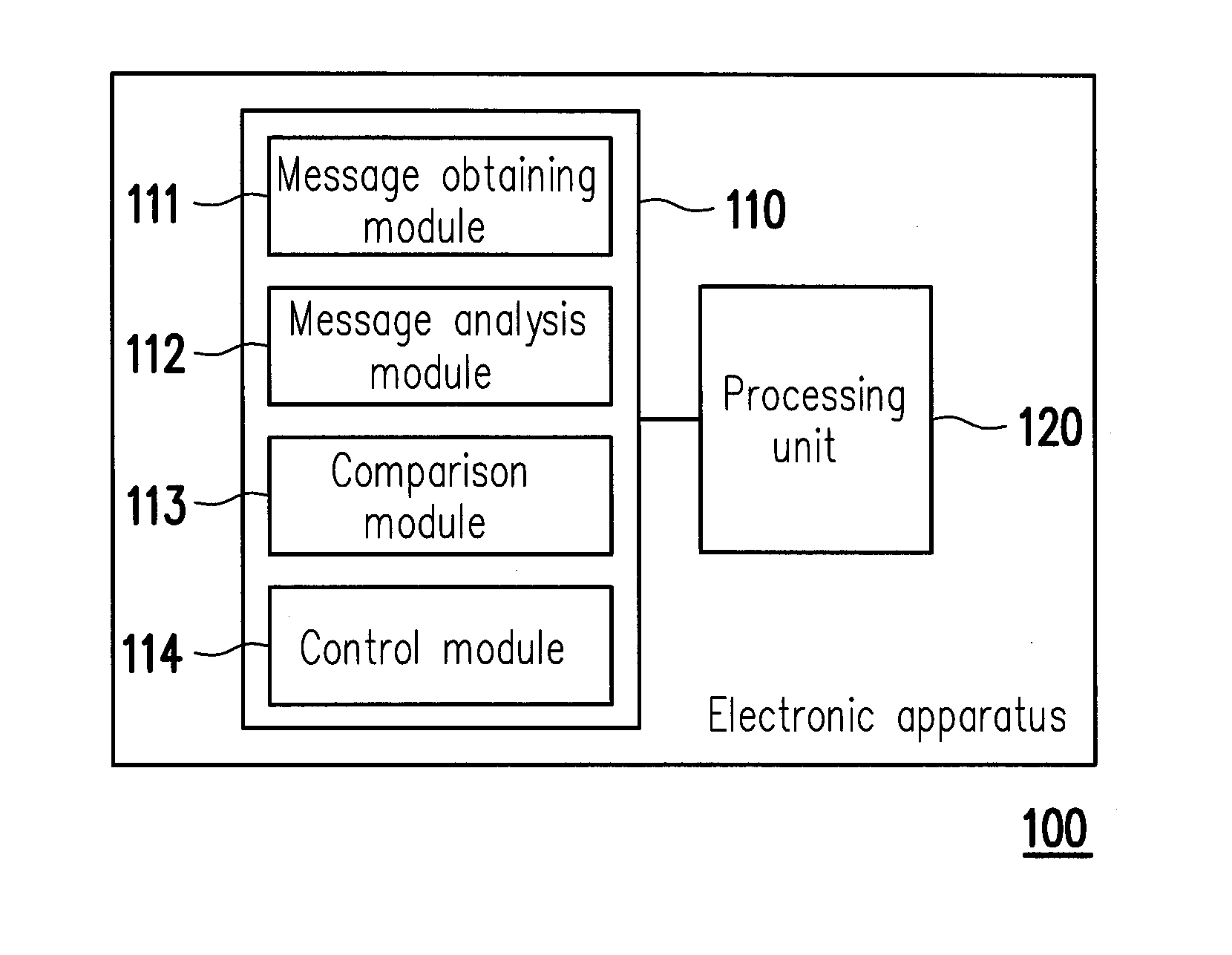

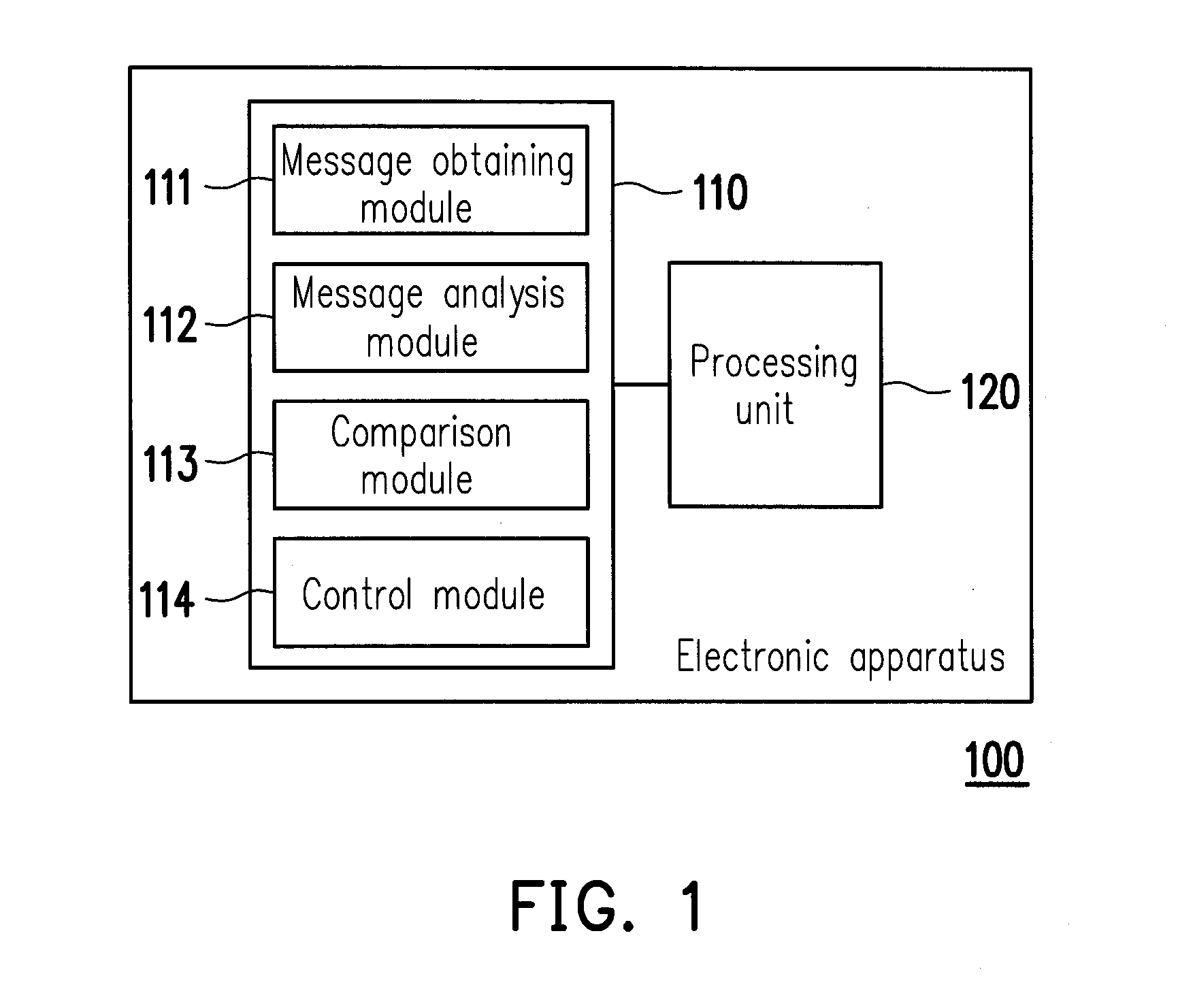

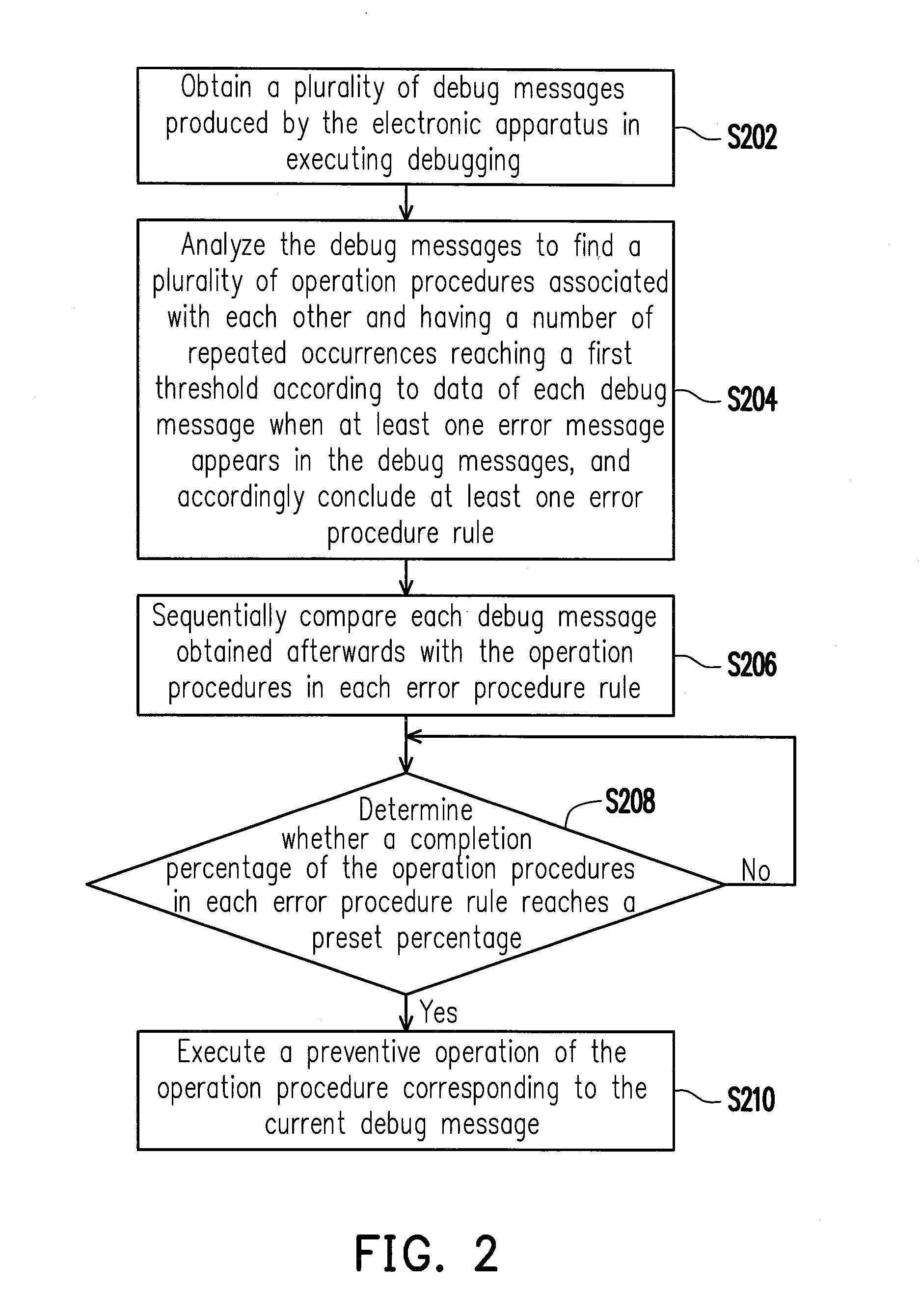

Method, apparatus and computer readable medium for automatic debugging and error prevention

InactiveUS9256513B2Improve stabilityImprove operating experienceSoftware testing/debuggingSpecific program execution arrangementsComputer hardwareError prevention

A method, an apparatus and a computer readable medium for debugging and error prevention are provided. In the method, a plurality of debug messages produced by the electronic apparatus in executing debugging is obtained. The debug messages are analyzed to find a plurality of operation procedures associated with each other and having a number of repeated occurrences reaching a threshold according to data of each debug message when at least one error message appears in the debug messages and accordingly conclude at least one error procedure rule. Then, each debug message obtained afterwards is compared with the operation procedures in each error procedure rule sequentially, so as to determine whether a completion percentage of the operation procedures in each error procedure rule reaches a preset percentage. When the completion percentage reaches the preset percentage, a preventive operation of the operation procedure corresponding to the current debug message is executed.

Owner:WISTRON CORP

Gage and source integrated device for anti-interference digital high-voltage gage calibration

ActiveCN104297712AReduce electromagnetic interferenceConsistent errorElectrical measurementsElectricityTransformer

The invention discloses a gage and source integrated device for anti-interference digital high-voltage gage calibration. The device is characterized by comprising a shell, a voltage regulator, a voltage booster and an anti-electromagnetic interference device located between the voltage regulator and the voltage booster, wherein the voltage regulator, the voltage booster and the anti-electromagnetic interference device are arranged in the shell; a high-voltage terminal is arranged on the top of the shell; the anti-electromagnetic interference device comprises an electric shielding device and a magnetic shielding device. The device has the advantages that a boosting power source and the voltage regulator are integrated, primary leads are connected inside, primary ground wires are connected inside, the gage and source integrated device is formed, the electromagnetic shielding means is adopted, the voltage regulator in the integrated device is shielded, and the electromagnetic interference on the voltage regulator from the boosting power source is reduced. A high permeability magnetic material is added between the booster and the voltage regulator to serve as a magnetic shielding device, magnetic field interference does not exist in the rated capacity range of the booster, and the errors of standard voltage transformers are consistent.

Owner:STATE GRID CORP OF CHINA +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com