Method and apparatus for tracking error detection in optical disk driver

a technology of optical disk driver and error detection, applied in the direction of data recording, instruments, disposition/mounting of heads, etc., can solve the problems of tracking error signal generation, difficult to precisely control tracking in a high-density track structure, and decrease in the magnitude and gain of tracking error signal according to the conventional dpd te method, etc., to achieve the effect of improving such drawbacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Reference will now be made in detail to the present preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings, where like reference numerals refer to like elements throughout.

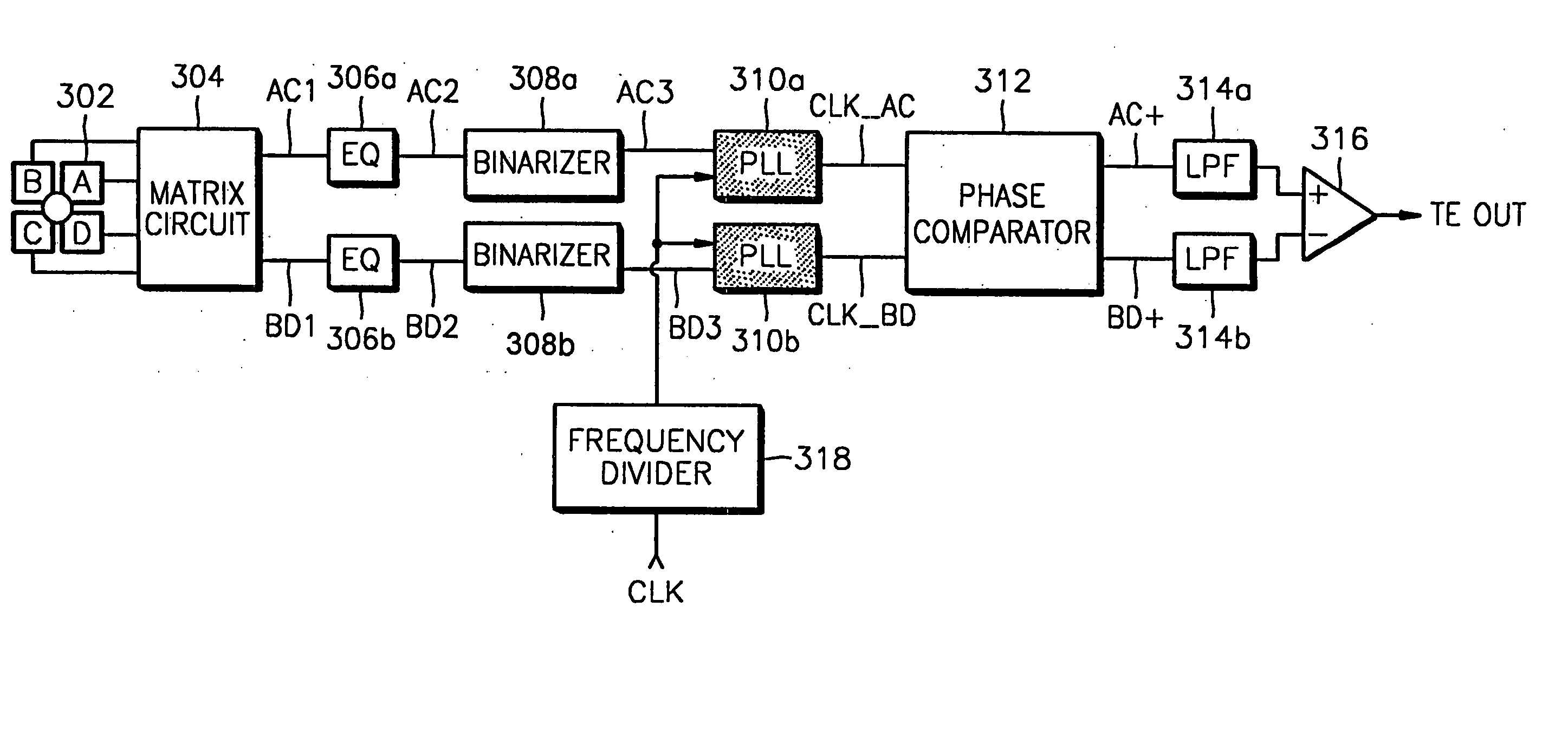

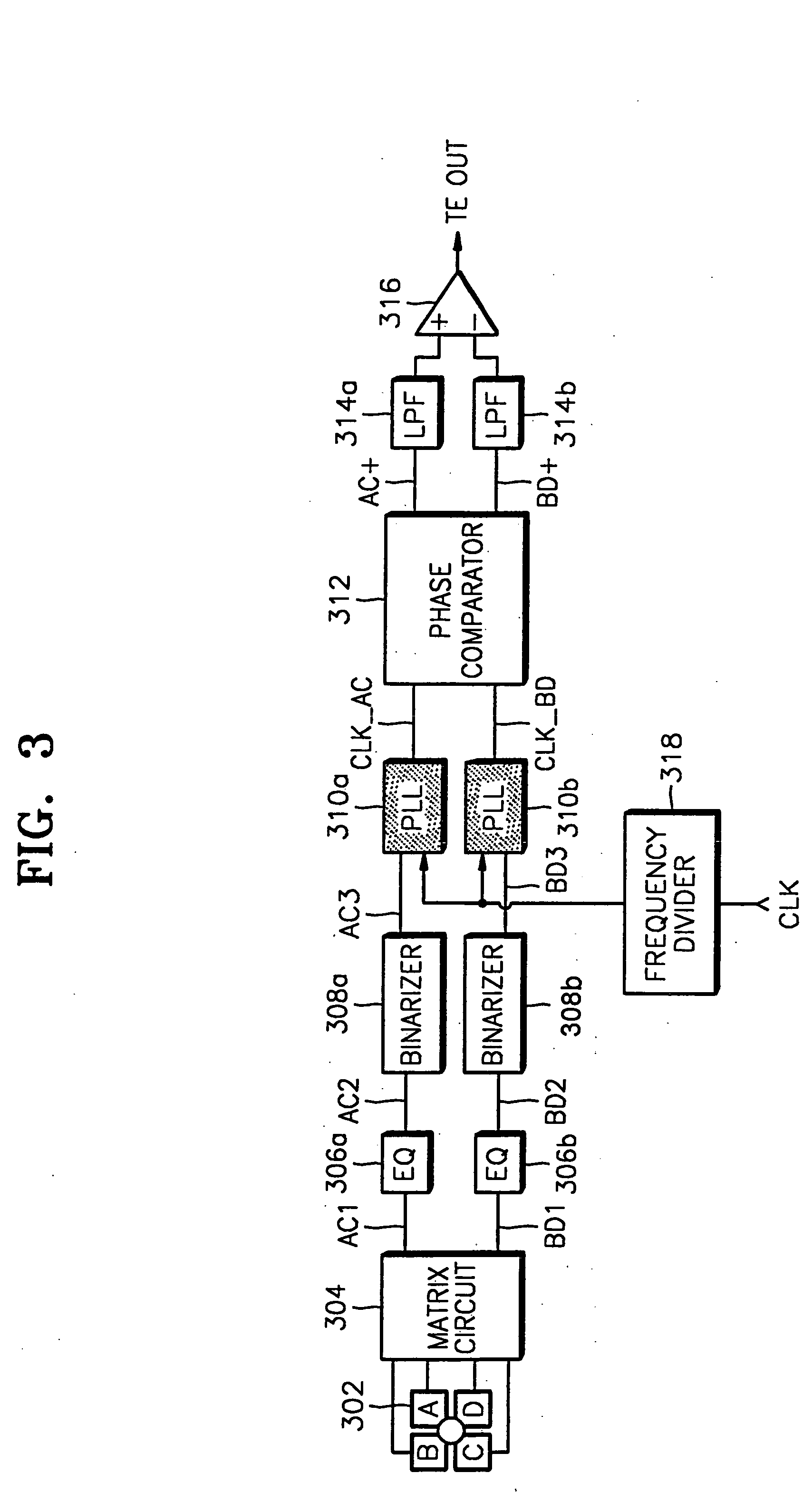

[0031]FIG. 3 is a block diagram showing a first preferred embodiment of a tracking error detecting apparatus according to the present invention. The apparatus shown in FIG. 3 includes a four-section optical detection unit 302, a matrix circuit 304, equalizers (EQs) 306a and 306b, binarizers 308a and 308b, PLLs 310a and 310b, a phase comparator 312, LPFs 314a and 314b, a differential amplifier 316, and a frequency divider 318.

[0032] The matrix circuit 304 adds optical detection signals A and C, and B and D among the outputs A, B, C and D of the four-section optical detection unit 302, and outputs AC1 and BD1 corresponding to A+C and B+D, respectively. That is, the matrix circuit 304 produces summation signals of the signals generated by optical detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com