Single-phase pouring type combination measuring dry transformer

A combined metering and pouring technology, which is applied in the field of transformers, can solve problems such as transformer oil leakage, transformer insulation breakdown, bubble tracking and other problems, and achieve simple procedures, uniform electric field strength, and oil leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

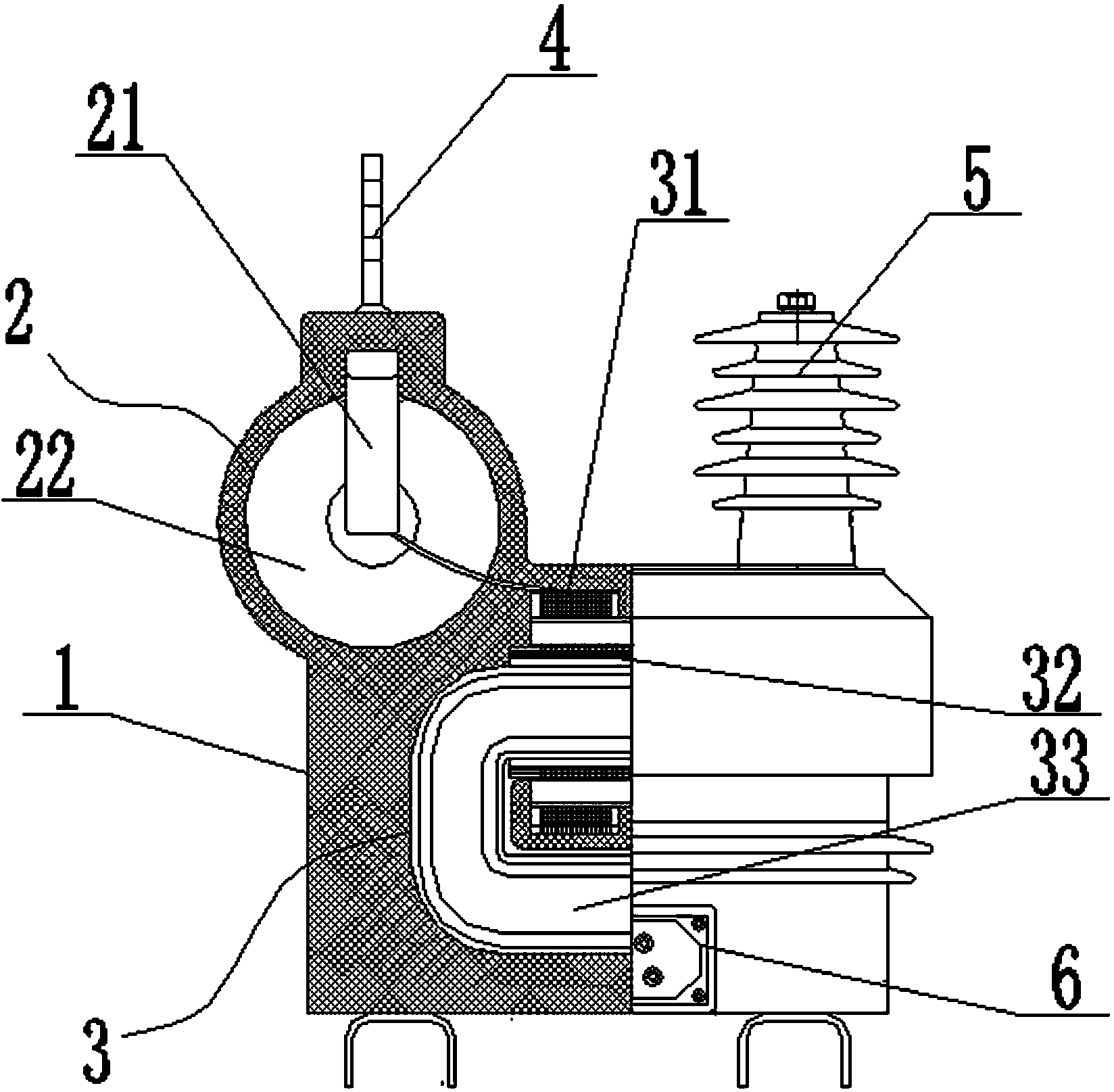

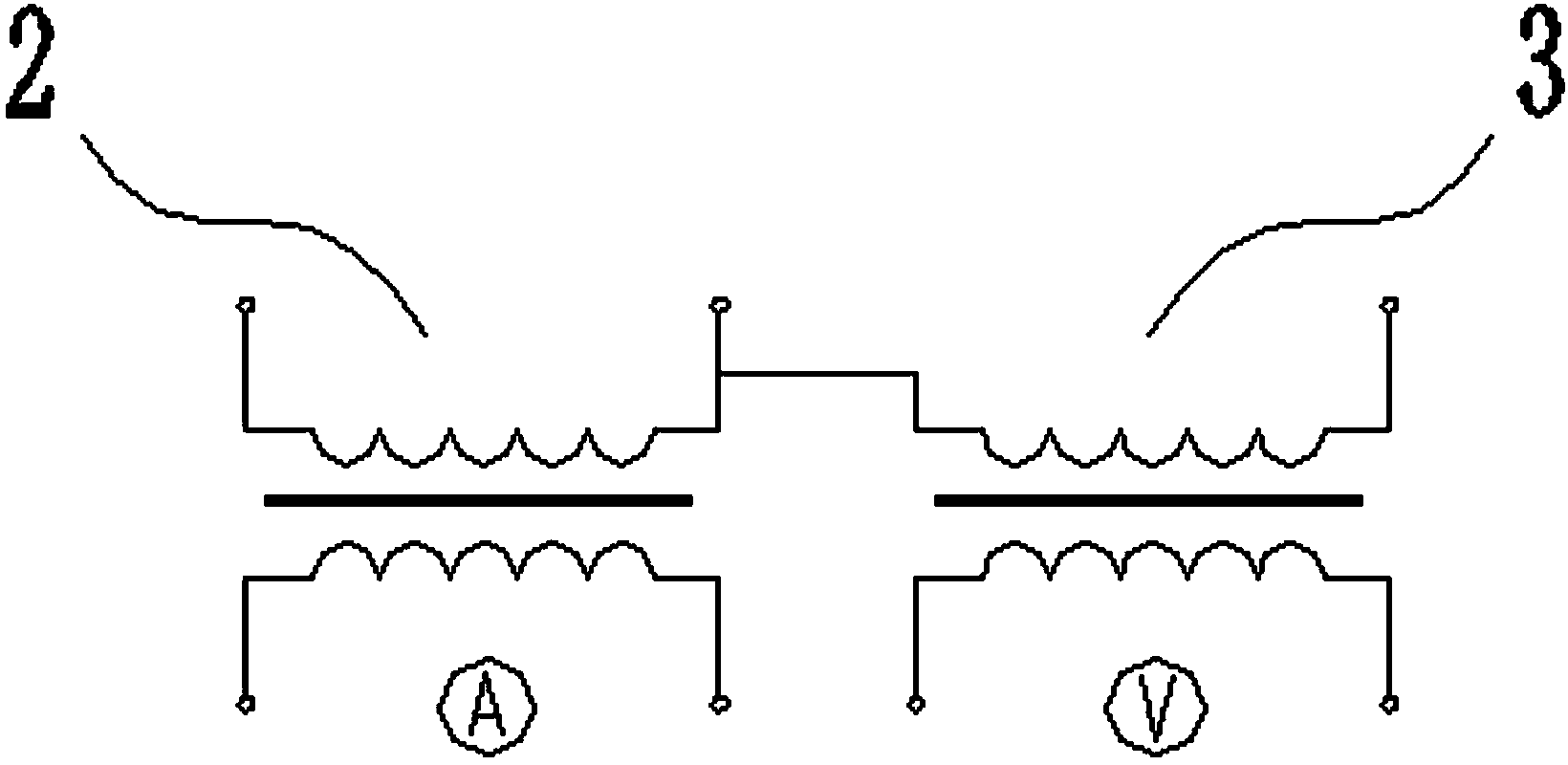

[0019] figure 1 , 2 As shown, a single-phase casting combined metering dry-type transformer includes an outdoor bisphenol A resin shell 1, a current transformer 2, a voltage transformer 3, a conductive rod 4, a plug post 5 and a secondary sealing junction box 6. The outer wall of the outdoor bisphenol A resin shell 1 is provided with a secondary sealing junction box 6, the upper left end of the outdoor bisphenol A resin shell 1 is provided with two conductive rods 4, and the upper right end of the outdoor bisphenol A resin shell 1 is provided with a Only the plug 5; the current transformer 2 is set on the upper left end of the outdoor bisphenol A resin shell 1, and the two terminals of the primary coil 21 of the current transformer 2 are respectively connected to two conductive rods 4; the voltage transformer 3 is set on the outdoor bisphenol A The lower part of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com