Leveling and aligning device and method for point of micro abrasive particle protruding edge of rough diamond abrasion wheel

A diamond grinding wheel and rough diamond technology, which is applied in the field of diamond grinding wheel tool sharpening and leveling, can solve the problems of uneven surface quality, low dressing efficiency, corrosive liquid treatment, etc. Effect, effect of preventing gap blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

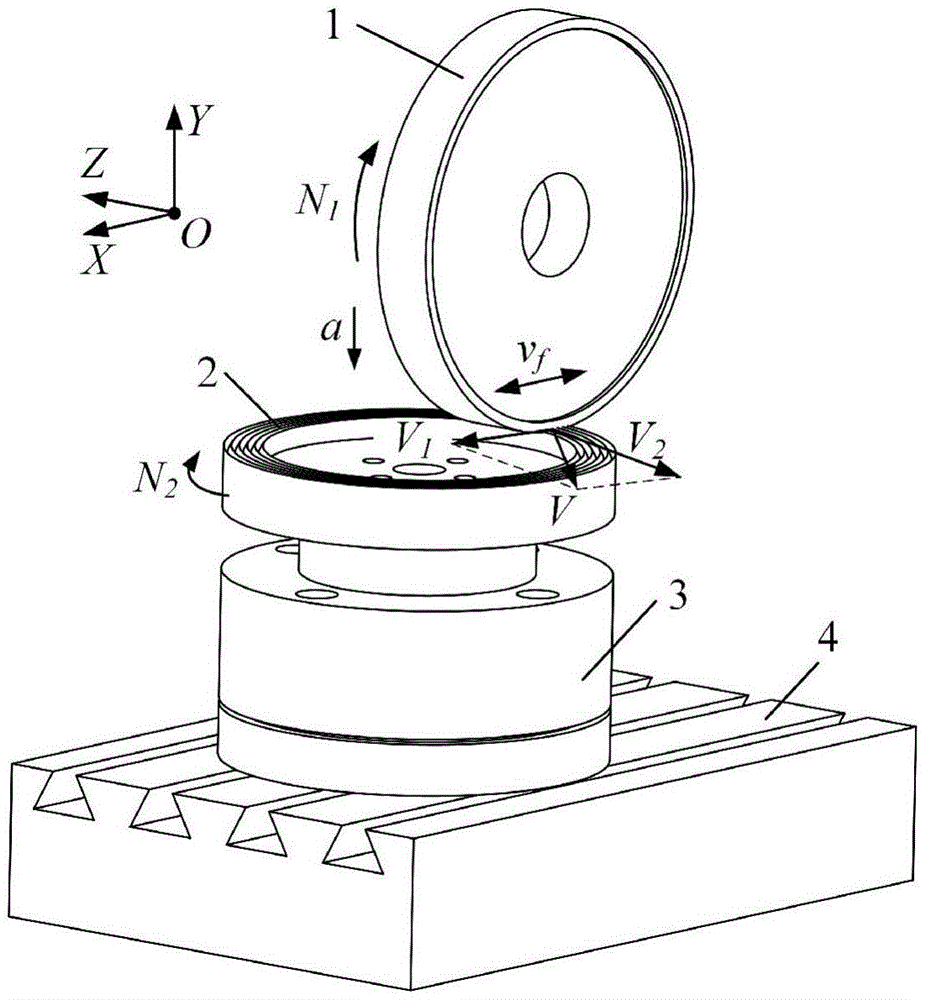

[0023] like figure 1 As shown, a device for smoothing and trimming the tip of a coarse diamond grinding wheel with microabrasive grains, including a grinding disc 2 with a particle size of 600 to 3000 meshes, and an air shaft 3, the grinding disc 2 is mounted on the air shaft 3, and the The air shaft 3 is fixed on the horizontal workbench 4 of the CNC machine tool, the grinding disc 2 is a diamond grinding disc containing cast iron micropowder, and the grinding surface of the grinding disc 2 is uniformly provided with A circular microstructure array, the cross-section of the microstructure array is a zigzag microgroove, the included angle of the zigzag microgroove is 60 degrees, the depth is 700 microns, and the distance between adjacent zigzag microgrooves is 808 Micron.

[0024] The microstructure array on the grinding disc 2, on the one hand, can ensure that the contact point between the grinding disc 2 and the diamond grinding wheel 1 changes at all times during the grind...

Embodiment 2

[0032] like figure 1 As shown, the present embodiment adopts the orthogonal grinding method, and the grinding disc 2 is installed on the workbench, the rotation axis is the Y axis, the rotation axis of the diamond grinding wheel 1 is the Z axis, and the diamond grinding wheel 1 moves back and forth along the surface of the grinding disc 2. Feed movement to realize the orthogonal grinding and trimming of the grinding wheel. The specific process is:

[0033] A method for smoothing and trimming the tip of the edge of the coarse diamond grinding wheel using the device, comprising the steps of:

[0034]1) The diamond grinding wheel 1 (135 mm in diameter and 8 mm in thickness) with a particle size of 46 objects is installed on the grinding wheel shaft of the surface grinder (PSG52DX) of the air static pressure shaft, and the grinding disc 2 (diameter 2) containing cast iron micropowder diamond is housed 160 millimeters, the air shaft 3 of thickness 15 millimeters) is fixed on the h...

Embodiment 3

[0041] like figure 1 As shown, the present embodiment adopts the orthogonal grinding method, and the grinding disc 2 is installed on the workbench, the rotation axis is the Y axis, the rotation axis of the diamond grinding wheel 1 is the Z axis, and the diamond grinding wheel 1 moves back and forth along the surface of the grinding disc 2. Feed movement to realize the orthogonal grinding and trimming of the grinding wheel. The specific process is:

[0042] A method for smoothing and trimming the tip of the edge of the coarse diamond grinding wheel using the device, comprising the steps of:

[0043] 1) Install the diamond grinding wheel 1 (diameter 150 mm, thickness 5 mm) with a particle size of 120 on the grinding wheel shaft of the CNC numerical control grinding machine (SMART-B818), and the grinding disc 2 (diameter 100 mm) containing cast iron micropowder diamond , the air shaft 3 of thickness 10 millimeters) is fixed on the horizontal table 4 of grinding machine, makes th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com