Aluminum shell lithium battery sealing equipment

A technology of sealing equipment and lithium batteries, which is applied to battery pack components, non-aqueous electrolyte batteries, non-aqueous electrolyte batteries, etc., and can solve problems such as very high requirements for operator proficiency, high manual proficiency requirements, and large manpower demand , to achieve the effect of compact structure, precise process control and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

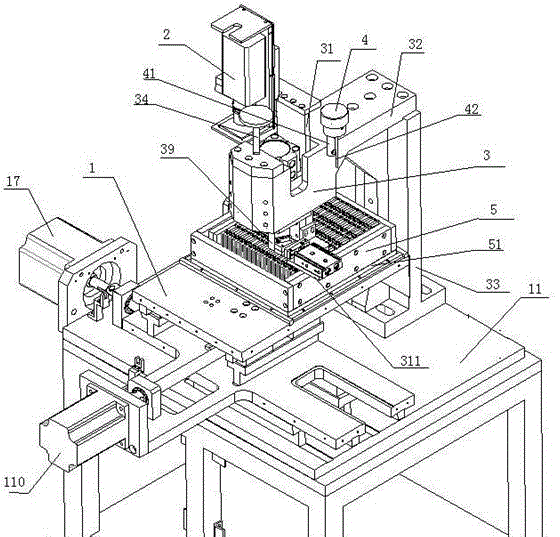

[0023] As shown in the figure, an aluminum shell lithium battery sealing equipment consists of an X / Y axis coordinate platform system (1), a camera system (2), a steel ball sealing system (3), a steel ball lowering system (4) and a battery installation system ( 5) Composition;

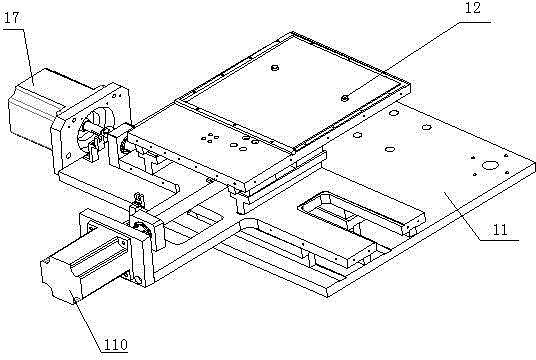

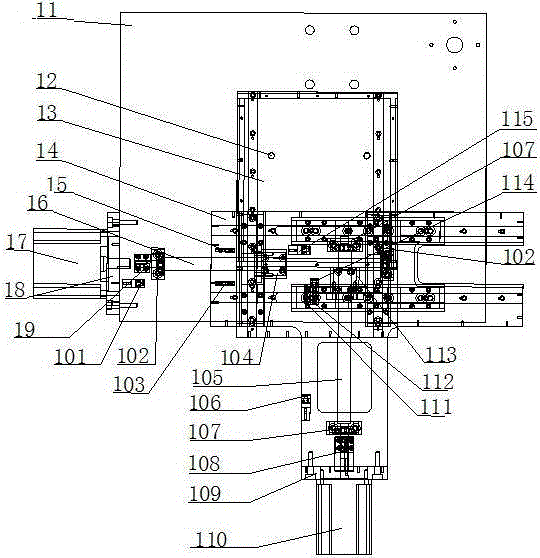

[0024] The X / Y axis coordinate platform system (1) includes an X plate (14), a Y plate (13), an X screw pair (16), a Y screw pair (105), a positioning pin (12), a bottom plate (11 ); the X-axis motor (17) is installed on the motor base (18) and fixed on the base plate (11), and the X-axis motor (17) outputs power through the connected X screw pair (16) to drive the The X screw seat (104), and the X plate (14) connected with the X screw seat (104) moves axially towards the X axis through the linear guide rail (119), and the photoelectric sensor installed on the bottom plate (11) Inductors (101) (115) respectively sense the induction block (15) (103) to control the X-axis movement limit, and the Y-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com