Seamless titanium welded pipe and manufacturing method thereof

A production method and technology of titanium welded pipes, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

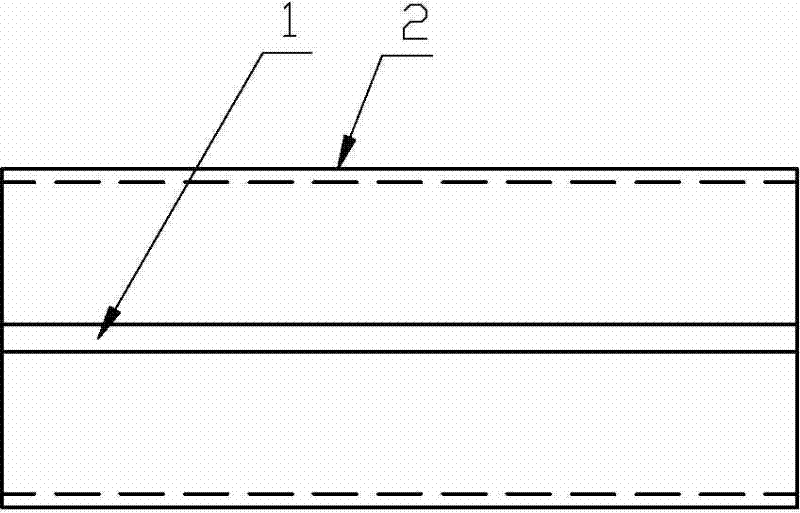

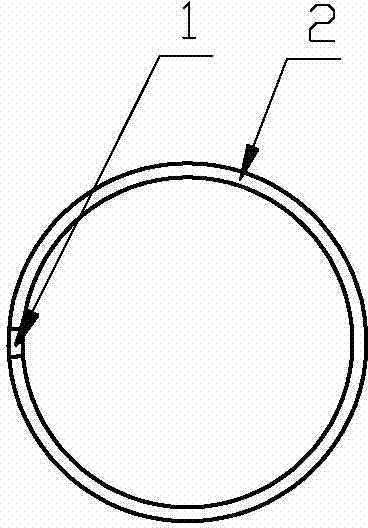

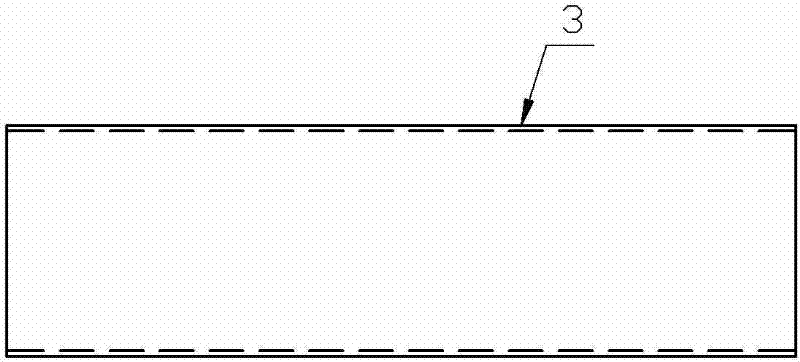

[0024] Depend on figure 1 , figure 2 , image 3 , Figure 4 It can be seen that a seamless titanium welded pipe is made of a mother pipe 2 after at least one pass of cold rolling, diameter reduction and wall reduction, and heat treatment. The mother pipe 2 is a straight seam welded titanium pipe, and the seamless titanium welded pipe prepared 3 Appearance The original weld 1 is not visible on the surface, and the wall thickness and outer diameter are uniform.

[0025] The outer diameter of the main pipe 2 in the present invention is 18 mm to 38 mm, and the wall thickness is 0.5 mm to 2.0 mm. The outer diameter of the seamless titanium welded pipe 3 is 16 mm to 35 mm, and the wall thickness is 0.3 mm to 1.5 mm. mm.

[0026] This embodiment takes the production of seamless titanium welded pipe 3 with an outer diameter of 25.4 mm, a wall thickness of 0.3 mm, and a length of 17000 mm as an example to further illustrate the present invention. The main pipe 2 is selected to ha...

Embodiment 2

[0038] Manufacture a seamless titanium welded pipe 3 with an outer diameter of 19mm, a wall thickness of 0.3mm, and a length of 15000mm.

[0039] In this embodiment, a TA2-grade straight seam welded titanium tube with an outer diameter of 22 mm, a wall thickness of 0.8 mm, and a length of 5000 mm is selected as the parent tube 2 .

[0040] In step (2), five cold rolling passes are carried out in this embodiment, and an intermediate annealing is added between every two passes of cold rolling.

[0041] In the first cold rolling, a mold with an inner diameter of 21.3mm and a mandrel with an outer diameter of 19.9mm is used; after intermediate annealing, the second cold rolling is performed with a mold with an inner diameter of 20.6mm and a mandrel with an outer diameter of 19.4mm; After annealing, the third cold rolling is carried out, using a mold with an inner diameter of 19.9mm and a core rod with an outer diameter of 18.9mm; after intermediate annealing, the fourth cold rolli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com