Preparation method of corrugated interface steel-titanium composite tube

A composite pipe and interface technology, which is applied in the field of bimetal composite pipe preparation, can solve the problems of low composite interface strength, low interface cleanliness, poor forming performance, etc., and achieve optimal design, simple and easy preparation method, and good sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

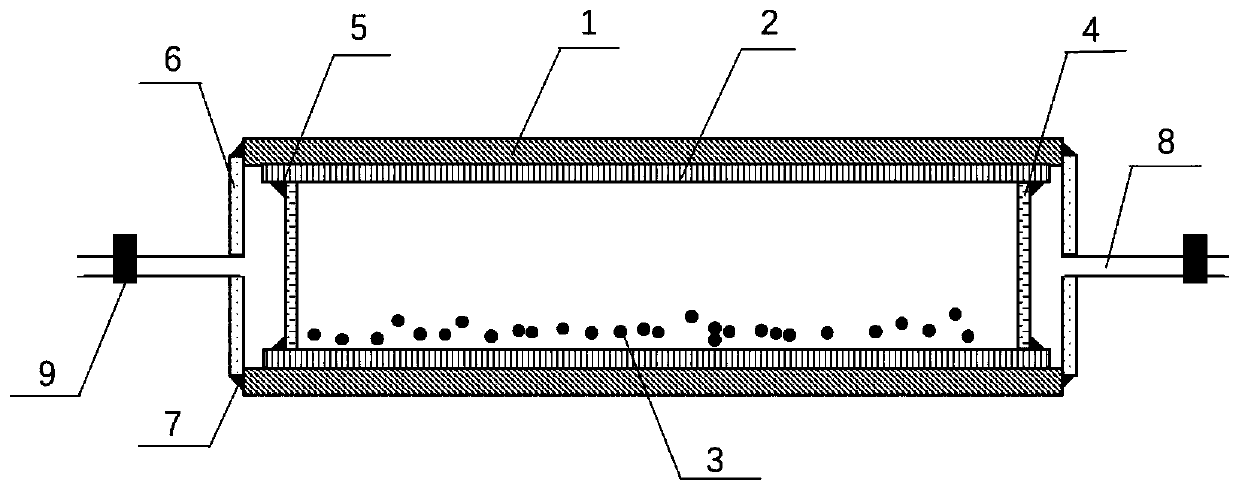

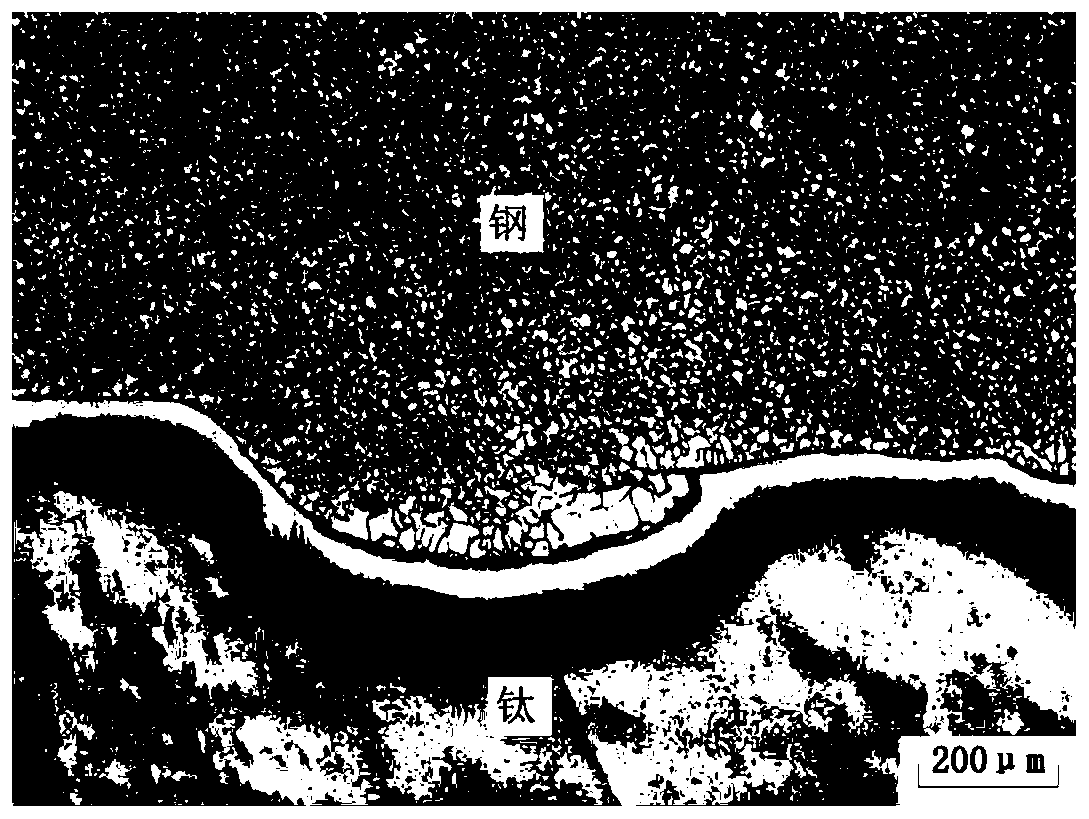

[0037] The invention provides a method for preparing a corrugated interface steel-titanium composite pipe, such as Figure 1 to Figure 4 As shown, the corrugated interface steel-titanium composite pipe includes a steel pipe 1 arranged on the outer layer and a titanium pipe 2 arranged on the inner layer, and its preparation method includes the following steps:

[0038] S1. Process the inner surface of the steel pipe 1 and the outer surface of the titanium pipe 2 into convex annular corrugations or double-sided annular spiral corrugated grooves by rolling process;

[0039] S2. Using degreasing and pickling processes to remove impurities and oxides on the surface of the steel pipe 1 and the titanium pipe 2;

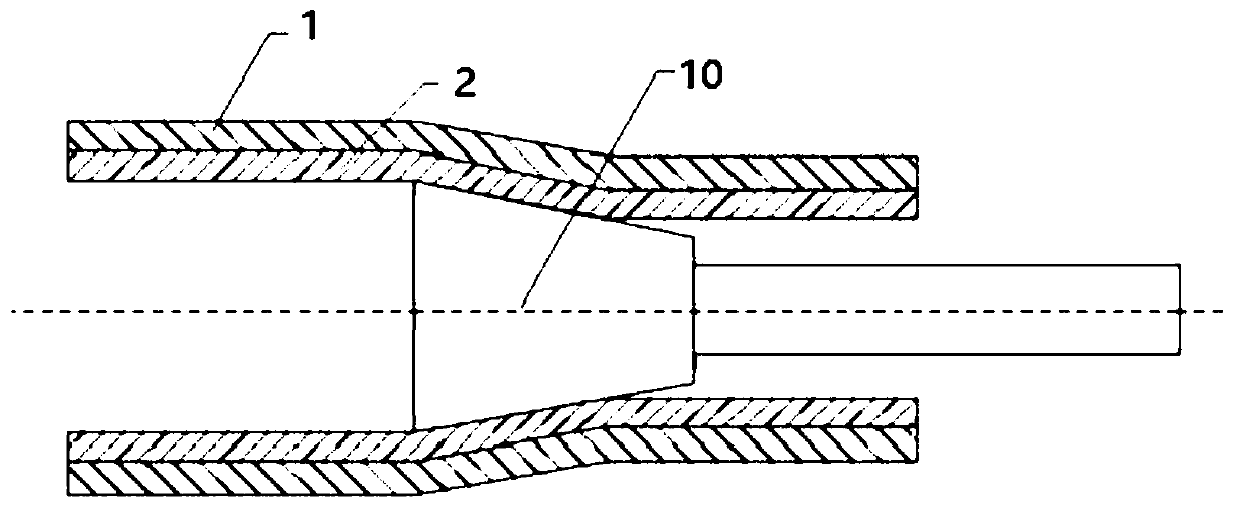

[0040] S3. After putting the titanium tube 2 and the steel tube 1 together, insert the mandrel 10 into the titanium tube 2, and use a drawing process to make the titanium tube 2 and the steel tube 1 form an interference mechanical fit;

Embodiment 1

[0057] S1. A Q235 steel pipe 1 with an outer diameter of Φ110mm, a wall thickness of 10mm, and a length of 1m and a TA2 titanium pipe 2 with an outer diameter of Φ89mm, a wall thickness of 4mm, and a length of 0.95m were selected as the composite outer and inner pipes, respectively. The inner surface of the steel pipe 1 and the outer surface of the titanium pipe 2 are processed into a convex annular corrugated channel by using a special rolling process. The distance between the peak and the trough of the corrugated channel is 0.5mm, and the wave pitch is 2mm;

[0058] S2. Embedding the TA2 titanium pipe 2 into the Q235 steel pipe 1 for pre-assembly and checking for dimension matching. After being successfully embedded, the steel pipe 1 and the titanium pipe 2 are dipped in NaOH solution with a temperature of 80-90° C. and a mass percent of 10% for 5-10 minutes to remove grease on the metal surface. After rinsing with clean water, use 15% HCl solution and 4% HF+10% HNO respecti...

Embodiment 2

[0066] S1. Select Q345 stainless steel pipe 1 with an outer diameter of Φ89mm, a wall thickness of 6mm, and a length of 2m, and a TA2 titanium pipe 2 with an outer diameter of Φ76mm, a wall thickness of 3mm, and a length of 1.9m as the composite outer pipe and inner pipe respectively. . The inner surface of the steel pipe 1 and the outer surface of the titanium pipe 2 are processed into a double-sided annular spiral corrugated channel by using a special rolling process. The distance between the peak and the trough of the corrugated channel is 1.5mm, and the wave pitch is 5mm;

[0067] S2. Embedding the TA2 titanium pipe 2 into the Q345 steel pipe 1 for pre-assembly and checking the size matching. After being successfully embedded, the steel pipe 1 and the titanium pipe 2 are dipped in NaOH solution with a temperature of 80-90° C. and a mass percent of 10% for 5-10 minutes to remove grease on the metal surface. After rinsing with clean water, use 15% HCl solution and 4% HF+10%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com