Fixture and method for winding rectangular-section wire torsional springs

A technology with rectangular cross-section and steel wire, which is applied in the field of spring winding, can solve the problems of large variation in outer diameter, different diameters, and large torque dispersion, etc., to achieve consistent outer diameter, ensure appearance quality, and uniform pitch Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

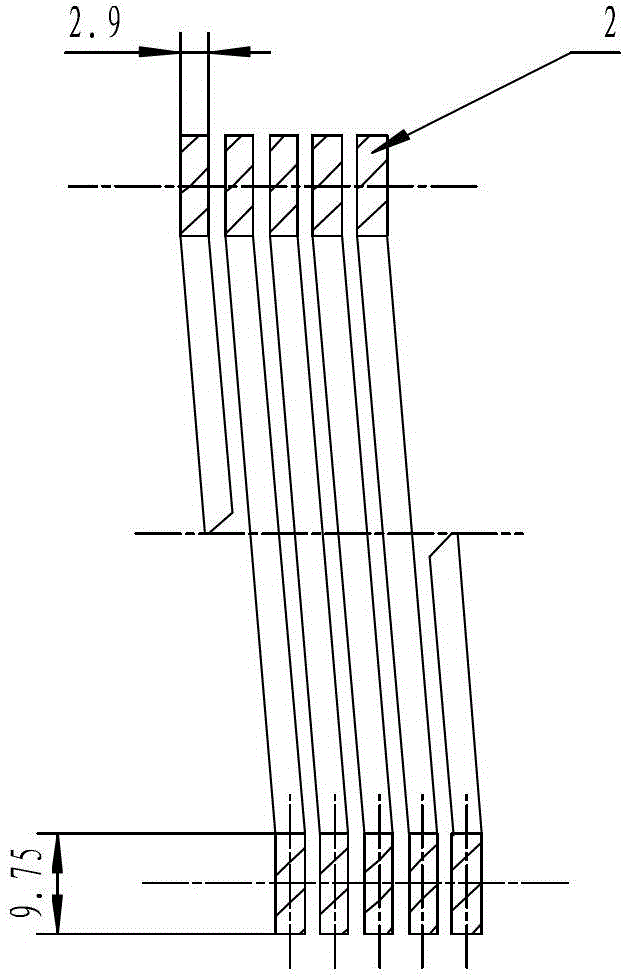

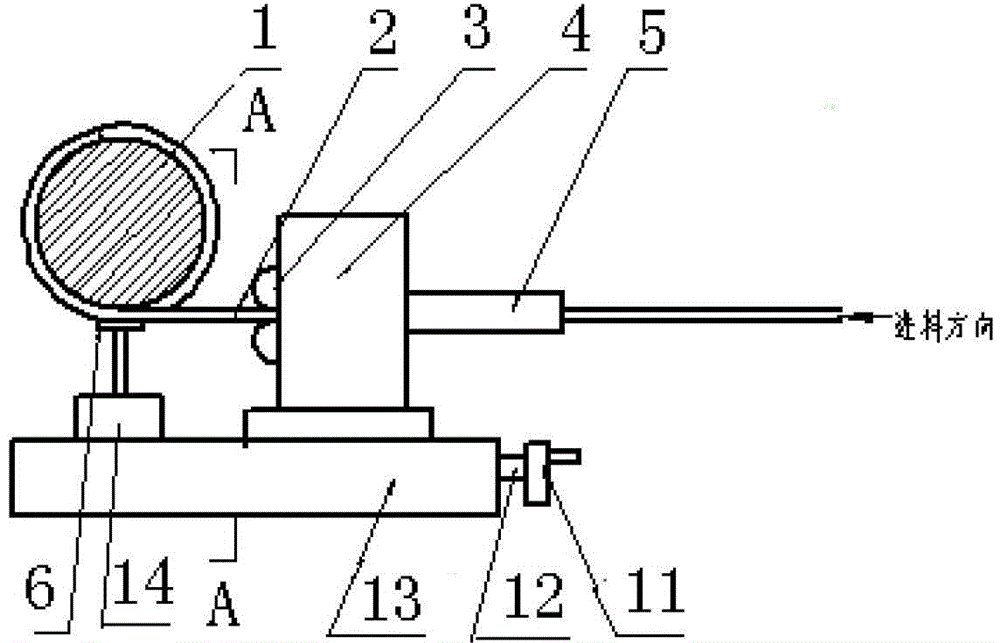

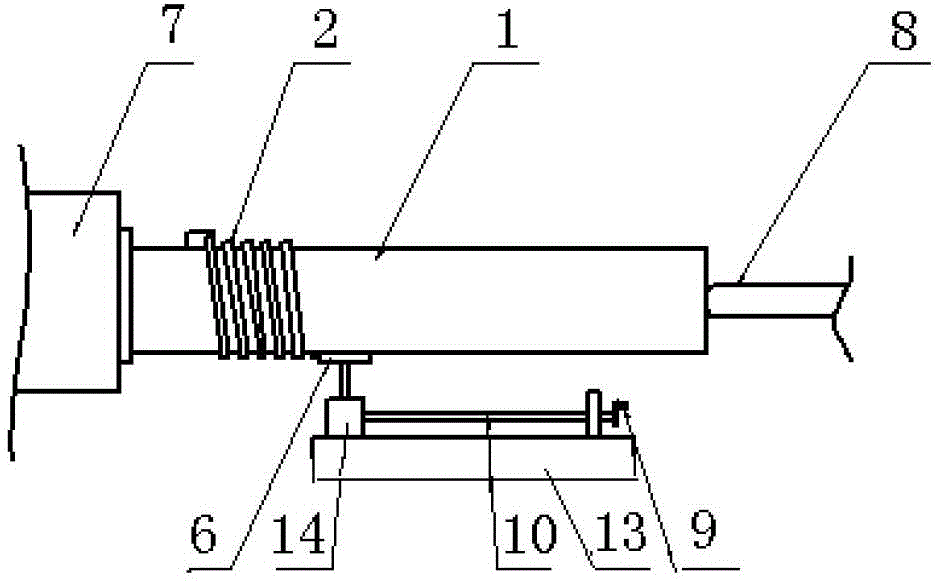

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , in order to ensure the consistency and reliability of the shape of the torsion spring wound with a rectangular cross-section steel wire, and to avoid the occurrence of skewing and lodging of the torsion spring during winding, the present invention provides a clamp for winding a rectangular cross-section steel wire torsion spring, Including the base plate 13 and the guide bracket 4 arranged thereon, the guide bracket 4 is connected with the base plate 13 through the first screw rod 12, and a bracket moving handle 11 is connected with one end of the first screw rod 12, Rotating the bracket moving handle can make the bracket move left and right on the base plate. It is characterized in that: the right side of the guide bracket 4 is provided with a correction splint 5, and the left side of the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com