Method for making wire cable packaged with flat yarn in appearance

A production method and technology of flat wire, which is applied to textiles, papermaking, textile cables, etc., can solve problems such as improper process, slipping, and the flat wire layer cannot be fastened with steel ropes, etc., to achieve uniform gaps and flexibility and excellent elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

[0017] The present invention is a kind of manufacture method of the steel rope with flat wire on the outer surface, and described method comprises the following steps:

[0018] 1), wrapping the flat wire: winding the flat wire on the surface of the steel rope;

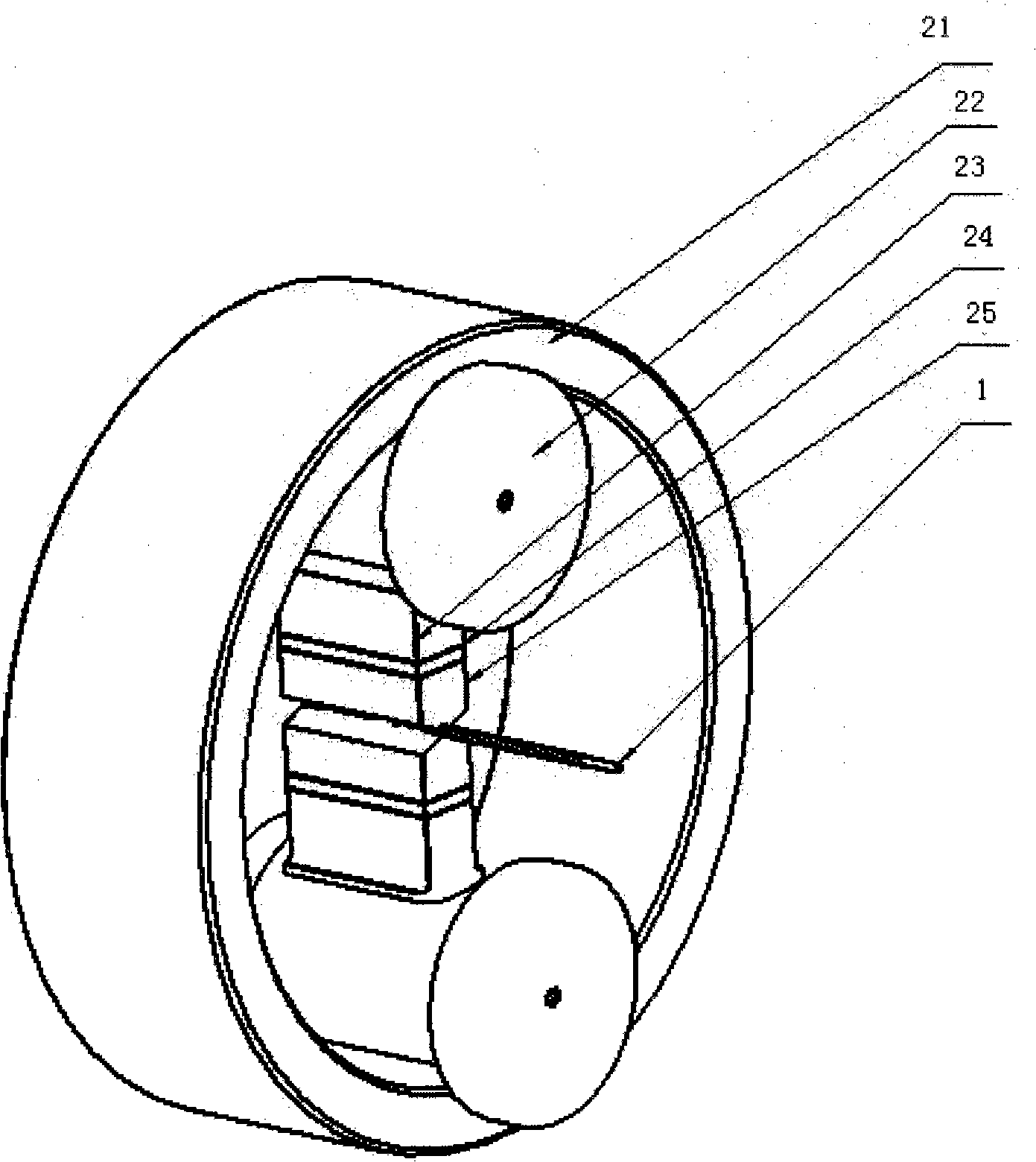

[0019] 2), radial rotation cold forging: make the flat wire fastened on the surface of the steel cable and increase the strength of the flat wire;

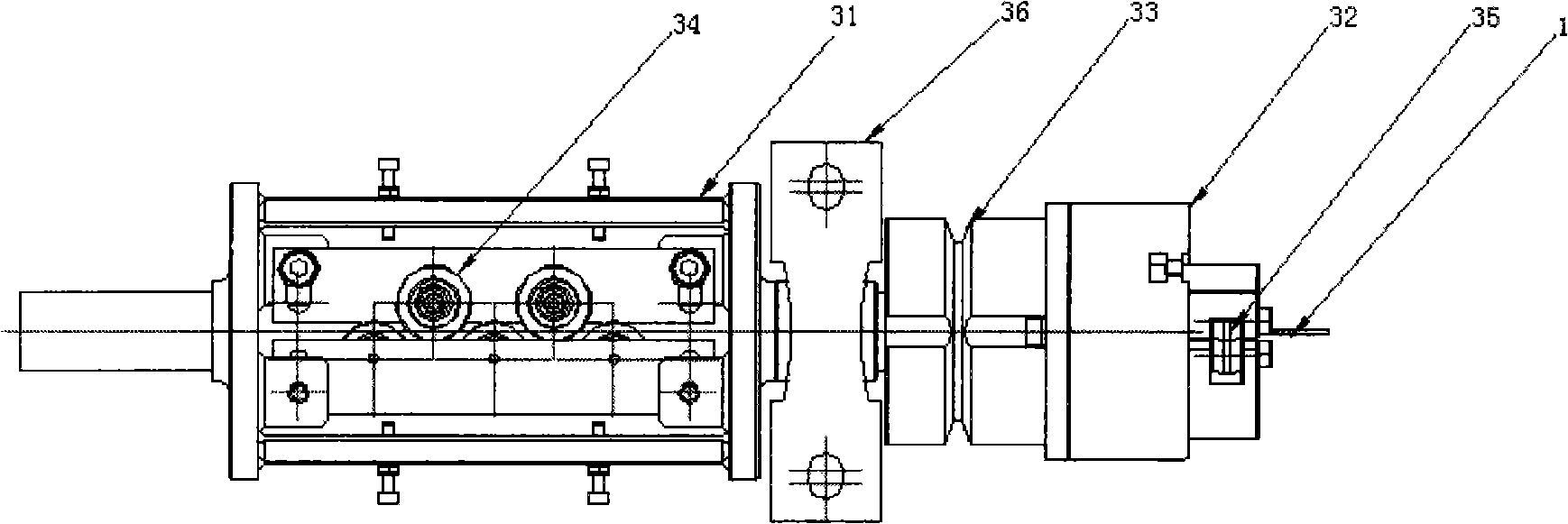

[0020] 3) Roller polishing: rolling and grinding the flat wire.

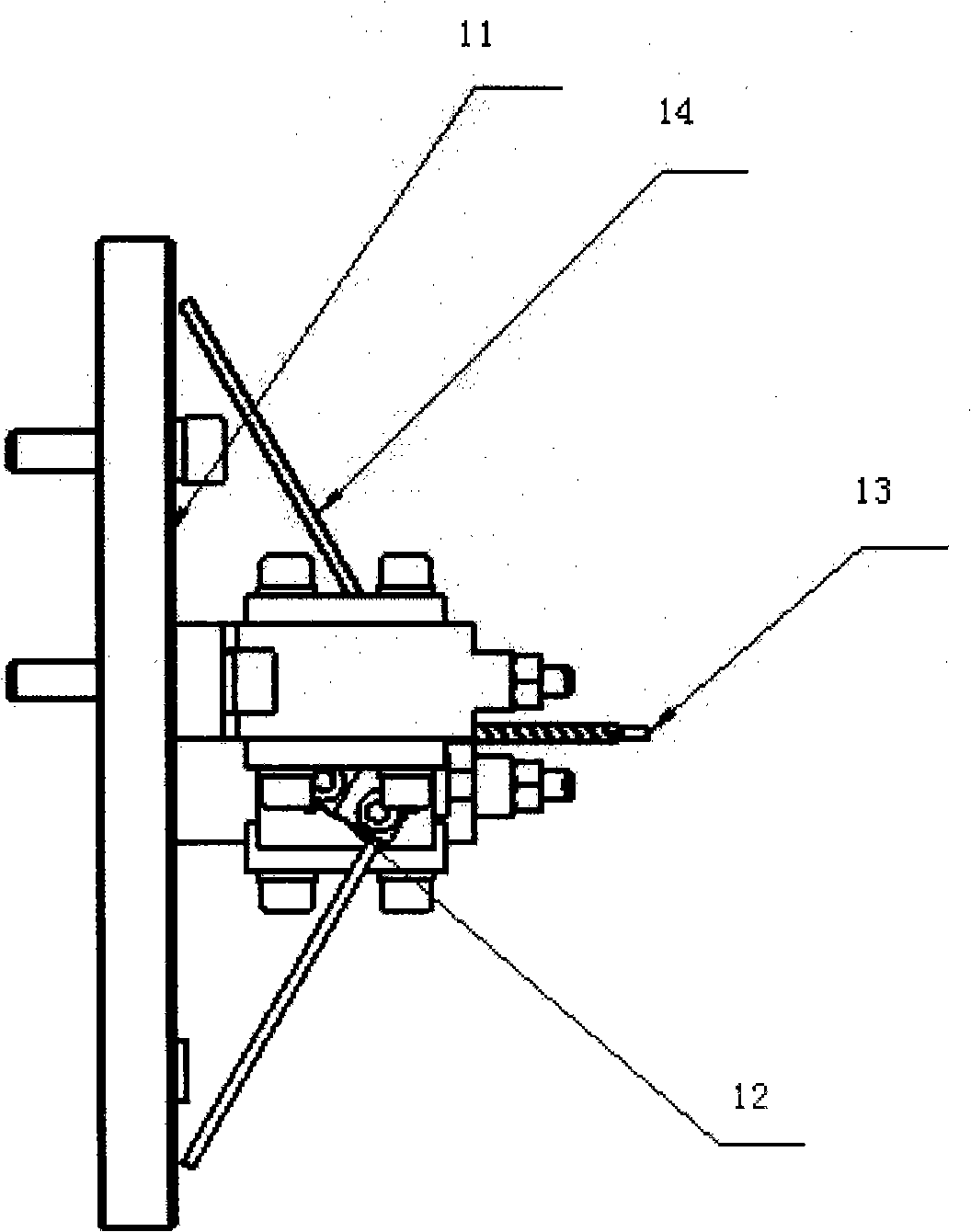

[0021] like figure 1 As shown, the flat wire wrapping step uses a flat wire wrapping device, and the flat wire wrapping device includes a flat wire wrapping machine 11. The steel rope 13 and the flat wire 14 are respectively introduced into the flat wire wrapping machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com