Stainless steel/aluminium tape longitudinal tubing corrector

A correction device and longitudinal wrapping molding technology, applied in the directions of light guides, optics, instruments, etc., can solve the problems of difficult to guarantee the quality of the optical cable, the outer diameter of the sheath is not round, and the outer diameter of the sheath is irregular, so as to achieve a uniform outer diameter. , to avoid quality problems, the effect of rounding the outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

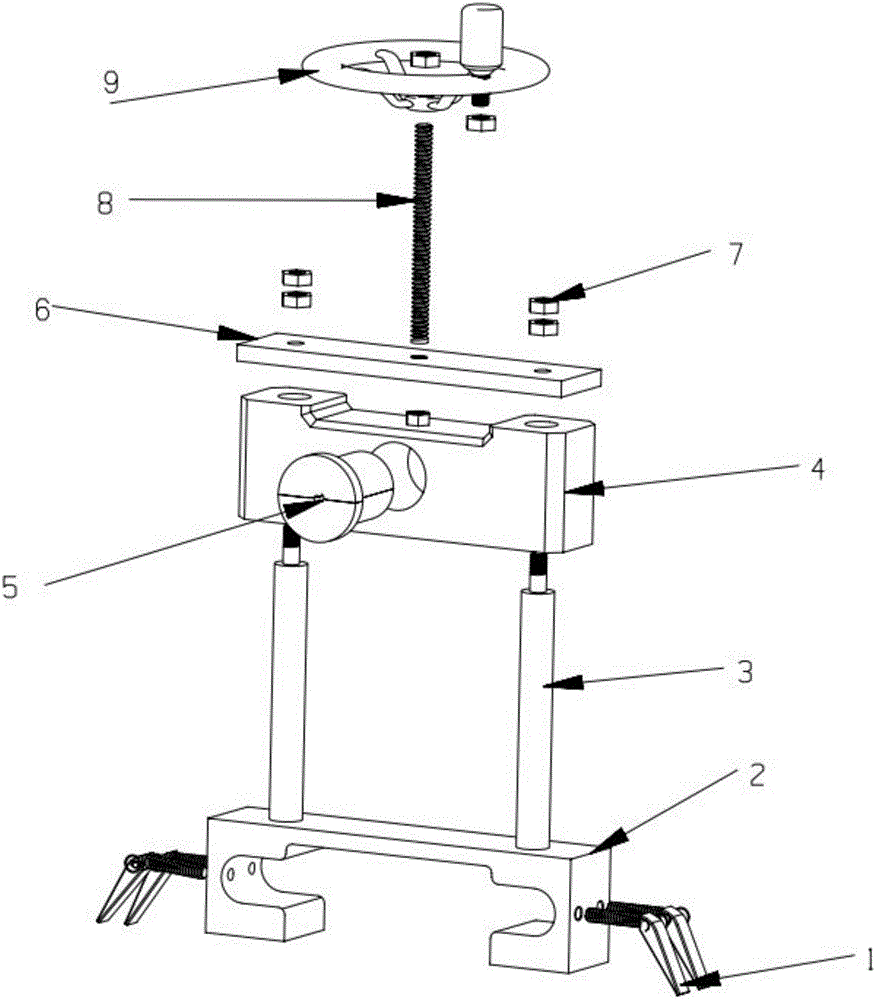

[0015] With reference to the accompanying drawings, the stainless steel / aluminum strip longitudinal wrapping correction device of the present invention is characterized in that a slider 2 is provided at the lowermost end, and rotatable and adjustable locking nuts 1 are respectively provided at the opposite side positions of the slider. There are 4 rotatable adjustable locking nuts, and two are distributed on each opposite surface of the slider. Put the slider on the original track and fix it by adjusting the rotatable adjustable locking nut. Adjust the locking nut to make the device more stable. Two light rods 3 are fixed on the upper end of the slide block, the top of the light rods is provided with threads, the light rod threads are connected with a mold frame 4, the center of the mold frame is provided with a mold hole for inserting a mold 5, and the mold is in the shape of a stepped shaft. The mold is fixed on the mold frame by relying on the front traction force of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com