Large-section milliken-conductor comprehensive water-retaining crosslinking electric cable

A technology for cross-linking power cables and dividing conductors, applied in power cables, power cables with shielding/conducting layers, cables, etc., can solve problems such as unstable quality and production difficulties, avoid conductor pollution and achieve high production efficiency. , The effect of excellent insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

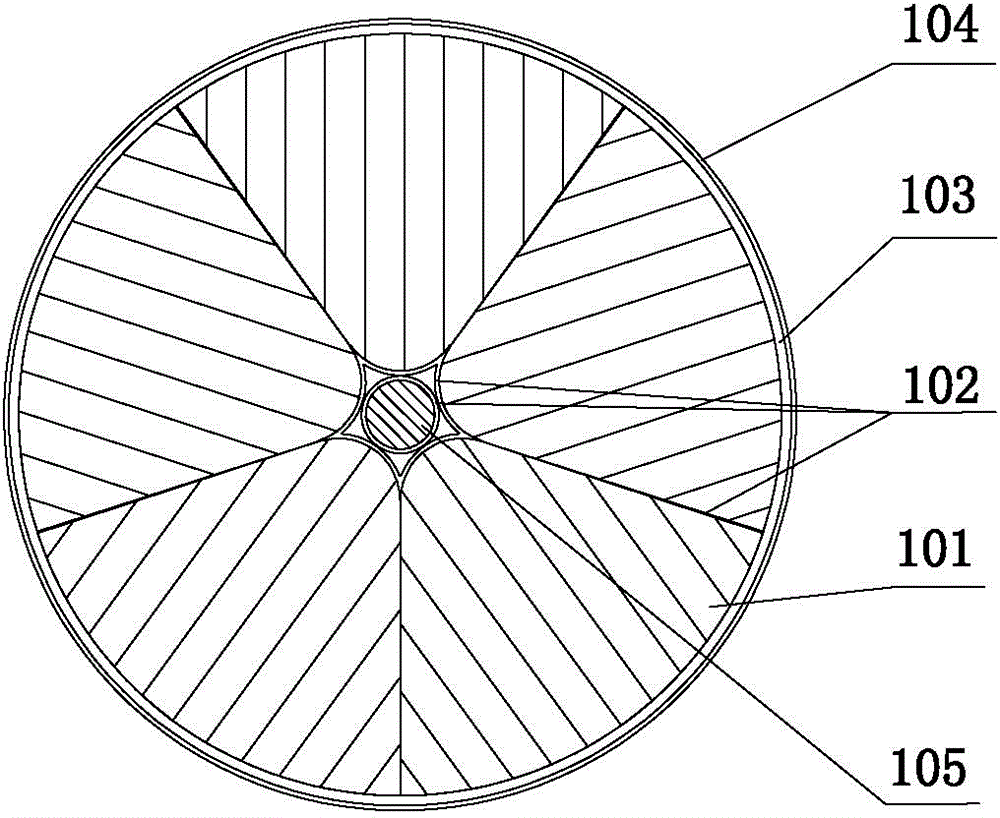

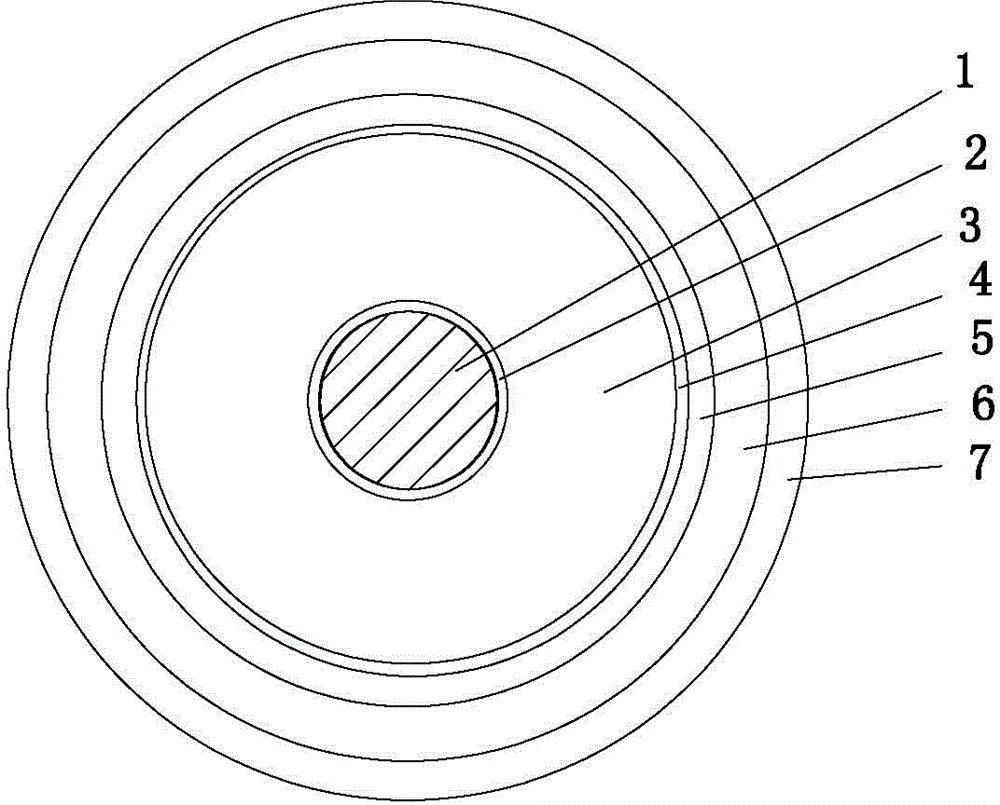

[0018] The present invention is a high electrical conductivity, comprehensive radial water resistance / water resistance, weather resistance, and has the characteristics of severe cold resistance, low temperature flexibility, good electrical performance, high tensile strength and long service life. Power cables for power distribution systems. Its specific structure is as figure 2 As shown, the conductor unit 1 is at its center, and the conductor unit 1 is covered with a conductor shielding layer 2, an insulating layer 3, an insulating shielding layer 4, a semiconducting resistance water buffer layer 5, and a corrugated aluminum sheath 6 in sequence from the inside to the outside. and outer sheath7. The material of the insulating layer 3 is preferably cross-linked polyethylene, and the material of the outer sheath 7 is preferably an environmentally friendly flame-retardant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com