Threaded pipe pulling device

A threaded pipe and pipe material technology, applied in the field of threaded pipe processing, can solve the problems affecting the quality of threaded pipes, poor uniformity of inner diameter of threaded pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

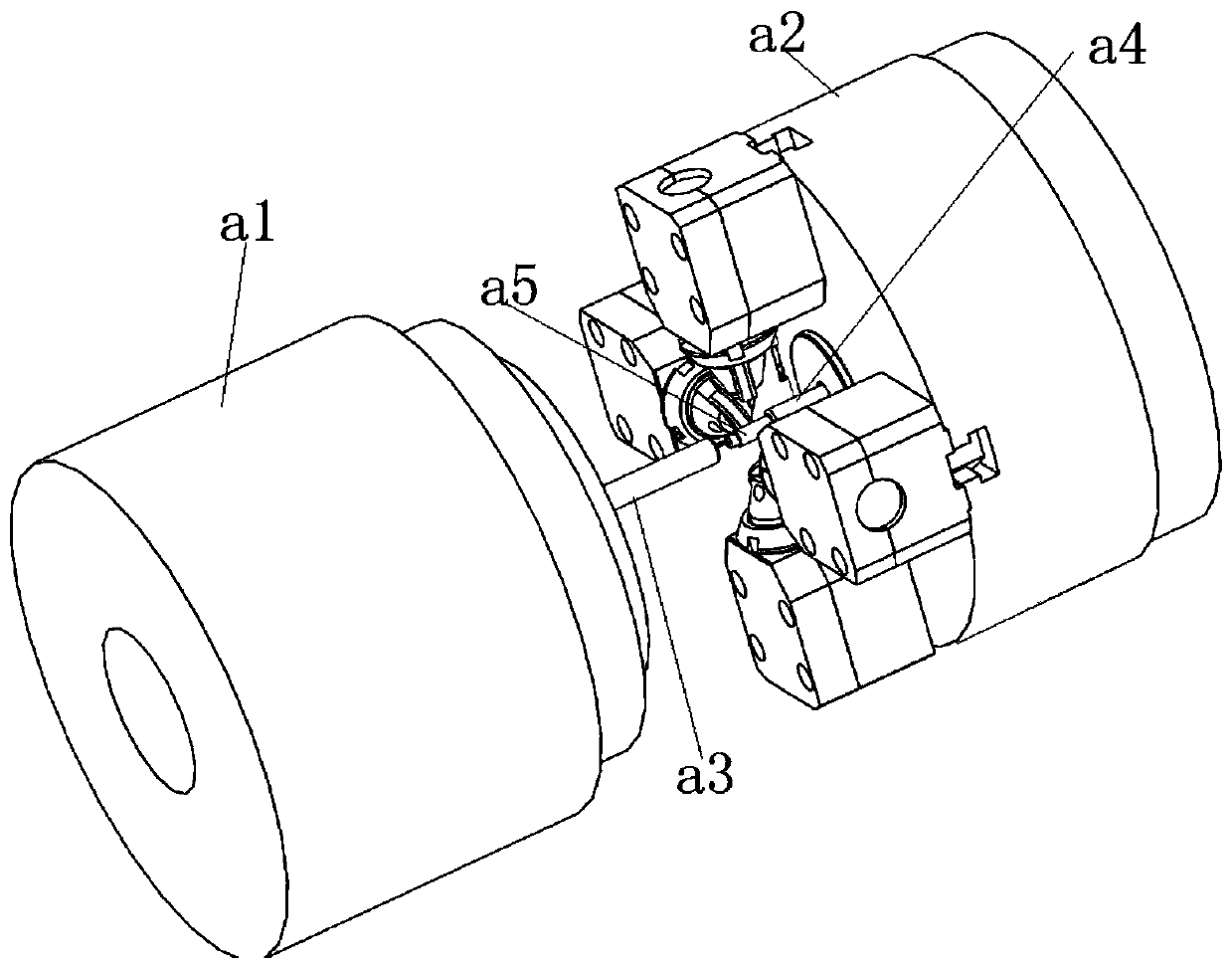

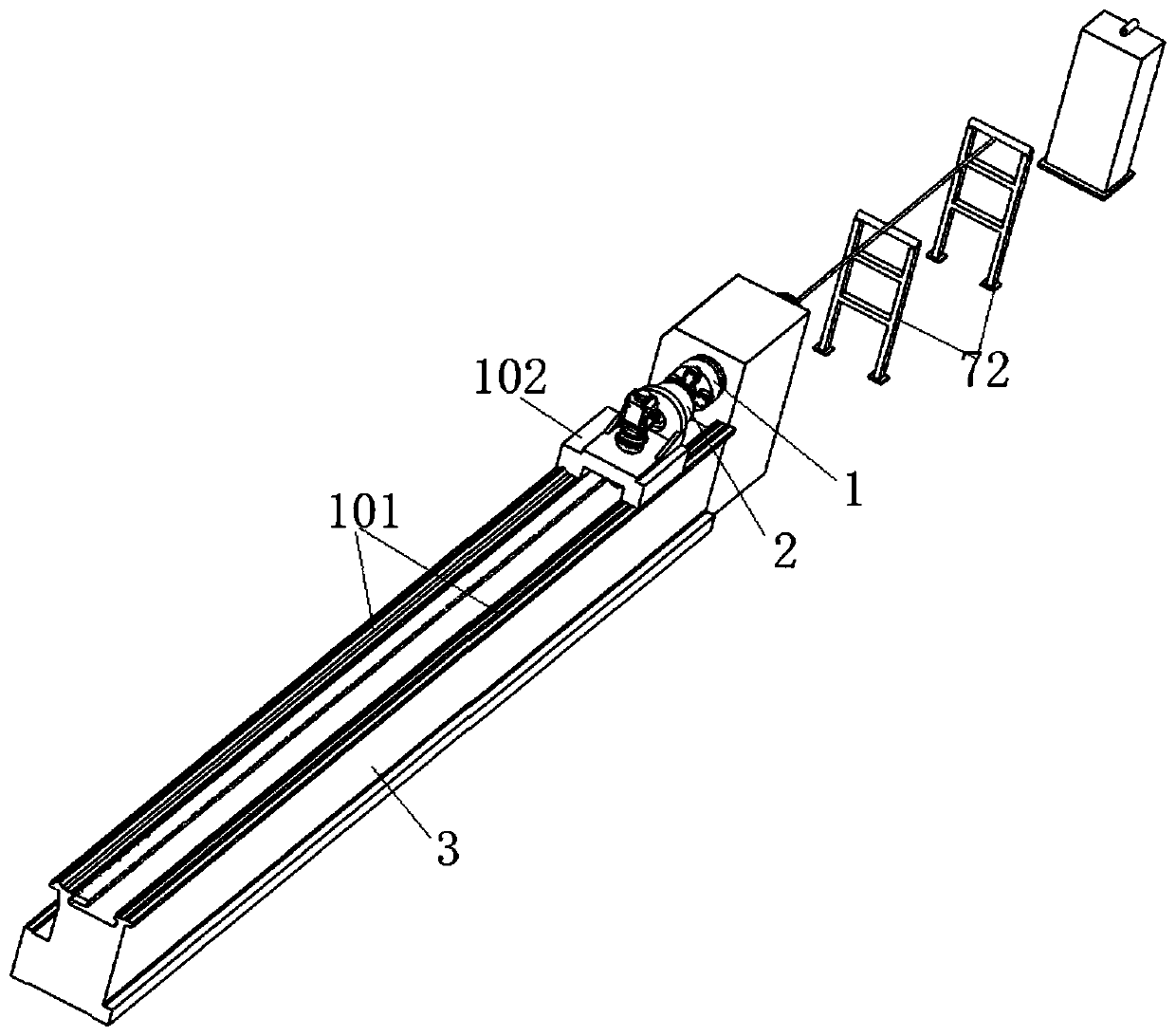

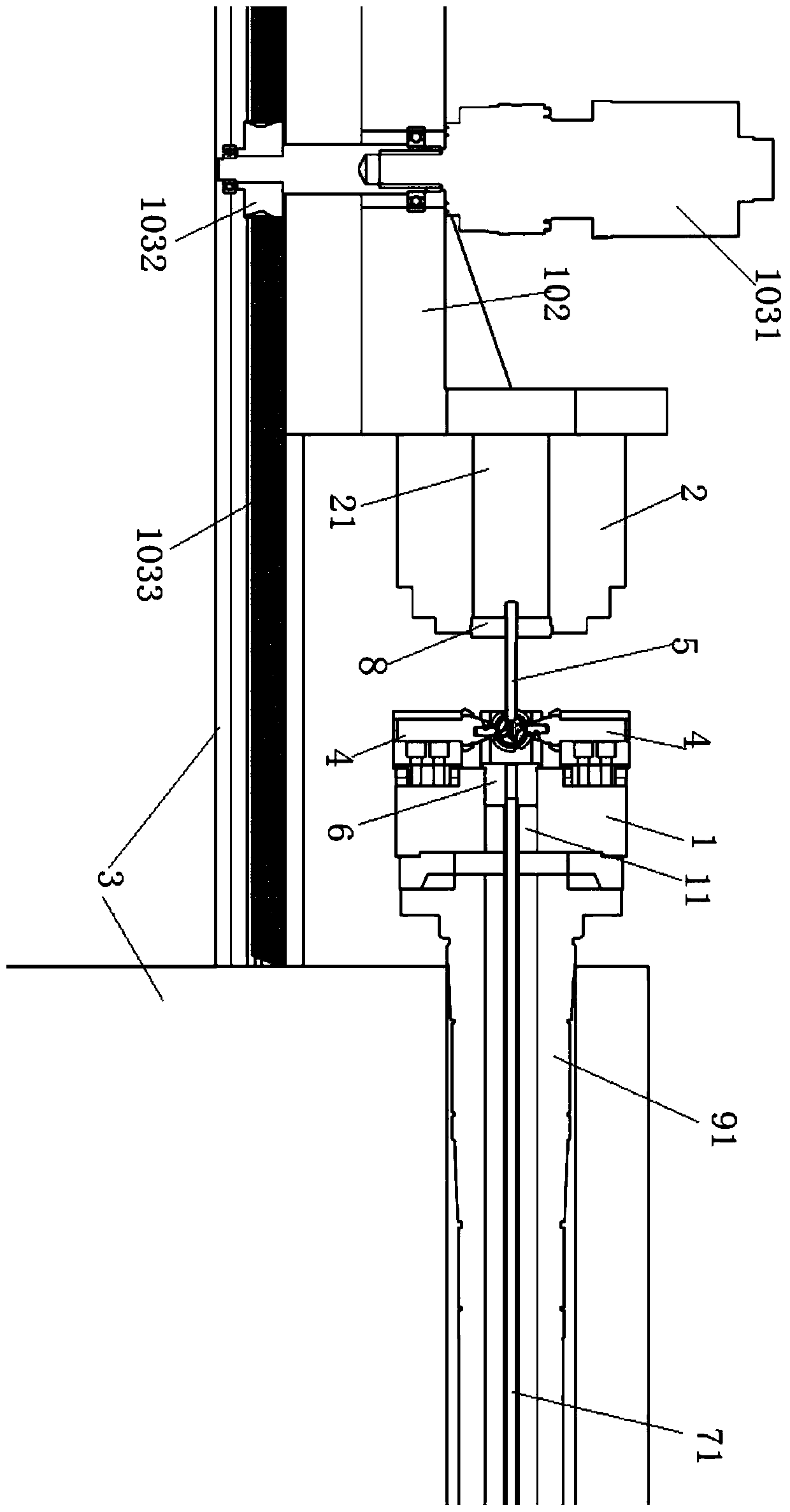

[0050] This embodiment provides a pipe drawing device for a threaded pipe, such as Figure 2 to Figure 9 As shown, it includes a machine tool 3 , a first chuck 1 , a second chuck 2 , a first bushing 6 , a fixing member 5 and several groups of roller assemblies 4 .

[0051] like figure 2 and image 3 As shown, the first chuck 1 and the second chuck 2 are relatively arranged on the machine tool 3, and the second chuck 2 is slidably arranged on the machine tool 3 in the direction of approaching or moving away from the first chuck 1; 1 is rotatably arranged on the machine tool 3 , and a first through hole 11 extending along the sliding direction of the second chuck 2 is provided in the middle of the first chuck 1 . For example, the sliding direction of the second chuck 2 is figure 2 in the left and right directions.

[0052] Several groups of roller assemblies 4 are arranged on the end face of the first chuck 1 facing the second chuck 2 (eg image 3 on the left end of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com