The Manufacturing Process of Copper Pipe with Equal Wall Thickness and Reduced Diameter

A manufacturing process and a technology of equal wall thickness, applied in the field of manufacturing process of copper pipes with variable wall thickness, can solve the problems of leakage at welded joints, reduce overall strength, increase production cost, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

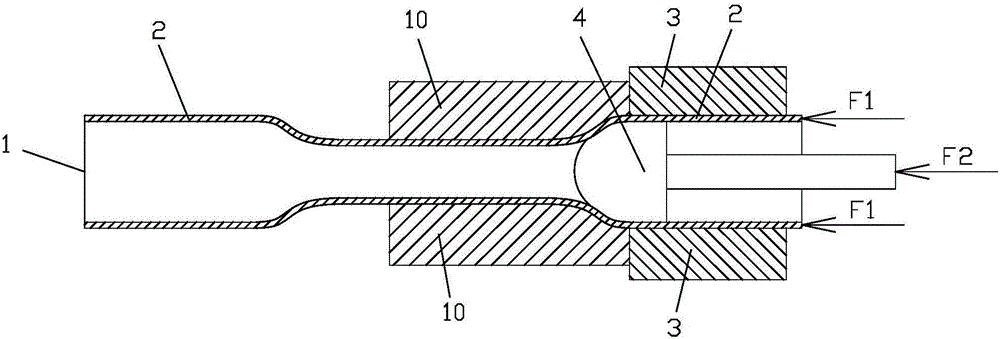

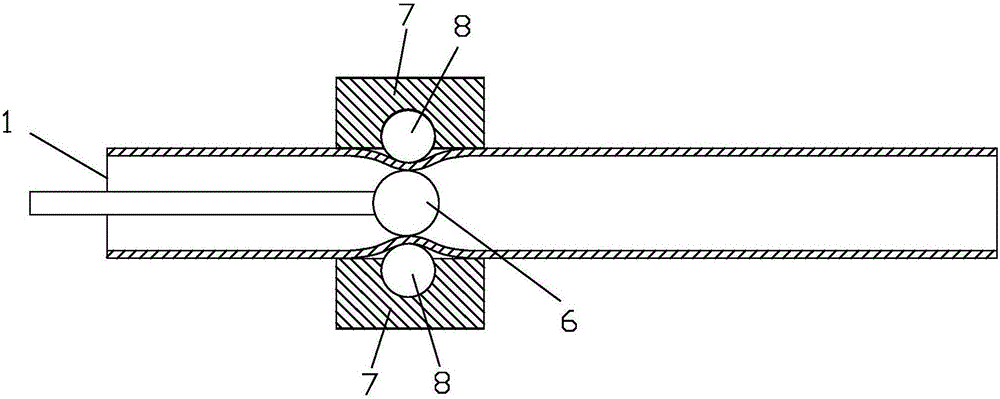

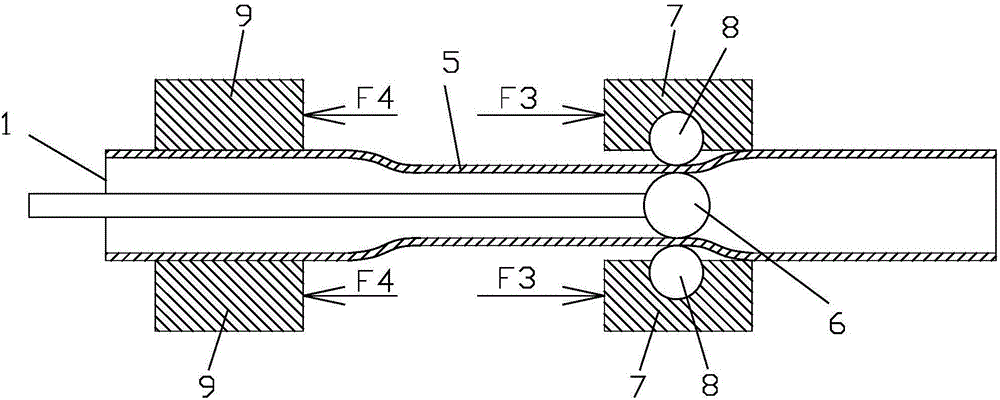

[0023] The manufacturing process of equal-wall thickness reducing pipe of the present invention, as Figures 1 to 2 shown, including the following steps:

[0024] Step 1: Select a piece of copper pipe 1 required for the design length.

[0025] The second step: if figure 1 As shown, the middle part of the copper pipe 1 is fixed, and the diameters of both ends are enlarged to process two diameter-expanded sections 2 . During the expansion process, the end of the copper tube clamps the protective body 3, and uses the mandrel 4 to axially push into the copper tube 1 from both ends of the copper tube 1 from the outside to the inside with the thrust F2, and the mandrel 4 is pushed in. The end of the copper tube 1 is heated to 60-240° C., and the end of the copper tube 1 is pushed axially from outside to inside with a thrust F1 of 50-250 kg and a propulsion speed of 10-55 cm / min. The diameter expansion is multiple step-by-step diameter expansion, and the mandrel 4 is inserted into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com