Method for preparing hollow fiber catheter for repairing nerves and bundling structure of hollow fiber catheter

A fiber catheter and nerve repair technology, which is applied in the fields of medical science, prosthesis, tissue regeneration, etc., can solve the problems of allergic reaction, low production efficiency, too thick, etc., and achieve the effect of increasing adhesion strength, easy operation, and uniform inner diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of Bundle Structure I for Nerve Repair

[0035] Specifically include the following steps:

[0036] 1. Preparation of Hydrogel Precursor Solution

[0037] Firstly, the water-soluble chitosan is made into a 2.5% (w / v) concentration solution, and the NHS-PCLPEG5000PCL-NHS is made into a 20 (w / v)% concentration solution.

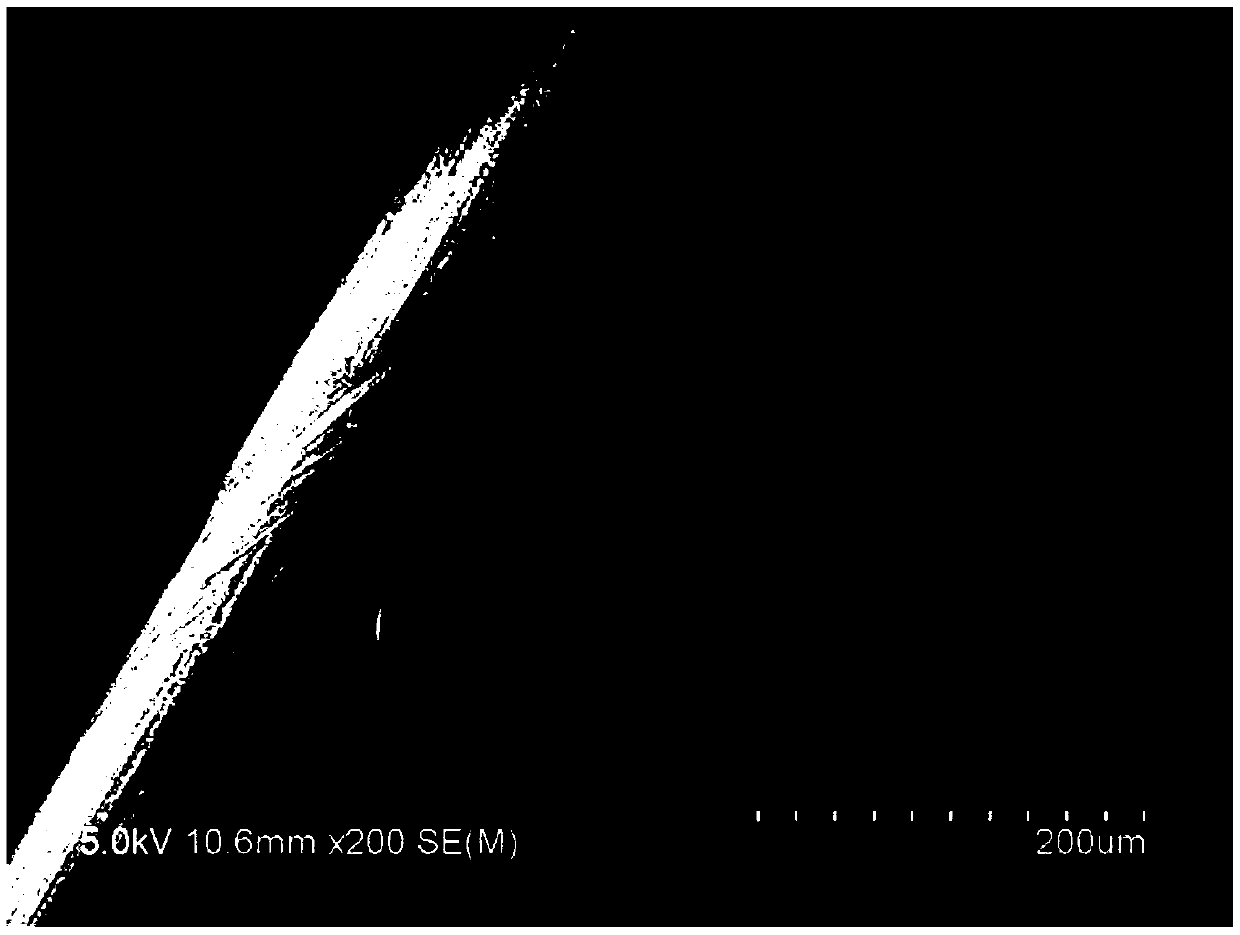

[0038] 2. Preparation of hollow fiber with secondary orientation structure

[0039] 2.1 Select PCL (Mn=80,000) with elongation at break as the raw material, and extrude it on a pipe making machine to obtain a tubular product with an outer diameter of 0.6 mm and a wall thickness of 0.2 mm.

[0040] 2.2 Insert a 0.1mm-diameter 316L stainless steel wire into the middle of a tubular object of a certain length, apply a traction force on both ends of the tubular object in opposite directions, and perform "cold drawing" on the tubular object. "Cold drawing" causes the diameter of the tubular object to shrink and the thickness Thin until...

Embodiment 2

[0047] Example 2: Preparation of Bundle Structure II for Nerve Repair

[0048] Specifically include the following steps:

[0049] 1. Preparation of Hydrogel Precursor Solution

[0050] First, the water-soluble chitosan was made into a 2.5% (w / v) concentration solution, and the NHS-PCLPEG5000PCL-NHS (Mn=7000) was made into a 20 (w / v)% concentration solution.

[0051] 2. Preparation of hollow fiber with secondary orientation structure

[0052] 2.1 Select a blend of four-arm branched PCL (Mn=76,000) and PCL-poly (L-lysine) as a raw material, and extrude it on a tube machine to obtain a tube with an outer diameter of 0.6 mm and a wall thickness of 0.2 mm.

[0053] 2.2 Insert a 0.2mm-diameter 316L stainless steel wire into the middle of a tubular object of a certain length, apply reverse traction force at both ends of the tubular object, and perform "cold drawing" on the tubular object. "Cold drawing" makes the tubular object begin to shrink in diameter and change in thickness. ...

Embodiment 3

[0058] Example 3: Preparation of Bundle Structure III for Nerve Repair

[0059] Specifically include the following steps:

[0060] 1. Preparation of Hydrogel Precursor Solution

[0061] Prepare four-arm PEG5000PCL-NHS and four-arm PEG5000PCL-NH respectively 2 The concentration is 10% (w / t) PBS solution.

[0062] 2. Preparation of hollow fiber with secondary orientation structure

[0063] 2.1 Select the mixture of PCL (Mn=80,000) and VB6 as the raw material, and extrude it on a pipe making machine to obtain a pipe with an outer diameter of 0.6mm and a wall thickness of 0.2mm.

[0064] 2.2 Insert a 0.1mm-diameter 316L stainless steel wire into the middle of a tubular object of a certain length, apply reverse traction force at both ends of the tubular object, and perform "cold drawing" on the tubular object. "Cold drawing" causes the diameter of the tubular object to shrink and the thickness to change. Thin until the tube is tightly wrapped on the outer surface of the steel w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com