Die structure for producing agricultural tractor wheel seat rings

A tractor and wheel technology, which is applied to manufacturing tools, forging/pressing/hammering machinery, forging/pressing/hammer devices, etc. Reduced machining time and material savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

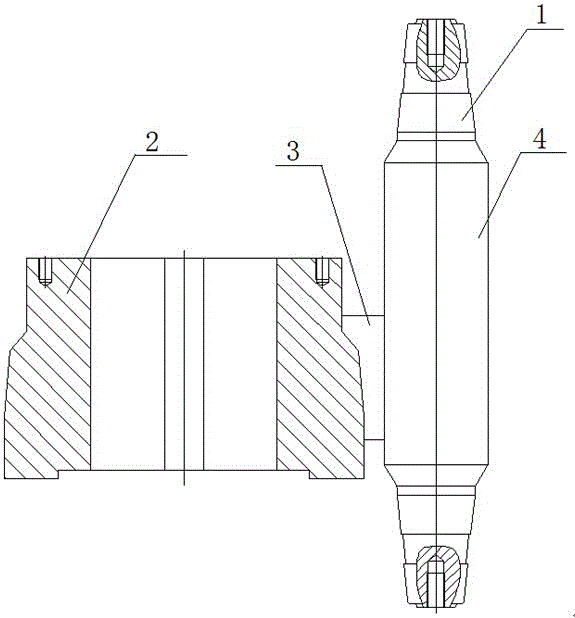

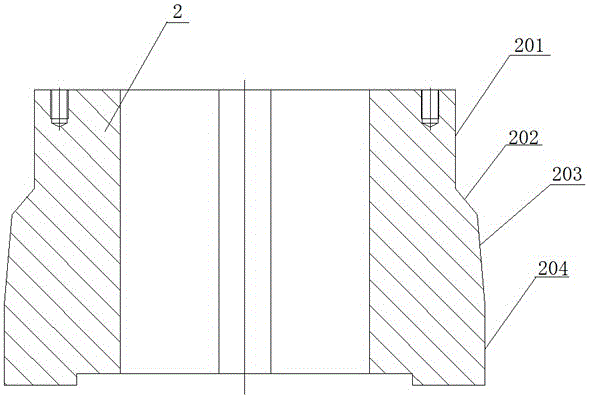

[0015] Such as Figure 1 to Figure 2 As shown, the present invention is a mold structure for producing agricultural tractor wheel seat rings, which includes a core roll 1 and a main mold 2, and a forging 3 is arranged between the core roll 1 and the main mold 2, so The middle part of the core roller 1 is a cylindrical section 4 with a cylindrical structure; the main form 2 is sequentially provided with a first vertical section 201, a first slope section 202, a second slope section 203 and a second vertical section from top to bottom. 204.

[0016] The angle between the first vertical section 201 and the first slope section 202 is 135°.

[0017] The included angle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com