A touch screen manufacturing method for improving etching traces

A manufacturing method and technology of etching traces, applied in the input/output process of data processing, instruments, coatings, etc., can solve the problems of high production cost of high-quality touch screen, high manufacturing cost and mold opening cost, and high cost of end products and other issues, to achieve the effect of wide application range, low manufacturing cost, and material cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further specifically described below in conjunction with the accompanying drawings and embodiments.

[0025] A method for manufacturing a touch screen for improving etching marks comprises the following steps:

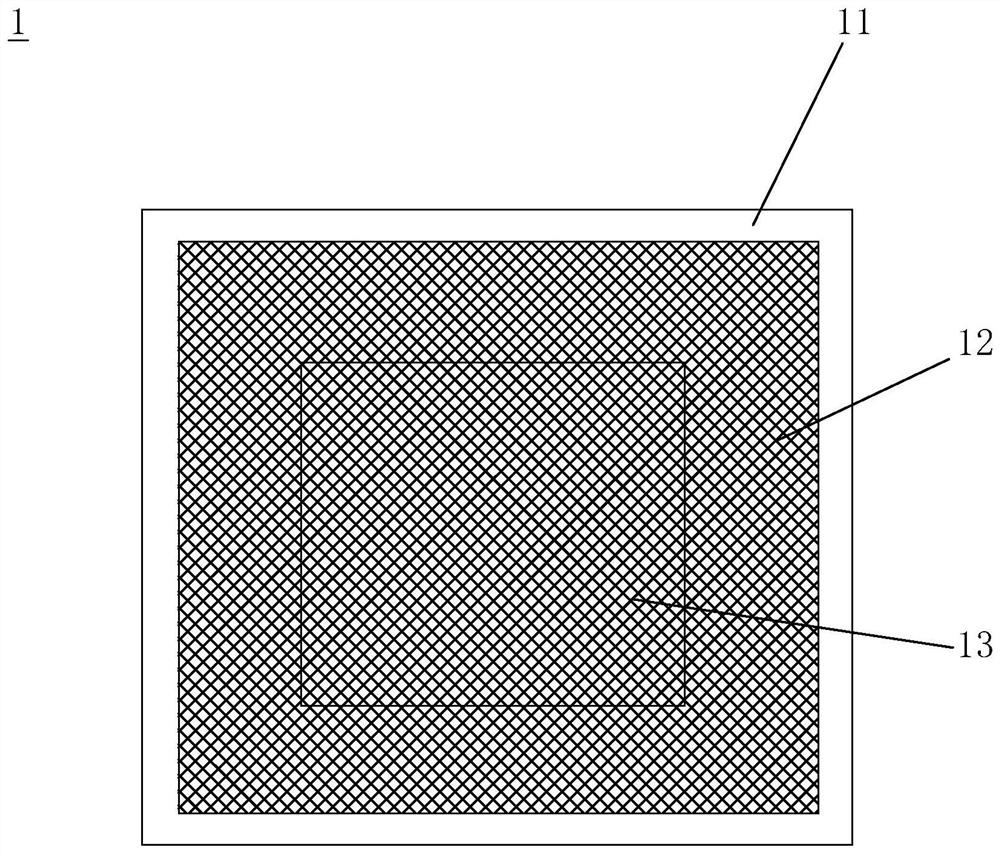

[0026] Step 1: Provide a composite screen, the mesh area of the composite screen is composed of a polyester mesh on the periphery and a steel wire mesh in the middle, wherein the mesh of the polyester mesh is 80-200 mesh, and the wire The diameter is 15-25 μm; the mesh number of the steel wire mesh is 420-520 mesh, the wire diameter is 12-20 μm, and the opening angle is 45°; the steel wire mesh area has several coatings arranged in strips and arranged in parallel at intervals area, the gap between adjacent coating areas forms a slurry leakage area, wherein the width of the coating area is 0.07-0.15 mm; the area ratio of the polyester mesh to the steel wire mesh is 1-5:1;

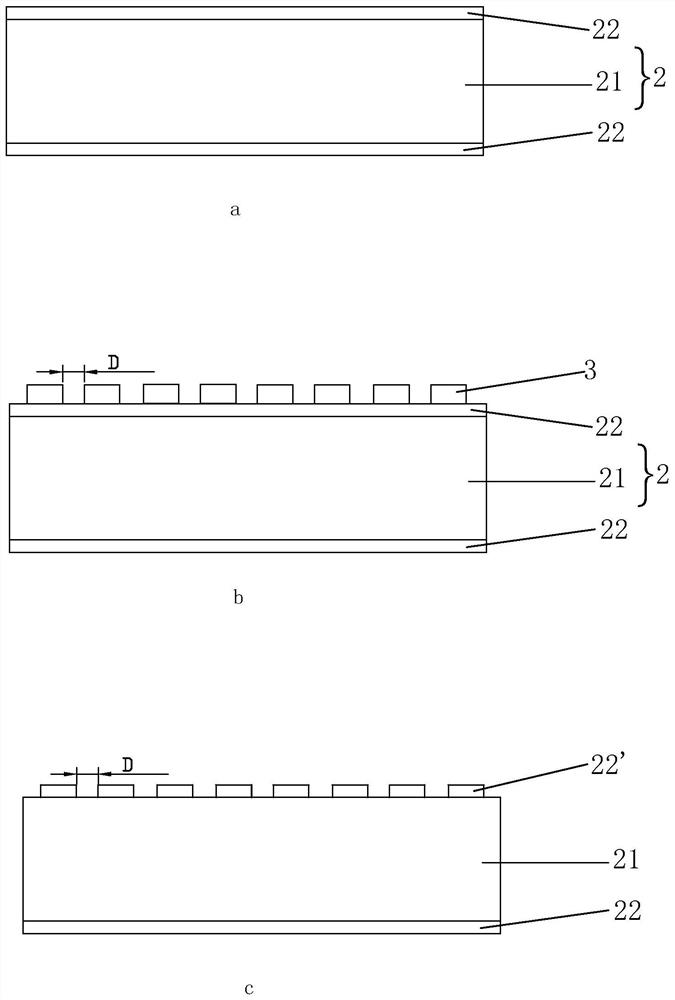

[0027] Step 2: Provide a touch screen substrate, the touc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com