Method for producing grey mask

A technology of gray-tone mask and manufacturing method, which is applied in the photoengraving process of the pattern surface, the manufacture of semiconductor/solid-state devices, the original for opto-mechanical processing, etc. Calibrate offsets, reduce time, ensure quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, embodiments of the present invention will be described in detail.

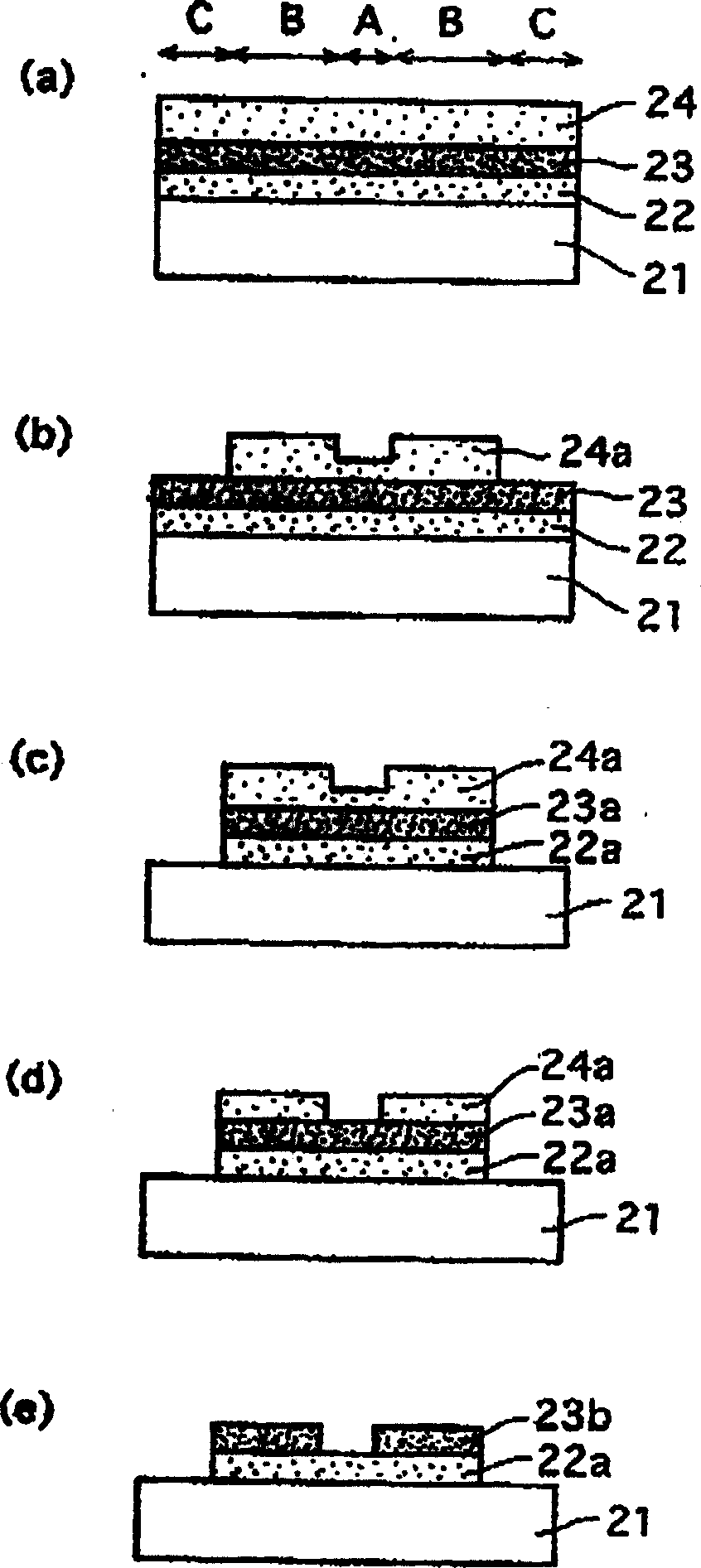

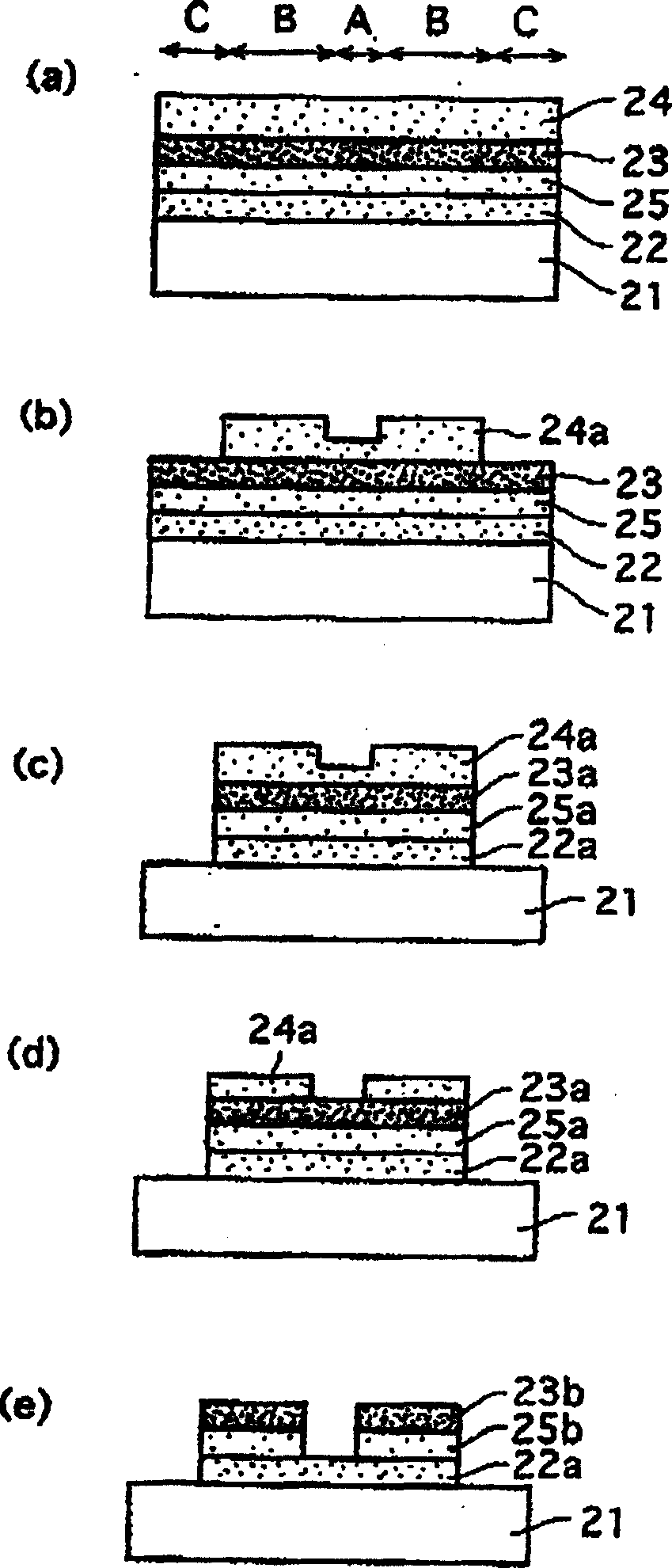

[0038] figure 1 This is a schematic cross-sectional view showing the first embodiment of the method for producing a gray-tone mask of the present invention, and showing the production steps in the order of the steps.

[0039] The mask blanks used in this embodiment are as figure 1 As shown in (a), a semi-transparent film 22 and a light-shielding film 23 are sequentially formed on a transparent substrate 21 such as quartz. Here, as the material of the light-shielding film 23, a thin film and a material capable of obtaining high light-shielding properties are preferable, and examples thereof include Cr, Si, W, Al, and the like. In addition, as the material of the semi-transparent film 22, a thin film is preferable and a semi-transmissive material having a transmittance of about 50% is obtained when the transmittance of the light-shielding portion is 0%. oxides, nitrides, oxynitrides, flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com