Semiconductor structure and forming method of semiconductor structure

A semiconductor and structured surface technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., to improve performance, reduce capillary force, and improve flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] As mentioned in the background, the performance of semiconductor devices still needs to be improved. Now analyze and illustrate in conjunction with specific embodiment.

[0030] It should be noted that the "surface" in this specification is used to describe the relative positional relationship in space, and is not limited to direct contact.

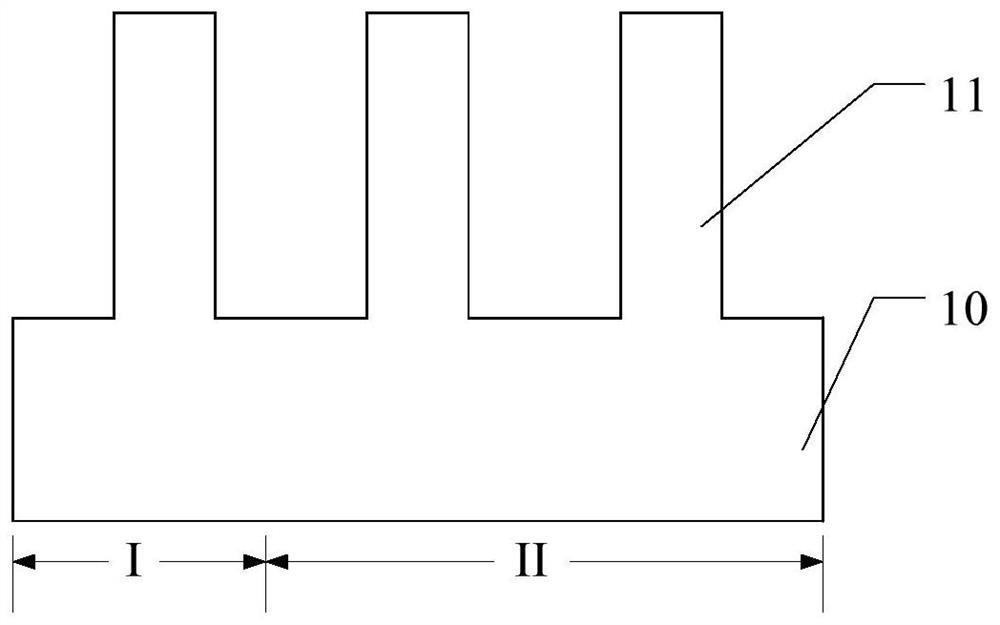

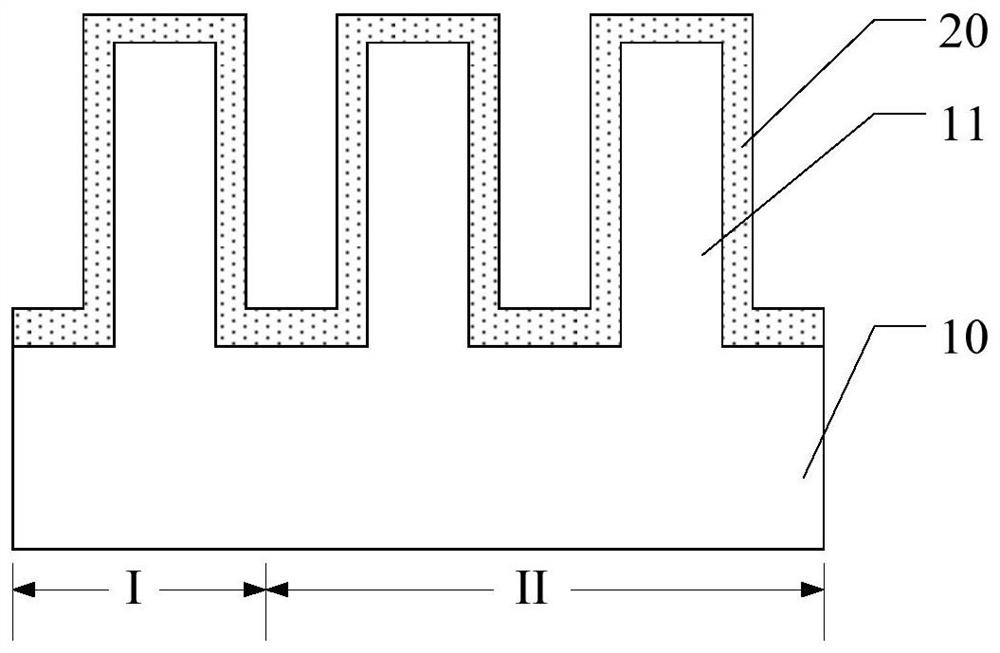

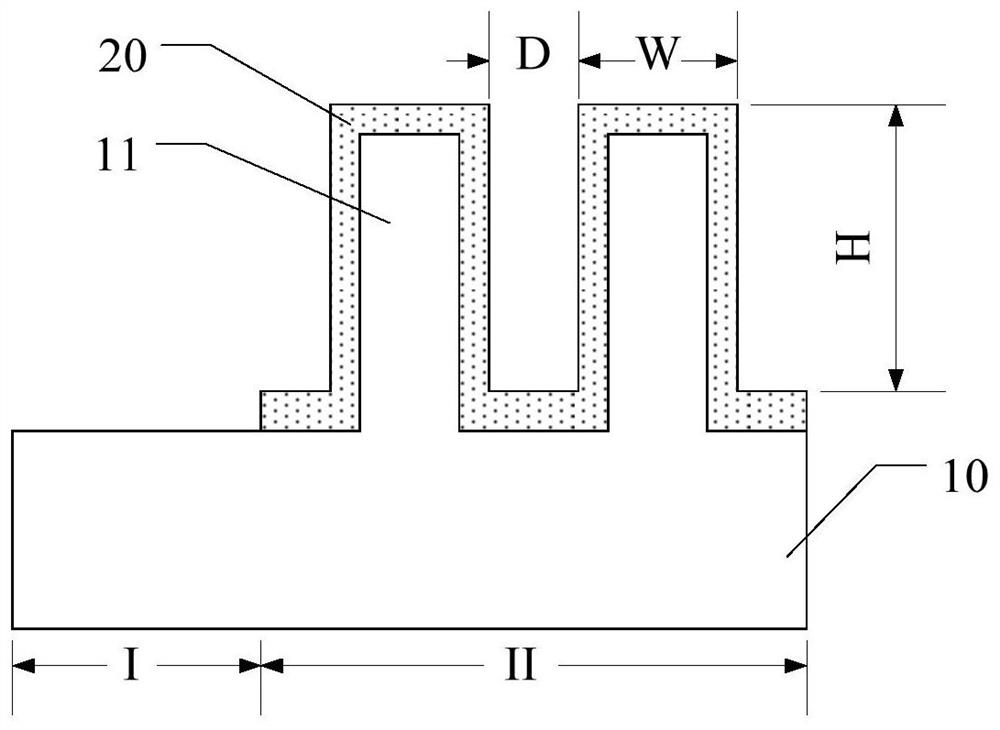

[0031] Figure 1 to Figure 4 It is a schematic cross-sectional structure diagram of each formation step in the formation process of a semiconductor structure.

[0032] Please refer to figure 1 A substrate 10 is provided, the substrate 10 includes a first region I and a second region II, the substrate 10 has fin structures on it, and the fin structures include several fin structures 11 .

[0033] Please refer to figure 2 , forming a passivation film 20 on the surface of the fin structure and the surface of the exposed portion of the substrate 10 .

[0034] The passivation film 20 is used to repair the surface of the fin struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com