Positioning nanoimprint lithography system for preparation of patterned substrate by utilizing AFM (Atomic Force Microscope) probe

A technology of nanoimprinting and graphic substrates, which is applied in the photoplate-making process, optomechanical equipment, optics, etc. High positioning accuracy, strong repeatability, and improved integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

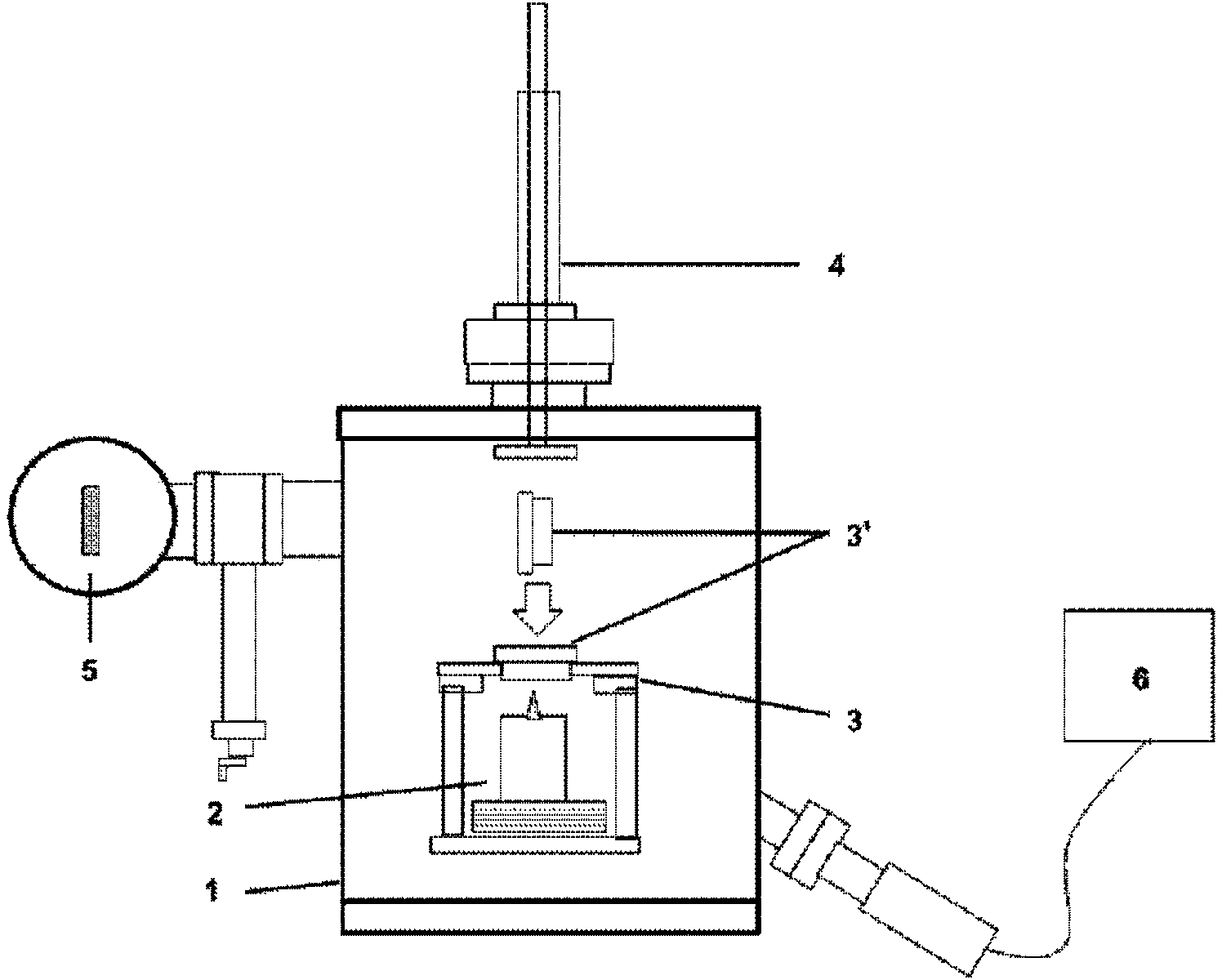

[0019] see figure 1 As shown, the present invention provides a positioning nanoimprinting system utilizing AFM probes to prepare patterned substrates, the system comprising:

[0020] An ultra-high vacuum chamber 1 compatible with other vacuum growth equipment. The vacuum degree 1 of the ultra-high vacuum chamber is generally about 1E-8 to 1E-10 Torr, which is conducive to maintaining the cleanliness of the epitaxial substrate, and corresponding adjustments can be made according to the vacuum epitaxy equipment connected thereto. The vacuum chamber is connected to other vacuum equipment through a flange, and the diameter of the flange is based on the premise that the substrate holder 3' can be transferred between chambers;

[0021] An atomic force microscope 2 is fixed on the bottom of the ultra-high vacuum chamber 1 . The atomic force microscope 2 is a redesigned atomic force microscope with imprinting function, the direction of the probe is upward, and the probe is generally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com